Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPressureLevel...........................................6

VibrationLevel.....................................................6

SafetyandInstructionalDecals.............................7

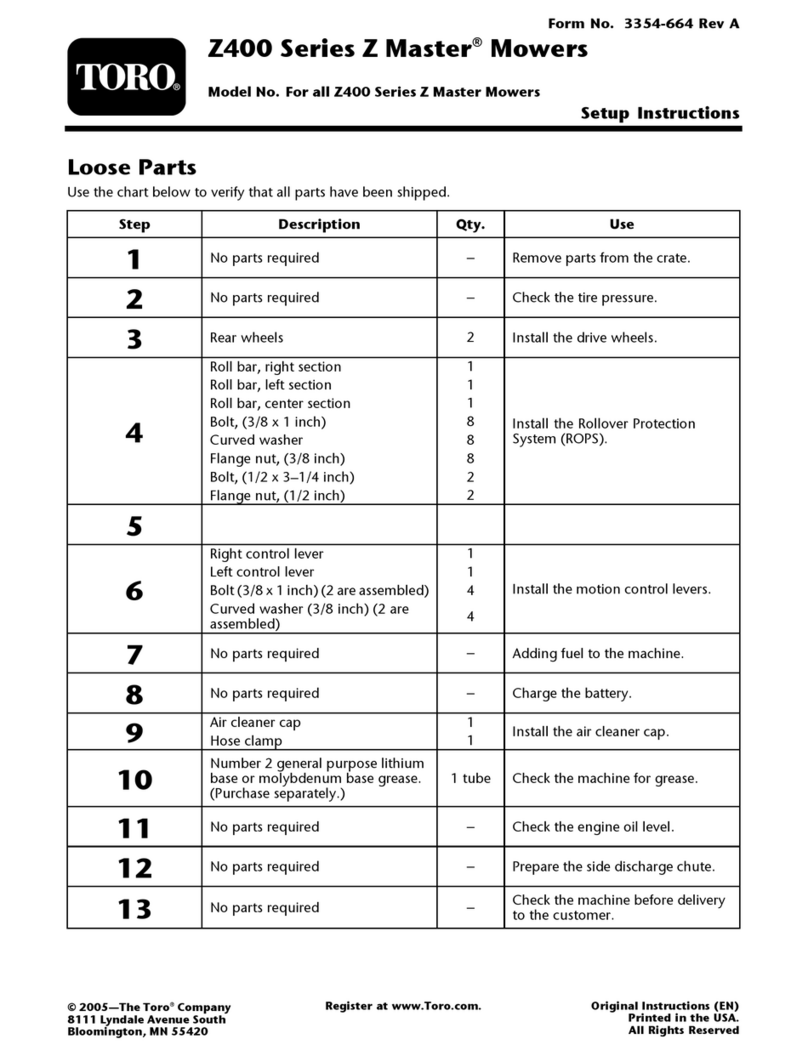

Setup..........................................................................12

1CheckingFluidLevels......................................12

2InstallingCuttingUnitsModels03860,03861

and03862.......................................................12

3InstallingCuttingUnitsModels03863and

03864.............................................................14

4MakingAlternateCuttingUnit

Adjustments...................................................18

5AddingRearBallast..........................................19

6InstallingCEDecals........................................19

7ReadingtheManualsandStoringAdditional

Parts...............................................................19

ProductOverview......................................................20

Controls.............................................................20

Specications.....................................................24

Attachments/Accessories...................................24

Operation...................................................................24

CheckingtheEngineOil.....................................24

CheckingtheCoolingSystem..............................25

FillingtheFuelTank...........................................26

CheckingtheHydraulicFluid..............................26

CheckingtheTirePressure.................................27

CheckingtheReeltoBedknifeContact................27

StartingandStopping.........................................27

BleedingtheFuelSystem....................................27

PushingorTowingtheMachine..........................28

CheckingtheInterlockSwitches.........................29

FaultMemoryandRetrieval................................30

HydraulicSolenoidValveFunctions....................31

OperatingTips...................................................31

Maintenance...............................................................33

RecommendedMaintenanceSchedule(s)................33

ServiceIntervalChart.........................................34

DailyMaintenanceChecklist...............................34

Lubrication.............................................................35

GreasingtheBearingsandBushings....................35

EngineMaintenance...............................................37

ServicingtheAirCleaner....................................37

ServicingtheEngineOilandFilter......................38

AdjustingThrottle..............................................38

FuelSystemMaintenance.......................................39

FuelTank...........................................................39

FuelLinesandConnections................................39

FuelFilter/WaterSeparator................................39

ReplacingtheFuelPre-Filter...............................39

BleedingAirFromInjectors...............................40

ElectricalSystemMaintenance................................41

BatteryCare.......................................................41

Fuses..................................................................41

OptionalLighting...............................................42

DriveSystemMaintenance.....................................43

CheckingtheTorqueoftheWheelNutsor

Bolts..............................................................43

CheckingthePlanetaryGearDrive

Oil..................................................................43

ChangingthePlanetaryGearDrive

Oil..................................................................43

CheckingtheRearAxleLubricant.......................44

ChangingtheRearAxleLubricant.......................44

RearWheelToe-In.............................................45

AdjustingtheTractionDriveforNeutral.............45

CoolingSystemMaintenance..................................46

RemovingDebris...............................................46

MaintainingtheCoolingSystem..........................46

BrakeMaintenance.................................................47

AdjustingtheServiceBrakes...............................47

BeltMaintenance....................................................47

CheckingtheAlternatorBelt...............................47

HydraulicSystemMaintenance...............................48

ChangingtheHydraulicFluid.............................48

ReplacingtheHydraulicFilter.............................48

CheckingtheHydraulicLinesandHoses.............48

HydraulicSystemTestPorts...............................49

CuttingUnitMaintenance.......................................50

CuttingUnitKickstandModels03863and

03864.............................................................50

Backlapping........................................................50

AdjustingtheCuttingUnitLoweringRate

......................................................................52

LiftedHeightofOuterFrontCuttingUnits

(EnablePosition)............................................53

AdjustingtheTraveloftheFrontThree

CuttingUnits..................................................53

Storage.......................................................................55

TractionUnit......................................................55

Engine...............................................................55

Schematics.................................................................56

3