ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Introduction

Thiscabprovidesrolloverprotectionandfullweather

protection.Itcomeswithaheatingandairconditioning

systemforoperatorcomfortandtode-mistthe

windscreenandasound-reductionkittoreduce

operatornoiselevels.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanauthorizedToro

distributororT oroCustomerServiceandhavethe

modelandserialnumbersofyourproductready.

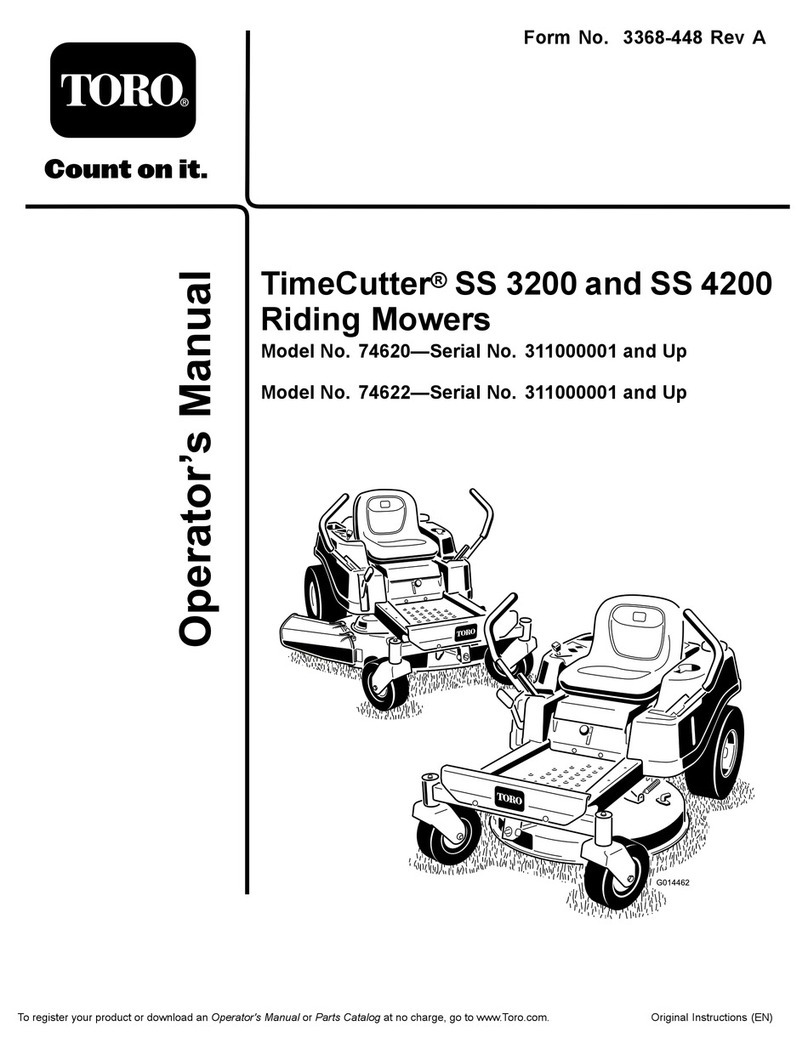

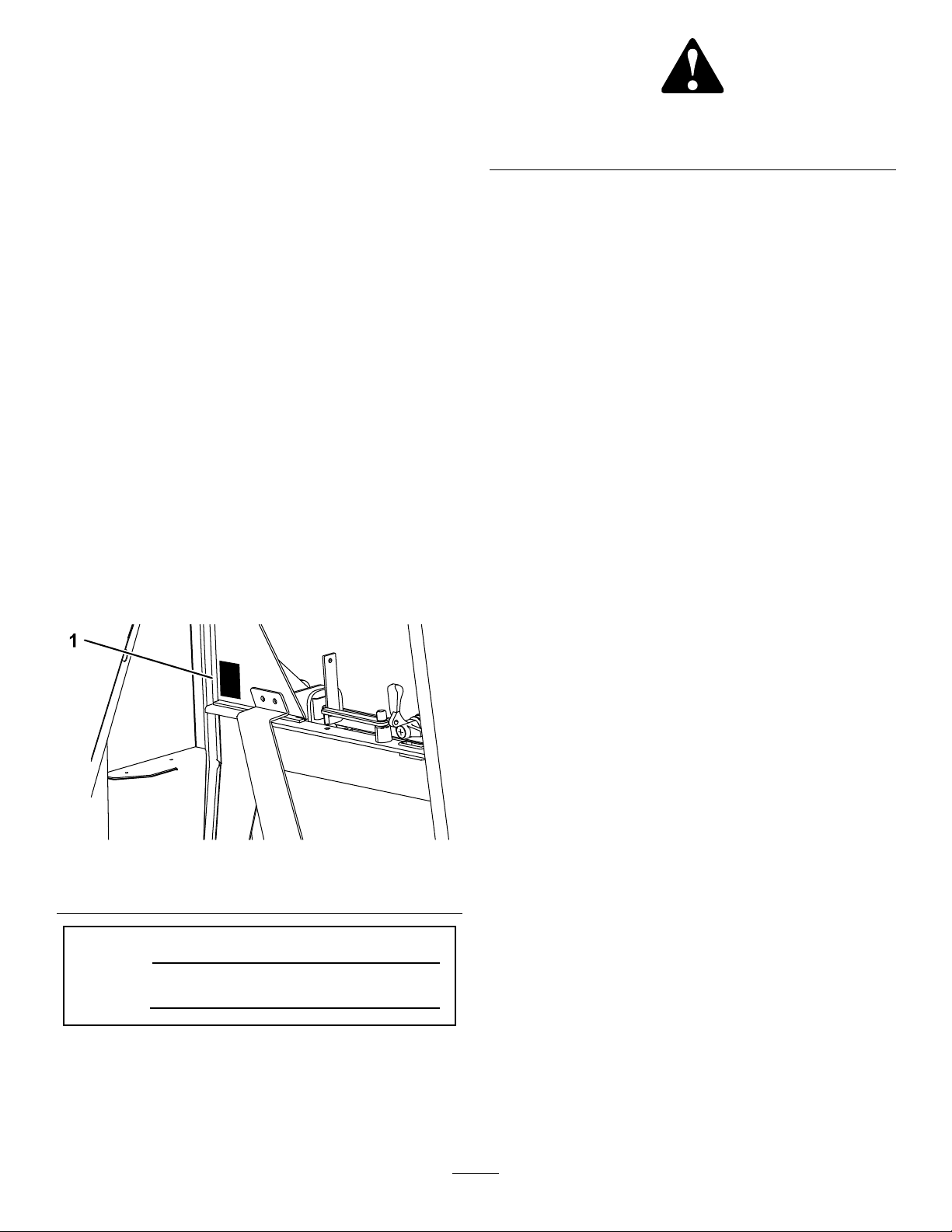

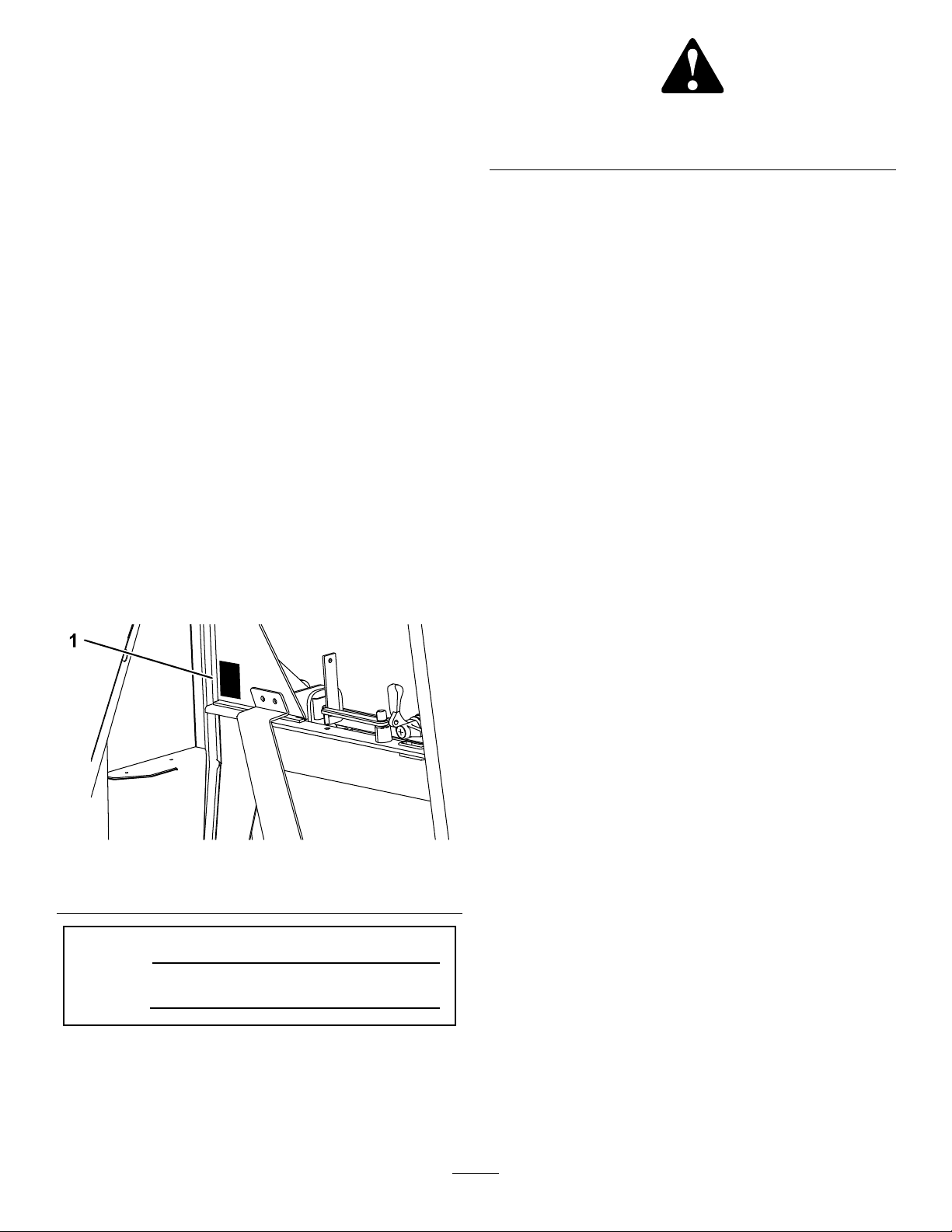

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

g245764

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

MaximumSlopeAnglesofMowerswith

Cab.................................................................3

SafetyandInstructionalDecals..........................3

ProductOverview.....................................................5

Controls.............................................................5

Specications....................................................7

Attachments/Accessories...................................7

Operation..................................................................7

UsingtheSunshade...........................................7

UsingtheAirConditionerfortheFirst

Time................................................................7

OperatingtheHeatingandAir-Conditioning

System............................................................8

OperatingtheWindscreenWiperand

Washer...........................................................8

FillingtheScreenWasherBottle.........................8

OperatingtheWindows......................................9

OperatingtheDoors.........................................10

AdjustingtheMirrors..........................................11

Maintenance...........................................................12

RecommendedMaintenanceSchedule(s)...........12

PreparingforMaintenance...............................13

TiltingtheCab...................................................13

LocatingtheFuses...........................................14

CheckingtheAir-ConditionerCompressor

Clutch............................................................15

RemovingtheRoof...........................................15

InstallingtheRoof.............................................16

CheckingtheRefrigerantLevel.........................16

InspectingandCleaningtheCondenser...........16

CheckingtheDrainTubes.................................17

CheckingtheCompressor-FanBelt..................17

CheckingtheRefrigerantPressure...................18

TroubleshootingthePressureReadings...........18

WashingtheMachineandCab.........................18

Storage...................................................................19

Schematics.............................................................20

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved