Toro Z Master Series Manual

Other Toro Lawn Mower manuals

Toro

Toro TimeMaster 20975 User manual

Toro

Toro Z Master Professional 7000 Series User manual

Toro

Toro 71189 User manual

Toro

Toro 30881 User manual

Toro

Toro Recycler 20372 User manual

Toro

Toro 30495TC User manual

Toro

Toro 3540 User manual

Toro

Toro GrandStand 74568TE User manual

Toro

Toro 14AQ81RP748 User manual

Toro

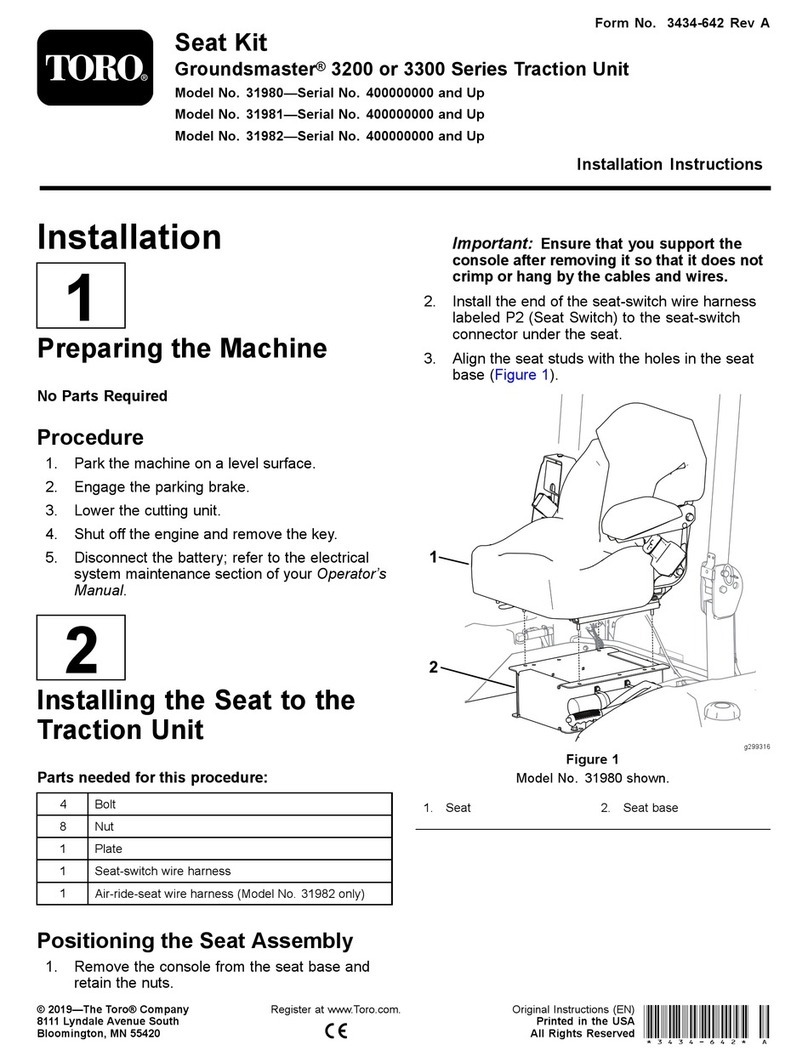

Toro Groundsmaster 3300 Series User manual

Toro

Toro 03672 User manual

Toro

Toro Groundsmaster 360 User manual

Toro

Toro 30739 User manual

Toro

Toro TimeMaster 20199 User manual

Toro

Toro 02617 User manual

Toro

Toro 20340 User manual

Toro

Toro Recycler 20339 User manual

Toro

Toro 25433 User manual

Toro

Toro 74656 User manual

Toro

Toro Lawn-Boy TimeCutter Z Series User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual