9

SPECIFICATIONS

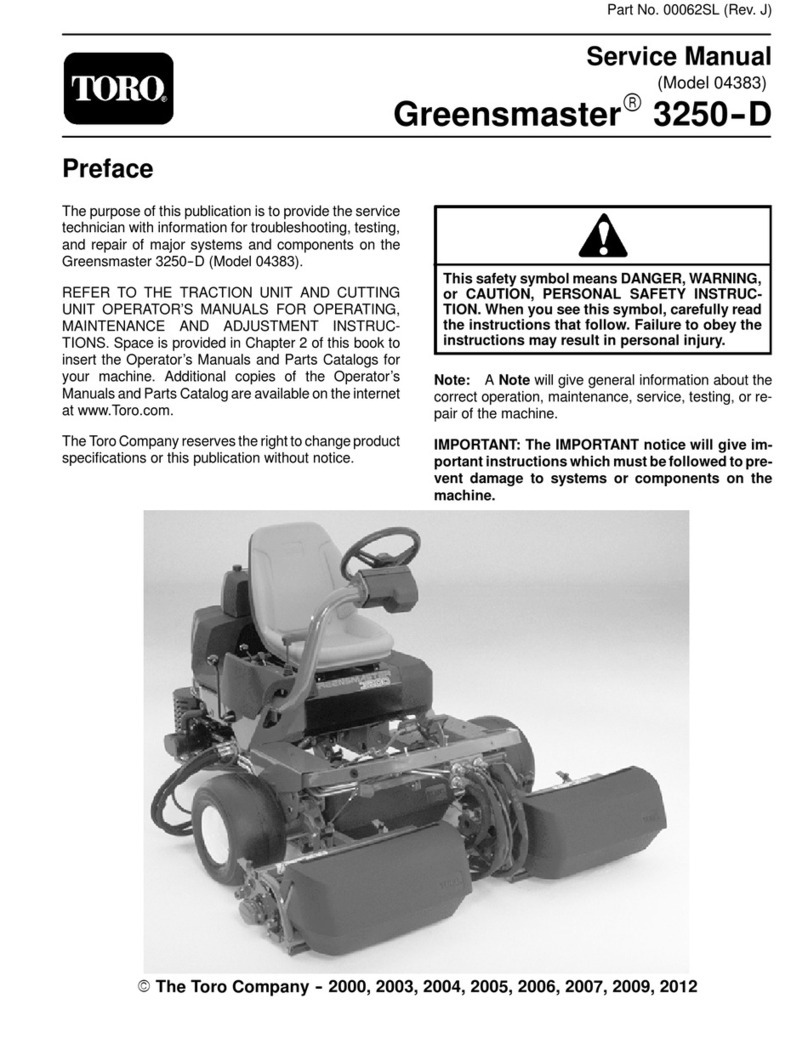

Engine: Peugeot TUD5, 4 cylinder, 4 cycle, in-line,

over-head cam, liquid cooled diesel engine with

centrifugal water pump. Available power, 36 hp at 2625

RPM. 1.5 liter displacement, governed to a maximum

speed of 2780 RPM. Compression ratio 23.5:1. Glow

plugs controlled by pre/post heat relay. Oil capacity

4.75 quart (4.5 liters) with oil filter. 12 volt type 4 starter

motor with integral solenoid. 70 amp type 7 alternator

with integral regulator.

Fuel Tank Capacity: 12 gallons diesel fuel

Radiator : Rear mount industrial radiator with tube and

fin construction: 4 rows, 5 fins per inch. Thermally

stable water cooled hydrostatic system regulates

operating temperature. Separate degassing bottle to

remove air from cooling system fluid. System capacity

approximately 11.5 quarts (10.9 liter).

Controls: Hand operated throttle, PTO switch,

hydraulic lift/lower/counterbalance of implement,

ground speed high/low range switch, ignition switch.

Foot operated tilt steering locking lever, traction pedal,

steering/parking brake pedals.

Gauges and Diagnostics: Gauge package includes

fuel gauge, engine coolant temperature gauge, and

hour meter. Indicator light for high engine coolant

temperature, low engine oil pressure, alternator, low

engine coolant level, water in fuel, glow plugs.

Electrical Features: 12 volt automotive type electrical

system. 650 cold cranking amp battery performance at

00F. Dash mounted ignition switch. 70 amp alternator.

PTO, seat and traction interlock switches.

Transaxle/PTO: Sauer-Sundstrand integrated

hydrostatic transaxle (IHT-M15) incorporating the

hydrostatic transmission, mechanical gearbox,

differential, drive axle, power-take-off (PTO) system,

implement hydraulic system pump and reservoir in a

single component. Variable speed, axial piston,

hydrostatic U-type transmission: gear type charge

circuit hydraulics with filtration provides hydraulic flow

for power steering and implement lift. Approximately

12 quart oil capacity. Single foot pedal control of

forward/reverse ground speed. Two speed axle with

"shift on the fly" speed range selection. 4wd is

mechanically driven from front axle by a universal shaft.

Double overrunning clutch provides 4wd function in

forward and reverse preventing rear tire scuffing in

turns. Both 2wd and 4wd have the same turning radius.

Optional cruise control available.

Implement Lift: Twin hydraulic lift cylinders (2.5" bore

x 3.5" stroke) provide lift, lower and counterbalance of

implement via electrically actuated hydraulic control

manifold.

Steering: Eaton Series 2 steering control unit with

power beyond. Steering valve controls single steering

cylinder. Steering system is single tie-rod type which

provides identical steering performance on both two

and four wheel drive versions. Tilt steering wheel with

single lever control. 14" diameter steering wheel.

Ground Speed

Low speed - 0-8 mph, infinitely variable

High speed - 0-15 mph, infinitely variable

Clearance

Front ground clearance - 8.25 inches

Rear ground clearance - 2wd : 6.00 inches

4wd : 4.75 inches

Tires/Wheels/Pressures

Two front traction drive tires

Models 30301 TC and 30302 TC - 25 x10.5-15 turf

tread, 6 ply rating.

Models 30301 and 30302 - 24 x13-12 turf tread, 4 ply

rating.

Two rear steering tires

Models 30301 TC and 30302 TC - 20 x 8-10, turf

tread, 6 ply rating.

Models 30301 and 30302 - 18 x 8.50-10, turf tread,

4 ply rating.

Tire pressure - 15 psi

Brakes: Individual mechanical caliper disc brakes

provide both independent application for steering

assist and combined application for parking brake

function. Dynamic braking through the hydrostatic

traction drive.

Seat: Deluxe high back seat. Optional seat suspension

kit, Model 30395, or deluxe adjustable suspension kit,

Model 30396.

Storage: Toolbox with cover located to the left of the

seat base. Beverage holder integral to toolbox cover.

Operator manual storage tube furnished for

attachment to seat frame.

Weight: 2wd - 1930lbs (875kg)

4wd - 2030lbs (920kg)

Wheel Base: 55 inches

Tread Width: 53 inches

Specifications and design subject to change without notice.