Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup.......................................................................11

1CheckingFluidLevels....................................12

2InstallingtheCuttingUnits..............................12

3MakingAlternateCuttingUnit

Adjustments..................................................17

4AddingRearBallast.......................................18

5ApplyingtheCEDecals.................................18

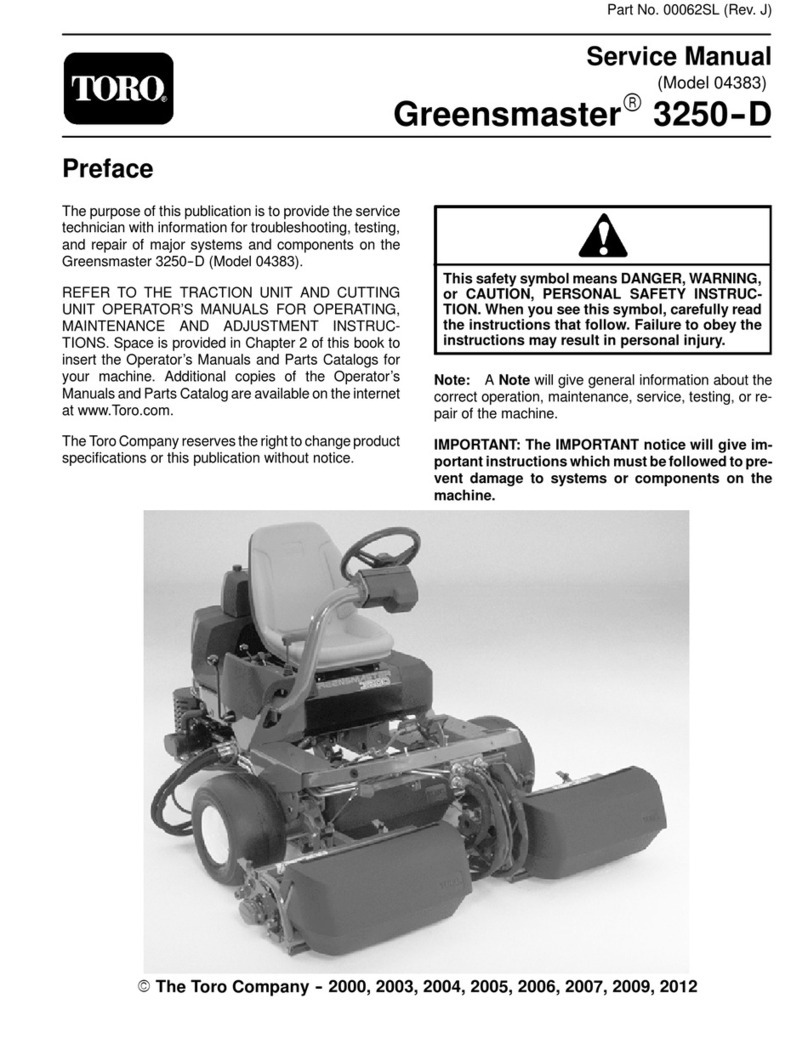

ProductOverview...................................................18

Controls...........................................................18

Specications..................................................21

Attachments/Accessories.................................21

BeforeOperation.................................................22

BeforeOperationSafety...................................22

PerformingDailyMaintenance..........................22

FillingtheFuelTank..........................................23

DuringOperation.................................................23

DuringOperationSafety...................................23

StartingtheEngine...........................................24

ShuttingOfftheEngine.....................................25

BleedingtheFuelSystem.................................25

CheckingtheInterlockSwitches.......................25

FaultMemoryandRetrieval..............................27

OperatingTips.................................................27

AfterOperation....................................................28

AfterOperationSafety......................................28

HaulingtheMachine.........................................28

IdentifyingtheTie-DownPoints........................28

PushingorTowingtheMachine........................29

HydraulicSolenoidValveFunctions..................29

Maintenance...........................................................30

MaintenanceSafety..........................................30

RecommendedMaintenanceSchedule(s)...........30

DailyMaintenanceChecklist.............................31

Lubrication..........................................................32

GreasingtheBearingsandBushings................32

EngineMaintenance...........................................34

EngineSafety...................................................34

ServicingtheAirCleaner..................................34

CheckingtheEngineOil...................................35

ServicingtheEngineOilandFilter....................36

AdjustingtheThrottle........................................37

FuelSystemMaintenance...................................38

DrainingtheFuelT ank......................................38

CheckingtheFuelLinesand

Connections..................................................38

ServicingtheWaterSeparator.........................38

BleedingAirfromtheInjectors..........................39

ElectricalSystemMaintenance...........................39

ElectricalSystemSafety...................................39

ServicingtheBattery.........................................39

CheckingtheFuses..........................................40

DriveSystemMaintenance..................................40

CheckingtheTirePressure...............................40

CheckingtheTorqueoftheWheelNutsand

Bolts..............................................................40

CheckingthePlanetaryGearDrive

Oil.................................................................40

ChangingthePlanetaryGearDrive

Oil.................................................................41

CheckingtheRearAxleLubricant.....................41

ChangingtheRearAxleLubricant....................42

CheckingtheRearWheelT oe-In......................42

AdjustingtheTractionDriveforNeutral.............42

CoolingSystemMaintenance..............................43

CoolingSystemSafety.....................................43

RemovingDebris..............................................43

CheckingtheCoolingSystem...........................44

MaintainingtheCoolingSystem........................44

BrakeMaintenance.............................................45

AdjustingtheServiceBrakes............................45

BeltMaintenance................................................46

CheckingtheAlternatorBelt.............................46

HydraulicSystemMaintenance...........................46

HydraulicSystemSafety...................................46

CheckingtheHydraulicFluid............................46

HydraulicFluidSpecications...........................47

HydraulicFluidCapacity...................................47

ChangingtheHydraulicFluid............................47

ReplacingtheHydraulicFilter...........................48

CheckingtheHydraulicLinesand

Hoses............................................................48

UsingtheHydraulicSystemT estPorts..............48

CuttingUnitSystemMaintenance........................50

BladeSafety.....................................................50

CheckingtheReel-to-BedknifeContact............50

BacklappingtheCuttingUnits...........................50

AdjustingtheCuttingUnitLowering

Rate..............................................................51

AdjustingtheLiftedHeightoftheOuterFront

CuttingUnits(EnablePosition)......................51

AdjustingtheTraveloftheFront3Cutting

Units..............................................................52

Storage...................................................................53

StorageSafety..................................................53

PreparingtheTractionUnit...............................53

PreparingtheEngine........................................53

3