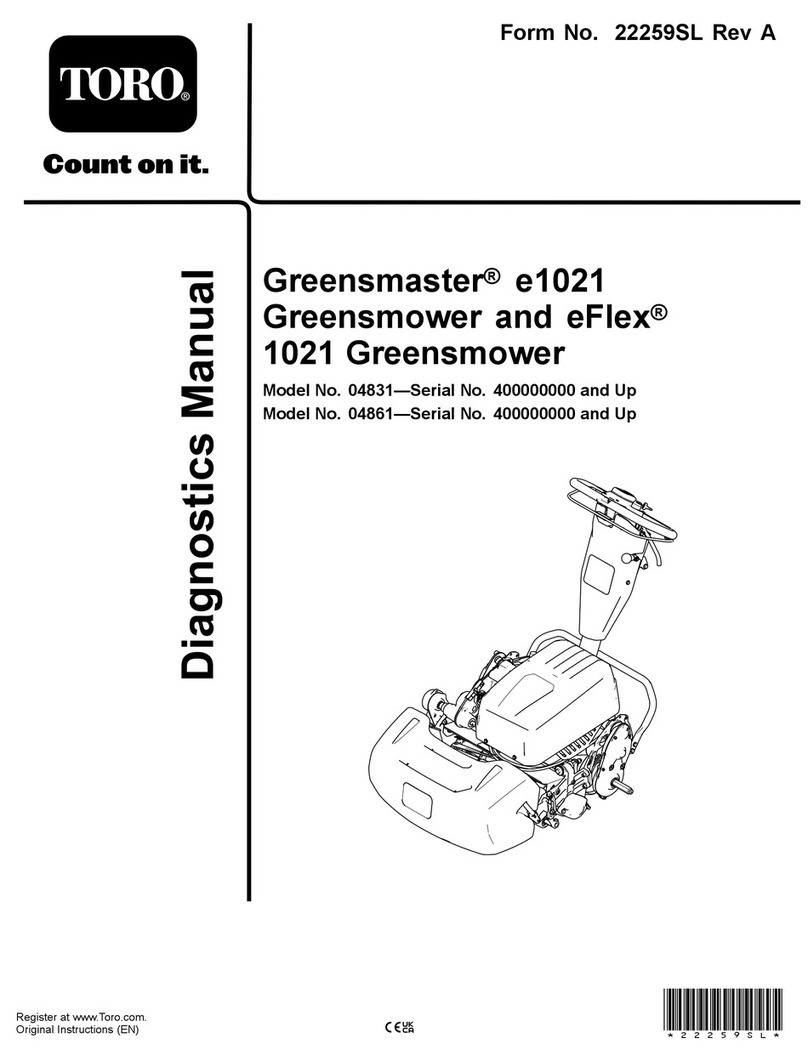

Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................4

BladeSafety.......................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1InstallingtheReelGreaseFitting......................5

2AdjustingtheCuttingUnit.................................6

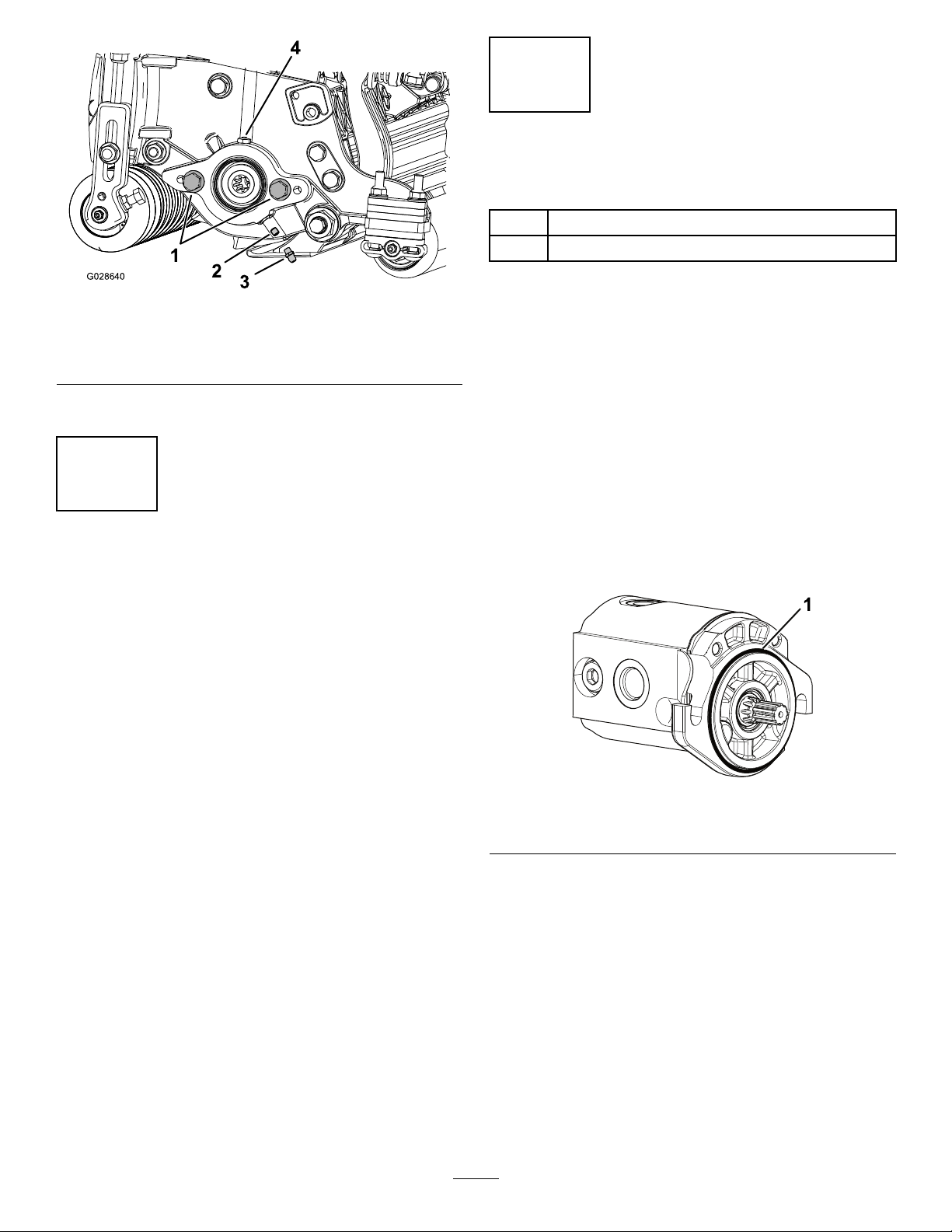

3InstallingtheReelMotors.................................6

4AdjustingtheShopRollerAssemblies..............7

ProductOverview.....................................................7

Specications....................................................7

Attachments/Accessories...................................7

Operation..................................................................8

AdjustingtheCuttingUnit...................................8

AdjustingtheShopRollerAssemblies................11

AdjustingtheHeightofCut(HOC).....................12

AdjustingtheHeightofCut(HOC).....................14

Height-of-CutChartTerms................................16

Maintenance...........................................................17

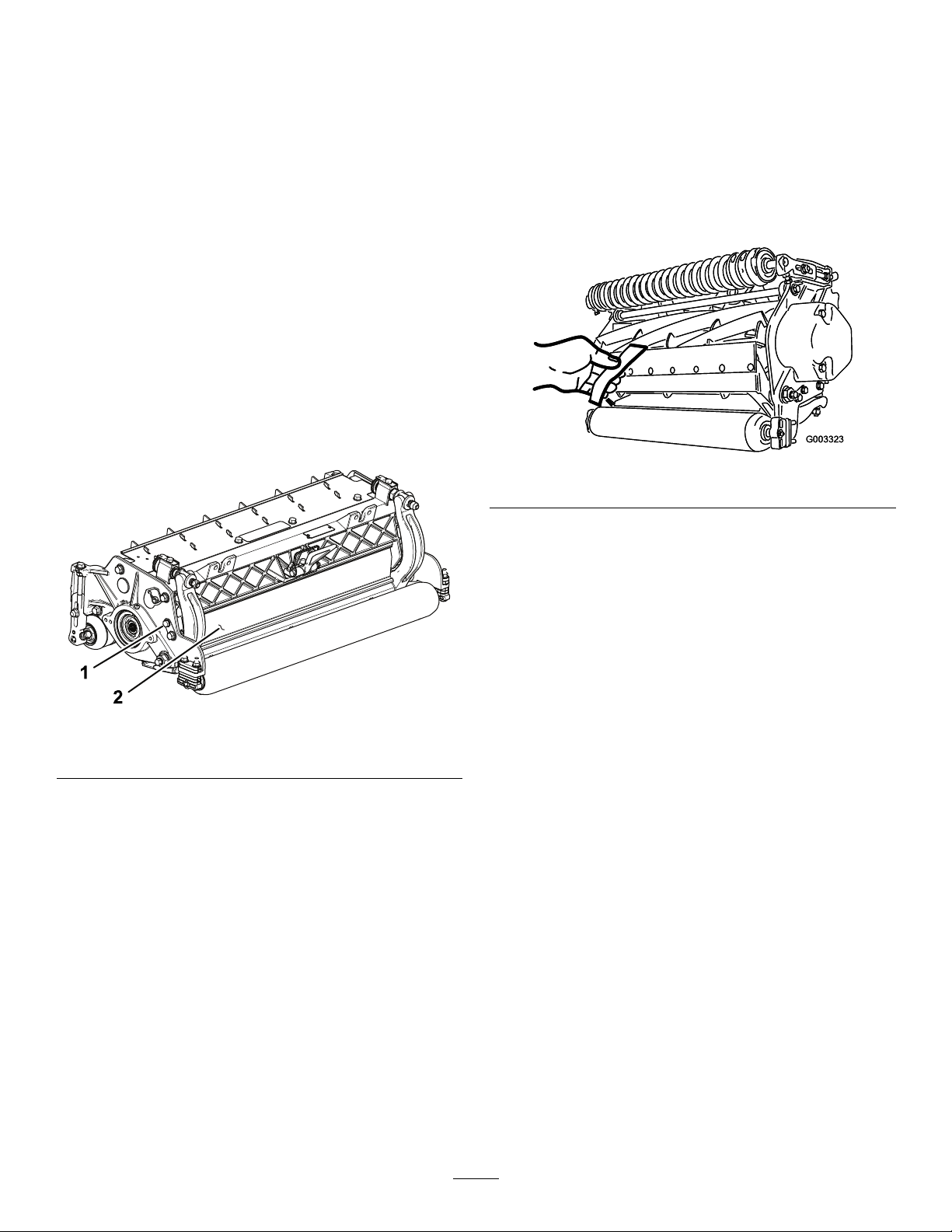

UsingtheKickstandwhenTippingthe

CuttingUnit...................................................17

LubricatingtheCuttingUnits.............................17

Relief-GrindingtheReel...................................18

InstallingtheFrontShaftAssemblyforReel

Grinding........................................................19

ServicingtheBedknife.....................................20

ServicingtheBedbar........................................21

ServicingtheHDDualPointAdjusters

(DPA)............................................................23

ServicingtheRoller...........................................24

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395andANSIB71.4–2017.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3