Contents

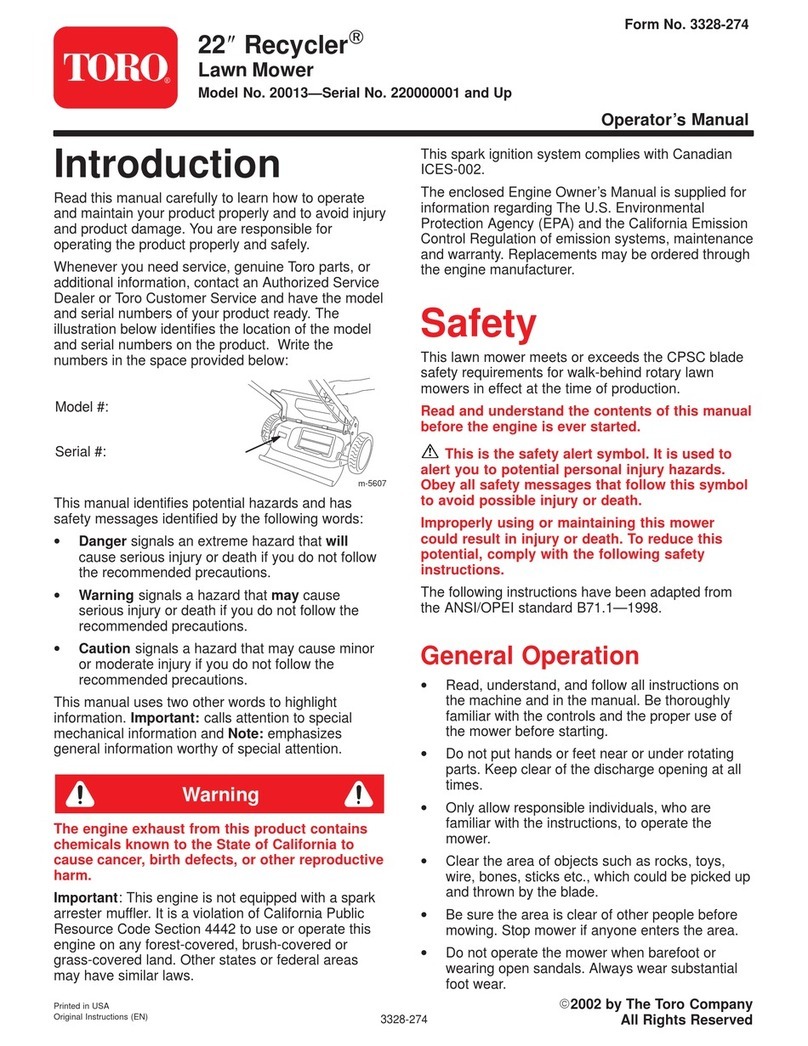

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

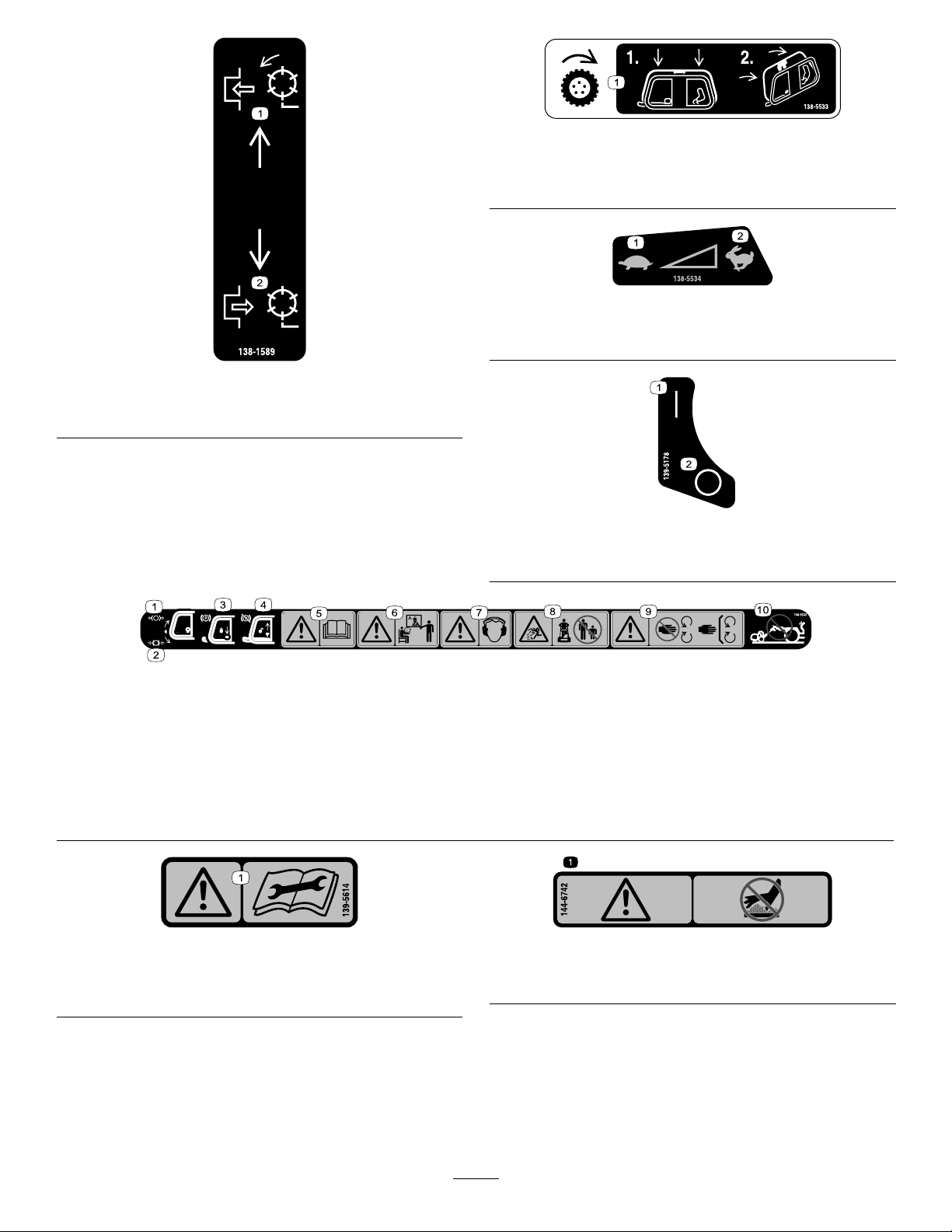

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 4

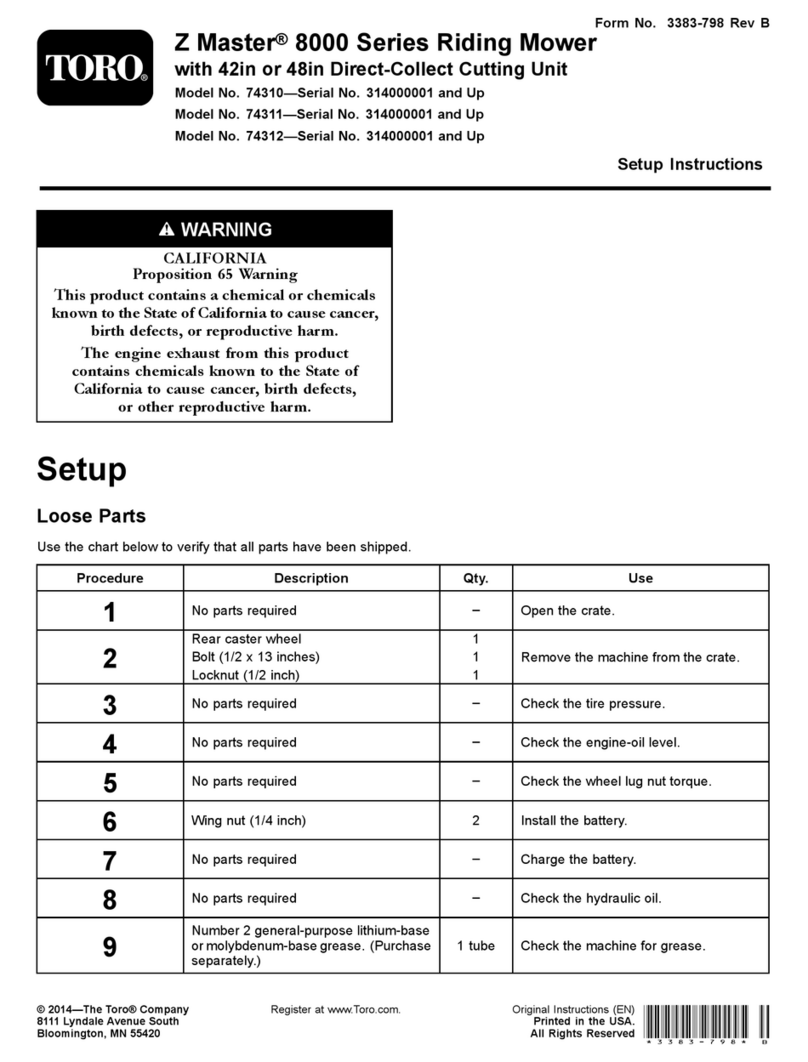

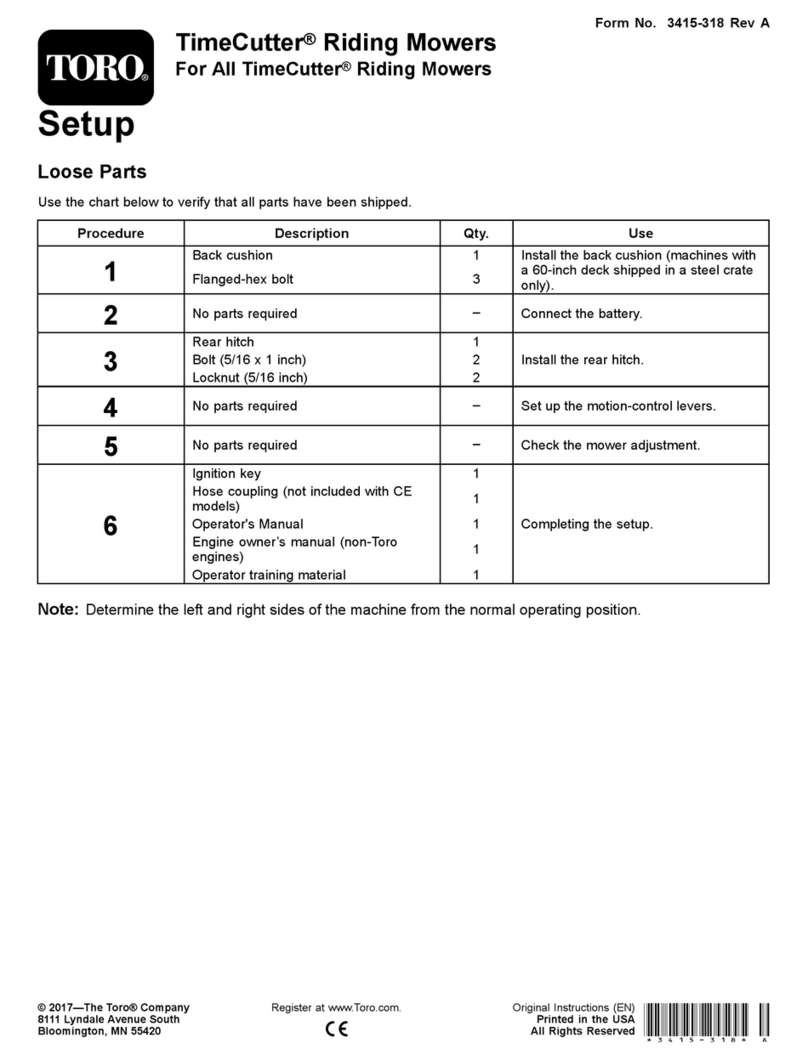

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 Adjusting and Installing the Cutting

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Installing the T ransport Wheels . . . . . . . . . . . . . . . . . . . . . . 10

3 Installing the Grass Basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

4 Adjusting the Latch Bolt for the

Handle-Height Adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Mounting the Battery Charger on a

W all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Before Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Performing Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Clip Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Reel Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the T raction-Drum Position . . . . . . . . . . . . . . . . 19

Adjusting the Handle Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

T ransporting the Machine to a Job

Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Removing the T ransport Wheels . . . . . . . . . . . . . . . . . . . . . . . 20

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

During Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Starting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the InfoCenter LCD Display . . . . . . . . . . . . . . . . . . . . 21

Operating T ips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shutting Of f the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

After Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

After Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating the Controls after Mowing . . . . . . . . . . . . . . . . . 26

T ransporting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing the T ransport Wheels . . . . . . . . . . . . . . . . . . . . . . . . . 26

Engaging or Disengaging the

T ransmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintaining the Lithium-Ion Battery

Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Caring for the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Understanding the Battery Charger . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Recommended Maintenance Schedule(s) . . . . . . . . . . . 30

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Pre-Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Preparing the Machine for Maintenance . . . . . . . . . . . . 31

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Electrical System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Servicing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Disposing of the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Maintaining the Battery Charger . . . . . . . . . . . . . . . . . . . . . . . 32

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Acknowledging the Battery Interface

Panel ............................................................. 33

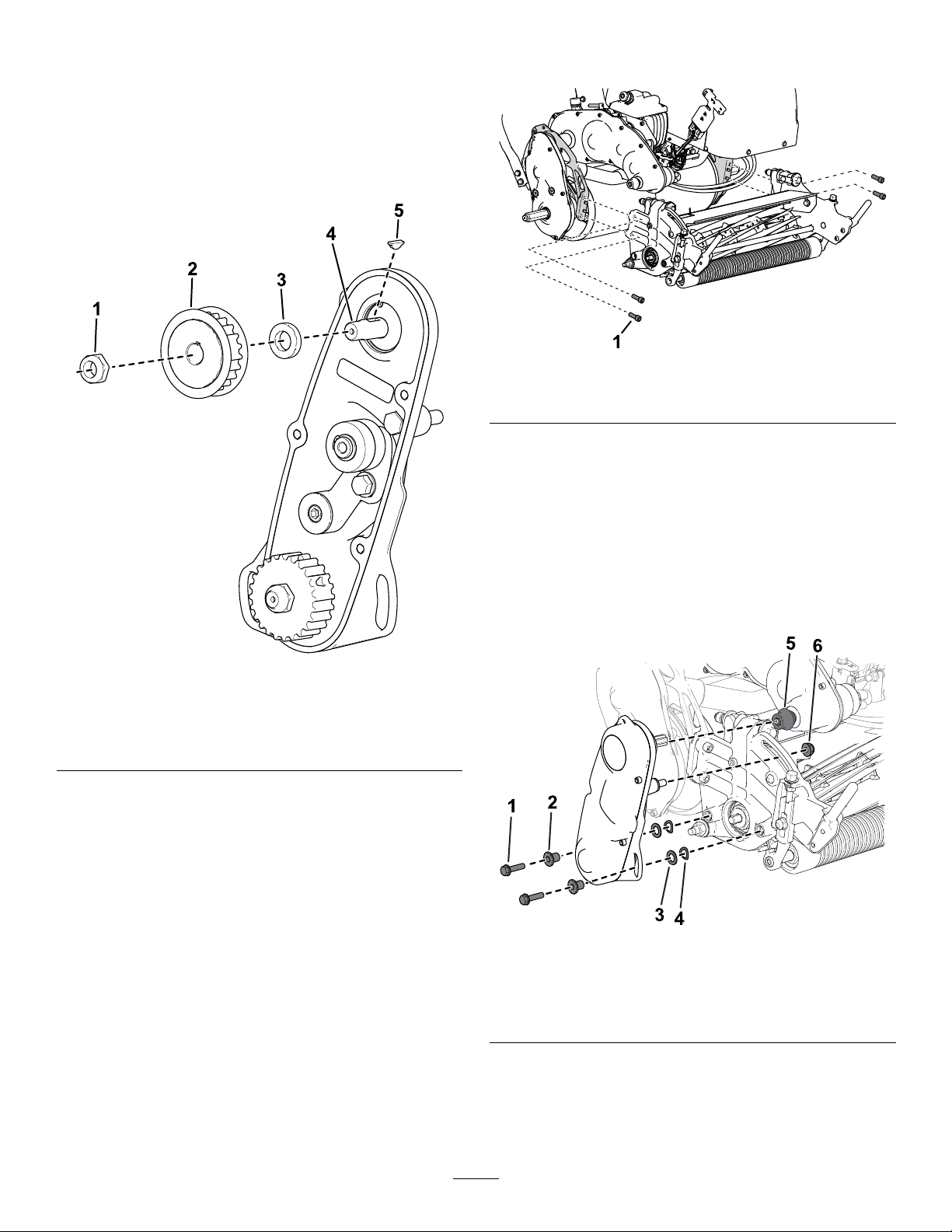

Drive System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Changing the T ransmission Fluid . . . . . . . . . . . . . . . . . . . . . . 34

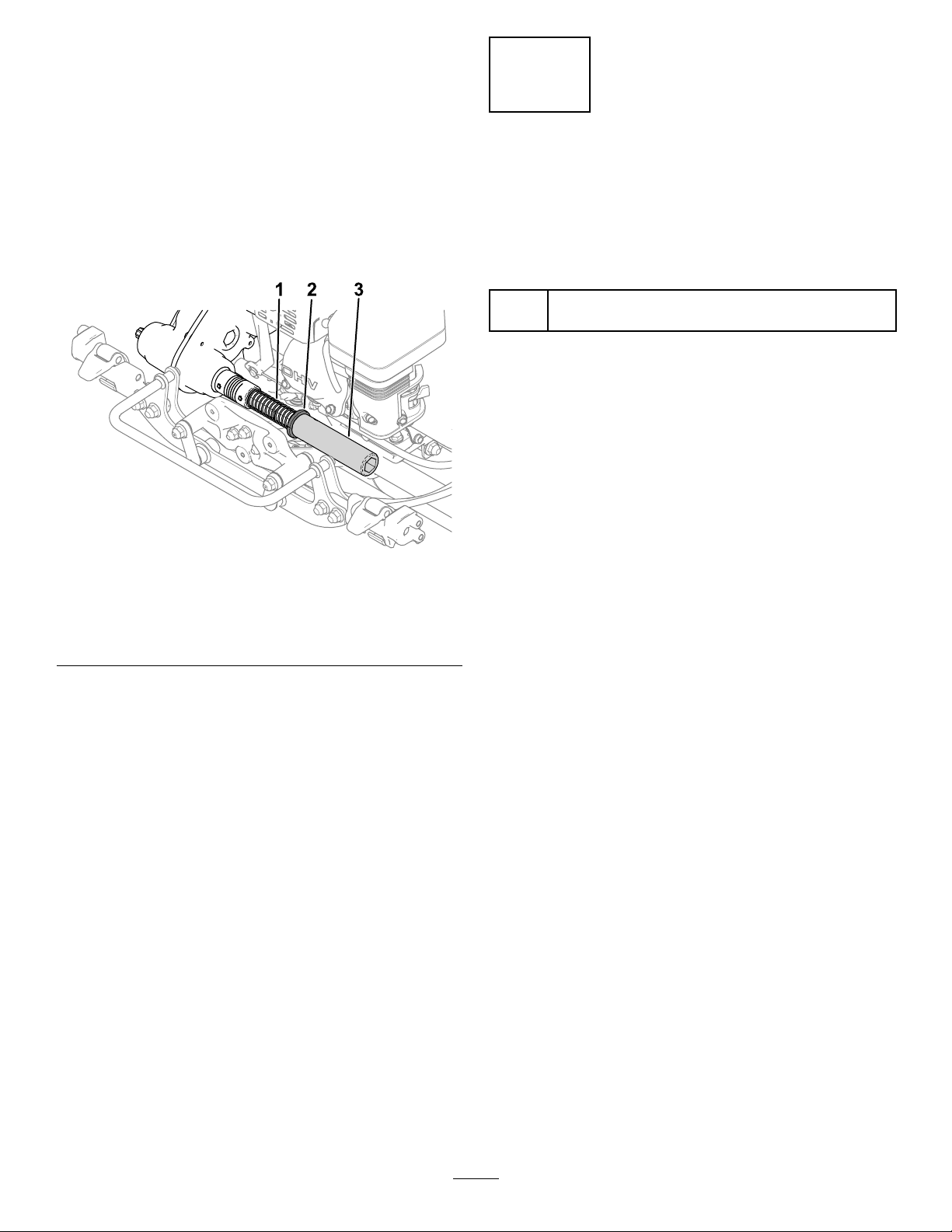

Controls System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjusting the Service/Parking Brake . . . . . . . . . . . . . . . . . 34

Cutting Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Blade Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the Cutting Unit (Models 04835

and 04845) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the Cutting Unit (Model 04865) . . . . . . . . . . . 36

Removing the Cutting Unit (Models 04835

and 04845) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing the Cutting Unit (Model

04865) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Backlapping the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Battery Storage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storing the Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3