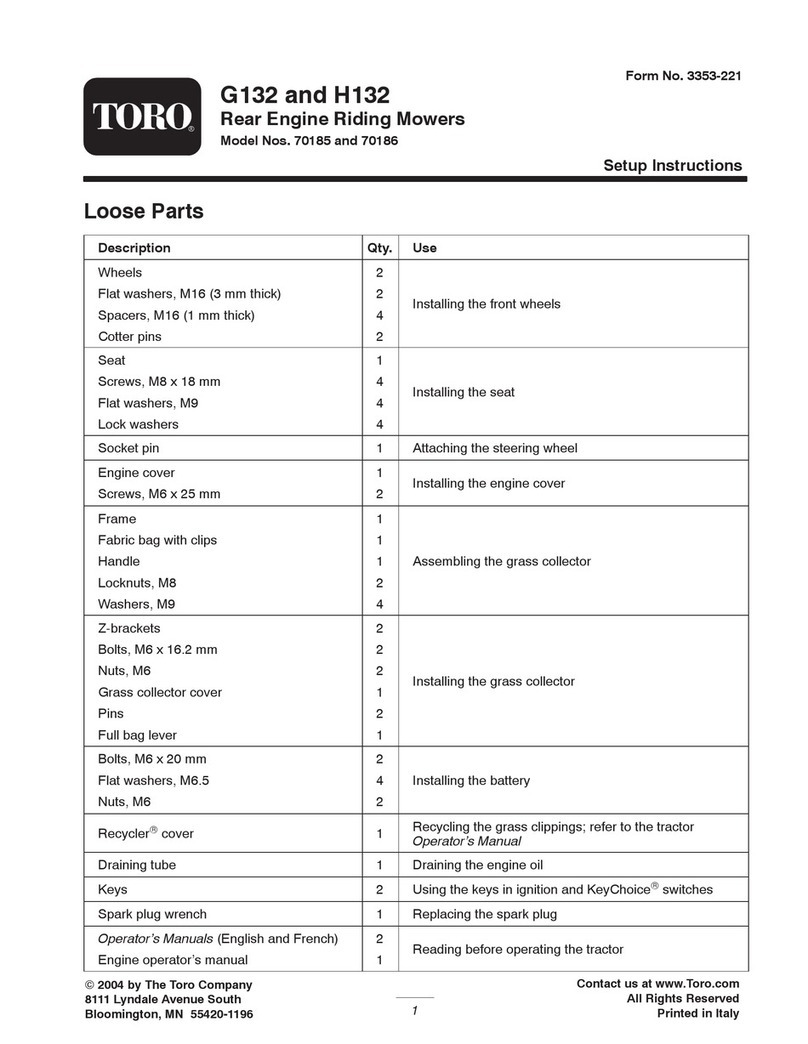

Contents

Safety.......................................................................4

GeneralSafety...................................................4

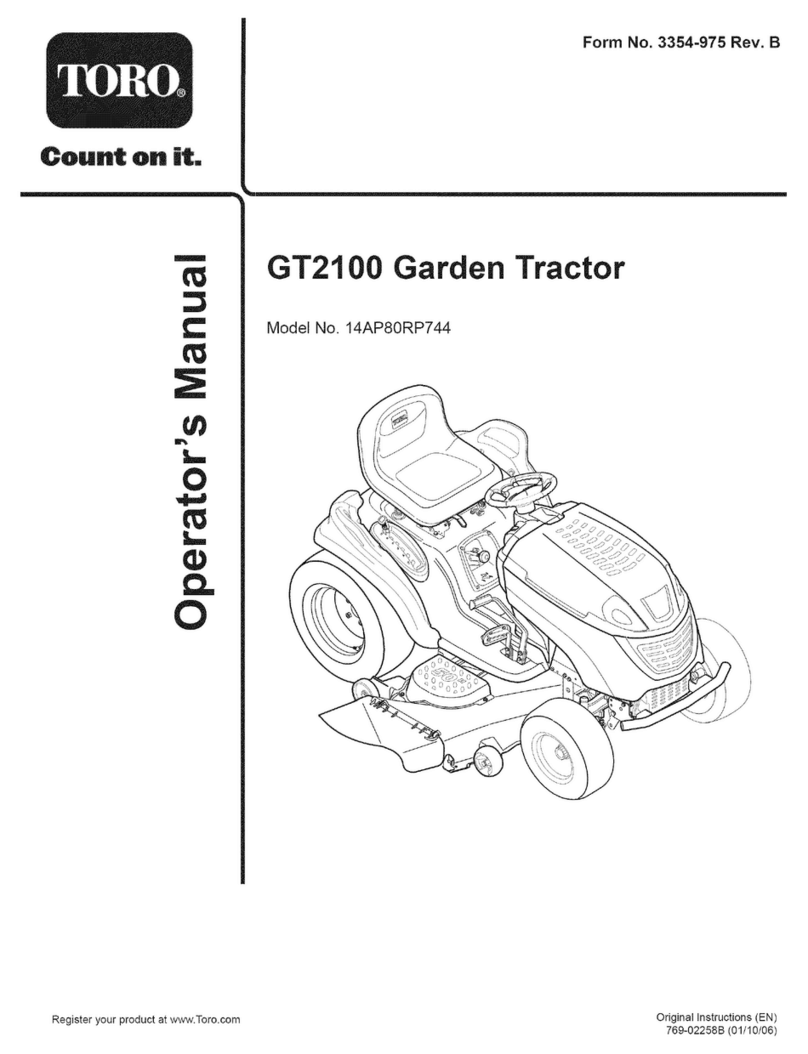

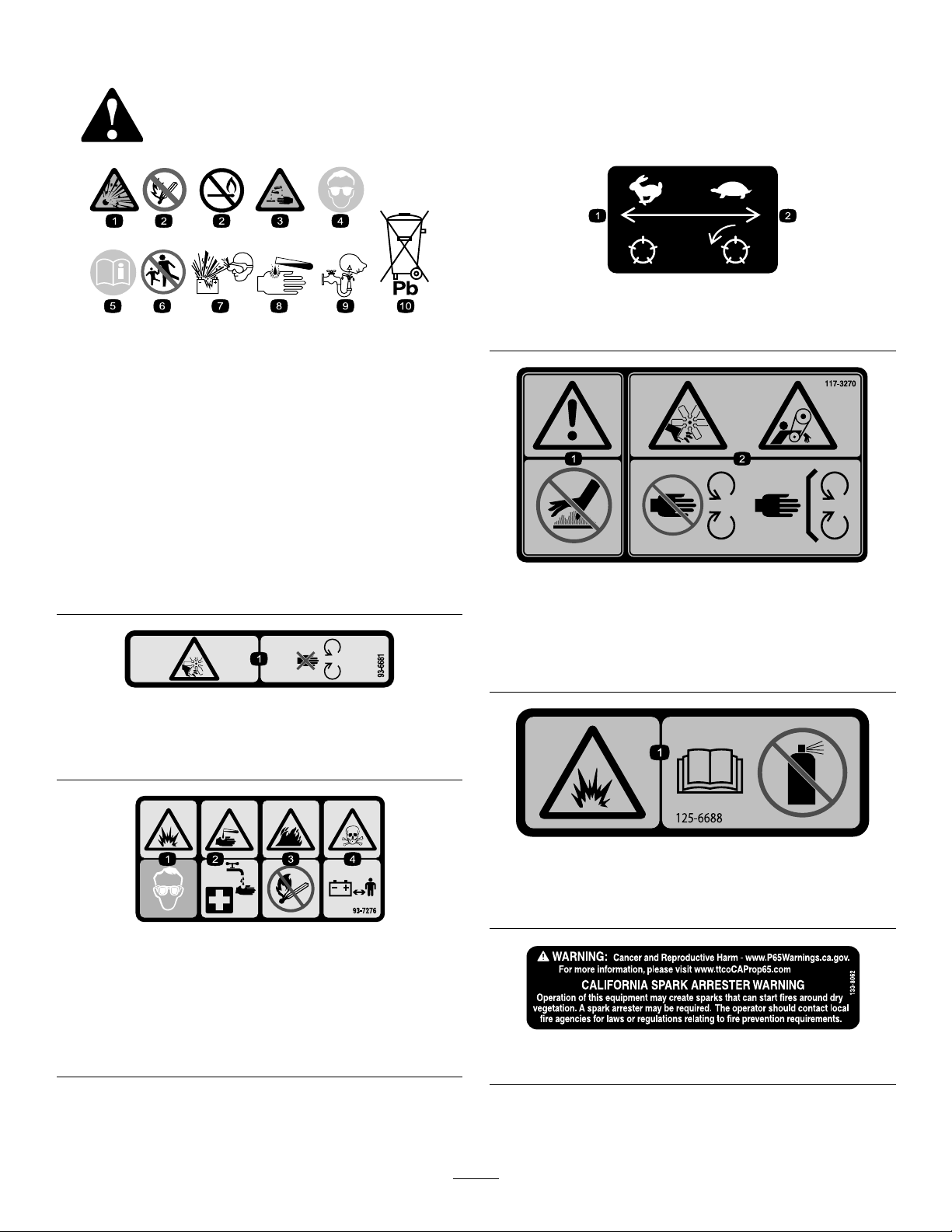

SafetyandInstructionalDecals..........................5

Setup.......................................................................11

1InstallingtheWheels......................................12

2InstallingtheSteeringWheel..........................12

3ChargingandConnectingtheBattery.............13

4InstallingtheRollBar.....................................14

5InstallingtheFrontLiftArms...........................15

6InstallingtheCarrierFramestotheCutting

Units..............................................................17

7InstallingtheCuttingUnits..............................19

8InstallingtheCuttingUnitDrive

Motors...........................................................20

9AdjustingtheLiftArms...................................20

10AdjustingTireAirPressure...........................23

11InstallingtheHoodLatch..............................23

12InstallingtheExhaustGuard........................24

13ApplyingtheCEDecals...............................24

14InstallingtheTipperRollerKit

(Optional)......................................................25

ProductOverview...................................................26

Controls...........................................................26

ControlConsole............................................27

MowerManifold.............................................28

Specications..................................................29

Attachments/Accessories.................................29

BeforeOperation.................................................29

BeforeOperationSafety...................................29

FuelSpecication.............................................30

FillingtheFuelTank..........................................30

PerformingDailyMaintenance..........................30

CheckingtheInterlockSystem..........................31

DuringOperation.................................................32

DuringOperationSafety...................................32

StartingtheEngine...........................................33

ShuttingOfftheEngine.....................................33

CuttingGrasswiththeMachine........................33

DrivingtheMachineinTransportMode.............34

ClipRate(ReelSpeed).....................................35

AdjustingReelSpeed.......................................36

BleedingtheFuelSystem.................................36

OperatingTips.................................................36

AfterOperation....................................................37

AfterOperationSafety......................................37

AfterMowing....................................................37

TowingtheMachine..........................................37

IdentifyingtheTie-DownPoints........................38

HaulingtheMachine.........................................38

Maintenance...........................................................39

MaintenanceSafety..........................................39

RecommendedMaintenanceSchedule(s)...........39

DailyMaintenanceChecklist.............................41

Pre-MaintenanceProcedures..............................42

PreparingforMaintenance...............................42

LiftingtheFrontoftheMachine.........................42

LiftingtheBackoftheMachine.........................42

LiftingtheBackoftheMachine.........................43

RemovingtheBatteryCover.............................43

OpeningtheHood............................................43

Lubrication..........................................................44

GreasingtheBearingsandBushings................44

CheckingtheSealedBearings..........................45

EngineMaintenance...........................................46

EngineSafety...................................................46

EngineOilSpecication....................................46

CheckingtheEngine-OilLevel..........................46

ChangingtheEngineOilandtheFilter..............46

ServicingtheAirCleaner..................................47

FuelSystemMaintenance...................................48

ServicingtheFuelT ank.....................................48

InspectingtheFuelLinesandFittings...............48

DrainingtheWaterSeparator...........................48

ChangingtheFuelFilterCanister......................49

BleedingAirfromtheInjectors..........................49

ElectricalSystemMaintenance...........................50

ElectricalSystemSafety...................................50

ServicingtheBattery.........................................50

ServicingtheFuses..........................................50

DriveSystemMaintenance..................................51

CheckingtheTirePressure...............................51

TorquingtheWheelNuts...................................51

AdjustingtheTractionDriveforNeutral.............51

CoolingSystemMaintenance..............................53

CoolingSystemSafety.....................................53

CoolantSpecication........................................53

CheckingtheCoolantLevel..............................53

CleaningtheEngineCoolingSystem................54

BrakeMaintenance.............................................54

AdjustingtheParkingBrake..............................54

BeltMaintenance................................................55

ServicingtheEngineBelts................................55

ControlsSystemMaintenance.............................56

AdjustingMowGroundSpeed..........................56

AdjustingtheThrottle........................................56

HydraulicSystemMaintenance...........................57

HydraulicSystemSafety...................................57

CheckingtheHydraulicLinesand

Hoses............................................................57

HydraulicFluidSpecications...........................57

CheckingtheHydraulicFluid............................57

HydraulicFluidCapacity...................................58

ChangingtheHydraulicFluid............................58

ChangingtheHydraulicFilter............................59

CuttingUnitSystemMaintenance........................60

BladeSafety.....................................................60

CheckingtheReel-to-BedknifeContact............60

BacklappingtheCuttingUnits...........................60

Cleaning..............................................................62

WashingtheMachine.......................................62

Storage...................................................................62

StorageSafety..................................................62

PreparingtheTractionUnit...............................62

PreparingtheEngine........................................63

3