TORONTO TOOL Pro-Cut 50 User manual

TORONTO TOOL MANUFACTURING INC.

Pro-Cut 50

User Manual

Pro-Cut 50 User Manual Version 03:02:115:04

The contents of this manual are subject to change without notice. For any updates or improvements please visit our web

site at: www.torontotool.com

1

Pro-Cut 50 User Manual

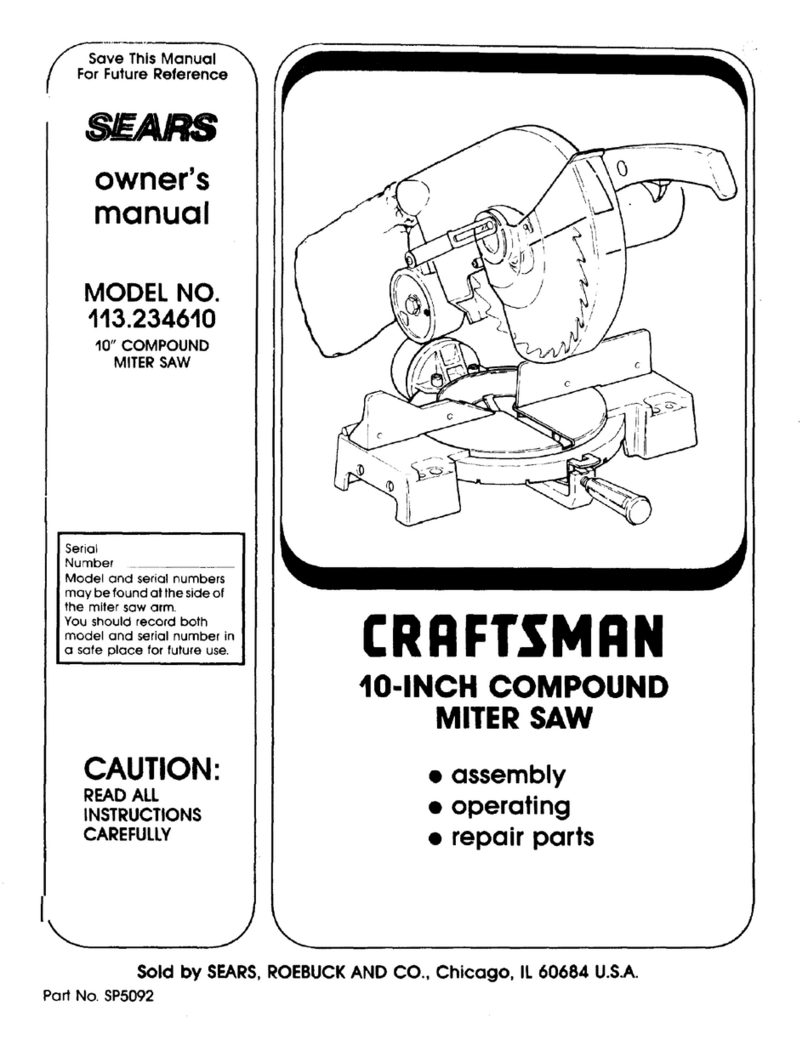

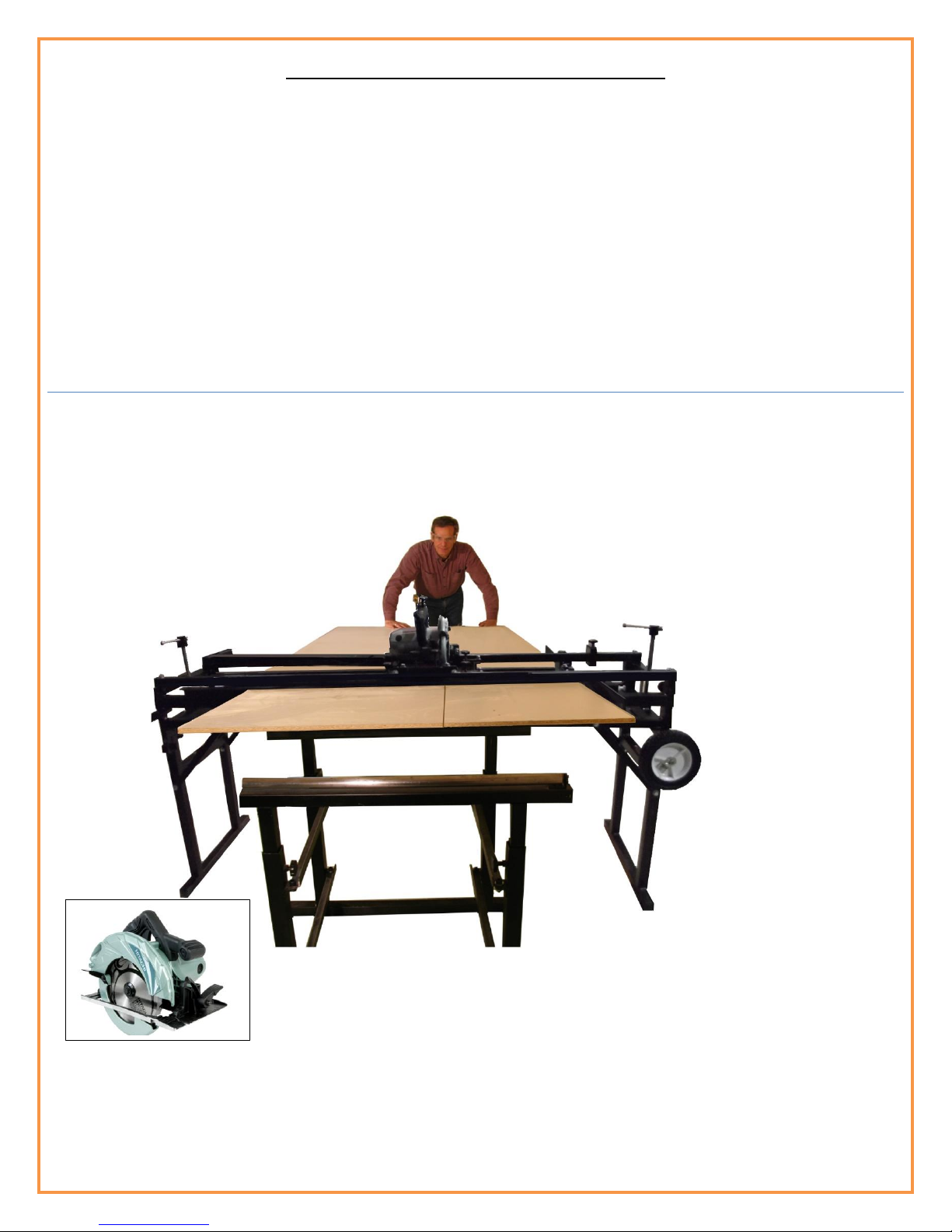

Pro-Cut 50 (Professional Table Saw and Router System)

Thank you for purchasing the Pro-Cut 50 (Professional Table Saw and Router System). Below you will find

Safety Procedures, set-up procedures and operating instructions. For video demonstrations, be sure to visit

the “How To” section of our web site www.torontotool.com

Canadian Made, Professional Grade Products

It’s time for a change! Introducing the Pro-Cut 50 Professional Table Saw and Router System!Conventional table

saws have been around for years and have been virtually unchanged from the original design. There are a number of

challenges when using a conventional table saw that many people have struggled with and tried to improve over the

years. A conventional table saw is good for rip cutting boards and panels, but depends on the operator to feed material

evenly and tight against the side fence to produce straight cuts. You also have to ensure the material is held down on

the table top so it doesn’t “ride the blade” while feeding. This is true more so with thinner material such as ¼” plywood.

A conventional table saw also relies on the side fence clamping exactly parallel to the blade. If the side fence is not

parallel to the blade, the resulting cut will have excessive “tear out” and also greatly increases the possibility “kick back”.

The fact that a side fence moves means it will have some play and a good possibility of error.

Next Generation Table Saw

The new Pro-Cut 50 is the next generation table saw with numerous features and benefits to address the inherent

disadvantages of a table saw. The Pro-Cut 50 rip cuts material like a conventional table saw but, unlike a conventional

table saw, the material is fully guided on both sides thus eliminating feed errors. The side fence is fixed at exactly 90o to

the saw thus eliminating any side fence error as can be experienced on conventional table saws. For cutting angles you

simply tilt the saw to any desired angle. The Pro-Cut 50 is based on Toronto Tool’s industrial design where the saw

moves along precision guide rails for cross cutting and locks to any position for rip cutting. The Pro-Cut 50 has adjustable

height for cutting material up to 3-1/2” thick. The smooth movement of the sled includes 8 sealed roller bearings and 4

industrial grade bearing blocks to ensure precision and accuracy of movement. Rip cutting narrow boards or full 4’ x 8’

panels has never been easier. A conventional table saw is prone to “kick back” due to design but the top mounted saw

of the Pro-Cut 50 encapsulates your material thus virtually eliminating the possibility of “kick back”. The Pro-Cut 50

comes standard with a top of the line, premium grade Hitachi PCC7BMR saw chosen for its quality of construction,

power and accuracy. You can also opt to up-grade to the C7YA saw with built in dust collection.

2

Cross Cutting Advantage

Cross cutting on a conventional table saw can be a challenge at the best of times and involves moving the entire piece of

material through the blade. An uneven feed while cross cutting can cause pinching of the material and most likely result

in “kick back”. A number of people build a cross cut sled for their table saw that rides in the small grove on the table top.

This method generally works for smaller panels and boards but does not work well for larger panels. A good number of

people don’t even attempt cross cutting large panels on their table saw. They resort to a guide and circular saw. Even if

you are fortunate enough to have a sliding cross cut table set up for your table saw, you still have to move the entire

sheet. In a lot of cases, the crosscut add-on costs more than the table saw itself and takes up a tremendous amount of

valuable floor space in your shop. Cutting wood across the grain in one pass will most likely produce chipping or tear

out. This can be minimized by using a quality finish blade with a high tooth count but still doesn’t eliminate “tear out”

and/or “chipping”. The only proven method for eliminating “tear out” or “chipping” is by kerf cutting. A pre-cut or kerf

blade is only found on the most expensive table saws.

A Different Approach

The Pro-Cut 50 uses an entirely different approach to crosscutting. The board or panel is locked in place on the Pro-Cut

50 and the saw slides through the material on precision guide rails. No more reaching over the panel or trying to hold a

panel square and tight against the side fence while also making sure to keep the panel flat on the table surface so it

doesn’t “ride the blade” and, at the same time, trying to feed it smoothly into the saw blade.

INCLUDED with the PRO-CUT 50

Hitachi PCC7BMR 7-1/4" Saw Featuring IDI

Technology

Powerful15 amp motor to tackle the toughest cutting jobs. Patented

IDI (Internal Double Insulation) technology reduces vibration and

extends tool life Bevel capacity adjustable from 0-55° with positive

stops at 45° and 55° Heavy duty die-cast aluminum base with

integrated scale provides stability and accuracy. Large all metal

leavers for adjusting depth and bevel angles. Electric brake stops the

blade quickly after the switch is released. Magnesium housing, gear

cover, blade cover and lower guard for increased strength and smooth

operation.

PRO-CUT 50

Professional Table Saw and Router Guide System

PCC7BM

R

3

The Pro-Cut 50 will eliminate “tear out” and “chipping” when cutting across the grain. Easily perform by kerf cutting a

board or panel for perfectly smooth cuts. Due to the precision guide system of the Pro-Cut 50, you simply raise the blade

of the saw to make a pre- cut (also known as a kerf cut) on the board or panel and then lower the blade to complete the

cut. The result is a perfectly smooth cut against the grain on both the top and bottom of any material including

hardwood, softwood, veneer panels and melamine.

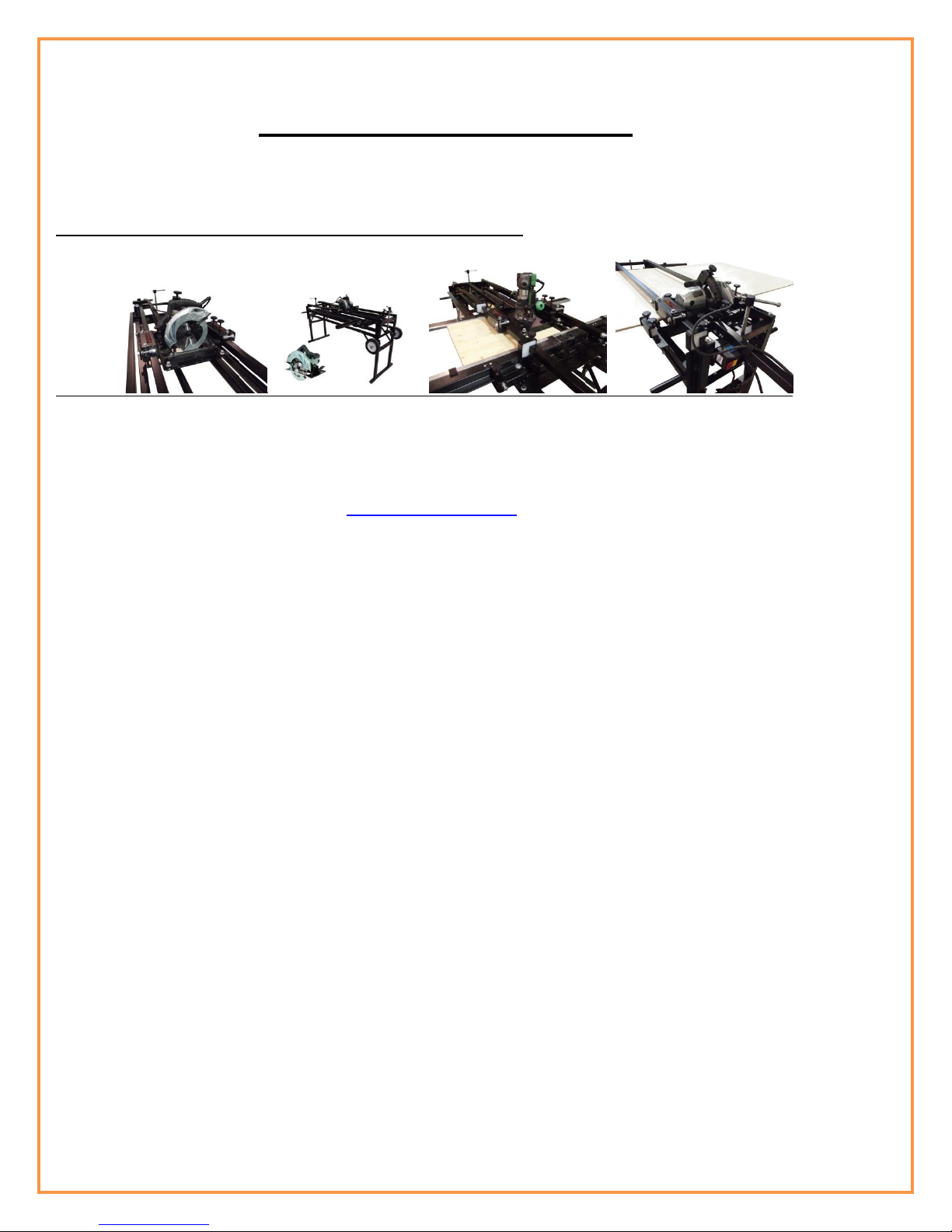

The PRO-CUT 50

is also a full “X” and “Y” Router Table

Take full advantage of your router using the Pro-Cut 50

By simply unlocking and removing the saw from the Pro-Cut 50 sled and placing the router in its place, you have

instantly converted your Pro-Cut 50 from a precision table saw to a full size precision “X” & “Y” router table. The Pro-Cut

50 has the ability to rout in both the “X” and “Y” directions on all projects from something as small as a bread board

right up to 50” wide panels. Your material can be of any length in the “Y” direction. Perfect for making your own custom

moldings, window frames, small and large cabinet doors, custom table tops, picture frames, fluted rails just to name a

few. You can also dado both side panels of a cabinet at the same time on the Pro-Cut 50. This is perfect for exact

placement of shelves in cabinets of any height. Routing cutouts for inlays in any project is also a breeze on the Pro-Cut

50. The Pro-Cut 50 comes with the router insert plate, 2 router guide stops and 2 panel stops for quick and easy set-up

for routing any project. Virtually anything you can imagine can be made using the Pro-Cut 50. The router is top mounted

on the Pro-Cut 50 so you can always see the cut in progress. This is a huge advantage over a conventional router table

where the router is mounted underneath. A conventional router table is one dimensional and will only produce cuts in

one direction and is also limited in width of cut thus limiting the wide range of uses a router is capable of. The Pro-Cut

50 allows an operator to take full advantage of the router and the countless operations a router is able to perform. You

can even glue another board(s) or panel to the top of your project and continue routing. Great for making true raised

panel doors for example. The Pro-Cut 50 is designed for ease of use, precision and productivity for rip cutting,

crosscutting and all your router needs. The Pro-Cut 50 is also designed for easy storage when not in use with fold up legs

and wheels.

Available for the Pro-Cut 50

Hitachi Router kit KM12VC

PRO-CUT 50

4

For Your Own Safety Read Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY PRECAUTIONS

(For All Tools)

1. KNOW YOUR POWER TOOL. Read the 6. KEEP CHILDREN AWAY. All visitors

owner’s manual carefully. Learn the tool’s should be kept safe distance from work area.

applications and limitations, as well as the

specific potential hazards particular to it. 7. MAKE WORKSHOP KID PROOF with padlocks,

2. KEEP GUARDS IN PLACE and in working master switches, or by removing starter keys.

order.

3. REMOVE ADJUSTING KEYS AND 8. DON’T FORCE TOOL. It will do the job better

WRENCHES. Form habit of checking to and safer at the rate for which it was designed.

see that keys and adjusting wrenches are

removed from tool before turning it on. 9. USE RIGHT TOOL. Don’t force tool or

4. KEEP WORK AREA CLEAN. Cluttered attachment to do a job for which it was not designed.

areas and benches invite accidents.

5. DON’T USE IN DANGEROUS ENVIRONMENT. 10. WEAR PROPER APPAREL. Do not wear

Don’t use power tools in damp or loose clothing, gloves, neckties, rings,

wet locations, or expose them to rain. bracelets, or other jewellery which may get

Keep work area well lit. Don’t use caught in moving parts. Nonslip footwear

tool in presence of flammable liquids or is recommended. Wear protective hair

gases. covering to contain long hair. Always wear safety glasses.

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to safety

rules. If you use this tool unsafely or incorrectly, you can suffer

serious personal injury.

Always use a push stick to complete cuts. Never place fingers near the cutting blade under

any circumstances.

Setting up your Pro-Cut 50 Professional for the first time

When un-packaging your new Pro-Cut 50 please inspect all parts for damage and report any damage to

Toronto Tool Manufacturing Inc. right away.

The Pro-Cut 50 and Pro-Cut 50DC come fully assembled and adjusted at our facility however it is always good

practice to make a few test cuts to ensure the adjustments did not move during shipping. Adjusting the Pro-

Cut 50 is straight forward and will be discussed in detail later in this user guide.

There are basically two points to keep in mind during adjustment.

1) The sled slides freely along the guide rails with minimal side to side play.

2) The saw cuts at exactly 900 to the side fence when cross cutting.

The following diagrams show the different parts of the Pro-Cut 50 starting with the fold down leg assemblies

and securing the leg struts.

5

Release the leg lock levers, lift one end of the Pro-Cut 50 to fold down the leg assembly on one end of

the machine (Fig. 1b) making sure the leg assembly is resting tightly against the leg stops. A leg strut is

attached to each side of the leg assembly. A bolt and wing nut is located on the Pro-Cut 50 frame on

either side of the frame that the leg struts attach to. Remove the wing nut from the bolt along with the

washer on one side of the leg assembly. Fold the leg strut up to allow the drilled hole in the leg strut to

line up with the bolt on the frame. Insert the bolt into the leg strut, attach the washer and wing nut

and hand tighten. Follow the same procedure for the leg strut on the opposite side of this leg

assembly. Follow the same procedure for the leg assembly on the other end of the Pro-Cut 50.

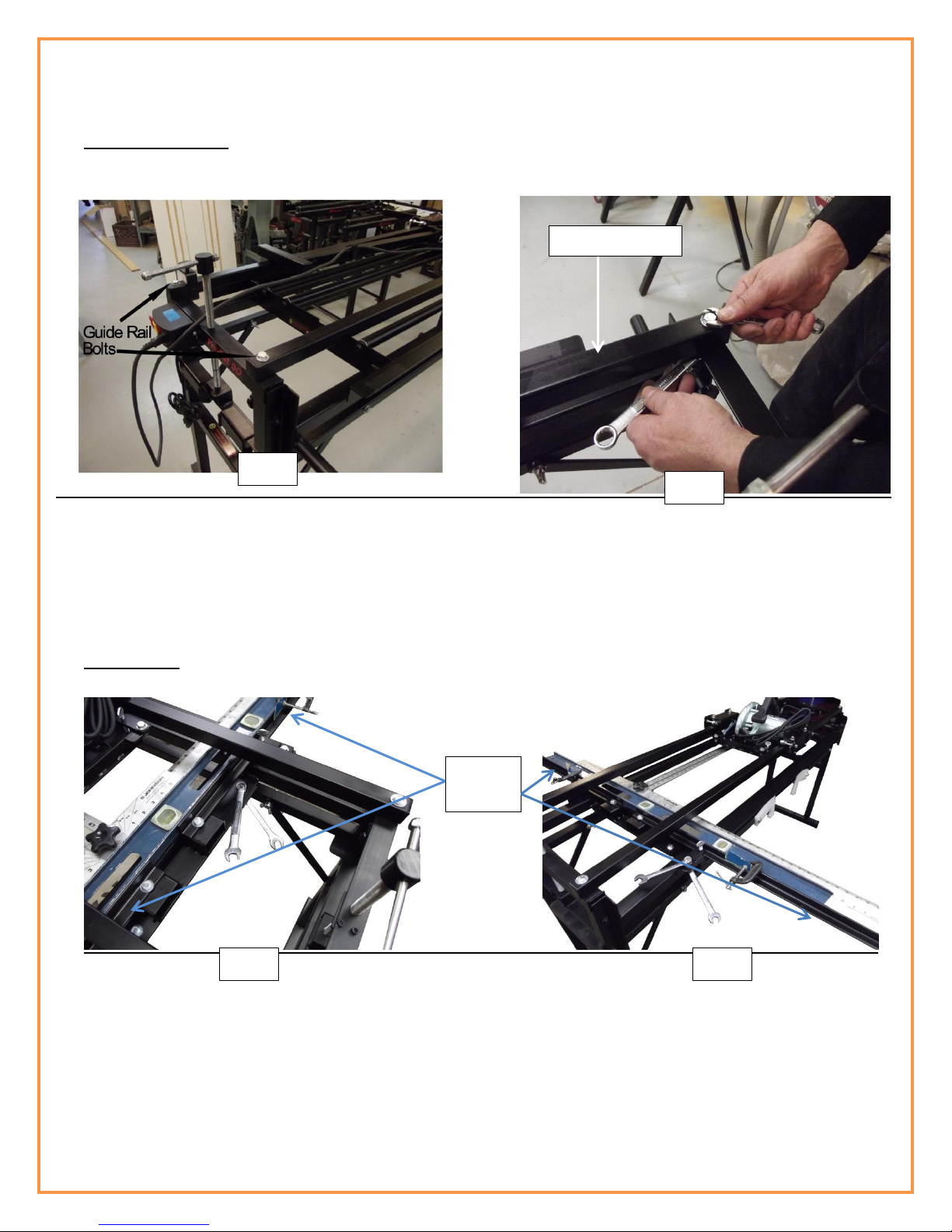

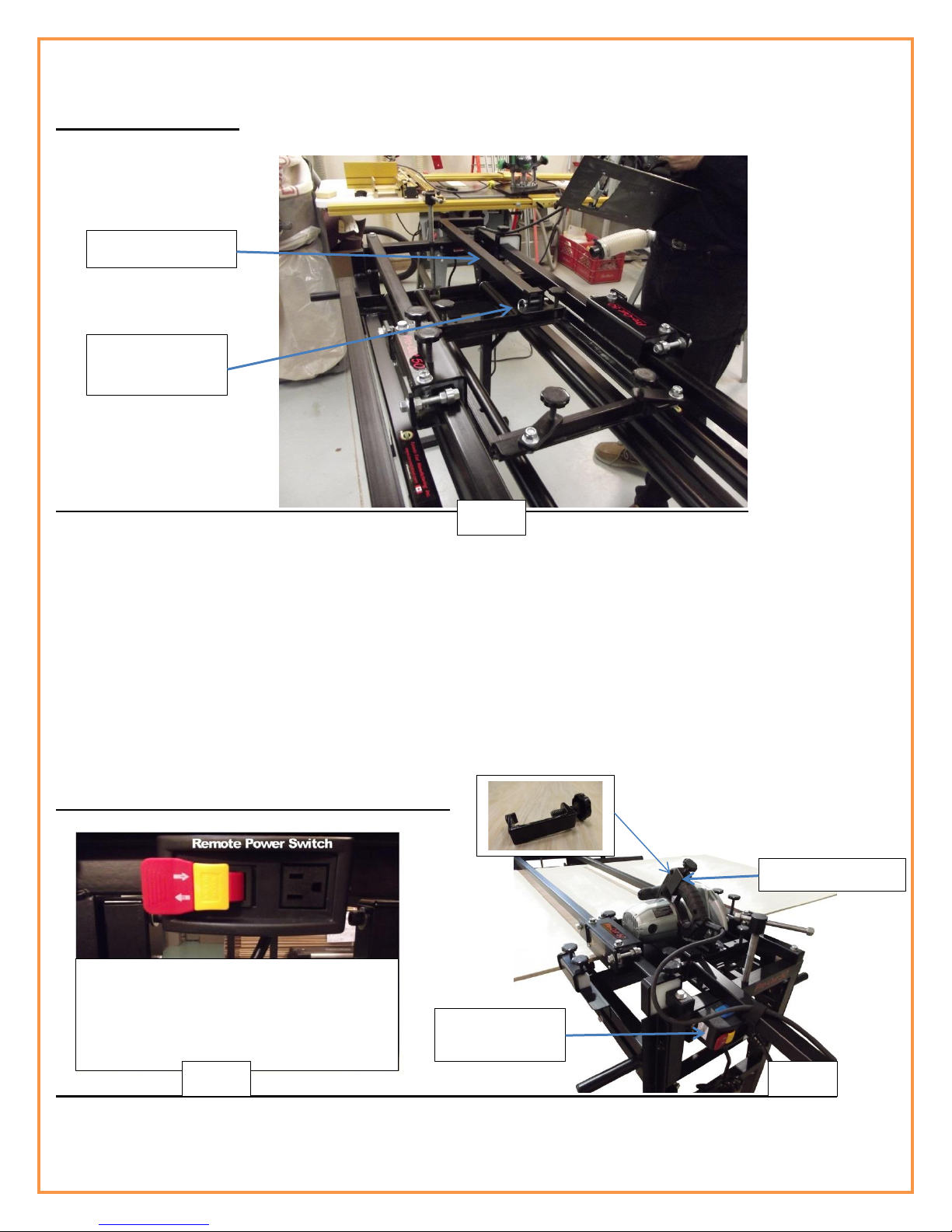

Sled Guide Rail Sub Frame.

1) The Sled Guide Rail Sub Frames have a 5/8” x 14” Clamp Screw and 5/8” Clamp Screw Nut.

2) There are (2) knobs on either side of the Pro-Cut 50 Sub Frame (Fig 2). These are used to lock the Sled

Guide Rail Sub Frame in place after adjusting the height of the sled carriage.

3) Sled Guide Rail (Fig 3)

4) Clamp screw Nut (shown in Fig 2 &Fig 3). If it becomes necessary to tighten the clamp screw nut, use

an adjustable wrench and, holding the clamp screw handle, tighten the clamp screw nut onto the

Spacer

Washer

Fig 1

Fig 2

Fig 3

Fold down legs and lock

leg struts

Fig. 1a

Fig. 1b

6

clamp screw. Loosen the (2) frame knobs to raise and lower the guide rail sub frame using the clamp

screw. Carriage height adjustment and the use of spacers will be discussed later in this user guide.

Sled Guide Rails

(Fig 4 & 5) shows the Sled Guide Rail and Sled Guide Rail Bolts. There are 1” slots in the Sled Guide Rail Sub

Frame to allow independent adjustment of each Sled Guide Rail. The slots will be used to allow the exact

positioning of the Sled Guide Rails (explained later).

Side Fence

The side fence assembly has 4 adjustment points. The side fence base has two slots to allow squaring

of the entire side fence assembly to the saw blade (fig 6). The clamp rails have slots to allow alignment

of the side fence wings (Fig 7) explained later in this manual.

Fig 4

Side

Fence

Fig 5

Fig 6

Fig 7

Sled Guide Rail

7

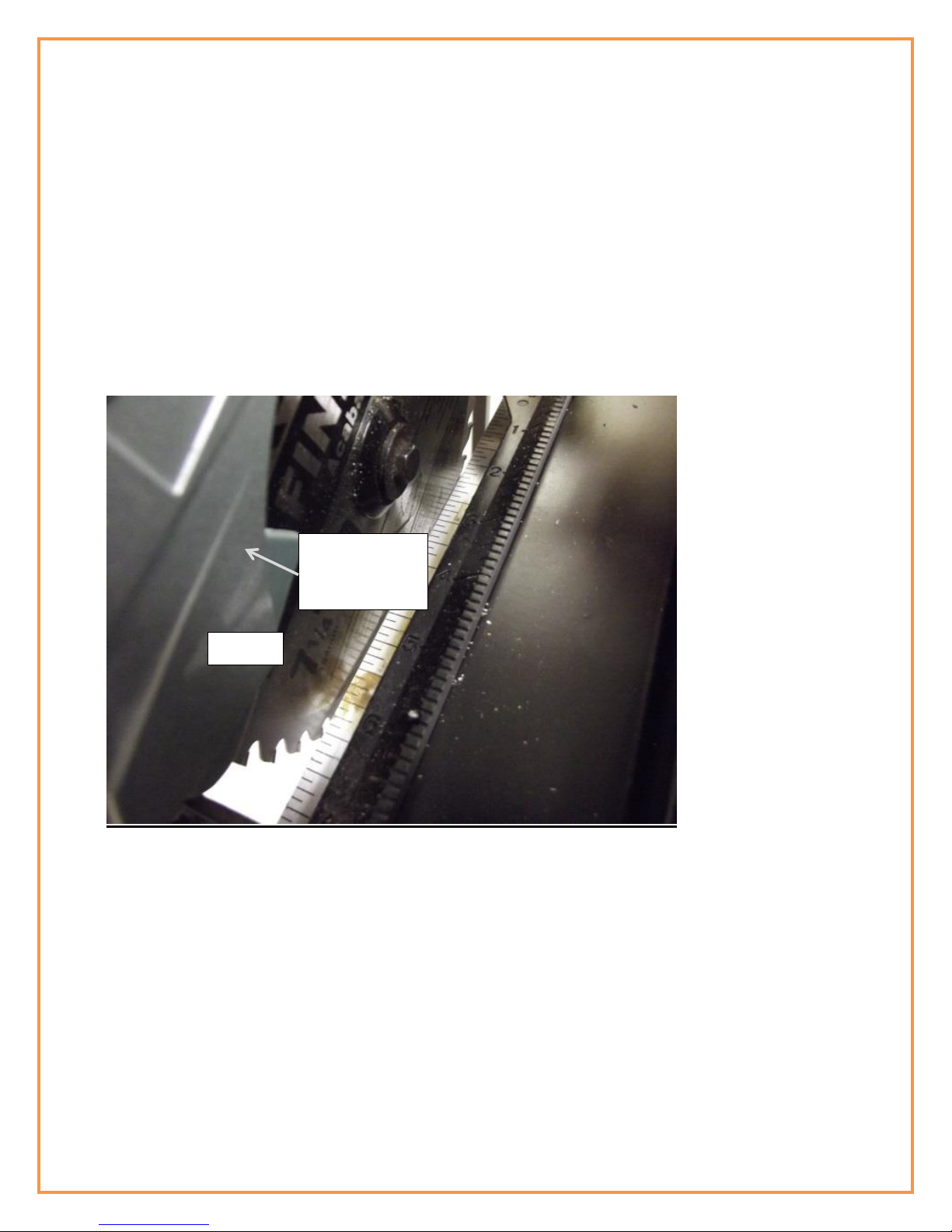

Measuring scale

The Pro-Cut 50 and Pro-Cut 50 DC now come with a built in measuring scale mounted to the non-operator side

of the machine. The sled has a scale marker attached to it that moves along the top of the measuring scale.

When setting the machine up for rip cutting, simply slide the sled along the rails until you reach the desired

measurement as indicated by the sled scale marker. With the sled set at the desired measurement, lock the

sled in place using the 2 sled locks.

NOTE: All hand held tape measures are slightly different and can be out by as much as 1/16 to 1/8” from one

measuring tape to another. It is always good practice to use the same tape measure for all measurements

throughout your entire project. A common problem on most equipment with built in tape scales is that they do

not always measure the same as the hand held tape measure you are using and therefore a lot of seasoned

woodworkers never use built in scales on any equipment.

The Pro-Cut 50 allows an operator to adjust the entire measuring scale on the machine to exactly match your

hand held tape measure with one easy adjustment of the scale. Follow the steps below.

1) To make this adjustment only use the hand held tape measure you will use for your project. We will set

the scale on the Pro-Cut 50 to exactly match your hand held tape measure.

2) Set the saw sled (with the saw in the sled set in the rip cut position) at 15” as indicated on the built in

scale. With your hand held tape measure, measure from the outside tooth of the saw blade to the side

fence. If the measurement is identical, no adjustment is necessary. If the measurement is not the same

then loosen the two thumb screws on either end of the Pro-Cut 50 scale and move the entire scale

until the Pro-Cut 50 scale measurement is identical to the measurement on your hand held measuring

tape. Tighten the two thumb screws on the Pro-Cut 50 measuring scale. Your Pro-cut 50 scale is now

identical to your hand held scale.

Saw Blade Depth Gauge ……..IMPORTANT

To achieve the best results when cutting material with a minimum amount of tear-out and a smooth cut, it is

general practice in woodworking to set the saw blade depth no more than ¼” below the thickness of the

material you are cutting. With this in mind the new version of the Pro-Cut 50 has a built-in depth gauge rail

that will automatically set your saw blade to ¼” below the material you are cutting. (Fig C1 Page 26) shows the

depth gauge rail and (Fig C2 Page 26) shows the saw placed over the depth gauge rail.

Setting the saw blade depth is covered in greater detail in the section called Cross-Cutting starting on page 25.

To set the depth of your saw blade, raise the saw blade all the way up using the blade height adjustment on

the saw. Place the saw over the saw blade depth rail making sure the saw blade guard of the saw is covering

the blade. Lower the saw blade until the saw blade guard just touches and skims the surface of the depth

gauge rail on the Pro-Cut 50. The saw blade is now set to ¼” below the material you will cut. NOTE: always use

the depth gauge rail to set the saw blade depth to prevent cutting too deep into the table top and, in the

worst case scenario, cutting into the frame of the Pro-Cut 50.

The depth of the blade must be set to no more than ¼” below the material you are cutting for both cross

cutting and rip cutting. You will notice both a kerf cut and a grove are cut into the table top insert. The kerf cut

is ¼” deep and used for cross cutting. The grove is ¼” deep at the bottom of the grove and is used for rip

cutting.

8

For cross cutting set the blade depth using the depth gauge rail as explained above.

For rip cutting

1) Raise the saw blade height all the way up.

2) Move the saw to the desired position using the built in measuring scale.

3) Using the saw blade guard lever (Be sure the saw is unplugged) raise the saw blade guard to expose the

blade.

4) Lower the blade until the blade just touches the bottom of the grove in the table top insert.

5) Raise the saw blade slightly so it doesn’t scuff the grove and lock the saw blade height on the saw. You

are now ready to rip cut.

Aux Side Fence

The pro cut 50 comes with an Aux Side Fence used when rip-cutting material. It can also be used in

conjunction with your router. The Aux Side Fence takes the guess work out of feeding material

through the Pro-Cut 50. It acts like a giant feather board and keeps material tight against the side fence

and allows you to simply push the material though. In addition this method provides a smoother more

even cut without burns. The Aux Side Fence will not allow the board or panel to skew while feeding.

The Aux Side Fence has 2 heavy duty toggle clamps that clamp to the clamping rails of the Pro-Cut 50

frame. To set the Aux Side Fence, place your panel or board against the Pro-Cut 50 side fence and slide

the Aux Side fence up the opposite side of your board or panel. The Aux Side Fence should be placed

firmly against the side of your board or panel but not so tight as to restrict the smooth feed of the

material. Once you have the Aux Side Fence set, lock the 2 toggle clamps to the clamp rails of the Pro-

Cut 50 and you are ready to cut.

Pro-Cut 50 adjustment

This section will cover the adjustment of the Pro-Cut 50. Take your time with this procedure as it will

determine the accuracy of cut on the Pro-Cut 50.

There are only two key points to keep in mind when setting up the Pro-Cut 50.

a) That the sled moves back and forth smoothly with very little side to side play (do not worry about

making sure it is 90oto the side fence when setting up the sled. Only concentrate on getting the

sled moving back and forth smoothly and that it has very little side to side play).

b) After the sled is set up and running smoothly then adjust the side fence for square to the saw. This

is the step where you concentrate on making sure the saw blade is cutting exactly 90 degrees to

the side fence when cross-cutting.

The Pro-Cut 50 has a number of adjustment points listed below.

a) Both sled guide rails can be adjusted within the slots of the (2) guide rail sub frames. (Fig 4 &5)

b) The four sled roller bearings that ride on the sides of the guide rails can be adjusted to limit side to

side movement of the sled assembly within the guide rails. (the four sled roller bearings that ride

on top of the guide rails are fixed and do not require adjustment)

9

c) The saw can be adjusted for “skew” on the saw insert plate by loosening the 4 mounting bolts that

hold the saw to the insert plate. If necessary, you can adjust for Skew on the saw to the insert plate

and re-tighten the (4) mounting nuts and bolts. (This is one of the last procedures discussed later)

d) The side fence base is slotted to allow the side fence assembly to be adjusted for square to the saw

blade.

e) The adjustable “Side Fence Wing Locks”allow the side fence wings to be adjusted so they are

exactly in line with each other.

After adjustment, the sled should glide smoothly back and forth within the guide rails with virtually no side to

side “play”, the blade of the saw is running “true” and the saw cuts exactly 90o to the side fence in the cross

cut position.

ADJUSTMENTS

First we will focus on the sled and the sled guide rails. All we want to accomplish here is to make the

sled move back and forth smoothly on the guide rails and that the sled has very little side to side play

or wiggle.

For a complete set-up follow the steps listed below.

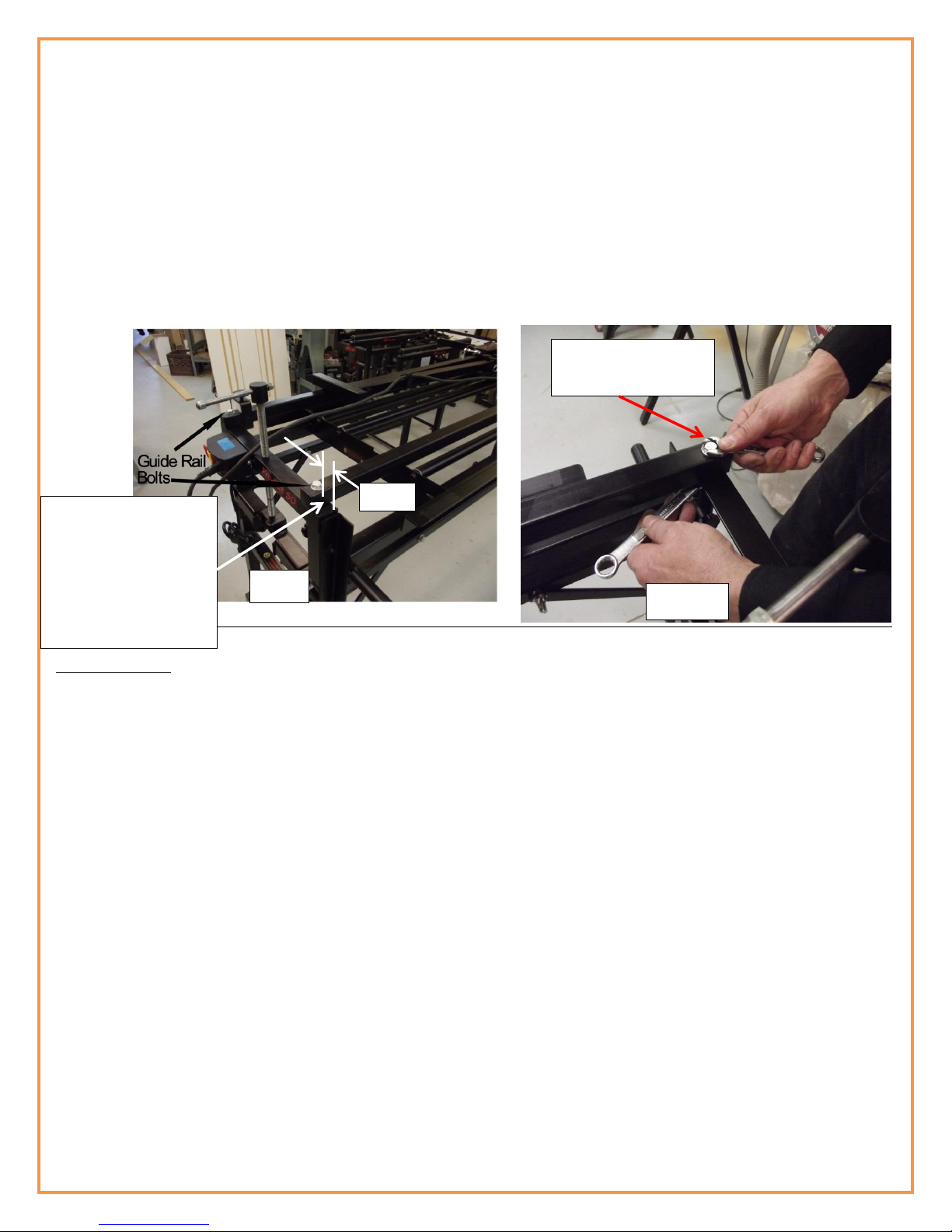

Loosen all 4 bolts holding both sled guide rails in place (Fig. 8a), loosen the 2 SIDE ROLLER bearings on

each side of the sled that ride against the sides of the sled guide rails (Fig 8b & Fig 8c below). There are

a total of 4 bearings to loosen. (Do not loosen the rollers that ride on top of the sled guide rail) (do not

worry about squaring at this point as that is taken care of in the last step). Start by adjusting the

operator side, sled guide rail first. This is the side opposite the measuring scale and the side you feed

material through for rip cutting.

Step1) Set-up only the “operator side” sled guide rail at this point. (Fig 8b) (the rest of the machine uses this

sled guide rail as the reference). This sled guide rail should measure 5/8" from the frame to the side of the sled

guide rail shown in (Fig. 8). When you are sure that the guide rail is 5/8" from the frame on both ends, tighten

the bolts on either end of this sled guide rail. Re-check your 5/8” measurement on both ends of the guide rail.

Fig 8

The measurement

from the guide rail to

the guide rail frame

should be equal on

both ends of the

guide rail.

Fig 8a

5/8”

One of the (4) Sled

Guide Rail Bolts

10

There are a total of 8 roller bearings located on the sled. 4 of the 8 roller bearings roll along the top of the sled

guide rail called the “TOP ROLLERS” (These roller bearing are fixed and do not require adjustment). The other

4 roller bearings roll against the sides of the sled guide rail called the “SIDE ROLLERS”. The 4 side roller

bearings determine how smooth the sled rolls back and forth and the side bearings also determine the

tolerance in the sled. The tighter you make the side roller bearings, the closer the tolerance but the more

resistance in pushing the sled. We generally set the sled up to 5 thousands of an inch tolerance. (Keep in mind

also there are 4 close tolerance bearing blocks inside the sled that work with the 4 side bearings. Be careful not

to “Pinch” the bearing blocks by adjusting the side roller bearings too tight).

Step 2) Next we will adjust the (2) SIDE ROLLER bearings on the sled (Fig 8b) that roll against the sides of the

“Operator Side” sled guide rail that you just adjusted and bolted down tight. (Note the TOP roller bearings that

ride on top of the sled guide rails are pre-set and do not require adjusting)

Included with your machine were (2) white 1/2" spacers. Anything that is ½” thick will work fine. Place the 2

spacer blocks on the side of the sled between the frame of the sled and the “Operator Side” sled guide rail

(FIG. 8c). With the ½” spacers in place, lock the sled with the two black sled lock knobs, slide a SIDE ROLLER

bearing up against the side of the sled guide rail so it is snug against the sled guide rail (Fig 8c). Using (2) 9/16”

wrenches (one placed on the nut below, inside the sled, and one wrench placed on the top nut), tighten the

Side Roller Bearings

Top Roller Bearing

(Do Not Adjust)

“Operator Side”

Sled Guide Rail

Fig. 8b

½” spacer blocks

Use, two, 9/16”

wrenches

FIG 8c

Side Roller Bearings

Side Roller Bearings

Sled

Bearing

Block

Side Roller bearings

11

nuts on this roller bearing (Fig 8c). After tightening the side roller, the spacer block should be snug with

resistance when removing it but not so tight as it is difficult to remove. With both ½” spacers still in place, and

the sled still locked, follow the same procedure for the other SIDE ROLLER bearing on the other side of the sled

(Fig 8b & Fig 8c). Both spacers should now provide resistance when removing them but not so tight as to be

difficult to remove.

Now you have adjusted the operator side, sled guide rail and the 2 sled side bearings that run against the

operator side, sled guide rail. (Be sure the Bolts on the other sled guide rail are loose). Roll the sled back and

forth to be sure it moves freely. (Do not worry about the “play” in the sled at this point). The (2) roller bearings

on the other side of the sled will take care of the play. Run the sled back and forth from one end of the

machine to the other a few times. The white bearing blocks inside the sled will help adjust the other sled guide

rail.

Step 3) If you are satisfied the sled is moving freely, move on to adjusting the other sled guide rail. The

measurement between the inside of the “operator side” sled guide rail to the inside of the other sled guide rail

should be between 13 - 1/16” to 13 - 3/16” (Fig 8d). There can be some variance between machines but the

important point is to be sure the measurement between the sled guide rails is the same on both ends of the

machine. If you measure 13 - 1/16” on the inside of the guide rails on one end of the machine then the

measurement between the inside sled guide rails should be exactly 13 - 1/16” on the other end of the

machine. (NOTE: the corners of the sled guide rails are rounded so it is best to use a flat edge such as a steel

ruler to measure to). With both measurements exactly the same, tighten the sled guide rail bolts on both ends

of the sled guide rail making sure the guide rail does not move while you tighten the nuts and bolts. Re-Check

your measurement after the bolts are tight. Move the sled all the way back and forth a few times to ensure

the sled is moving freely. (NOTE: There will still be play in the sled as you move it back and forth at this point.

The next step will take care of this).

If the sled is difficult to move at one end but free on the other end then the distance between the guide rails

is not equal. Re-Check your measurement. (NOTE: There may be slight resistance in some points while moving

the sled back and forth. This is due to the powder coating on the guide rails. The inner bearing blocks will polish

the rails as you move it back and forth over time and the resistance will even out). To keep the guide rails clean

and polished, use a spray furniture polish or floor wax.

Measurement

adjusted to be

the same on

both ends.

Fig 8d

12

Step4) Adjusting the remaining 2 Sled Side Roller Bearings

1) At this point you have adjusted the operator side sled guide rail.

2) The sled side roller bearings on the operator side of the sled

3) The other sled guide rail.

We will now adjust the remaining (2) sled SIDE ROLLER bearings on the NON-operator side.

These are the roller bearings that will determine the amount of overall tolerance in the sled and adjust

for “play” or “wiggle” in the sled. The tolerance can be adjusted from one thousand of an inch to 10

thousands of an inch. We find that 5 thousands of an inch is perfect. (NOTE: the tighter you make the

tolerance the more resistance the sled will provide when moving it back and forth).

Place a 5 thousand inch feeler gauge between the (2) sled SIDE ROLLER bearings and the sled guide rail

Fig 8e). (NOTE: if you do not have a feeler gauge, one sheet of 20Lb bond paper compressed is

approximately one thousand of an inch. You can use 5 strips of paper). (NOTE: To make it easier, you

can tape the feeler gauge or paper to the sled guide rail until you have finished your adjustment).

Slide the side roller bearing snug up against the feeler gauge and tighten. Leave the feeler gauge in

place until you have adjusted the other side roller bearing in the same manor. With both side roller

bearings adjusted and tightened remove the feeler gauges and move the sled all the way back and

forth. At this point you should feel some resistance when moving the sled back and forth but it should

not be difficult to move.

To check for side to side play try to wiggle the sled. (NOTE: do not use the sled push rail to check for

side to side play as the push rail provides enough leverage to “Flex the guide rails)

If the sled is difficult to move back and forth after you have adjusted and tightened the two remaining

side roller bearings follow the steps below. You may have to make some slight adjustments to any one

of the 4 side roller bearings. (Note: a small adjustment of a roller bearing makes a big difference).

Place 5 thousand

feeler gauge

between the side

roller bearing and

the sled guide rail

Fig 8e

13

1) With your finger, try to move each of the (4) SIDE ROLLER bearings on the sled. The rollers should

move with some resistance. If you find that one of the bearings is impossible to move with your

finger but the other (3) seem to move okay then it will be necessary to adjust the side roller bearing

that will not move. In most cases this can be accomplished by simply loosening the bolt on the side

roller bearing, allowing it to self-adjust and then re-tighten the bolt.

2) If a side roller is easy to move at one end of the rails but difficult to move at the other end of the

rail then this indicates the rails are not perfectly parallel to each other. Re-check the distance

between rails.

3) Keep in mind that the machine has 4 internal floating bearing blocks. These are the white blocks

inside the casing of the sled. The side roller bearings work with these bearing blocks to virtually

eliminate side to side wiggle. If a side bearing is too tight, it is possible to pinch the internal bearing

block and it will act like putting on the breaks.

4) When the machine sled is properly adjusted the sled should move back and forth with some

resistance. You should be able to move each of the (4) sled Side Roller bearings with your finger.

The internal white bearing blocks are called floating bearing blocks designed to move freely within

the sled housing. You should be able to slide each of the (4) sled internal white bearing blocks back

and forth within the sled housing with your finger.

5) There should be very little side to side play when you wiggle the sled.

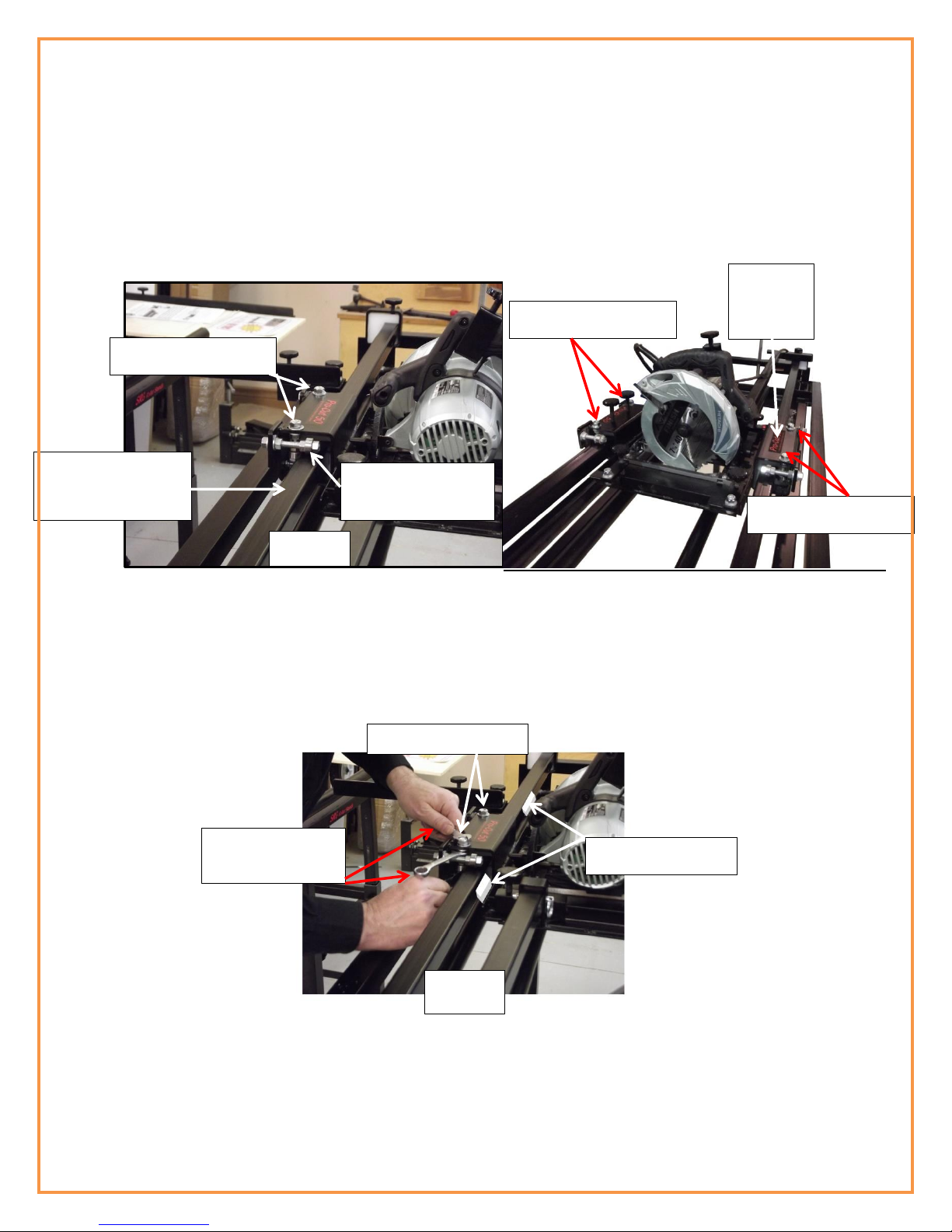

Step 5) Adjusting the Side Fence for Square

In this step we will adjust the side fence so it is exactly 90o to the saw blade when cross cutting. (Note when

the saw is set up at exactly 90o for cross cutting, the saw will be automatically squared to the side fence for rip

cutting). (The router will also be set up to rout in both the “X” and “Y” directions) (NOTE: The newer version of

the Pro-Cut 50 has a 2 section side fence while the earlier version has a 3 section side fence. The adjustment

method is exactly the same for both versions)

Start by:

1) Loosen the (2) side fence locking bolts (Fig F1) (These are the bolts that hold the entire side fence assy.)

Loosen the wing stop locks (Fig F2) and move them all the way back away from the wings. (on the Pro-

Cut 50 with the 3 part side fence, (1) center section and (2) wings, loosen the lock bolt on each wing

lock assy. and screw the bolts on each wing stop assy all the way back to allow the wings to move

back). The wing lock assemblies will be adjusted later.

Side Fence Bolts

Level

Clamped to

side fence.

“T” square

Against

Level

14

2) Place a long straight edge against the (2) side fence wings and clamp the straight edge to the side fence

wings using “C” clamps. For the straight edge you can use a 4’ level as shown in (Fig 8f) or any straight

edge that will accomplish the same thing. The idea is to clamp a straight edge to the side fence wings

to make it one it one complete fence to allow for easier squaring. (The side fence locks will be adjusted

later).

1) With the side fence wings clamped to a straight edge move the entire side fence assembly until it is close to

square to the saw blade.

2) Slide only one wing lock up to the wing and tighten the wing lock bolt to the clamping rail of the Pro-Cut 50

frame. Also tighten the thumb screw that locks the wing in place. With the side fence wings still clamped to the

straight edge and the one wing lock bolted in place, we will now fine tune for square to the saw blade. The

entire side fence will pivot on the one tightened wing lock to bring the entire side fence into square with the saw

blade.

3) Place the “T” of a large “T” square against the level as shown in (Fig 8f). Move the saw back and forth against

the “T” square. The saw blade should not deviate from the “T” square and you should hear a slight “scrapping”

sound for the full length of travel.

(NOTE: It may be easier to make this adjustment if you remove the sled push handle).

(TIP: the saw blade guard on the saw must be out of the way for this adjustment. Be sure the saw is

unplugged and place an elastic band over the saw blade guard lever and loop it over a locking knob on

the sled. This will hold the saw blade guard out of the way until you complete this adjustment).

If you do not have a large “T” Square, you can use a 4’ x 4’ panel such as melamine or MDF. Be sure the

panel you use is perfectly square on all sides. Measure 2’ to the center of the panel and draw a straight

line the full length of the panel. This panel, with the line on it, will take place of the “T” square. Place

the panel against the level instead of the “T” square as shown in (Fig 8f). Lower the saw blade of the

saw until it just touches the line. Follow the steps below.

3) To adjust, move the side fence (Remember that the side fence will pivot on the wing lock you tightened earlier)

until the side fence is square to the saw blade and you hear that slight scrapping sound for the full length of

travel of the saw.

4) When you are satisfied the saw blade is perfectly square to the side fence. Tighten the (2) side fence bolts that

hold the entire side fence to the frame of the Pro-Cut 50. (Fig F1)

NOTE: Fig 8f shows a 4’ level clamped to

the side fence wings to make one to

continuous surface and a “T” square

placed against the level.

(If you have a 3 section side fence then

clamp the straight edge to all 3 sections)

The “T” square is placed against the

straight edge already clamped to the side

fence sections. The clamped straight edge

will make it easier to square the side

fence to the saw.

Fig 8f

Fig F1

Fig F2

Side Fence

Wing Bolts

Wing Lock

15

5) With the side fence wings still clamped to the straight edge, slide the other wing lock up to the side fence wing

and tighten the wing lock bolt. (Fig F2) (NOTE: There are 2 wing locks in total that must be tightened).

Remove the “C” clamps and the straight edge from the side fence. Move the side fence wings back and

forth a few times. Then lock the side fence wings into the wing locks and tighten the thumb screw of

the wing lock to firmly hold the side fence wings in place. Check to be sure the side fence wings are still

in alignment with each other by placing the straight edge against the side fence wings.

6) You can further fine tune for square to the saw blade by clamping the straight edge to the wings as

before and loosen only both wing locking bolts. For slight adjustments you can square the wings to the

saw blade. Then slide the wing locks back up to the wings and tighten the wing lock bolts that hold the

wing lock assy to the clamp rail of the Pro-Cut 50 frame.

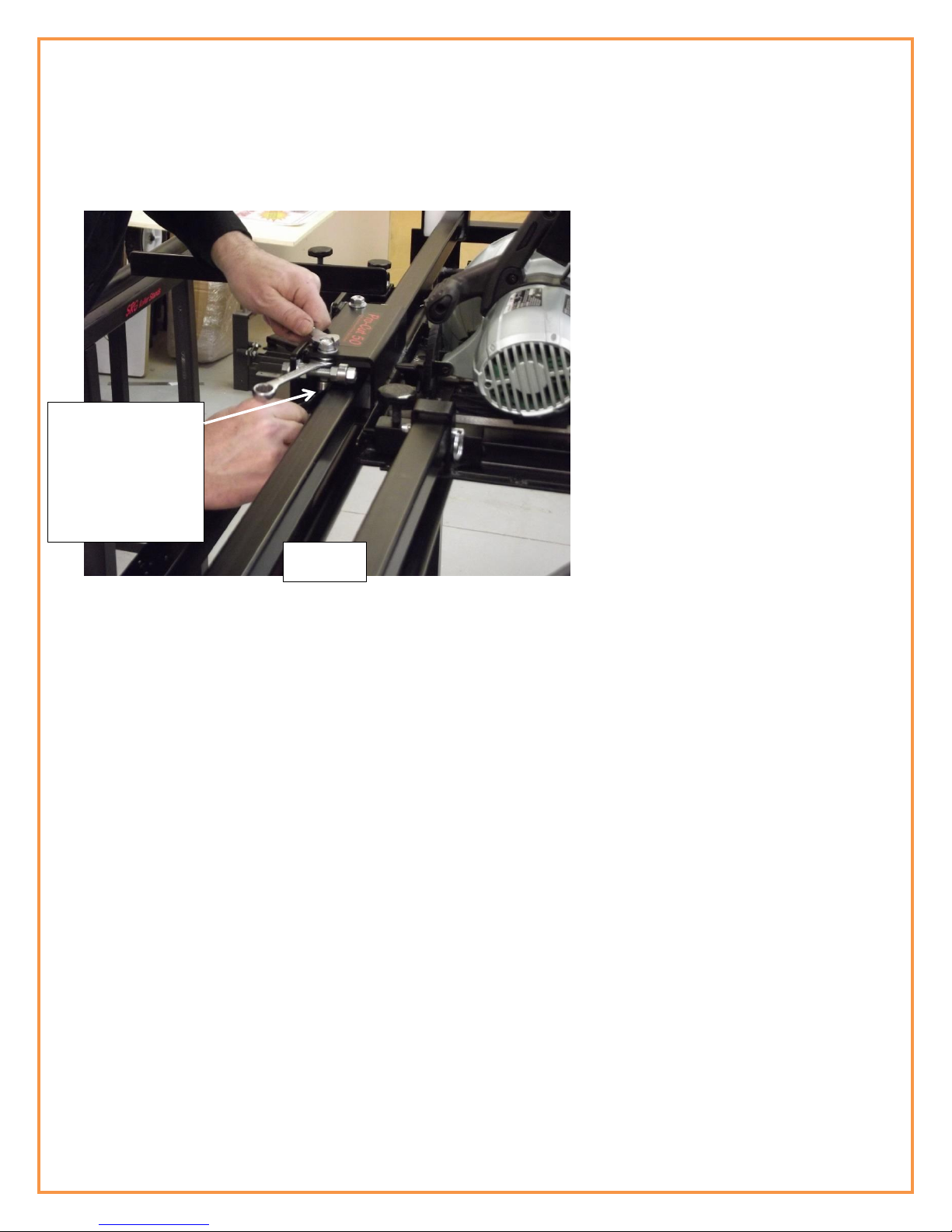

7) Now that the side fence is exactly square to the saw blade, check to be sure the saw blade is running

“true”. Show in Fig. 8g, the saw bade is “not true” and adjustment is required.

To adjust the saw blade for “true”, loosen the (4) bolts that fasten the saw to the insert plate. With the

bolts loose and the “T” Square in place against the side fence, move the saw until the flat of the saw

blade is flat to the “T” Square, bringing the saw blade to “True”. Tighten the saw mounting bolts.

This completes the set-up and alignment procedure. You should make a few test cuts to test your

set-up.

Fig 8g

Saw blade is

not flat to the

“T” square

16

Sled Push Handle

To install the sled push handle, insert the push rail into the push rail bracket located on the sled, line up the

holes and install the quick release pin. For most operations you will probably leave the sled push rail installed

however for small routing projects it may be easier to remove the sled push rail.

Remote Power Switch and Saw Trigger Lock

Sled Push Handle

Push Rail quick

Release Pin

The power switch box is used to plug the

power tool into and comes equipped with

a power lock out.

Saw Trigger Lock

Fig 21

Fig 22

Fig 23

Remote Power

Switch

17

The Pro-Cut 50 is designed to allow the saw to operate without the necessity of holding the power switch of

the saw in the “on”position while cutting material. To accomplish this, a saw trigger lock and remote power

switch are included with the Pro-Cut 50.

Caution must be taken when installing the saw trigger lock.

Be sure the saw is unplugged from the power source when installing the saw trigger lock.

Carefully place the saw trigger lock over the saw trigger. It will be necessary to depress the safety lock on the

saw trigger lock while holding the saw trigger lock up against the saw trigger. Slowly tighten the screw knob on

the saw trigger lock being careful not to damage the saw trigger switch. Do not over tighten the saw trigger

lock as it could result in damage to the saw trigger switch.

Pro-Cut 50 Table Top Insert

Be sure to read the section on Cross-Cutting and Rip-Cutting BEFORE you make any cuts. The new version of

the Pro-Cut 50 and the Pro-Cut 50DC comes with a table top insert rather than 4 rollers as on the previous

version of the Pro-Cut 50. Although the rollers made it easy to run large 4’ x 8’ sheets through the Pro-Cut 50,

the draw back was that it required a table top for smaller panels (more so for routing). The new version Pro-

Cut 50 with the table top insert addresses this situation and, by design, still allows for large panels to run

through the Pro-Cut 50 with ease. The table top insert has been designed from standard 5/8” thick melamine

material available at most building supply stores and is easy to replace should it become necessary. The table

top insert that comes with the Pro-Cut 50 will last for years but since it is possible to accidently cut into the

table top in some cases (more so with the router) it is important the table top insert is made of a material

other than metal. We choose a standard material so the woodworker is able to make a replacement table top

with ease should it become necessary. Making a replacement table top will be explained in detail later in this

user guide.

If you own a previous version Pro-Cut 50 you may decide to remove the rollers and make a table top using the

same procedure as described below. Your table top will have a finished thickness of 1-1/2” so it sits flush to

the clamping rails of the Pro-Cut 50 frame.

Placing the Saw in the Pro-Cut 50 Sled

Be sure to read the sections on Cross-Cutting and Rip-Cutting BEFORE you make any cuts. These

IMPORTANT sections will explain the saw depth gauge and setting the saw blade height.

A premium grade saw is included with the Pro-Cut 50 system. If you decide to upgrade to the Pro-Cut 50DC

that includes dust collection, it includes a different saw with a dust collection port and the necessary hoses

and hose hanging system. Both systems have the included saw pre-mounted to the saw insert plate. Installing

or changing the saw position in the sled is fast and easy. The saw is installed in one direction for cross cutting

and another direction for rip cutting as shown below.

18

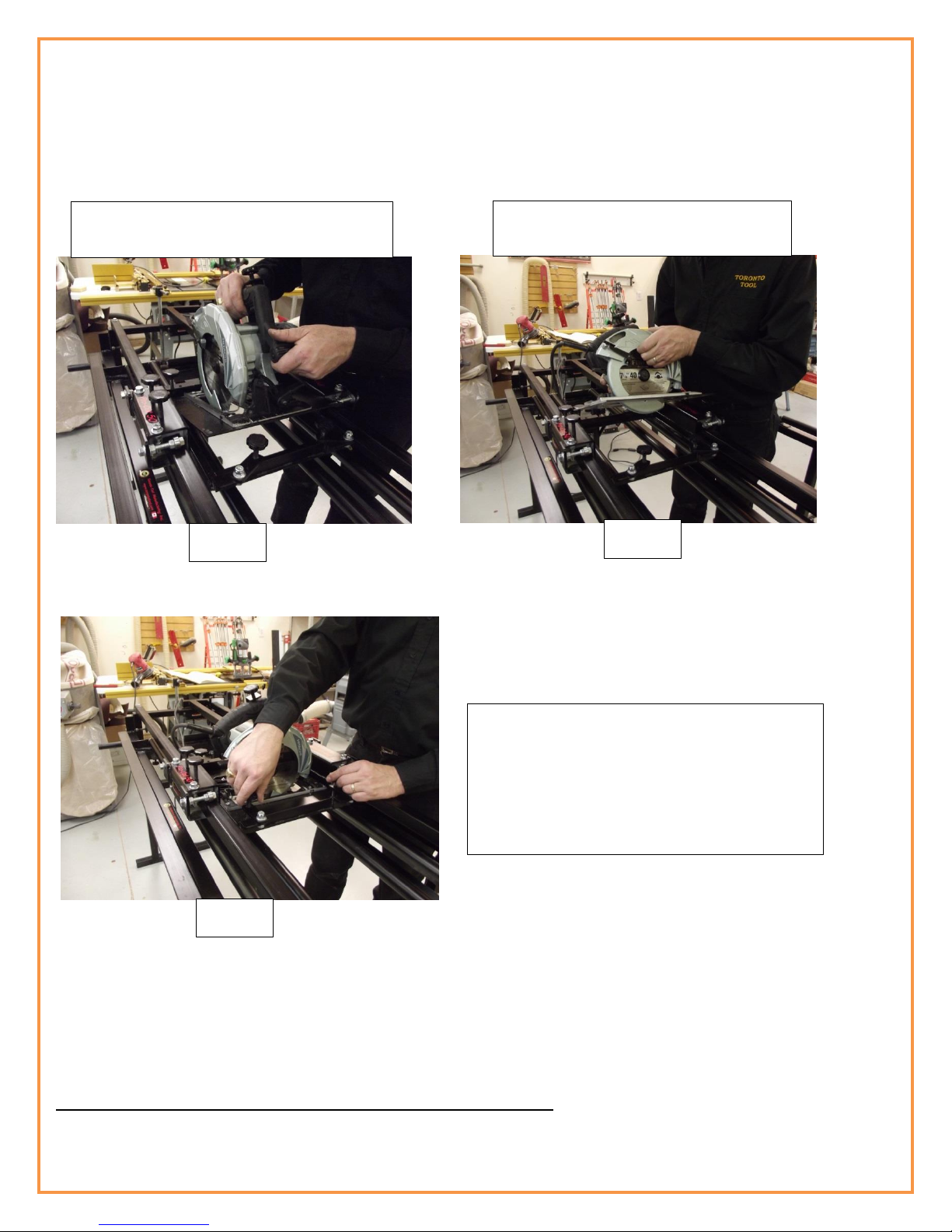

Installing the saw for cross cutting

The saw insert is locked into the sled using (4) separate locks. There are 2 back lock screws and two front

swing arm lock screws.

1) To install the saw for cross cutting, position the saw as shown in Fig 24.

2) Slide the insert plate under the two back lock screws as shown in Fig 24, 25 and tighten the back lock

screws against the insert plate.

3) Swing the front insert lock arms over the saw insert plate and screw down the lock knob screws tightly

against the insert plate.

Fig 24

Fig 25

Fig 26

Slide insert plate

under the back

lock screws

Tighten both back

insert lock screws

Swing the front insert lock arms over the

insert plate and screw the lock knobs

tight against the insert plate

19

Installing the Saw Insert for Rip Cutting

The steps for installing the saw insert plate for rip cutting are exactly the same as for cross cutting except the

saw insert plate is turned 900.

Installing Your Plunge Router to the Router insert Plate

Included with the Pro-Cut 50 is a separate router insert plate. The router insert plate is exactly the same size

as the saw insert plate so interchanging the two requires no adjustment.

Fig 27

Fig 28

Fig 29

Loosen all 4 lock screws and remove the

saw insert from the sled

Turn the saw 900 and place the saw

insert back into the sled for rip cutting.

Slide the saw insert plate under the back screw

locks and screw the locks down tight against

the saw insert plate. Swing the screw lock

brackets over the saw insert plate and tighten

the screw locks against the saw insert plate.

Table of contents