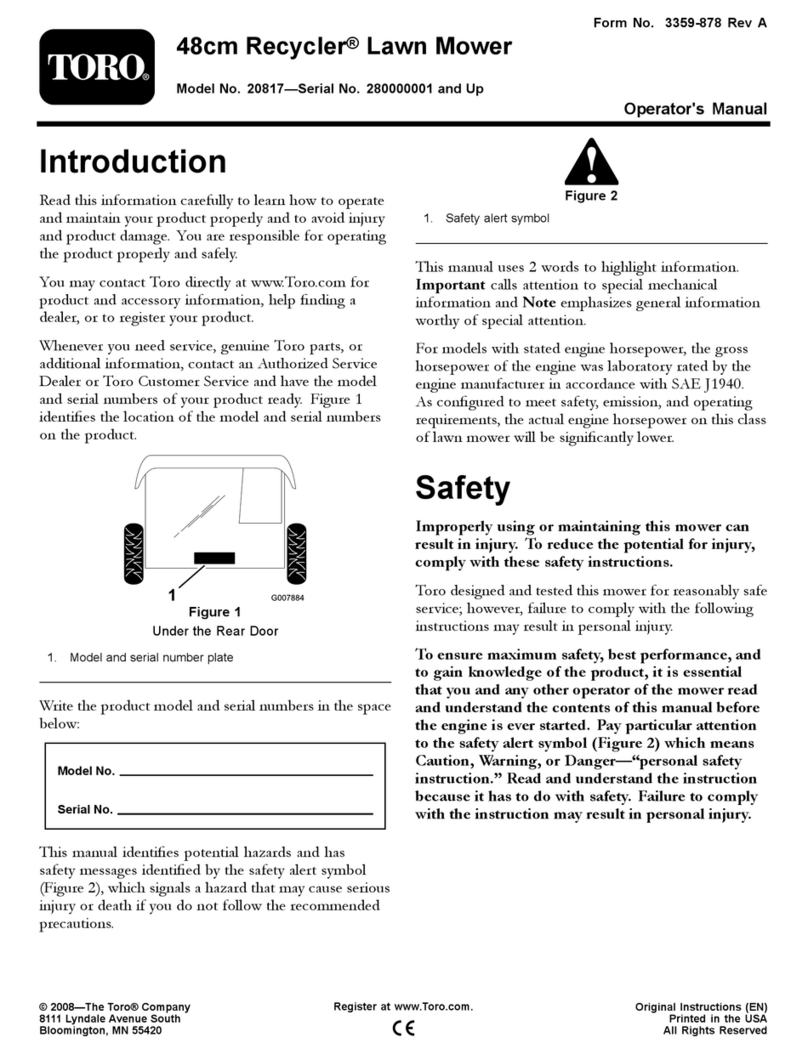

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................14

1InstallingtheDriveShafttoanOptionalMower

DeckorQAS.....................................................14

2OptionalMowerDeckMountingHardware.............15

3AdjustingtheROPS.............................................15

4CheckingtheTirePressure....................................16

5CheckingtheFluidLevels.....................................16

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

AddingFuel...........................................................19

FillingtheFuelTank...............................................20

UsingtheRolloverProtectionSystem(ROPS)

........................................................................20

ThinkSafetyFirst...................................................21

StartingandStoppingtheEngine..............................21

DrivingtheMachine...............................................22

SteeringSelection(4wheeldrivemodels

only).................................................................23

StoppingtheMachine.............................................23

OperatingaMowerDeckor

Attachment(Optional).........................................23

AdjustingtheHeight-of-Cut....................................24

TheSafetyInterlockSystem.....................................25

UnderstandingtheDiagnosticLight.........................25

DiagnosticAceDisplay...........................................26

CheckingtheInterlockSwitches..............................26

PositioningtheStandardSeat...................................28

PositioningtheDeluxeSeat......................................28

Raising/LoweringtheSeat.......................................29

PushingtheMachinebyHand..................................30

LoadingMachines..................................................30

TransportingMachines............................................31

Maintenance.................................................................33

RecommendedMaintenanceSchedule(s)......................33

DailyMaintenanceChecklist....................................34

PremaintenanceProcedures........................................35

UsingtheHoodPropRod.......................................35

Lubrication...............................................................35

GreasingtheBearingsandBushings..........................35

EngineMaintenance..................................................38

ServicingtheAirCleaner.........................................38

CheckingtheEngineOilLevel.................................38

ChangingtheEngineOilandFilter...........................39

AdjustingtheThrottle.............................................39

FuelSystemMaintenance...........................................40

ServicingtheWaterSeparator..................................40

BleedingtheFuelSystem.........................................40

BleedingAirfromtheFuelInjectors..........................40

CleaningtheFuelTank............................................41

FuelLinesandConnections.....................................41

ElectricalSystemMaintenance....................................42

CheckingtheFuses.................................................42

ServicingtheBattery...............................................42

StoringtheBattery..................................................43

DriveSystemMaintenance.........................................43

CheckingtheTirePressure......................................43

CorrectingSteeringMisalignment.............................43

CoolingSystemMaintenance......................................44

CheckingtheCoolingSystem..................................44

CleaningtheRadiator..............................................44

BrakeMaintenance....................................................45

AdjustingtheServiceBrakes....................................45

AdjustingtheParkingBrake....................................46

BeltMaintenance......................................................46

CheckingtheAlternatorBelt...................................46

ControlsSystemMaintenance.....................................47

AdjustingtheTractionDriveforNeutral....................47

AdjustingtheMaximumGroundSpeed.....................47

AdjustingtheSpeedLimiterLever............................48

HydraulicSystemMaintenance....................................49

CheckingtheHydraulicSystem................................49

ChangingtheHydraulicOilAndFilter.......................49

CabMaintenance.......................................................50

MaximizingAirConditionerPerformance..................50

CleaningtheCabAirFilters.....................................50

CleaningtheAirConditioningCoil...........................51

CleaningtheA/CCondenserScreen.........................52

Cleaning...................................................................52

CleaningtheCab....................................................52

WasteDisposal.......................................................52

Storage........................................................................53

Engine..................................................................53

Machine................................................................53

3