Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

SafetyandInstructionalDecals..........................5

Setup........................................................................7

1PreparingtheMachine.....................................7

2InstallingaCompletionKit................................7

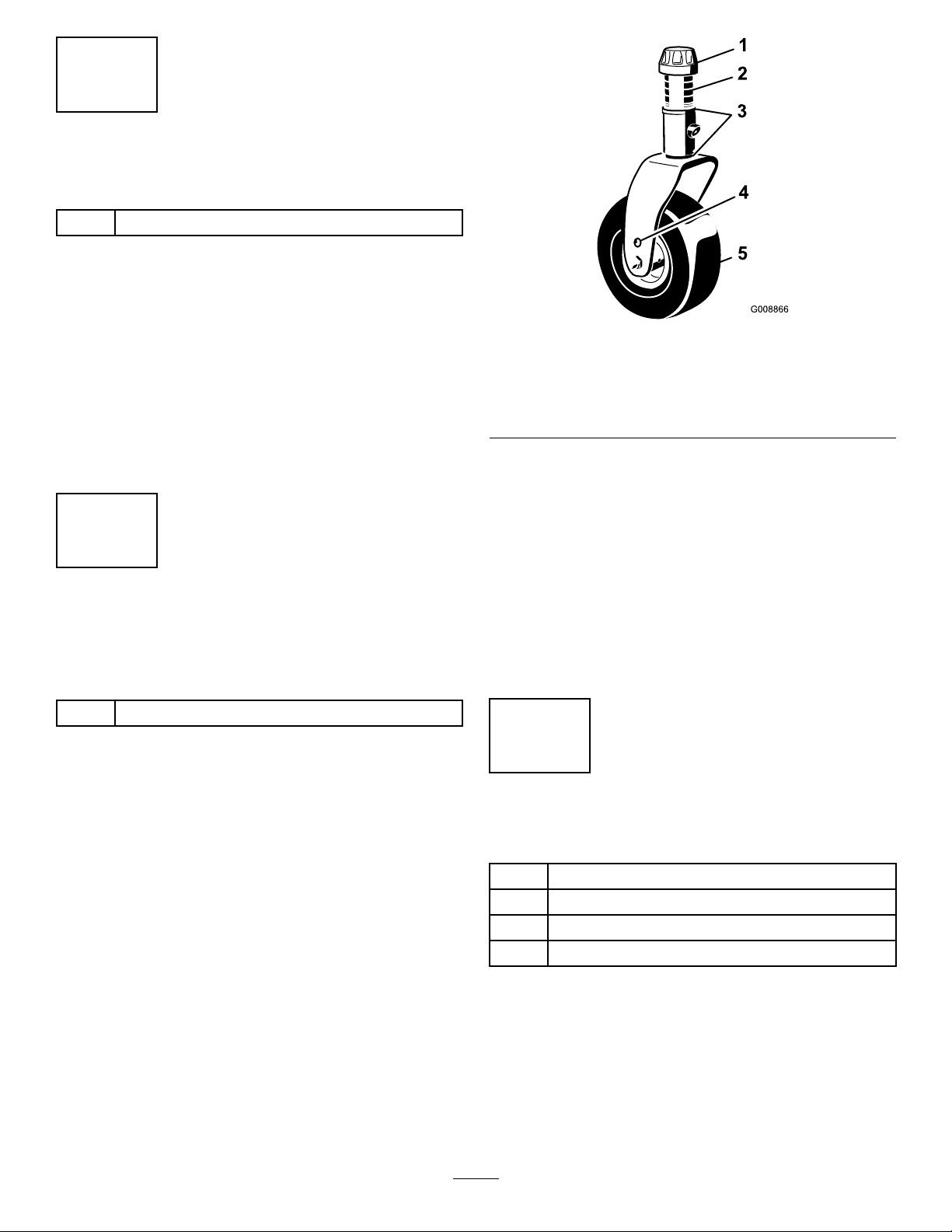

3InstallingtheCastorWheelAssemblies............8

4InstallingtheLiftArms......................................8

5InstallingtheCuttingUnitsontheLift

Arms...............................................................9

6ConnectingthePTOShafttotheCutting

UnitGearbox.................................................10

7GreasingtheMachine....................................10

ProductOverview....................................................11

Specications...................................................11

Attachments/Accessories..................................11

Operation.................................................................11

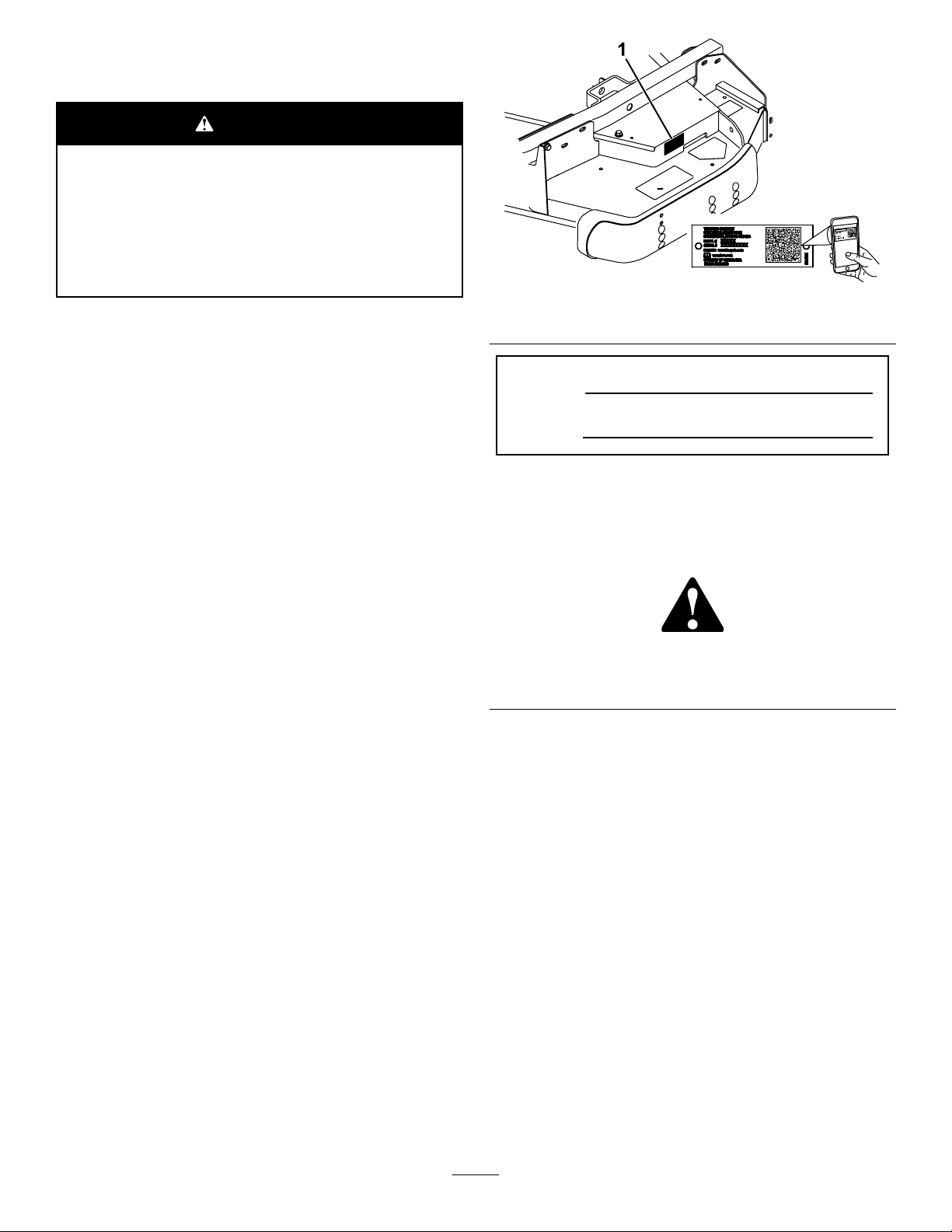

AdjustingtheHeight-of-Cut................................11

AdjustingtheCuttingUnitPitch.........................13

AdjustingtheSkids...........................................13

AdjustingtheRollers.........................................14

CorrectingCuttingUnitMismatch.....................14

OperatingTips.................................................15

Maintenance...........................................................16

RecommendedMaintenanceSchedule(s)...........16

DailyMaintenanceChecklist.............................16

Lubrication........................................................17

CheckingtheLubricantintheGearbox..............17

SeparatingtheCuttingUnitfromtheTraction

Unit...............................................................18

MountingtheCuttingUnittotheTraction

Unit...............................................................19

ServicingtheBushingsintheCastor

Arms.............................................................19

ServicingtheCastorWheelsand

Bearings........................................................20

ServicingtheCuttingBlades.............................20

CheckingandCorrectingMismatchof

Blades...........................................................22

ReplacingtheDriveBelt...................................22

CleaningUndertheCuttingUnit........................23

Storage...................................................................23

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface,lowerthe

cuttingunits,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

CuttingUnitSafety

•Thecuttingunitisonlyapartofacomplete

machinewheninstalledonatractionunit.Read

thetractionunitOperator’sManualcarefully

forcompleteinstructionsonthesafeuseofthe

machine.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

3