Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

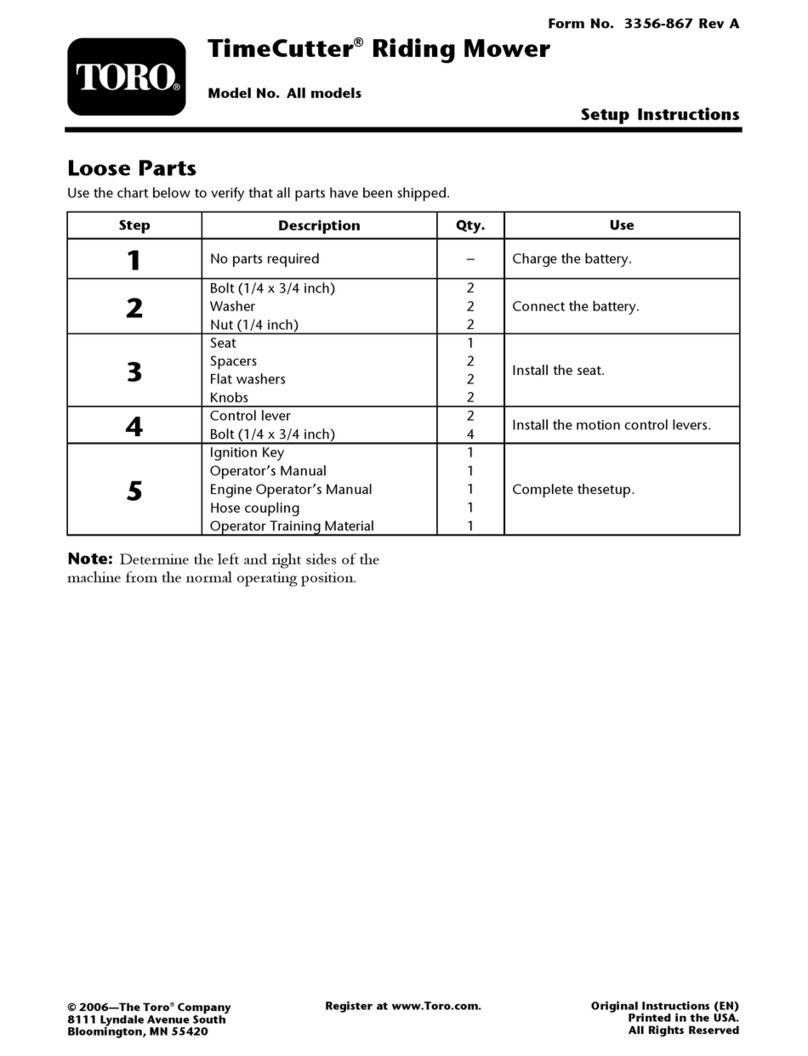

Setup...........................................................................14

1InstallingtheSteeringWheel..................................15

2InstallingtheHoodHandle...................................15

3InstallingtheSeat.................................................16

4InstallingtheSeatBelt..........................................16

5InstallingtheManualTube....................................16

6AdjustingtheROPS.............................................17

7ActivatingandChargingtheBattery........................17

8CheckingtheTirePressure....................................19

9InstallingtheLiftLockLever(ForCE

Only)................................................................19

10AdjustingtheCounterbalancePressure..................20

11InstallingRearWeights........................................21

12CheckingFluidLevels.........................................23

13ReadingtheManualsandViewingtheTraining

Materials............................................................23

ProductOverview.........................................................24

Controls...............................................................24

Specications........................................................27

Attachments/Accessories........................................27

Operation....................................................................27

CheckingtheEngineOilLevel.................................27

CheckingtheCoolingSystem..................................28

CheckingtheHydraulicSystem................................28

AddingFuel...........................................................29

CheckingtheRearAxleLubricant(Model30345

only).................................................................30

CheckingtheBidirectionalClutchLubricant

(Model30345only).............................................31

UsingtheRolloverProtectionSystem(ROPS)............31

Starting/StoppingtheEngine..................................32

BleedingtheFuelSystem.........................................32

CheckingtheInterlockSystem.................................33

PushingorTowingtheMachine................................33

StandardControlModule(SCM)..............................34

OperatingTips......................................................35

Maintenance.................................................................36

RecommendedMaintenanceSchedule(s)......................36

DailyMaintenanceChecklist....................................37

Lubrication...............................................................38

GreasingtheBearingsandBushings..........................38

EngineMaintenance..................................................41

GeneralAirCleanerMaintenance.............................41

ChangingtheEngineOilAndFilter..........................42

FuelSystemMaintenance...........................................42

ServicingtheWaterSeparator..................................42

CleaningtheFuelTank............................................42

FuelLinesandConnections.....................................43

BleedingAirfromtheInjectors................................43

ElectricalSystemMaintenance....................................43

ServicingtheBattery...............................................43

StoringtheBattery..................................................44

ServicingtheWiringHarness...................................44

AccessingtheFuses................................................44

DriveSystemMaintenance.........................................45

ChangingtheRearAxleLubricant(Model30345

only).................................................................45

CheckingSteeringCylinderBoltTorque(Model

30345only)........................................................45

ChangingtheBidirectionalClutchLubricant

(Model30345only).............................................45

AdjustingtheTractionDriveforNeutral....................45

AdjustingRearWheelToe-in....................................46

AdjustingSteeringStops(Model30345

only).................................................................47

CoolingSystemMaintenance......................................48

CleaningtheRadiatorandtheScreen.........................48

BrakeMaintenance....................................................48

AdjustingtheParkingBrakeInterlockSwitch..............48

AdjustingtheServiceBrakes....................................49

BeltMaintenance......................................................50

CheckingtheAlternatorBelt...................................50

ServicingthePTOBelt............................................50

ControlsSystemMaintenance.....................................51

AdjustingthePTOClutch.......................................51

AdjustingtheTractionPedal....................................51

AdjustingtheTiltSteeringControl............................52

HydraulicSystemMaintenance....................................52

ChangingtheHydraulicOilAndFilter.......................52

Storage........................................................................53

Machine................................................................53

Engine..................................................................53

3