Contents

Introduction.................................................................2

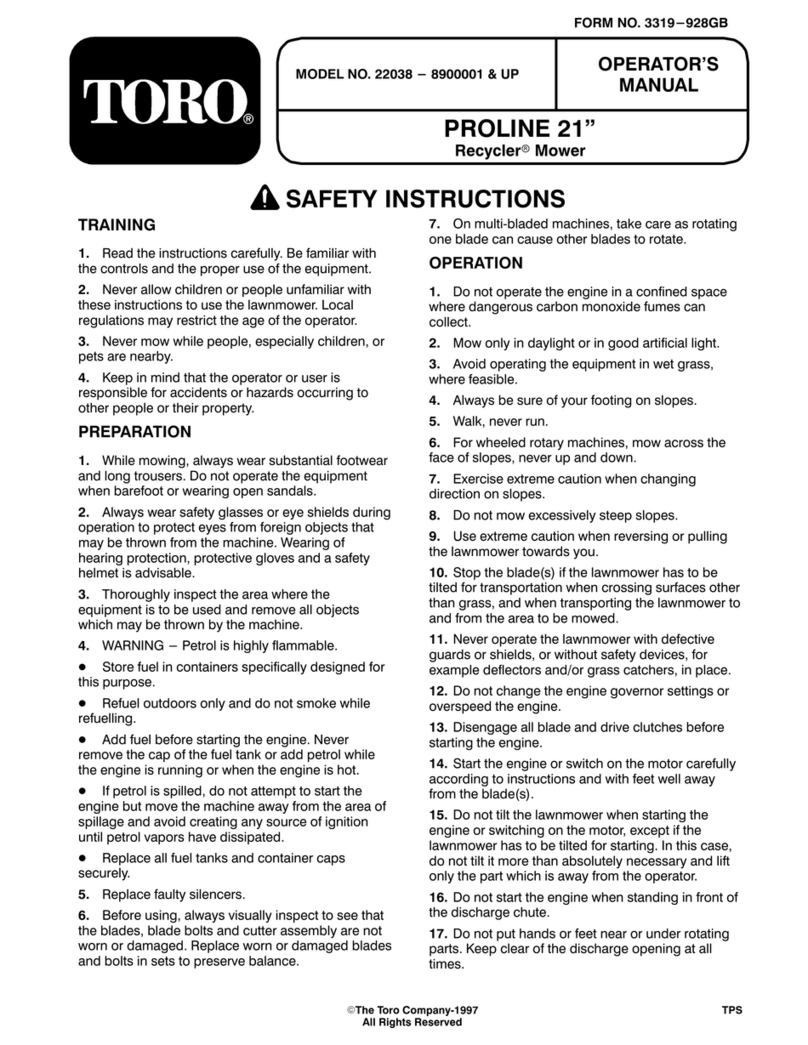

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel....................................................7

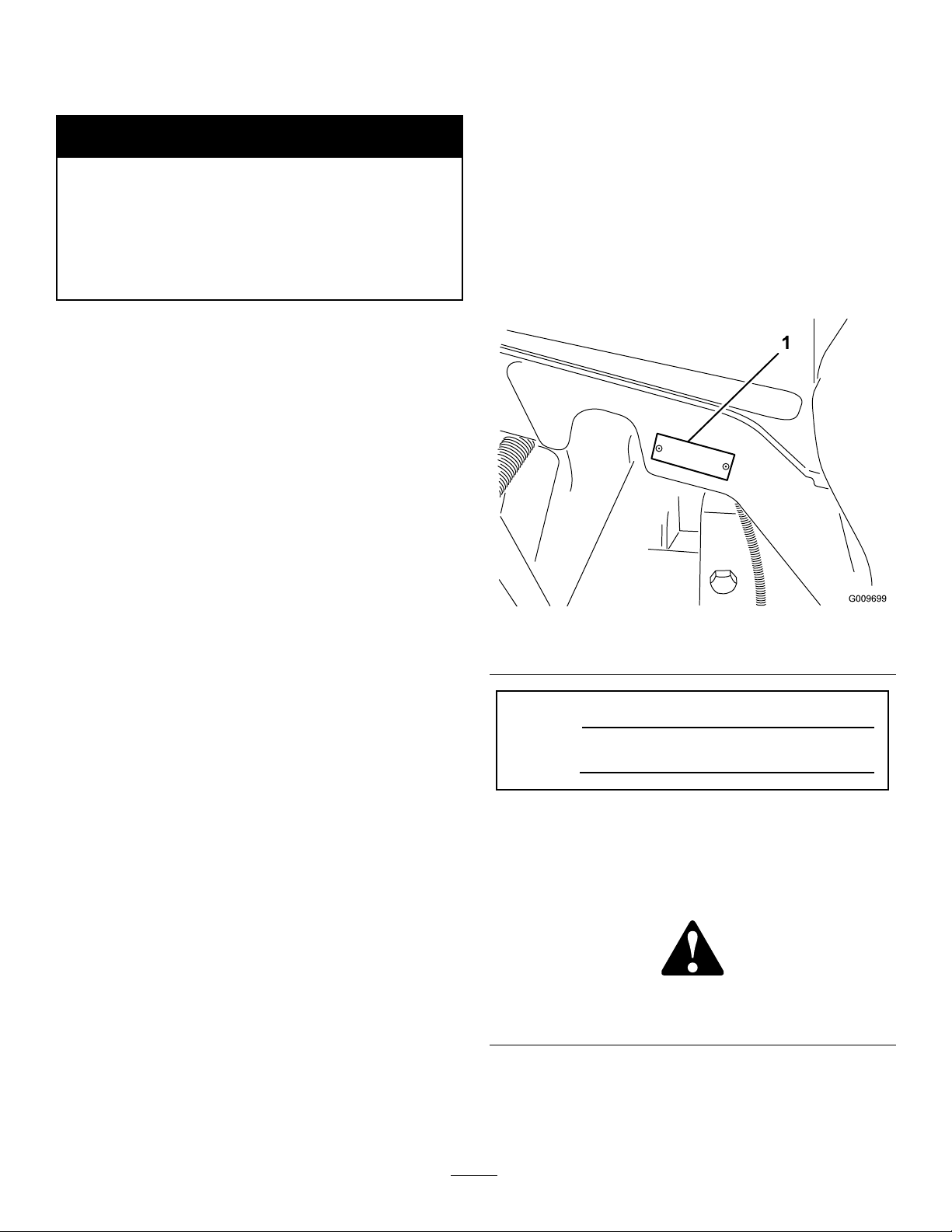

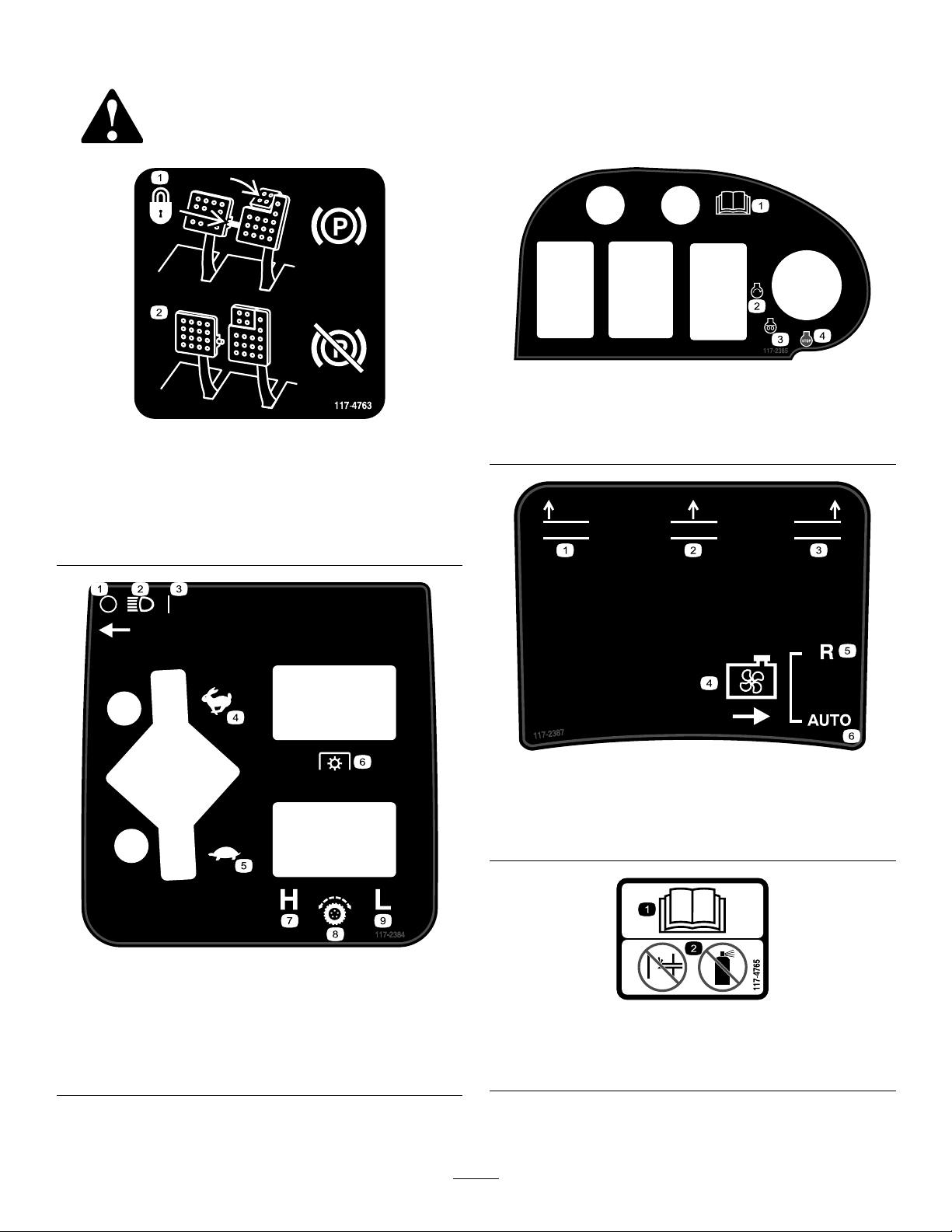

SafetyandInstructionalDecals.............................8

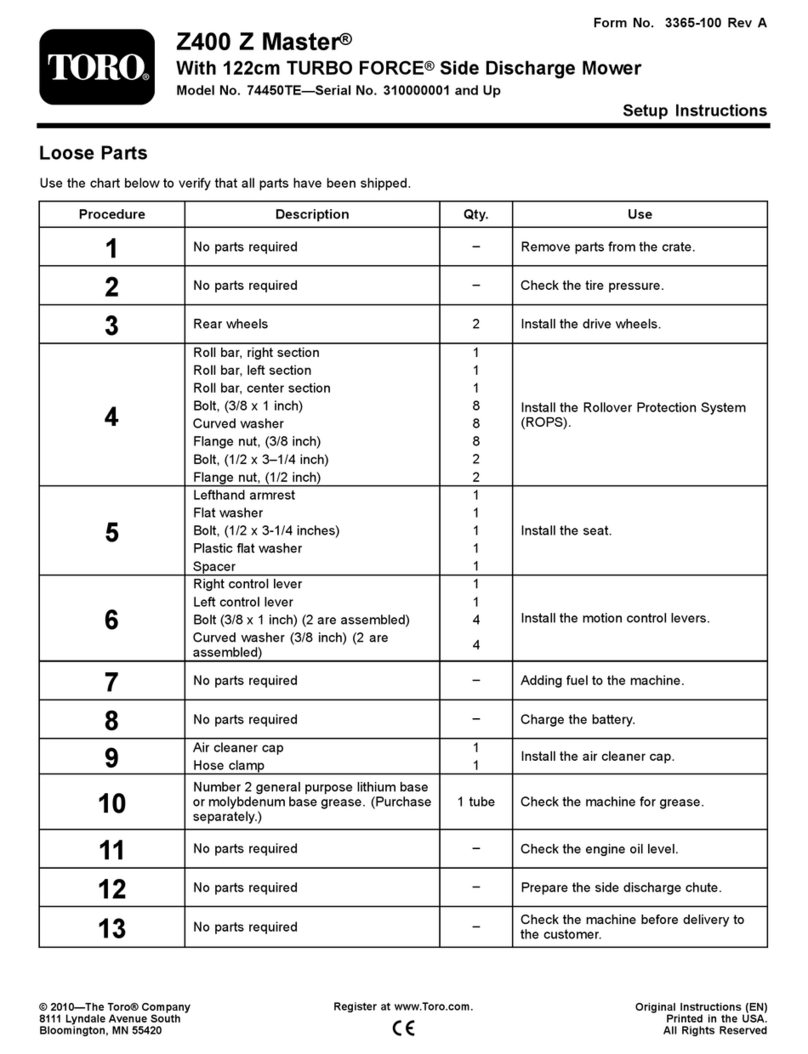

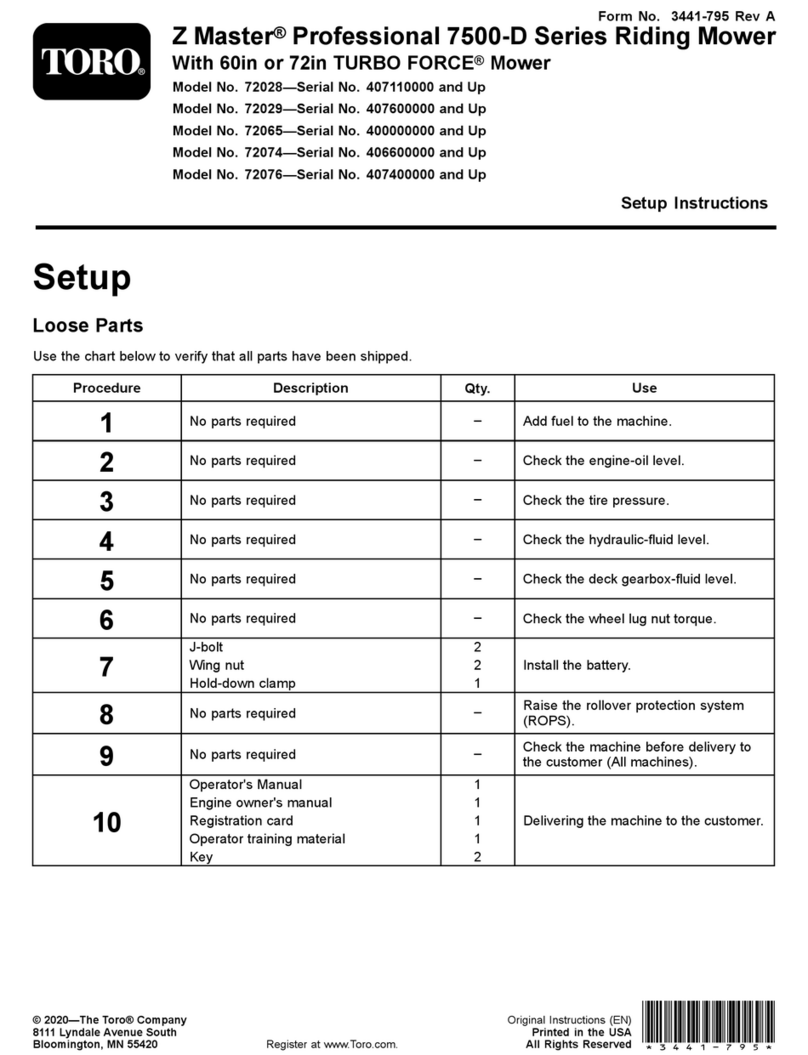

Setup.........................................................................12

1ReplacingtheWarningDecalforCE

Compliance....................................................13

2InstallingtheHoodLatch(CEOnly)................13

3InstallingtheThrottleStopforCE

CompliancewhenInstallingOptionalHigh

LiftBlades......................................................14

4GreasingtheMachine......................................14

5CheckingFluidLevels......................................14

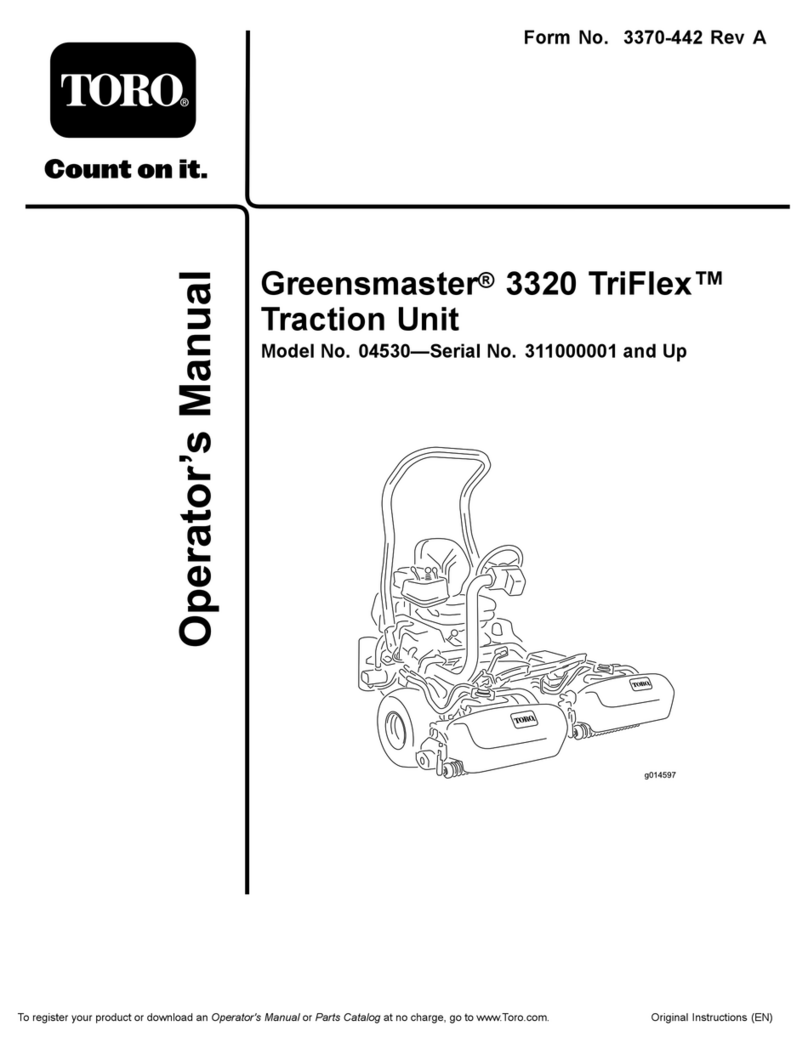

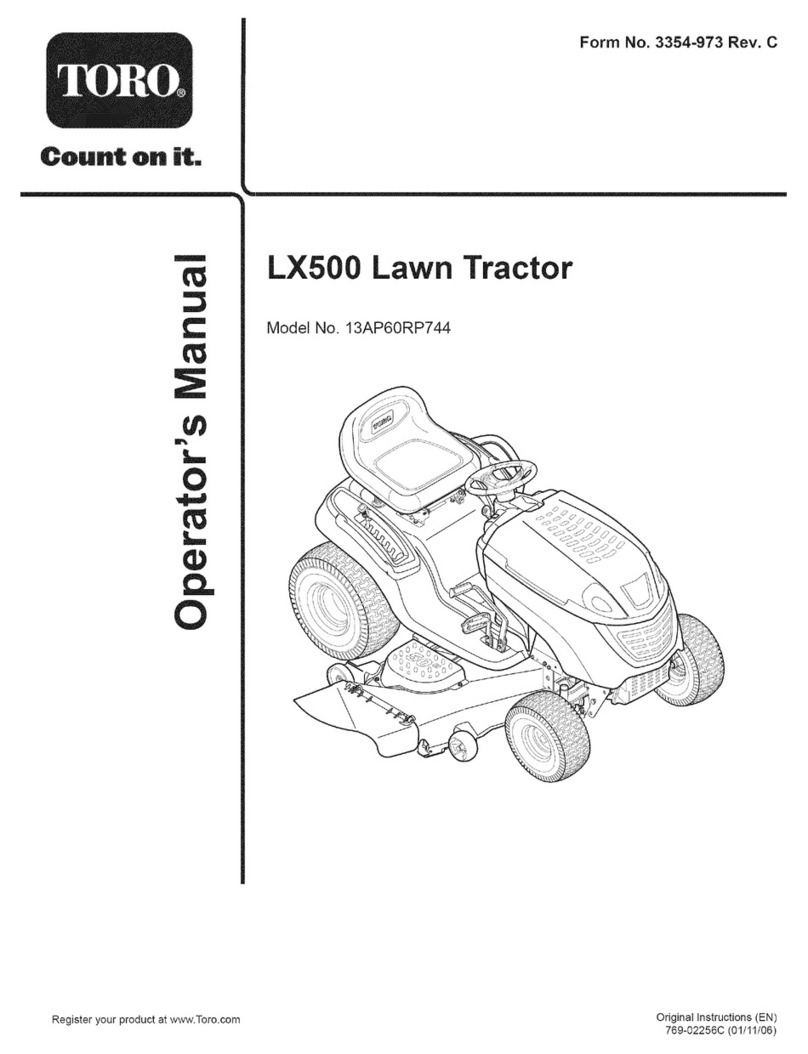

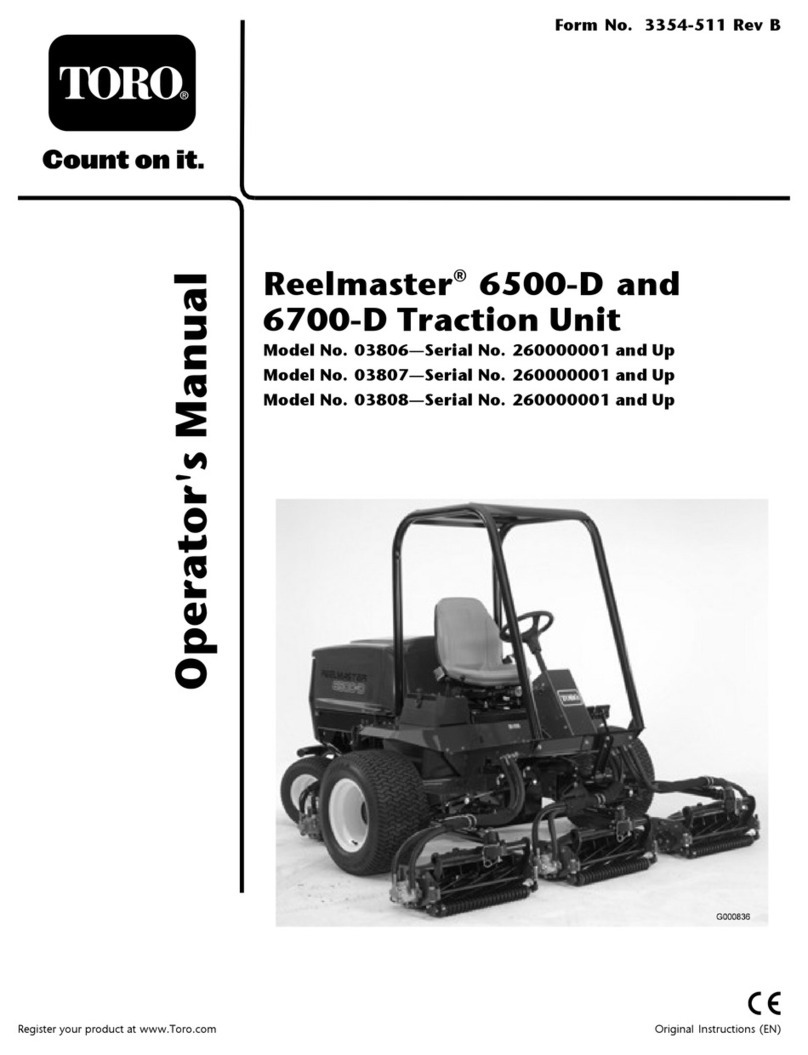

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................19

TractionUnitSpecications................................19

Attachments/Accessories...................................19

Operation...................................................................20

CheckingtheEngineOilLevel............................20

CheckingtheCoolingSystem..............................20

FillingtheFuelTank...........................................21

CheckingtheHydraulicFluidLevel.....................22

CheckingtheTirePressure.................................23

StartingandStoppingtheEngine........................23

CheckingtheInterlockSwitches.........................24

PushingorTowingtheMachine..........................24

JackingPoints.....................................................25

TieDowns.........................................................25

OperatingCharacteristics...................................25

EngineCoolingFanOperation...........................25

OperatingTips...................................................26

Maintenance...............................................................27

RecommendedMaintenanceSchedule(s)................27

DailyMaintenanceChecklist...............................28

ServiceIntervalChart.........................................29

PremaintenanceProcedures....................................30

RemovingtheHood...........................................30

Lubrication.............................................................30

GreasingtheBearingsandBushings....................30

EngineMaintenance...............................................32

ServicingtheAirCleaner....................................32

ServicingtheEngineOilandFilter......................33

AdjustingtheThrottle........................................34

FuelSystemMaintenance.......................................34

FuelTank...........................................................34

FuelLinesandConnections................................34

ServicingtheWaterSeparator.............................34

FuelPickupTubeScreen....................................35

BleedingAirfromtheInjectors...........................35

ElectricalSystemMaintenance................................36

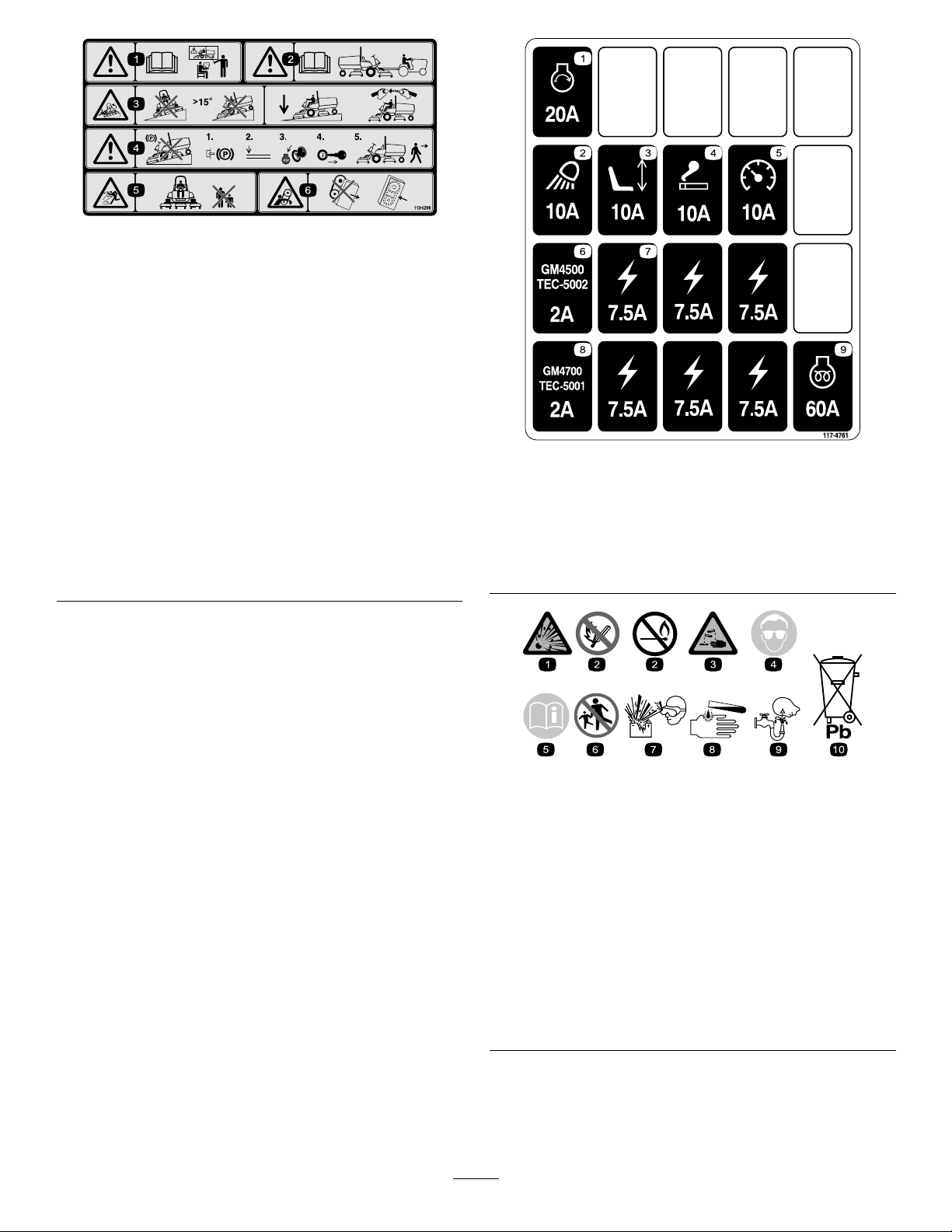

ChargingandConnectingtheBattery..................36

BatteryCare.......................................................37

Fuses..................................................................37

DriveSystemMaintenance.....................................38

CheckingtheTorqueoftheWheel

Nuts...............................................................38

CheckingthePlanetaryGearDrive

Oil..................................................................38

ChangingthePlanetaryGearDrive

Oil..................................................................39

CheckingtheRearAxleLubricant.......................39

ChangingtheRearAxleLubricant.......................40

AdjustingtheTractionDriveforNeutral.............40

CheckingtheRearWheelToe-In.........................40

CoolingSystemMaintenance..................................41

ServicingtheEngineCoolingSystem..................41

BrakeMaintenance.................................................42

AdjustingtheServiceBrakes...............................42

BeltMaintenance....................................................43

ServicingtheAlternatorBelt...............................43

HydraulicSystemMaintenance...............................43

ChangingtheHydraulicFluid.............................43

ReplacingtheHydraulicFilters...........................43

CheckingtheHydraulicLinesandHoses.............44

ChangingtheCounterbalanceSettings................44

Cleaning.................................................................46

ServicingtheSparkArrestorMufer...................46

Storage.......................................................................46

TractionUnit......................................................46

Engine...............................................................46

Schematics.................................................................47

3