Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel....................................................7

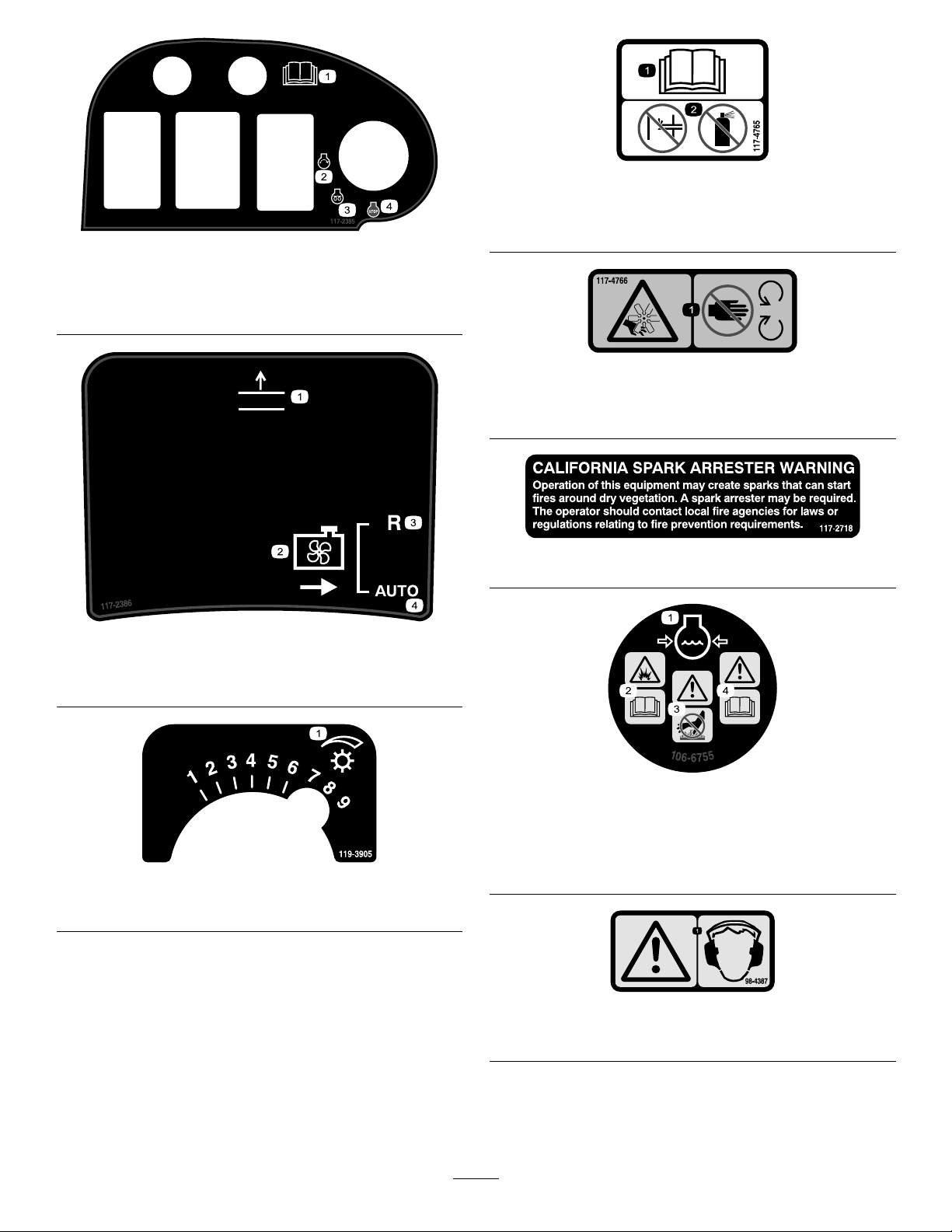

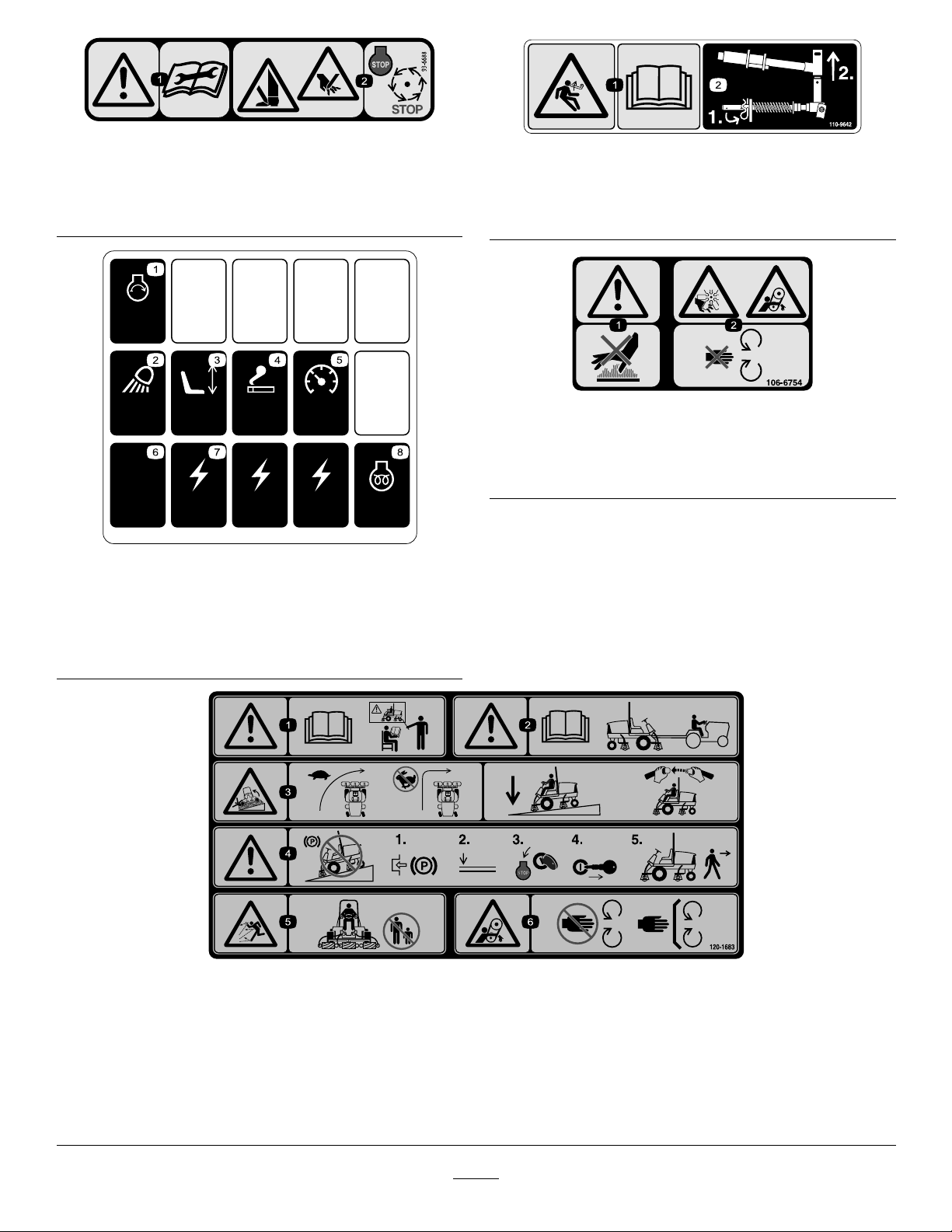

SafetyandInstructionalDecals.............................7

Setup.........................................................................12

1AdjustingtheSupportRollers...........................13

2ReplacingtheWarningDecalforCE

Compliance....................................................13

3InstallingtheHoodLockforCE

Compliance....................................................13

4InstallingtheCuttingUnits..............................14

5AdjustingtheTurfCompensation

Spring............................................................18

6UsingtheCuttingUnitKickstand.....................18

7GreasingtheMachine......................................19

8CheckingFluidLevels......................................19

9UsingtheGaugeBar........................................20

ProductOverview......................................................20

Controls.............................................................20

Specications.....................................................24

TractionUnitSpecications................................24

Attachments/Accessories...................................24

Operation...................................................................25

CheckingtheEngineOilLevel............................25

CheckingtheCoolingSystem..............................26

FillingtheFuelTank...........................................26

CheckingtheHydraulicFluidLevel.....................28

CheckingtheTirePressure.................................29

StartingandStoppingtheEngine........................29

CheckingtheInterlockSwitches.........................29

SettingtheReelSpeed.........................................30

AdjustingtheLiftArmCounterbalance...............31

AdjustingtheLiftArmTurnAround

Position..........................................................31

PushingorTowingtheMachine..........................32

JackingPoints.....................................................32

TieDowns.........................................................32

UnderstandingtheDiagnosticLight....................32

DiagnosticAceDisplay.......................................33

CheckingtheInterlockSwitches.........................33

OperatingCharacteristics...................................34

EngineCoolingFanOperation...........................35

OperatingTips...................................................35

Maintenance...............................................................36

RecommendedMaintenanceSchedule(s)................36

DailyMaintenanceChecklist...............................37

ServiceIntervalChart.........................................38

PremaintenanceProcedures....................................39

RemovingtheHood...........................................39

Lubrication.............................................................39

GreasingtheBearingsandBushings....................39

EngineMaintenance...............................................41

ServicingtheAirCleaner....................................41

ServicingtheEngineOilandFilter......................42

AdjustingtheThrottle........................................42

FuelSystemMaintenance.......................................43

FuelTank...........................................................43

FuelLinesandConnections................................43

ServicingtheWaterSeparator.............................43

FuelPickupTubeScreen....................................43

BleedingAirfromtheInjectors...........................44

ElectricalSystemMaintenance................................44

ChargingandConnectingtheBattery..................44

BatteryCare.......................................................45

Fuses..................................................................46

DriveSystemMaintenance.....................................47

CheckingtheTorqueoftheWheel

Nuts...............................................................47

CheckingthePlanetaryGearDrive

Oil..................................................................47

ChangingthePlanetaryGearDrive

Oil..................................................................47

CheckingtheRearAxleLubricant.......................48

ChangingtheRearAxleLubricant.......................48

AdjustingtheTractionDriveforNeutral.............48

CheckingtheRearWheelToe-In.........................49

CoolingSystemMaintenance..................................50

ServicingtheEngineCoolingSystem..................50

BrakeMaintenance.................................................51

AdjustingtheServiceBrakes...............................51

BeltMaintenance....................................................51

ServicingtheAlternatorBelt...............................51

HydraulicSystemMaintenance...............................52

ChangingtheHydraulicFluid.............................52

ReplacingtheHydraulicFilters...........................52

CheckingtheHydraulicLinesandHoses.............53

CuttingUnitMaintenance.......................................53

BacklappingtheCuttingUnits............................53

Cleaning.................................................................54

ServicingtheSparkArrestorMufer...................54

Storage.......................................................................55

Engine...............................................................55

TractionUnit......................................................55

Schematics.................................................................56

3