Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

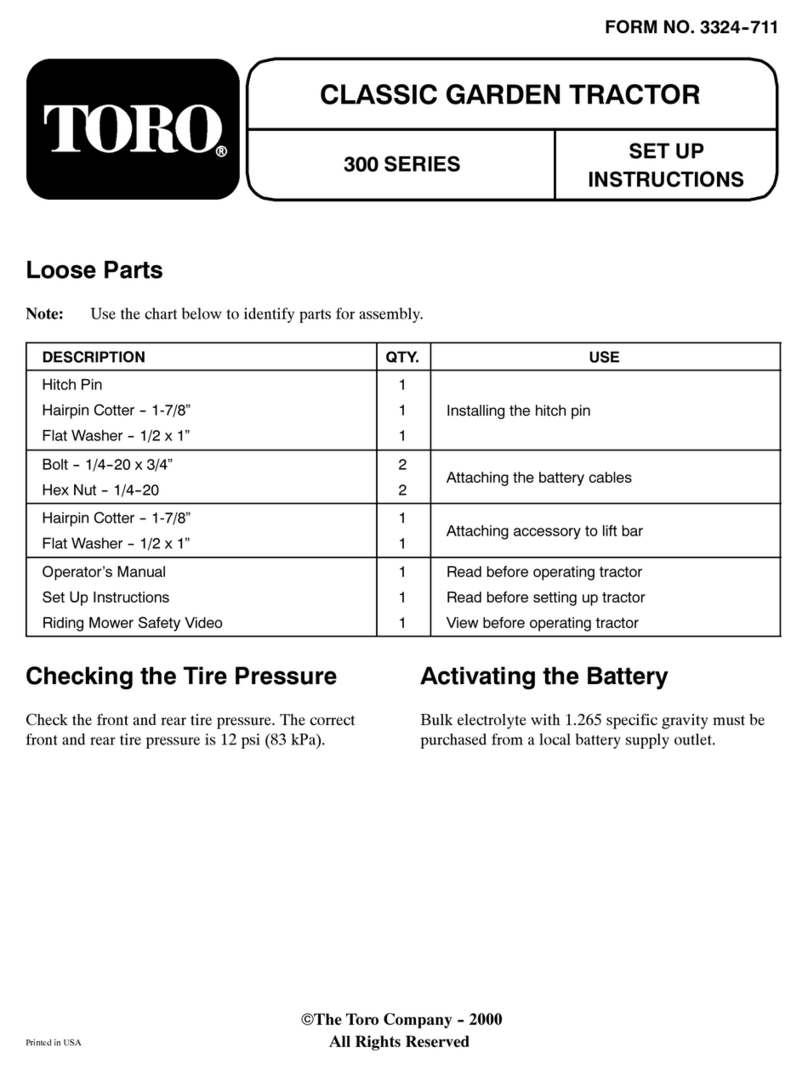

Setup........................................................................7

1InstallingandAdjustingtheHandle..................8

2InstallingtheTransport-WheelShafts...............9

3InstallingtheTransportWheels......................10

4AdjustingtheCuttingUnit...............................10

5InstallingtheOperatorPresence

Kit..................................................................10

6InstallingtheCEDecals..................................11

7InstallingtheGrassBasket..............................11

8BreakingintheMachine.................................12

ProductOverview...................................................12

Controls...........................................................13

Specications..................................................14

Attachments/Accessories.................................14

BeforeOperation.................................................15

BeforeOperationSafety...................................15

PerformingDailyMaintenance..........................15

CheckingtheEngine-OilLevel..........................15

FuelSpecications...........................................15

FillingtheFuelTank..........................................16

SettingtheMachinetoMatchTurf

Conditions.....................................................17

CheckingtheInterlock-Switch

Operation......................................................18

TransportingtheMachinetoaJob

Site................................................................18

RemovingtheTransportWheels.......................18

UsingtheChokeLever.....................................18

OpeningandClosingtheFuel-Shutoff

Valve.............................................................19

DuringOperation.................................................19

DuringOperationSafety...................................19

StartingtheEngine...........................................20

ShuttingOfftheEngine.....................................20

OperatingTips..................................................21

AfterOperation....................................................22

AfterOperationSafety......................................22

TransportingtheMachine.................................22

Maintenance...........................................................23

MaintenanceSafety..........................................23

RecommendedMaintenanceSchedule(s)...........23

DailyMaintenanceChecklist.............................24

Pre-MaintenanceProcedures..............................25

PreparingtheMachineforMaintenance............25

Lubrication..........................................................25

GreasingtheMachine.......................................25

EngineMaintenance...........................................26

EngineSafety...................................................26

ServicingtheEngineOil....................................26

ServicingtheAirCleaner..................................28

ServicingtheSparkPlug...................................29

ElectricalSystemMaintenance...........................29

ServicingtheTraction-InterlockSwitch

......................................................................29

BrakeMaintenance.............................................30

AdjustingtheService/ParkingBrake.................30

BeltMaintenance................................................31

AdjustingtheBelts............................................31

ReplacingtheDifferentialBelt...........................34

ControlsSystemMaintenance.............................35

AdjustingtheTractionControl...........................35

CuttingUnitMaintenance.....................................35

BladeSafety.....................................................35

LevelingtheRearDrumtotheReel...................35

AdjustingtheBedknifetotheReel.....................36

AdjustingtheHeight-of-Cut...............................37

AdjustingtheGrassShieldHeight.....................38

AdjustingtheCut-OffBar..................................38

IdentifyingtheBedbar.......................................38

ServicingtheBedbar........................................39

BacklappingtheReel........................................39

Storage...................................................................40

StorageSafety..................................................40

StoringtheMachine..........................................40

3