Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................3

SafetyandInstructionalDecals..........................4

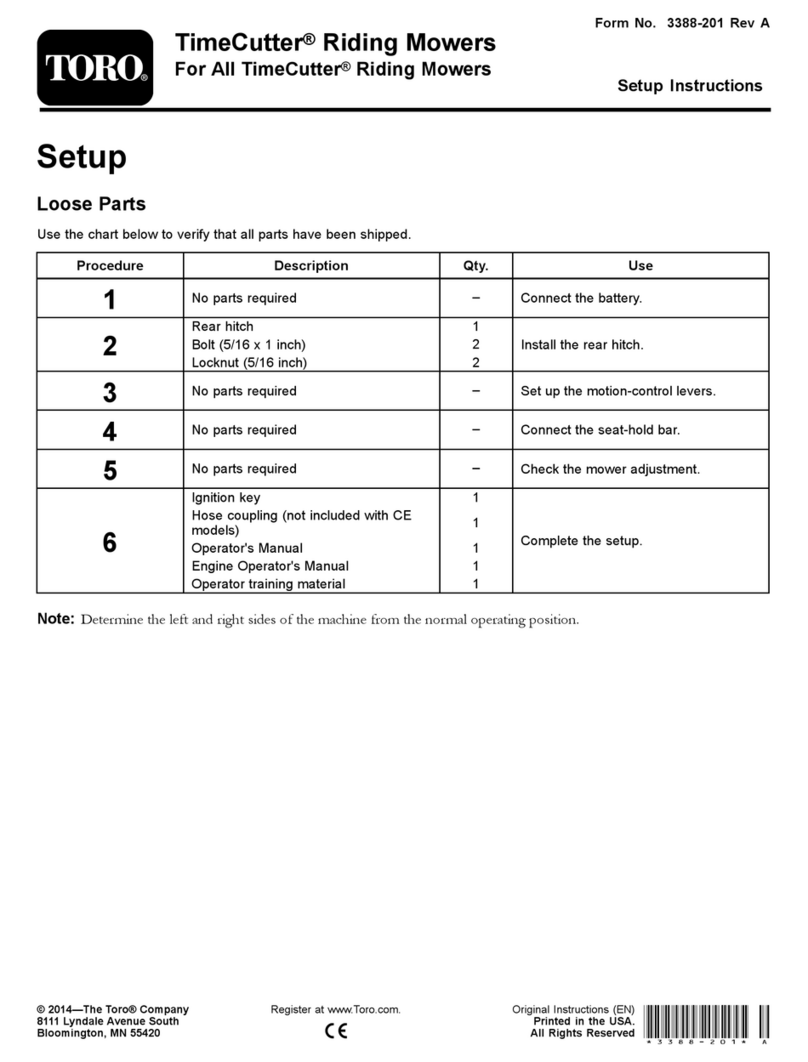

Setup........................................................................7

1InstallingtheLiftArmstotheTraction

Unit.................................................................8

2ConnectingtheLiftArmstotheCutting

Unit.................................................................8

3ReplacingtheTractionUnitPTO

Shaft...............................................................9

4ConnectingthePTOShafttotheCutting

UnitGearbox...................................................9

5GreasingtheMachine......................................9

ProductOverview...................................................10

Specications..................................................10

Attachments/Accessories.................................10

Operation.................................................................11

AdjustingtheHeightofCut................................11

AdjustingtheRollers.........................................12

AdjustingtheSkids...........................................13

AdjustingtheFlowBafe..................................13

PositioningtheFlowBafe................................13

AdjustingtheCuttingUnitPitch.........................14

CorrectingaCuttingUnitMismatch...................15

UsingtheSideDischarge.................................15

OperatingTips.................................................16

Maintenance...........................................................17

RecommendedMaintenanceSchedule(s)...........17

DailyMaintenanceChecklist.............................17

Lubrication........................................................18

CheckingtheLubricantintheGearbox..............18

SeparatingtheCuttingUnitfromtheTraction

Unit...............................................................19

ServicingtheBushingsintheCastor

Arms.............................................................19

ServicingtheCastorWheelsand

Bearings........................................................20

ServicingtheCuttingBlades.............................20

CheckingandCorrectingMismatchof

Blades...........................................................23

ReplacingtheDriveBelt...................................23

ReplacingtheGrassDeector..........................24

CleaningUndertheCuttingUnit........................24

Storage...................................................................25

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2017andwithENISO5395whenyou

completethesetupproceduresandinstalltheCEkit,

pertheDeclarationofConformity.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepyourhandsandfeetawayfromrotating

parts.Keepclearofthedischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition,Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

CuttingUnitSafety

•Thecuttingunitisonlyapartofacomplete

machinewheninstalledonatractionunit.Read

thetractionunitOperator’sManualcarefully

forcompleteinstructionsonthesafeuseofthe

machine.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Useonlyaccessories,attachments,and

replacementpartsapprovedbyToro.

3