Toro groundsmaster 3240-d User manual

Other Toro Lawn Mower manuals

Toro

Toro Z Master Professional 7500-DSeries Manual

Toro

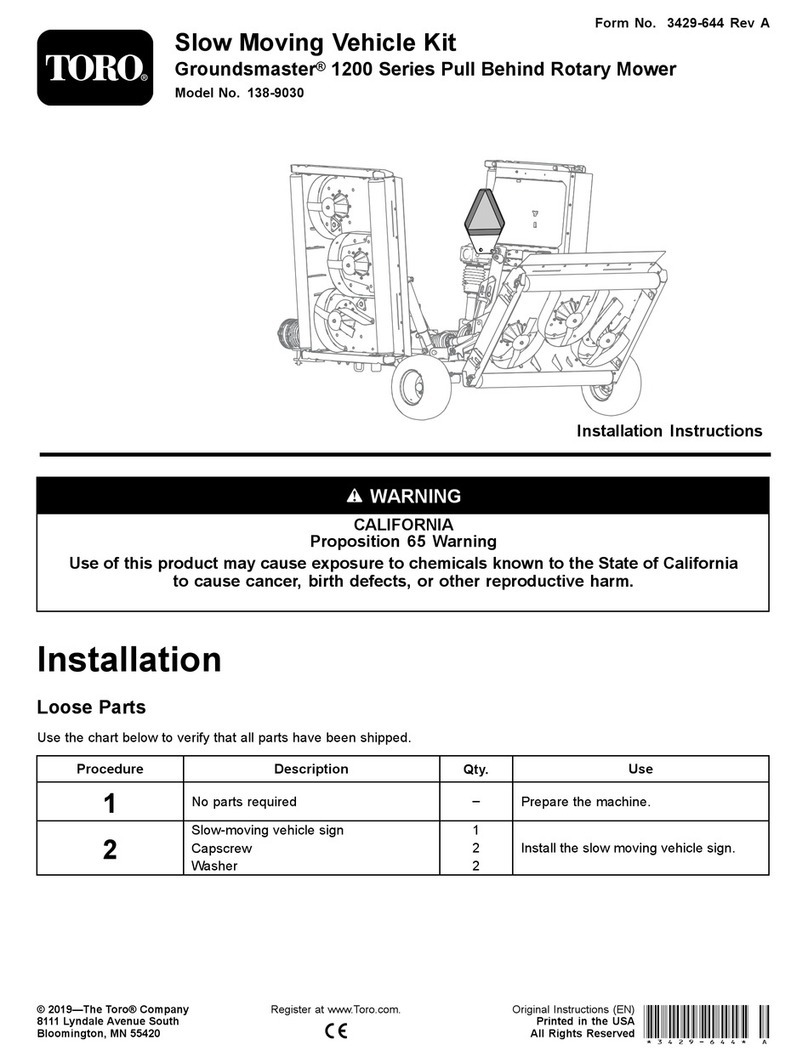

Toro Groundsmaster 1200 Series User manual

Toro

Toro 30253 User manual

Toro

Toro Wheel Horse XL380H 71252 User manual

Toro

Toro ProLine H800 User manual

Toro

Toro Flex-Force Power System 60V MAX 21in Recycler... User manual

Toro

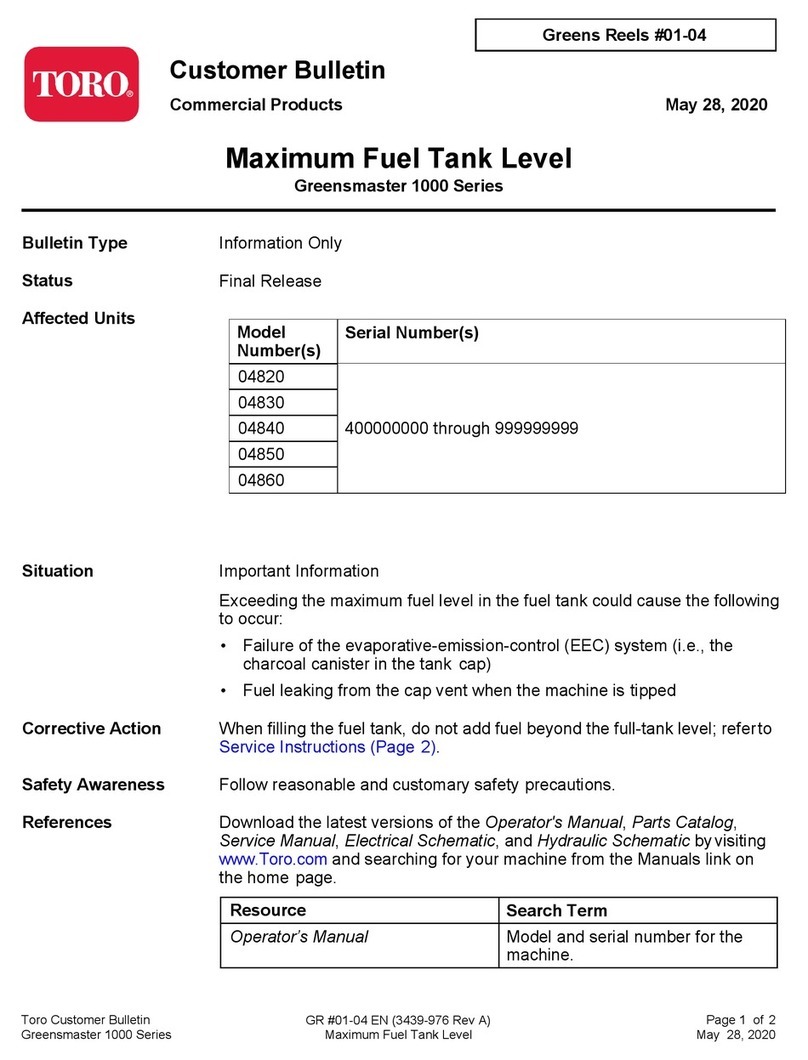

Toro Greensmaster 04820 Reference guide

Toro

Toro 39094 User manual

Toro

Toro TITAN 79348 User manual

Toro

Toro 22295 User manual

Toro

Toro 03200 Reelmaster 3100-D User manual

Toro

Toro Super Recycler Installation and operating instructions

Toro

Toro 74268TE User manual

Toro

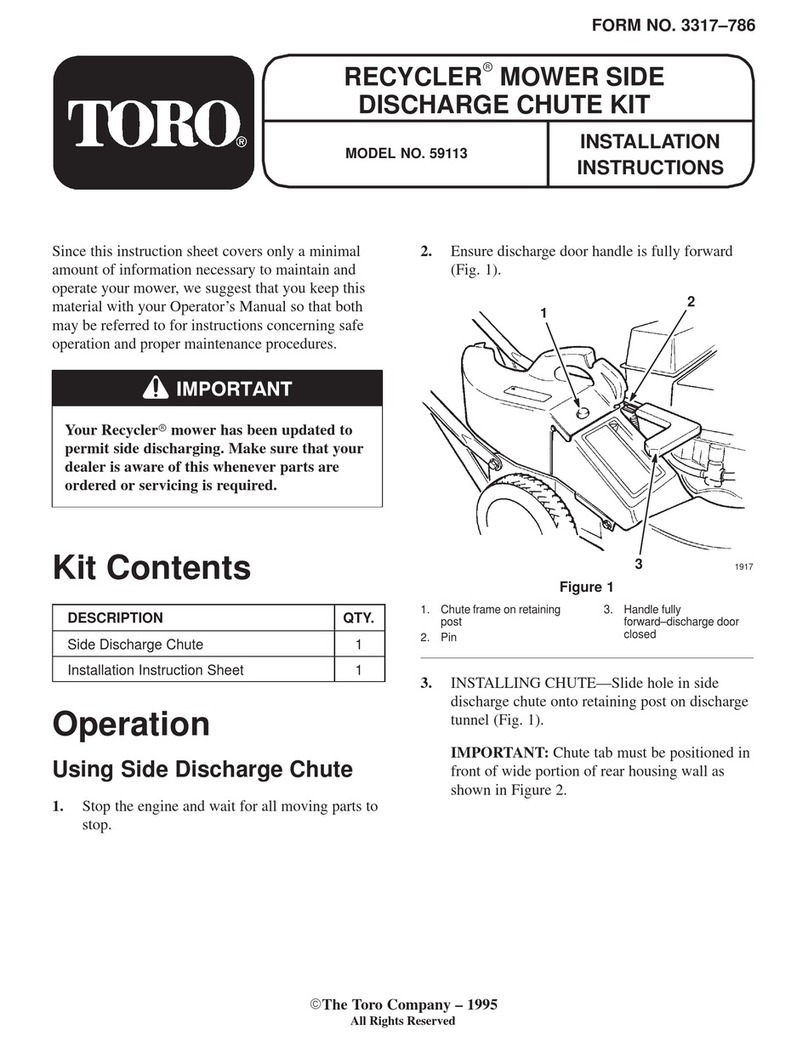

Toro RECYCLER 59113 User manual

Toro

Toro Recycler 20960 User manual

Toro

Toro 74227 User manual

Toro

Toro 30434 User manual

Toro

Toro 20197 User manual

Toro

Toro 30857N User manual

Toro

Toro ProLine 21 Recycler Series User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual