hydraulic oil level and high engine temperature pro-

tection systems stop the engine.

Warning Systems:

Water in fuel

Hydraulic oil filter

Engine coolant temperature

Engine oil pressure

Voltage Indicator

Air Cleaner Clogged

Hydraulic oil temperature

Hydraulic oil level

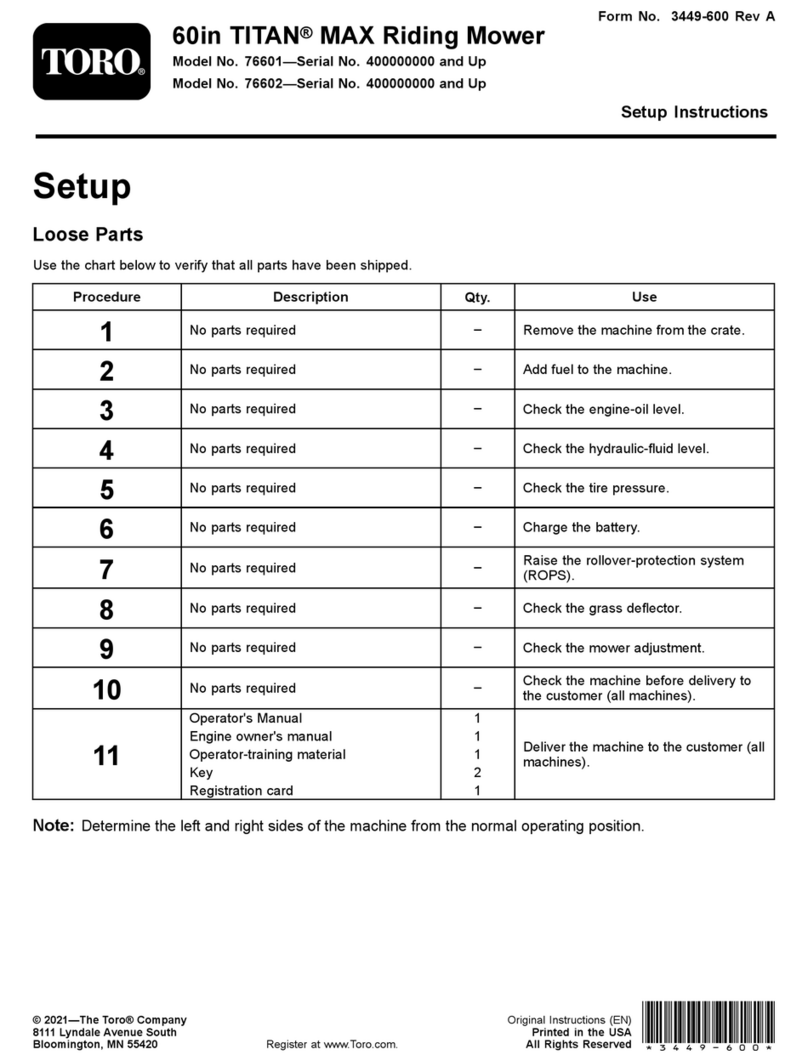

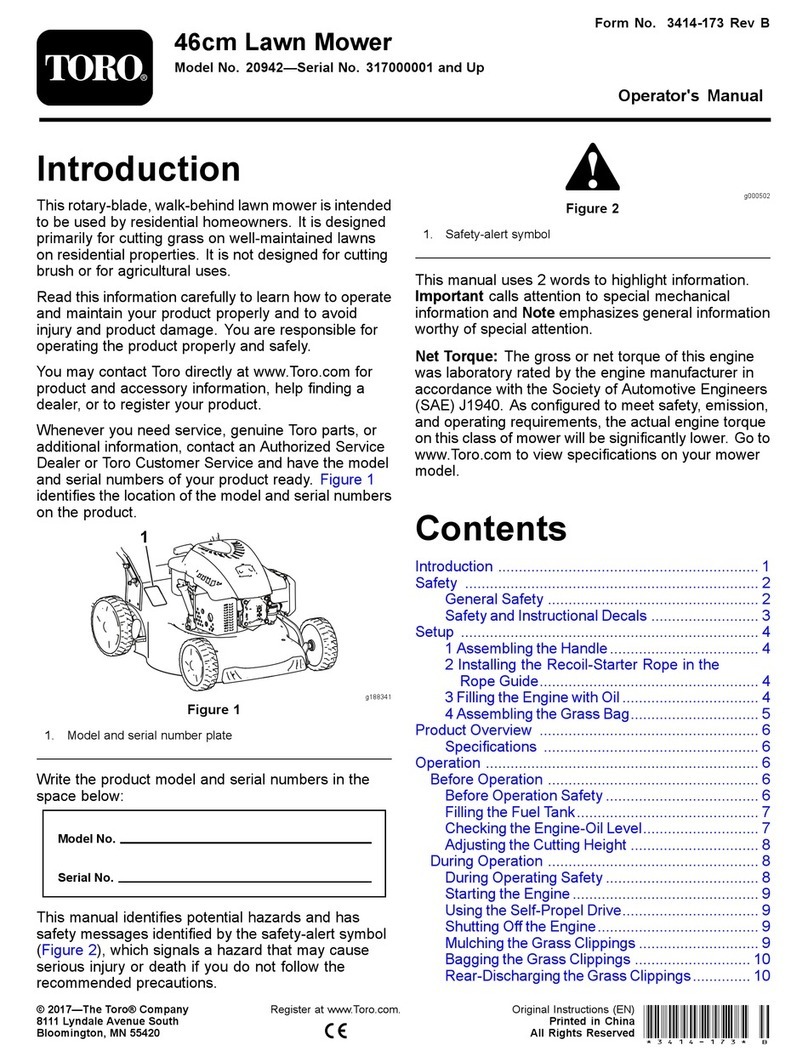

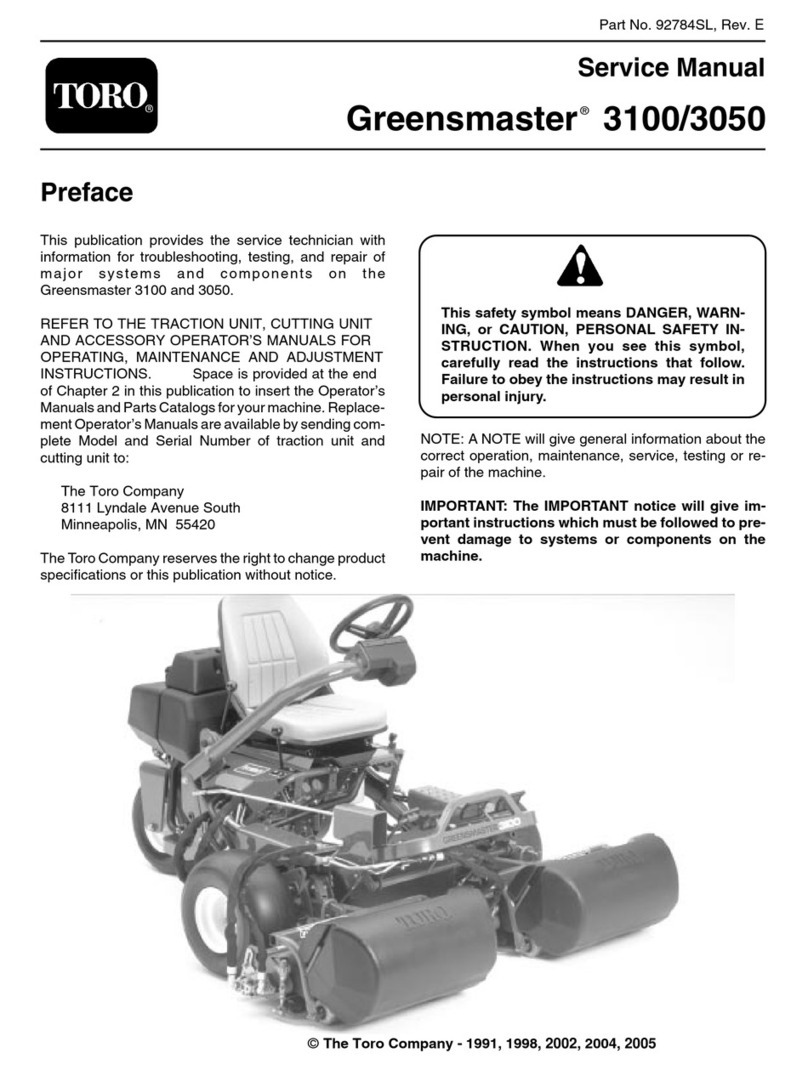

General Specifications:

Width-of-Cut:

5 Cutting Units 137 in. (348 cm)

4 Cutting Units 110 in. (279 cm)

3 Cutting Units 83 in. (211 cm)

1 Cutting Unit 29-1/2 in. (75 cm)

Overall Width:

Cutting Units Raised 91-1/2 in. (232 cm)

Cutting Units Down 147 in. (373 cm)

Overall Length: 110 in. (282 cm)

Height: 55-1/2 in. (141 cm)

Ground Clearance: approx. 7 in. (17.8 cm)

Recommended Height-of-Cut:

5-Blade Cutting Unit: 1–3 in. (25–76 mm)

7-Blade Cutting Unit: 3/8–1-3/4 in. (9.5–44 mm)

11-Blade Cutting Unit: 3/8–3/4 in. (9.5–19 mm)

Wheel Tread: 53 in. (135 cm)

Wheel Base: 57 in. (145 cm)

Operating Circle: 60 in. (152 cm)

Dry Weight: 3,786 lbs. (1,717 kg)

Reel Speed: 800–1,200 rpm, Model 03700

470–950 rpm, Model 03701

Engine: Mitsubishi, four-cycle, four-cylinder, 139 cu-in.

displacement, water cooled diesel engine. Rated 40 hp

@ 2,300 rpm, 21:1 compression ratio. Low idle—1,200

rpm, high idle—2,500 rpm. Injection Timing –20°

BTDC. Oil capacity is 6.9 qt (6.5 L) with filter.

Cooling System: Capacity is 3.7 gal. (14 L) of 50/50

mixture of ethylene glycol anti-freeze.

Fuel System: Capacity is 10.5 gal. (40 L) of #2 diesel

fuel.

Hydraulic System: Reservoir capacity is 9.3 gal. 35.2 L)

and total system capacity is 18.2 gal. (69 L). Replaceable

breather element. Replaceable spin-on filter element.

Traction System: Ground speed is 0–12.5 mph (0–20

km/h) Model 03700, 0–15 mph (0–23 km/h) Model

03701.

Cutting Unit Drive System: Adjustable reel speed to

match the grass clip to the ground speed. Backlap reel

speed is 385 rpm.

Seat: Adjusts 6 in. (15.2 cm) forward and backward.

Adjustable backrest with three-positions for operator

weight. Integral seat switch in the bottom of the seat

cushion.

Diagnostic System: Test ports for the traction system,

cutting unit drive system, lift/counterbalance, lift/relief,

steering circuits and charge pressure.

Steering System: Automotive type, full power.

Brakes: The hand brake automatically locks the traction

linkage in neutral. With the traction motor wheel locks

engaged, twin disc brakes provide positive emergency

braking.

Electrical System: 12-volt, 66-amp hour (DIN) battery

and 35-amp alternator. Negative ground.

Interlock System: Designed to stop the engine if you get

off the seat while the cutting unit drive lever is either in

forward or reverse. Prevents the engine from starting

unless the parking brake is engaged, the traction pedal is

in neutral and the cutting units are disengaged. Low

Specifications