Safety

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheownersresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator’sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk,don’trun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

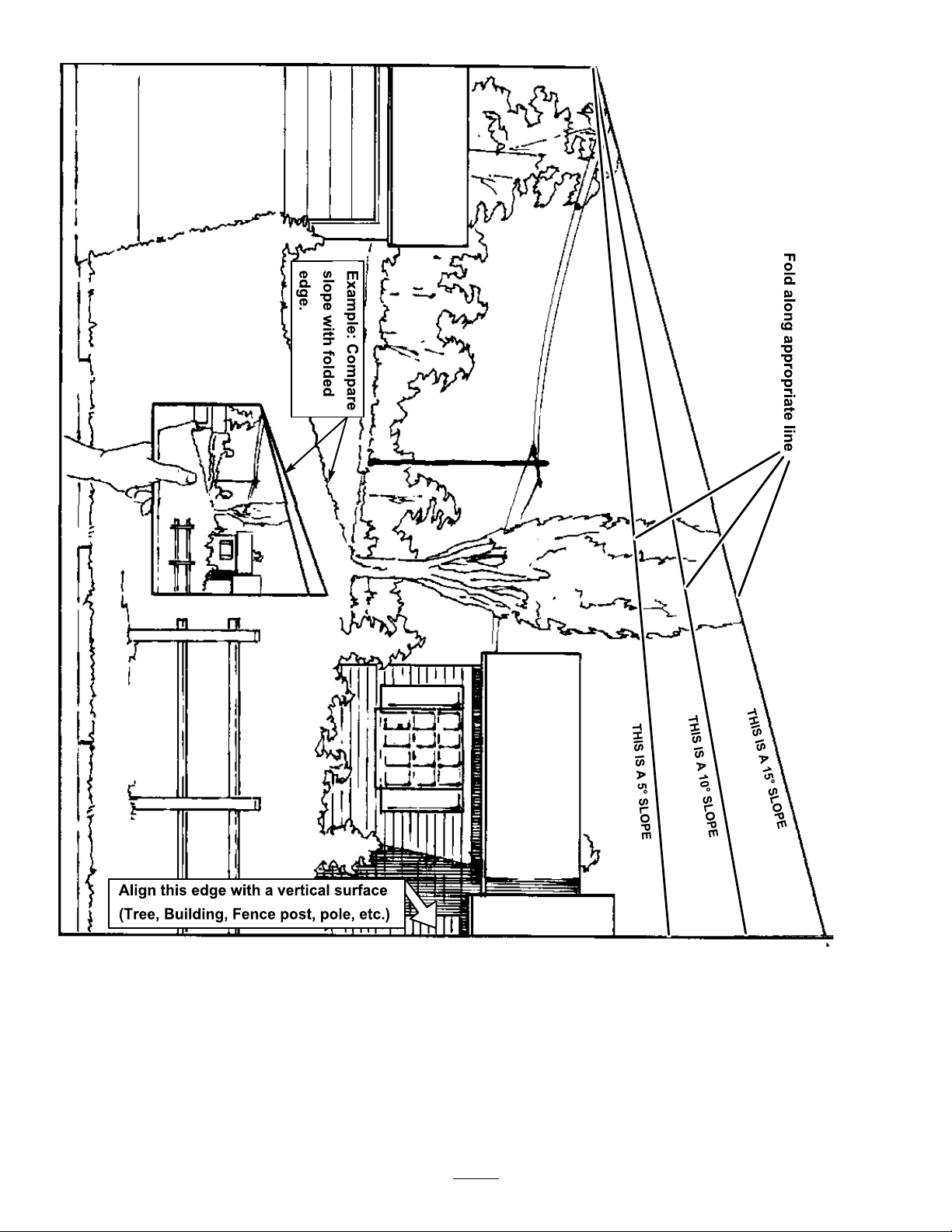

•Slowdownanduseextracareonhillsides.Besure

totravelsidetosideonhillsides.Turfconditions

canaffectthemachine’sstability.Usecautionwhile

operatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguards

notsecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

parkingbrake(ifprovided),shutoffenginebefore

leavingtheoperator’spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnot

mowing.

4