Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPressureLevelfora4500-D.......................7

SoundPressureLevelfora4700-D.......................7

SoundPowerLevel...............................................7

VibrationLevel.....................................................7

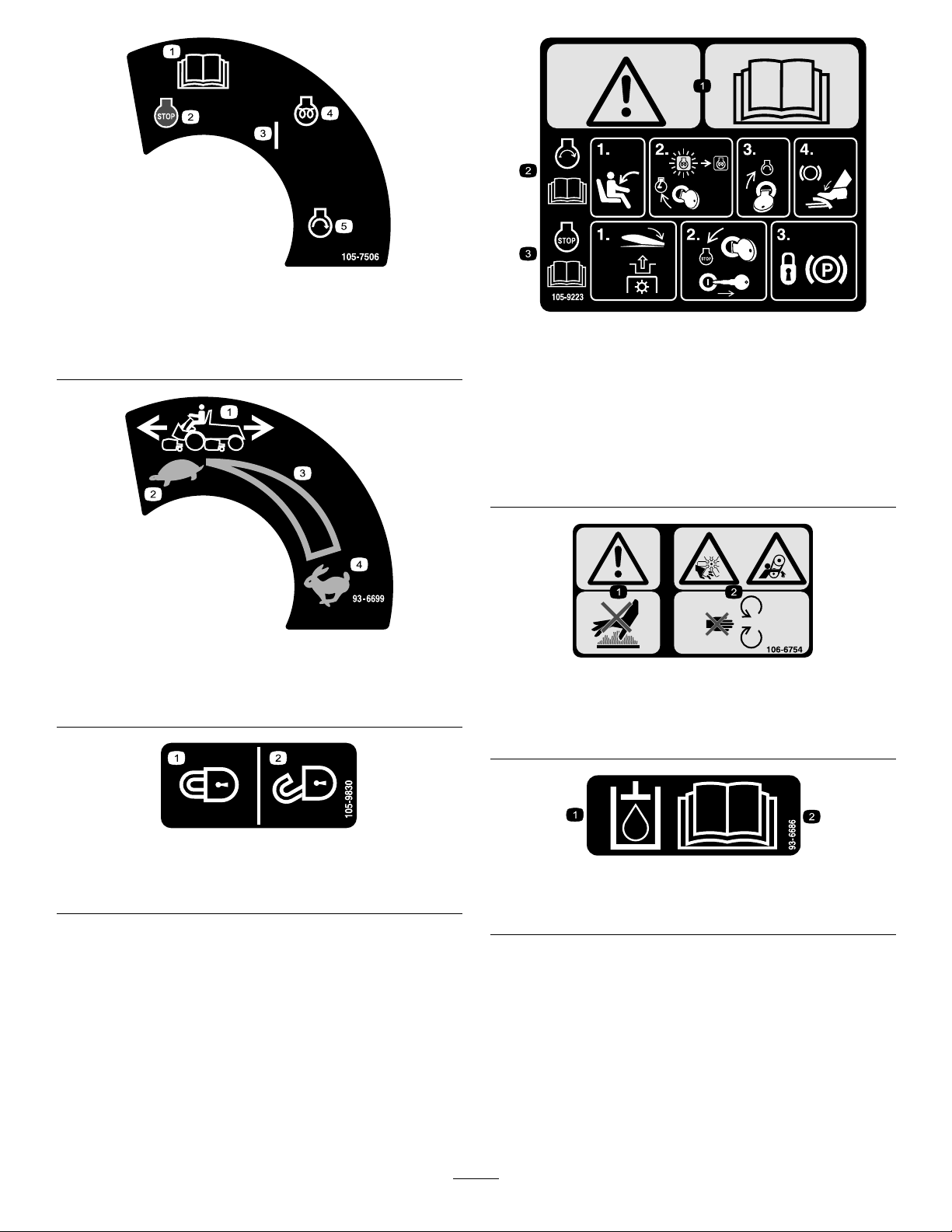

SafetyandInstructionalDecals.............................8

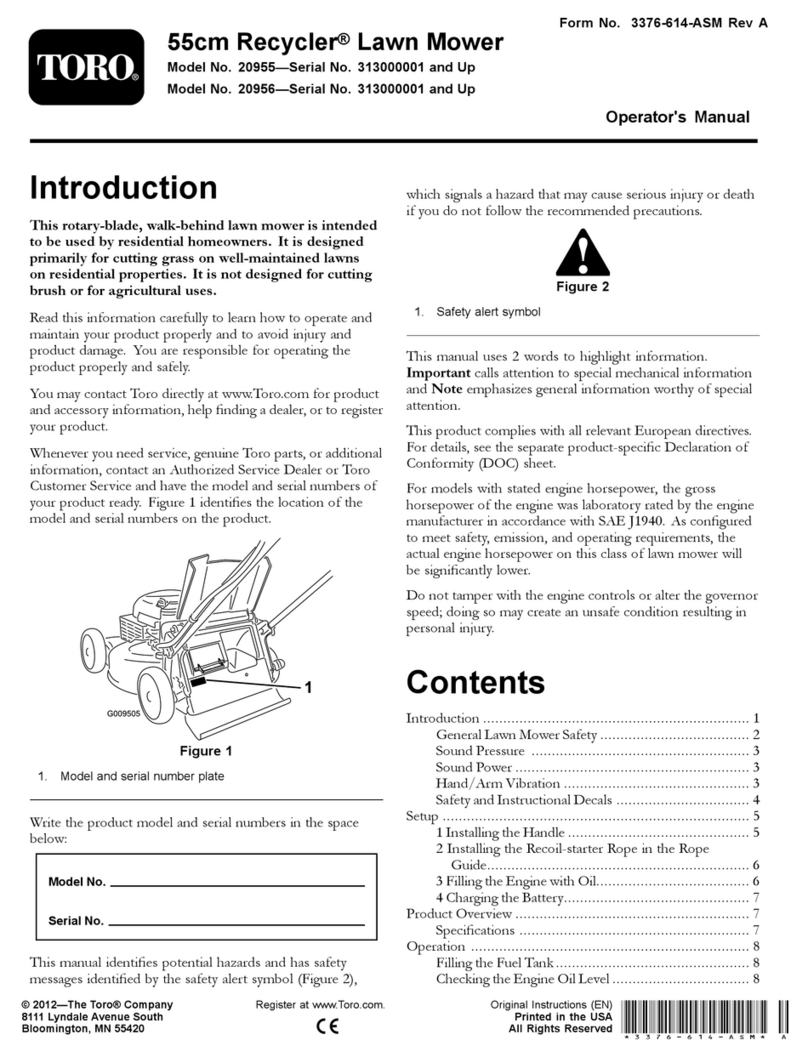

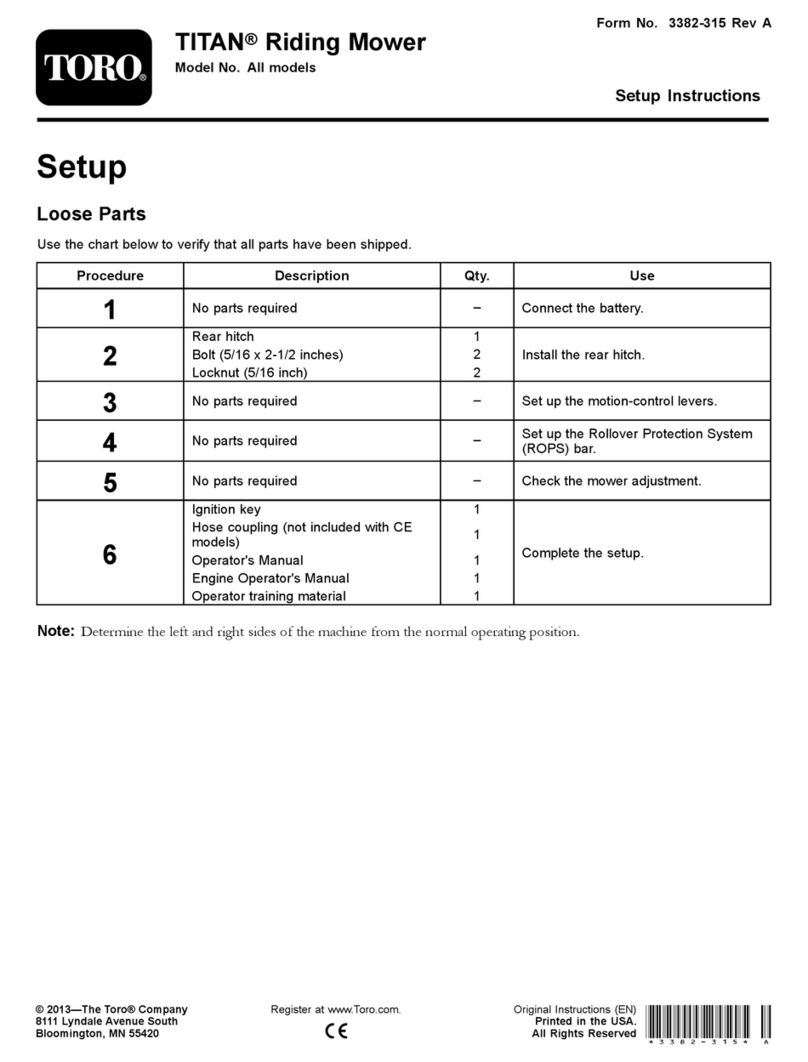

Setup..........................................................................13

1InstallingtheSeat,SeatBelt,andManual

Tube...............................................................13

2ReplacingtheWarningDecal............................14

3GreasingtheMachine......................................14

4CheckingFluidLevels......................................14

5ReadingtheManualsandViewingthe

TrainingMaterial............................................14

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................19

TractionUnitSpecications................................19

Attachments/Accessories...................................19

Operation...................................................................20

CheckingtheEngineOilLevel............................20

CheckingtheCoolingSystem..............................20

FillingtheFuelTank...........................................21

CheckingtheHydraulicFluidLevel.....................21

CheckingtheTirePressure.................................22

StartingandStoppingtheEngine........................22

CheckingtheInterlockSwitches.........................23

PushingorTowingtheMachine..........................24

JackingPoints.....................................................24

TieDowns.........................................................24

OperatingCharacteristics...................................24

StandardControlModule(SCM)........................25

OperatingTips...................................................26

Maintenance...............................................................28

RecommendedMaintenanceSchedule(s)................28

DailyMaintenanceChecklist...............................29

ServiceIntervalChart.........................................30

PremaintenanceProcedures....................................31

RemovingtheHood...........................................31

Lubrication.............................................................31

GreasingtheBearingsandBushings....................31

EngineMaintenance...............................................33

ServicingtheAirCleaner....................................33

ServicingtheEngineOilandFilter......................34

AdjustingtheThrottle........................................34

FuelSystemMaintenance.......................................35

FuelTank...........................................................35

FuelLinesandConnections................................35

WaterSeparator.................................................35

ReplacingtheFuelPre-Filter...............................35

FuelPick-upTubeScreen...................................36

BleedingtheFuelSystem....................................36

BleedingAirfromtheInjectors...........................36

ElectricalSystemMaintenance................................37

ChargingandConnectingtheBattery..................37

BatteryCare.......................................................38

Fuses..................................................................38

DriveSystemMaintenance.....................................39

CheckingtheTorqueoftheWheel

Nuts...............................................................39

CheckingthePlanetaryGearDrive

Oil..................................................................39

ChangingthePlanetaryGearDrive

Oil..................................................................39

CheckingtheRearAxleLubricant.......................40

ChangingtheRearAxleLubricant.......................40

AdjustingtheTractionDriveforNeutral.............41

CheckingtheRearWheelToe-In.........................41

CoolingSystemMaintenance..................................42

ServicingtheEngineCoolingSystem..................42

BrakeMaintenance.................................................43

AdjustingtheServiceBrakes...............................43

BeltMaintenance....................................................44

ServicingtheAlternatorBelt...............................44

HydraulicSystemMaintenance...............................44

ChangingtheHydraulicFluid.............................44

ReplacingtheHydraulicFilters...........................44

CheckingtheHydraulicLinesandHoses.............45

HydraulicSystemTestPorts...............................45

AdjustingtheCounterbalance.............................46

Cleaning.................................................................47

ServicingtheSparkArrestorMufer...................47

Storage.......................................................................48

TractionUnit......................................................48

Engine...............................................................48

Schematics.................................................................49

3