Safety

Thismachinehasbeendesignedinaccordancewith

CENstandardENISO5395:2013andANSIB71.4-2012

specicationsineffectatthetimeofproductionwhenthe

OperatorPresenceKit,PartNo.112-9282isinstalled.

GeneralSafety

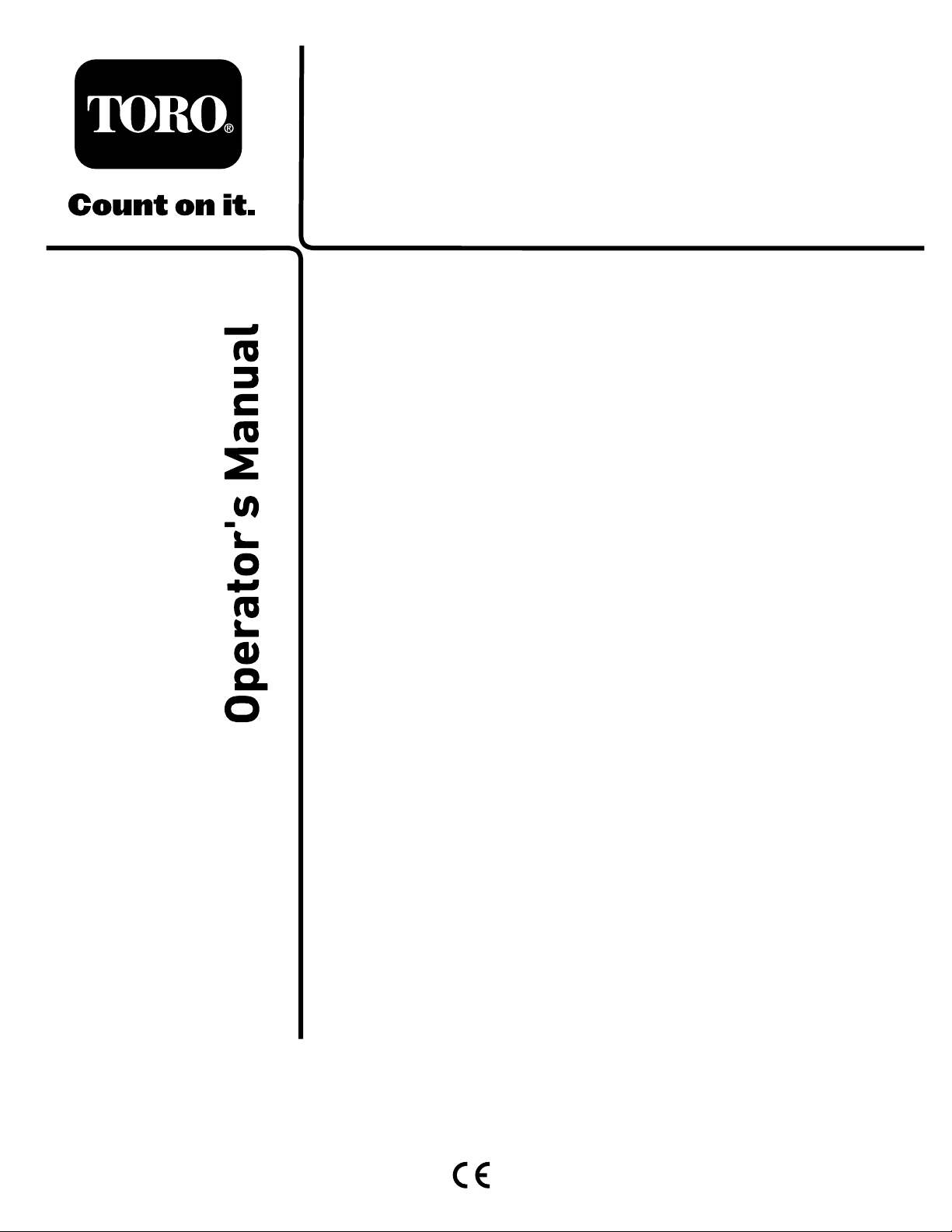

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’sManual

beforestartingtheengine.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystanders

andpetsasafedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Preparation

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghair,securelooseclothing,and

donotwearjewelry.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow .

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.

•UseaccessoriesandattachmentsapprovedbytheThe

Toro®Companyonly.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.

Operation

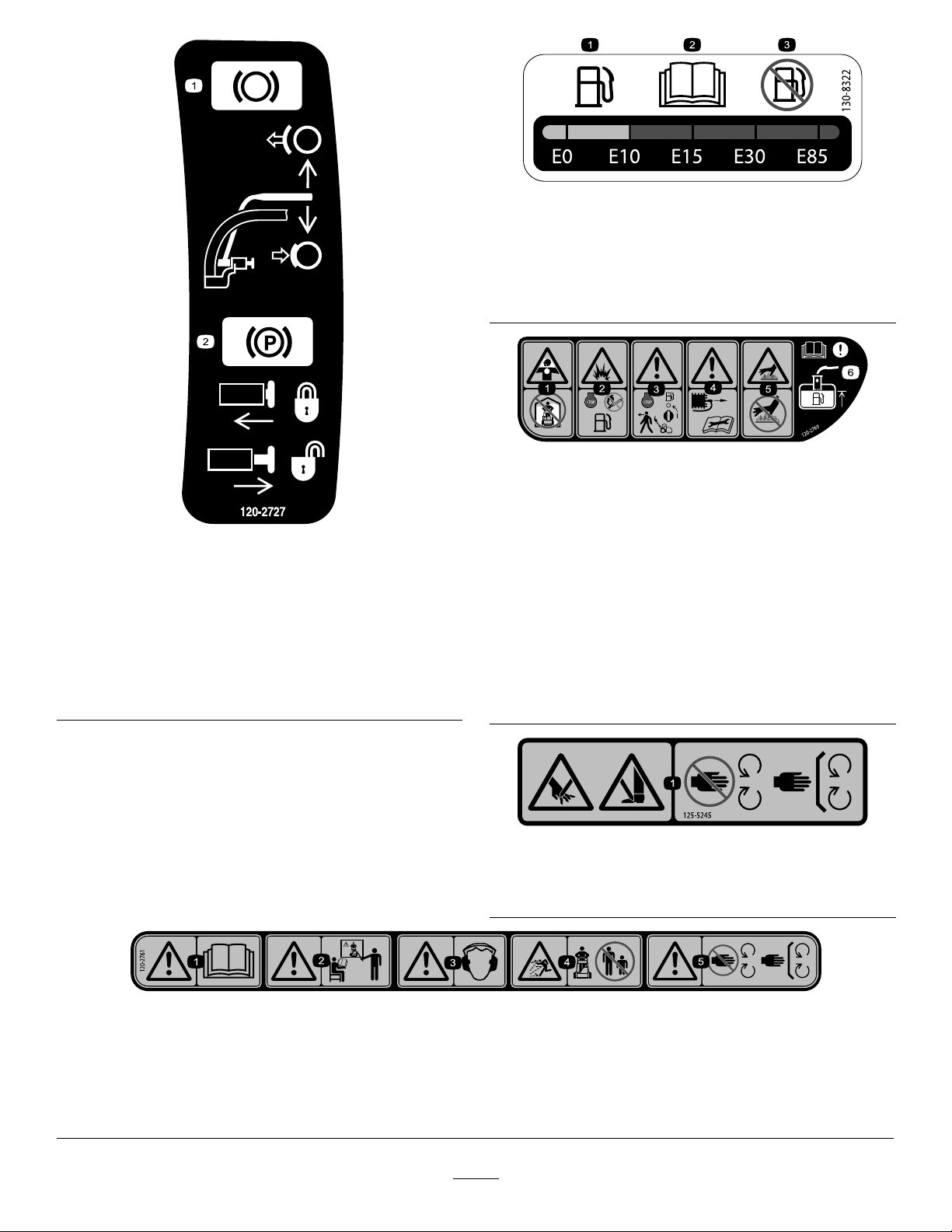

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflightning.

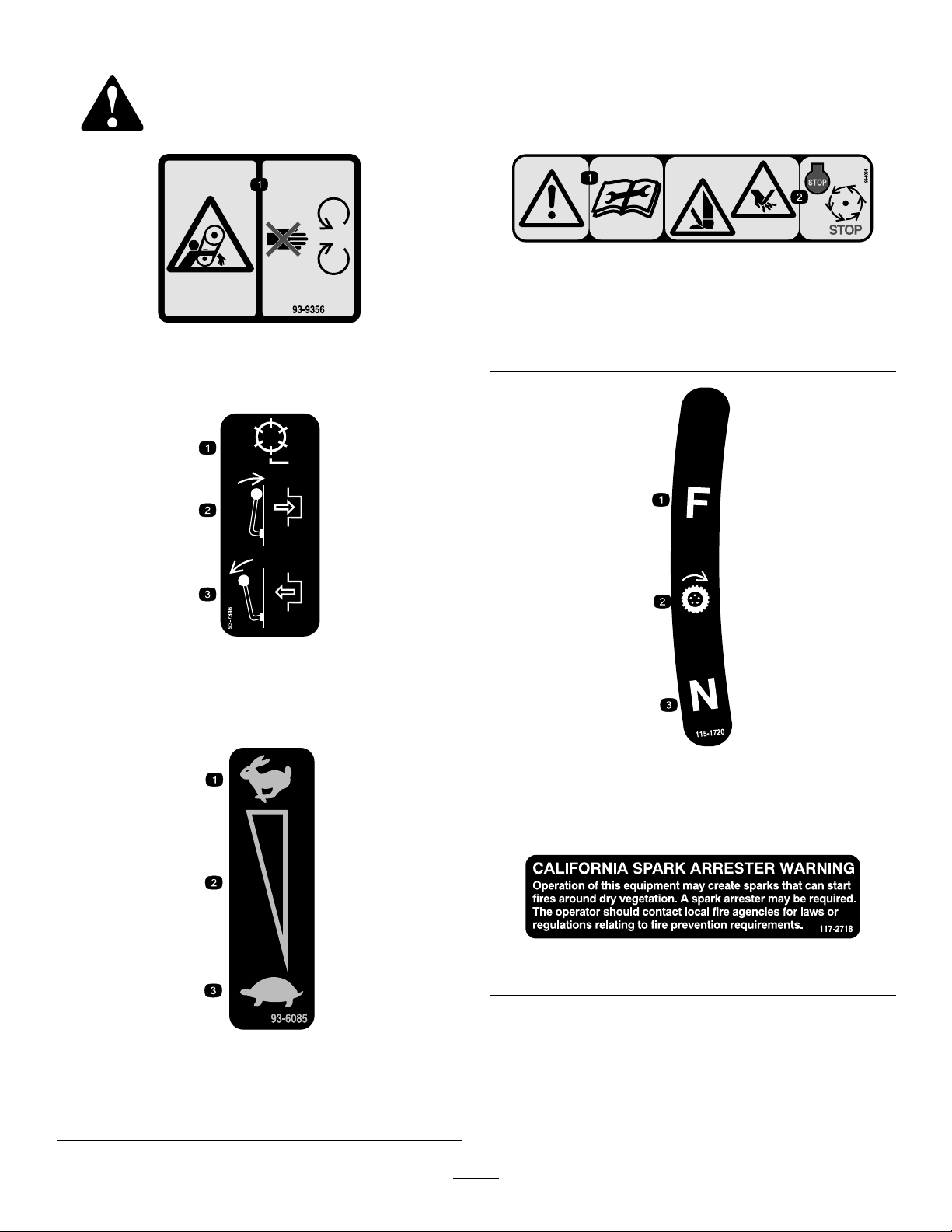

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslip-and-fall

accident.

•Donottipthemachinemorethan45degrees.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Shutofftheengineanddisengagethedrivetothe

attachment:

–Beforeleavingtheoperator’sposition

–Beforerefuelling

–Beforeremovingthegrassbasket

–Beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition

–Beforeclearingblockages

–Beforechecking,cleaning,orworkingonthemower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

Disengagedrivetoattachmentswhentransportingornot

inuse.

•Reducethethrottlesettingbeforeshuttingofftheengine

and,iftheengineisprovidedwithafuelshut-offvalve,

turnthevalveoffattheconclusionofmowing.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthereelswhennot

mowing.

•Donotoperatethemowerifyouareill,tired,orunder

theinuenceofalcoholordrugs

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview .

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

4