Contents

Safety.......................................................................4

GeneralSafety...................................................4

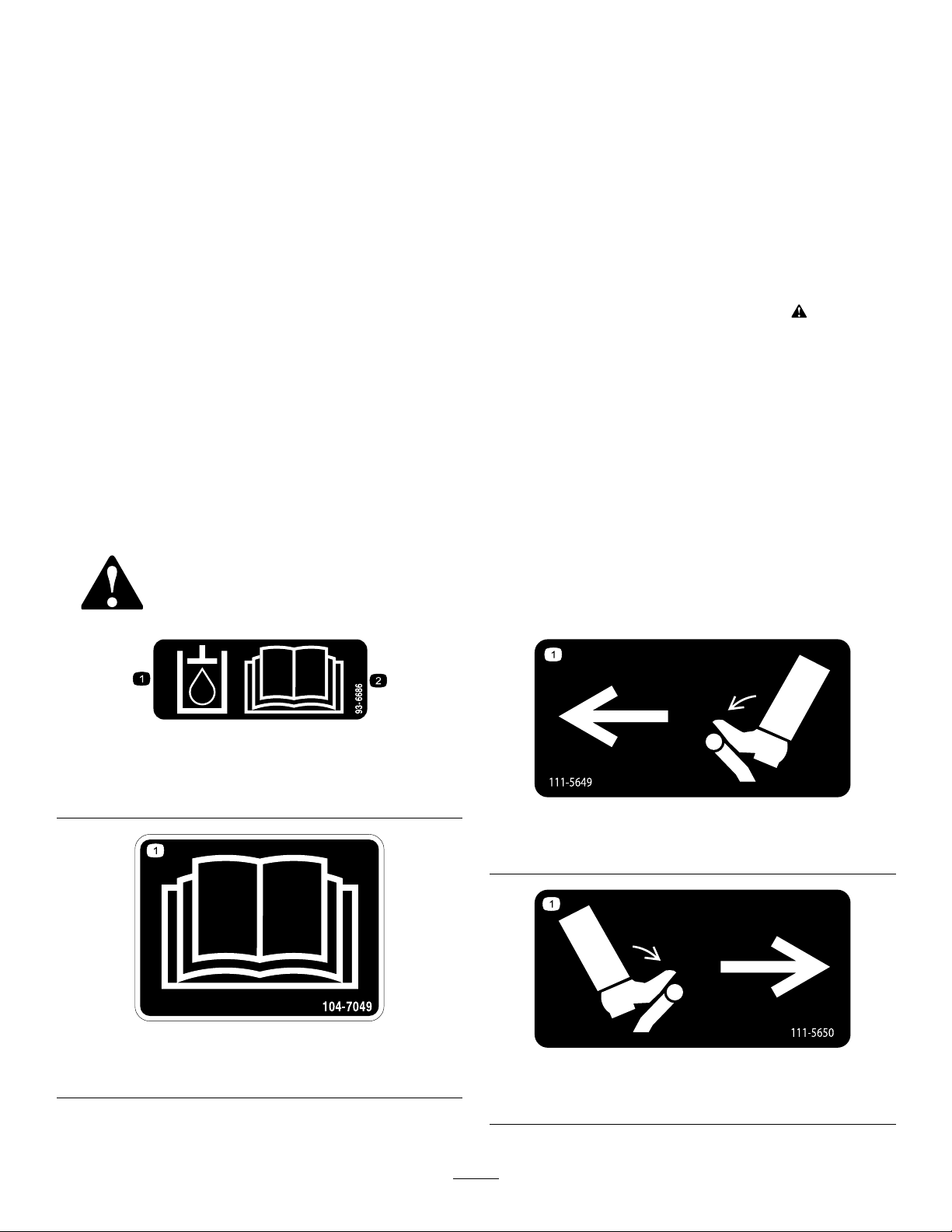

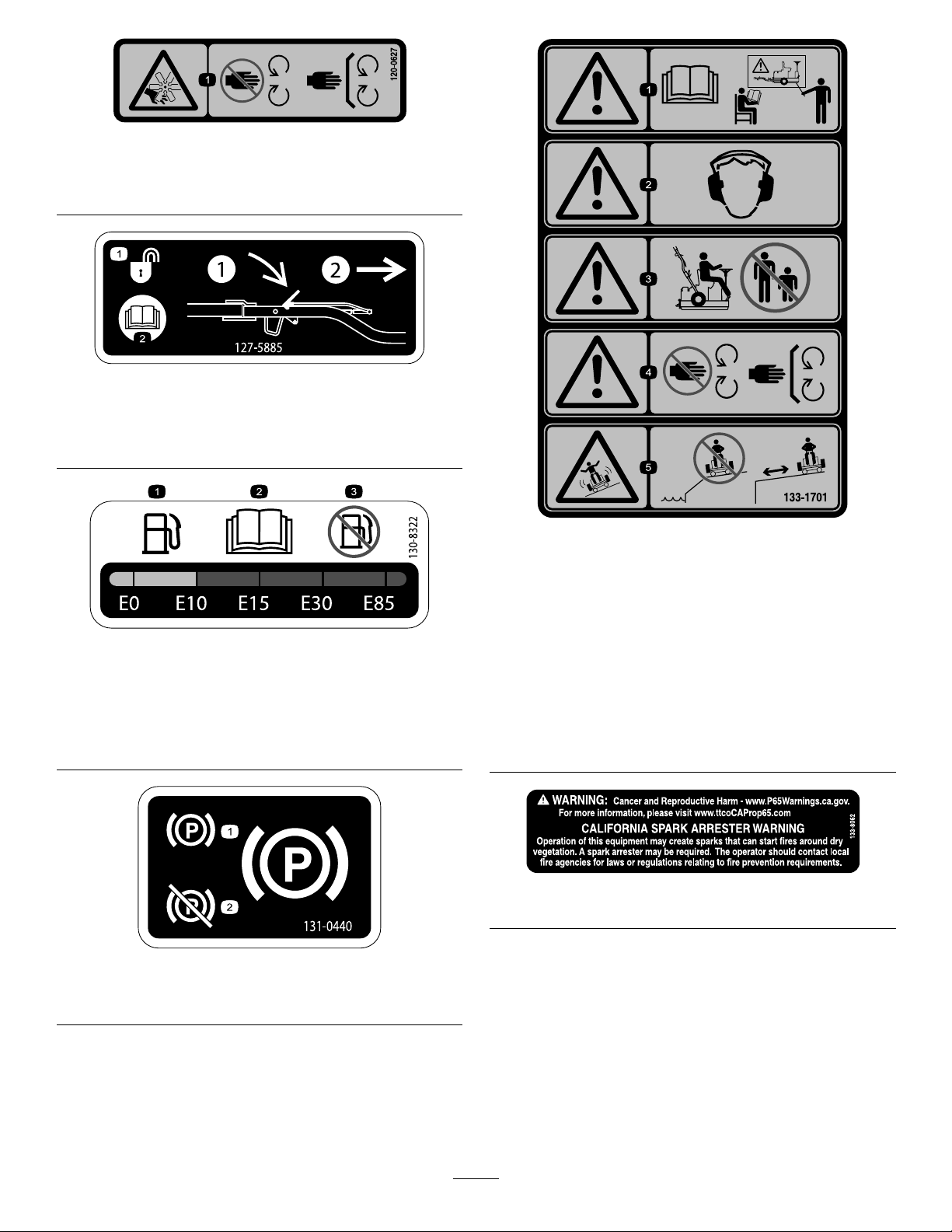

SafetyandInstructionalDecals..........................4

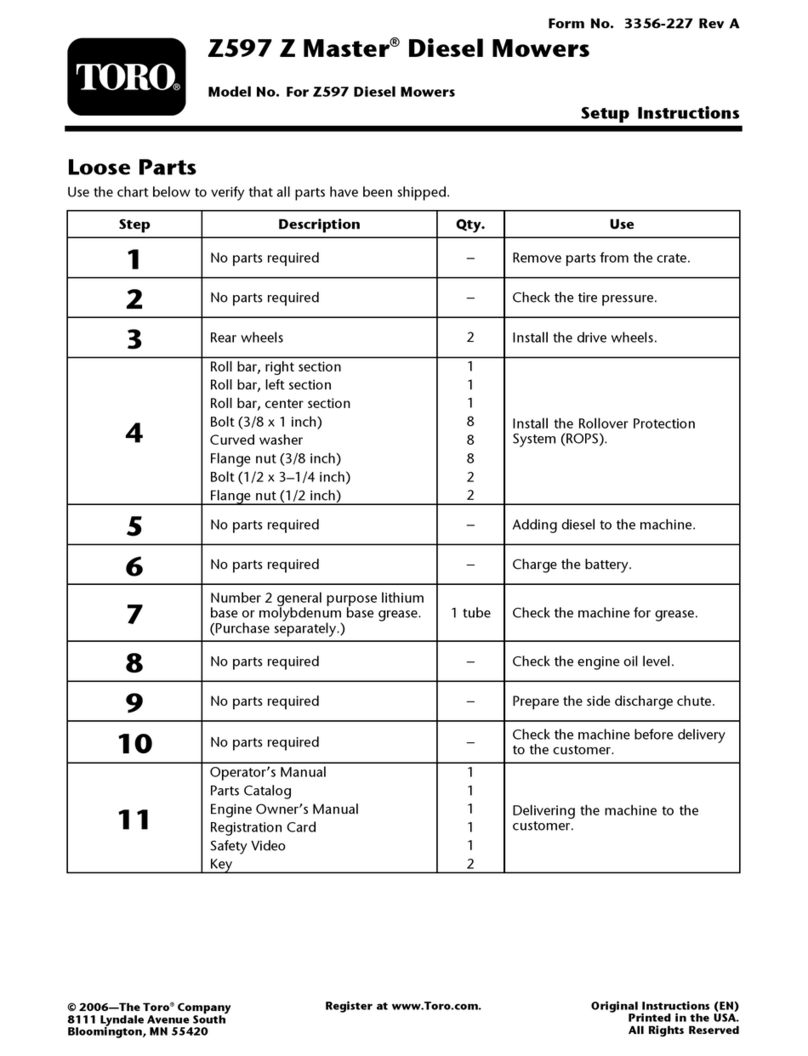

Setup........................................................................7

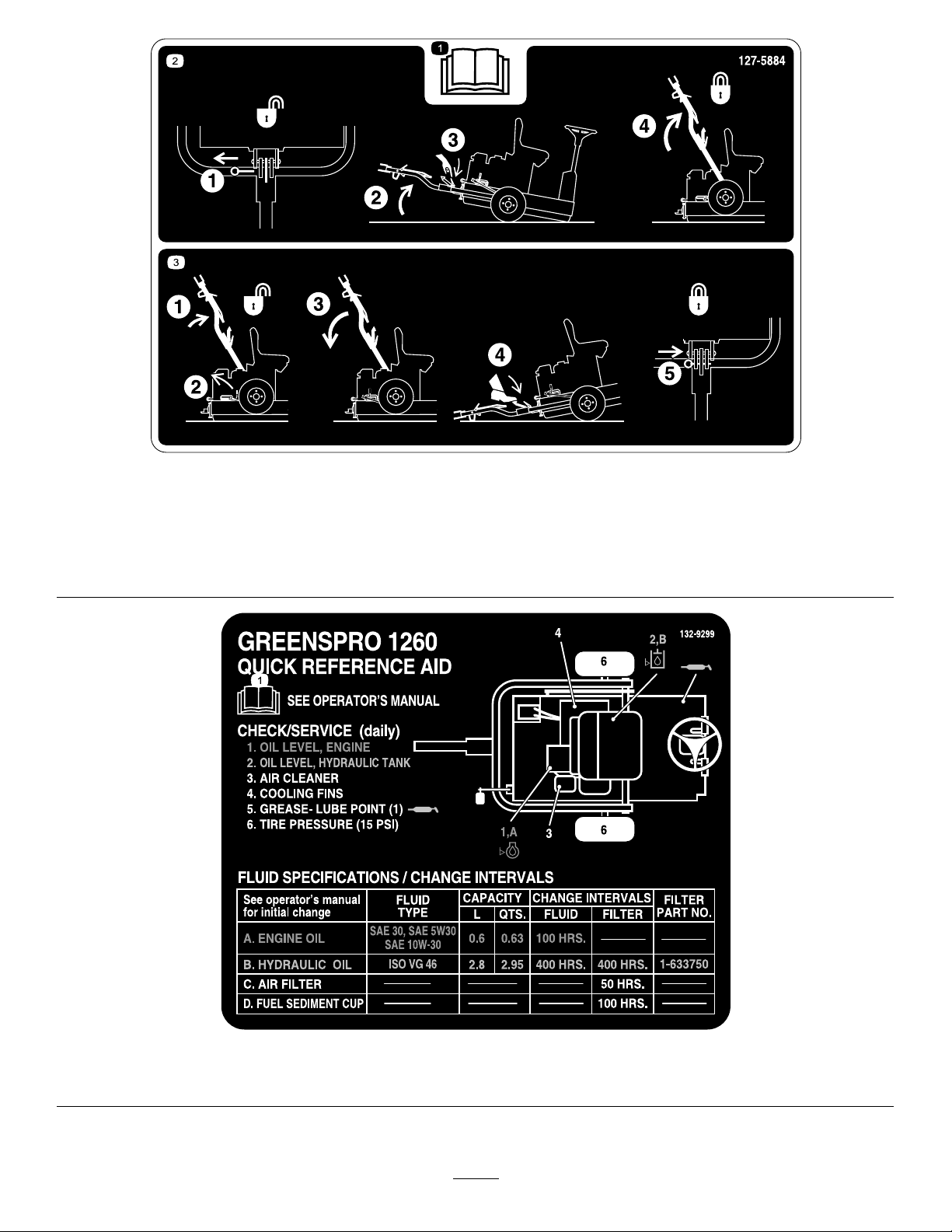

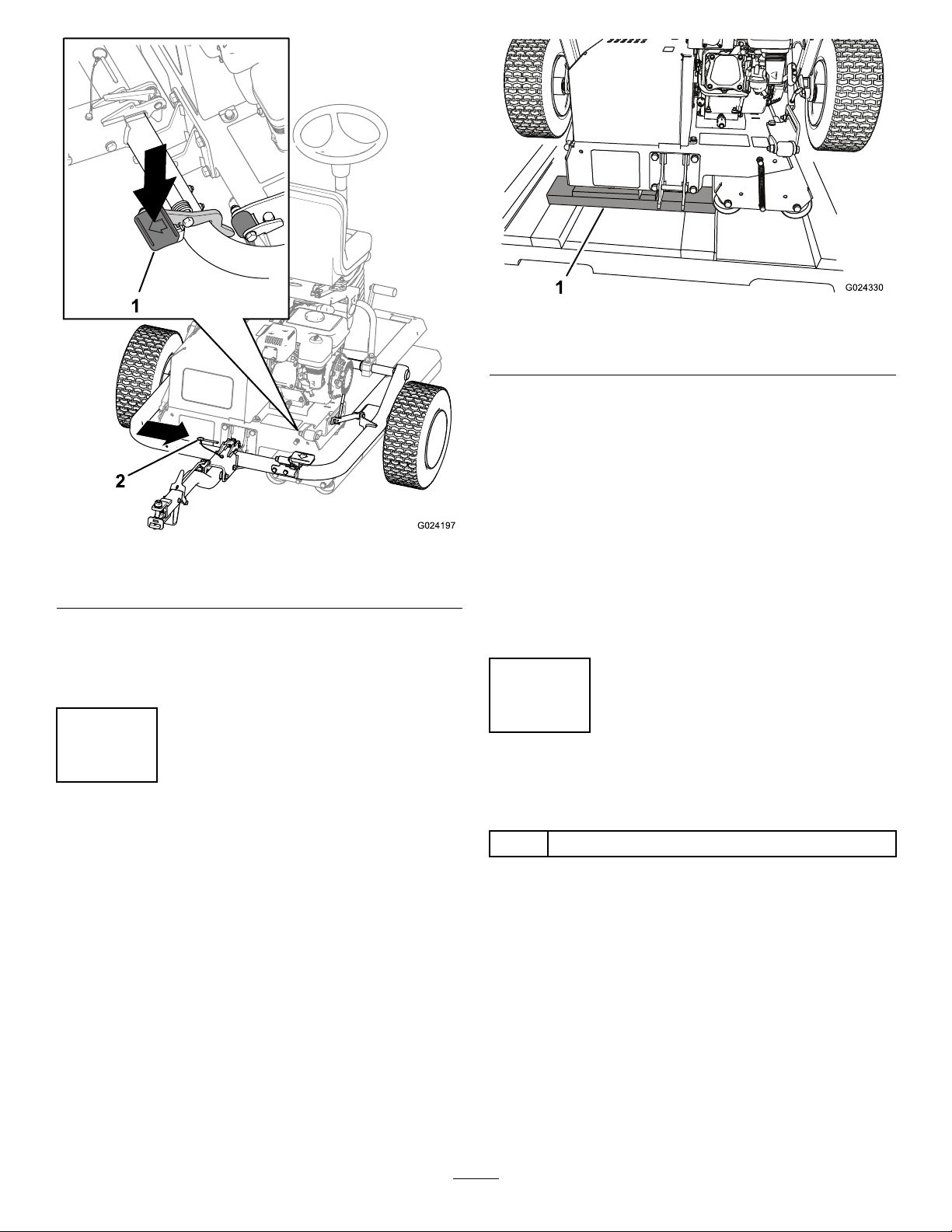

1InstallingtheTransportWheels........................8

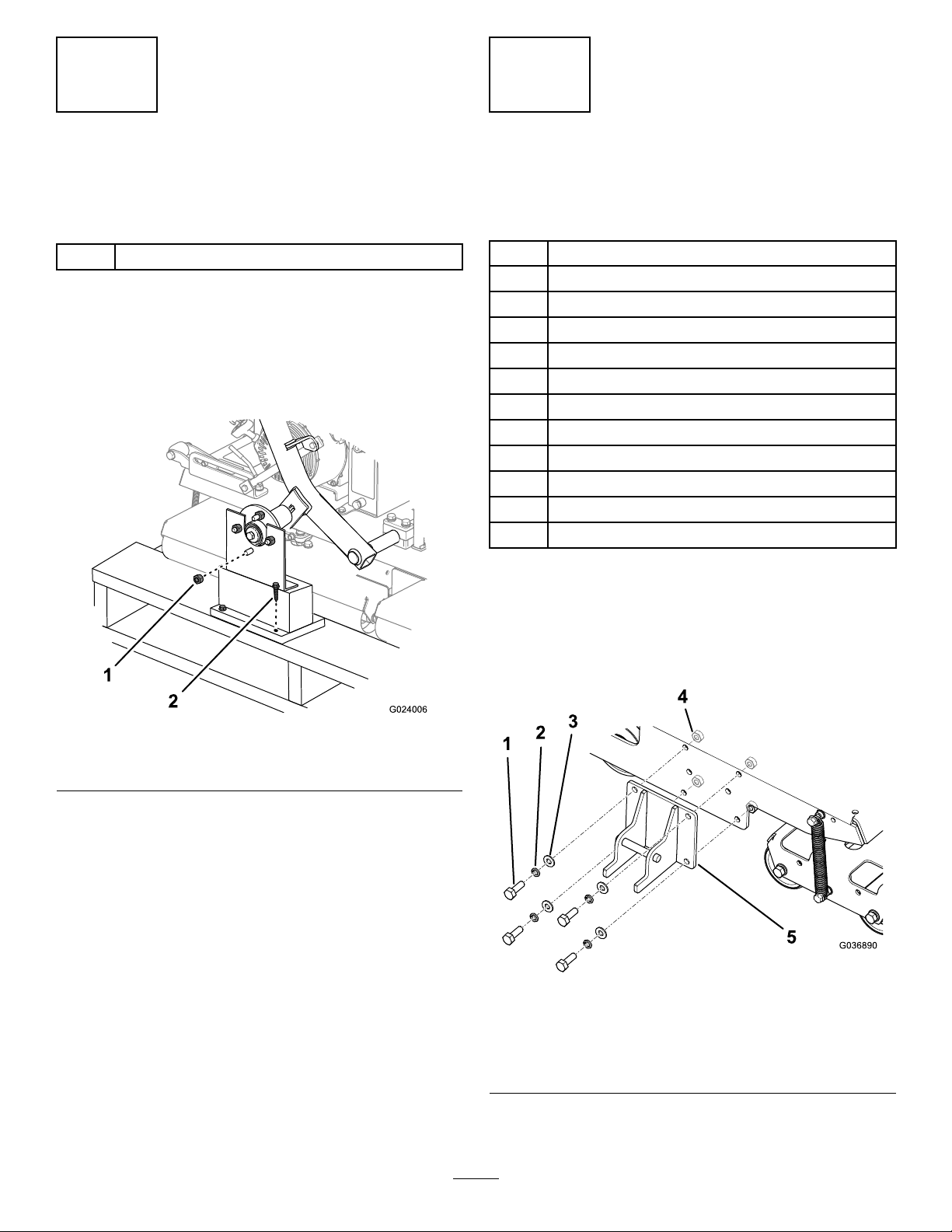

2InstallingtheHitchAssembly...........................8

3RemovingtheMachinefromthe

Pallet.............................................................10

4LubricatingtheMachine.................................10

ProductOverview....................................................11

Controls............................................................11

EngineControls............................................12

Specications..................................................13

Attachments/Accessories.................................13

Operation................................................................14

BeforeOperationSafety...................................14

PreparingtoUsetheMachine...........................14

CheckingtheHydraulicHosesand

Fittings..........................................................14

CheckingtheLeveloftheEngineOil.................14

CheckingtheLeveloftheHydraulic

Fluid..............................................................15

CheckingtheTirePressure...............................16

FillingtheFuelTank..........................................17

DuringOperationSafety...................................17

StartingtheEngine...........................................18

ShuttingOfftheEngine.....................................18

CheckingtheSafety-InterlockSystem..............19

AfterOperationSafety......................................19

UsingtheHitchLock.........................................19

TransportingtheMachine.................................20

OperatingtheMachine.....................................21

HaulingtheMachine.........................................21

OperatingTips.................................................21

Maintenance...........................................................22

RecommendedMaintenanceSchedule(s)...........22

NotationforAreasofConcern...........................24

DailyMaintenanceChecklist.............................24

Pre-MaintenanceProcedures..............................25

MaintenanceSafety..........................................25

Lubrication..........................................................25

LubricatingtheDrive-RollerBearing.................25

EngineMaintenance...........................................26

EngineSafety...................................................26

ChangingtheEngineOil...................................26

ServicingtheAirCleaner..................................27

ServicingtheSparkPlug...................................27

CheckingandAdjustingtheValve

Clearance.....................................................28

FuelSystemMaintenance...................................29

CleaningtheSedimentCup..............................29

DriveSystemMaintenance..................................30

HydraulicSystemSafety...................................30

ChangingtheHydraulicFluidandFilter

......................................................................30

BrakeMaintenance.............................................31

CheckingandAdjustingtheParking

Brake............................................................31

Cleaning..............................................................32

Storage...................................................................32

3