Toro 4502 User manual

Other Toro Lawn Mower manuals

Toro

Toro 74408TE User manual

Toro

Toro Z Master Professional 7000 Series User manual

Toro

Toro e-cycler 20360 User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

Toro Greensmaster e1021 User manual

Toro

Toro 31970 User manual

Toro

Toro Greensmaster eTriFlex 3360 User manual

Toro

Toro Greensmaster eFlex 1800 User manual

Toro

Toro LX423 User manual

Toro

Toro Z Master 77248 User manual

Toro

Toro 03698 User manual

Toro

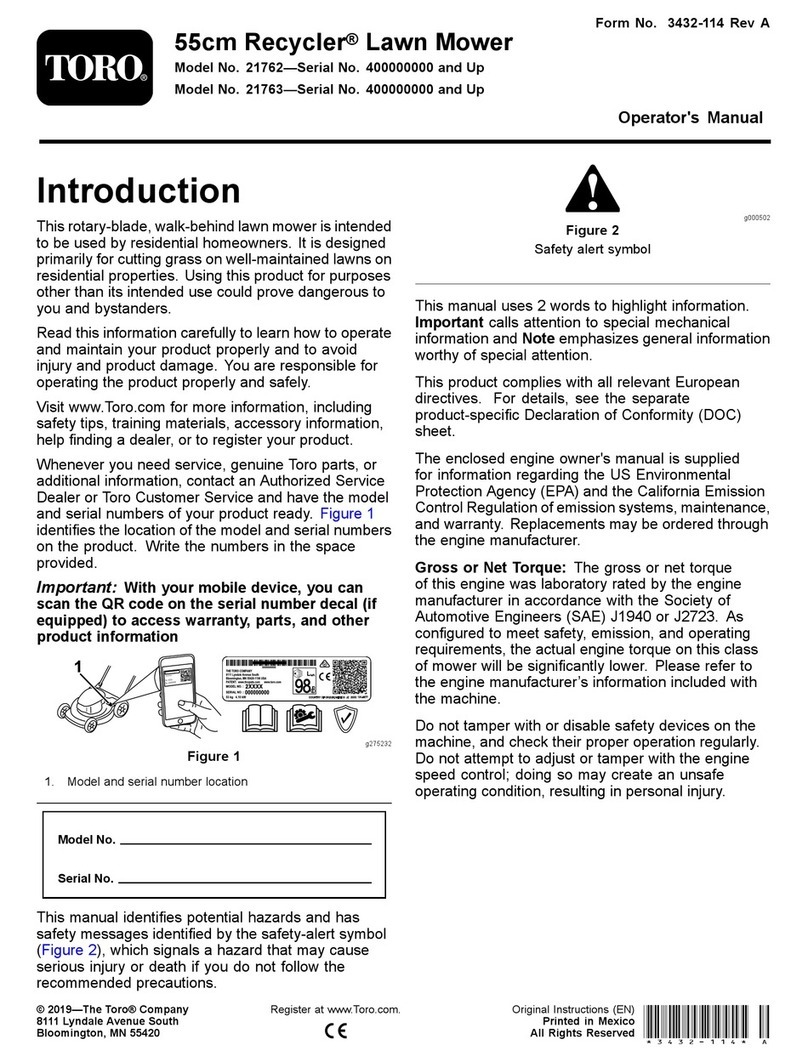

Toro Recycler 21762 User manual

Toro

Toro Groundsmaster 3200 Series User manual

Toro

Toro TimeMaster 20199 User manual

Toro

Toro Super Recycler 20382 User manual

Toro

Toro 30839N User manual

Toro

Toro Recycler 21131 User manual

Toro

Toro 20658 User manual

Toro

Toro 4383 User manual

Toro

Toro 22291 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual