Torrent 30" SHARK User manual

30"SHARK

Owner’s Manual

30" SHARK

Owner’s Manual

1

Table of Contents

Twelve Month Limited Hardware Warranty .................................................... 2

30" SHARK Operations and Maintenance ....................................................... 3

Audience............................................................................................................................................ 3

Precautions........................................................................................................................................ 3

Operation........................................................................................................................................... 5

Maintenance Schedule..................................................................................... 7

Lubrication......................................................................................................................................... 8

30" SHARK Technical Specifications.............................................................. 9

Preventive Maintenance Instructions ........................................................... 10

DAILY............................................................................................................................................ 10

WEEKLY –Every 50 Hours of Operation....................................................................................... 14

MONTHLY –Every 200 Hours of Operation ..................................... Error! Bookmark not defined.

ANNUALLY –Every 1000 Hours........................................................ Error! Bookmark not defined.

30" SHARK Installation .................................................................................. 15

Mounting......................................................................................................................................... 16

Hydraulic Connections..................................................................................................................... 18

Handling and Storage..................................................................................... 22

Key Components............................................................................................. 23

Parts List .......................................................................................................................................... 23

30" SHARK

Owner’s Manual

2

Twelve Month Limited Hardware Warranty

THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS OR

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT BY OF LIMITATION, ANY WARRANTY OR

MECHANANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. WITHOUT LIMITING THE GENERABILITY OF

THE FOREGOING, RWI SPECIFICALLLY DISCLAIMS AND EXCLUDES ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE OR USE.

Roughwater Industries Ltd.. (“RWI”) warrants to the Customer that commencing from the date of delivery to

the Customer and continuing for a period of 360 days, the RWI Hardware (i) to be free of defects in material

and workmanship under normal use and service, and (ii) to conform in all material respect to the printed

specifications for the Equipment which have been delivered to the Customer in connection with the Customer’s

purchase of the Equipment. This limited warranty covers only the original purchaser of the Equipment. RWI’s

and its supplier’s sole obligation and the Customer’s sole remedy for any failure of the Equipment is limited to

the repair or replacement of any part of the Equipment at RWI’s discretion. RWI’s and its supplier’s liability is

limited to the amount paid for the Equipment. RWI and its suppliers shall not be liable for indirect, special,

consequential or liquidated damages or penalties, including claims for lost revenues, profits or business

opportunities, even if RWI had or should have had knowledge, actual or constructive, of the possibility of such

damages.

Upon notification of possible defect, RWI will provide to the Customer a Return Material Authorization

(“RMA”). The customer, at its expense, may then ship the Equipment to RWI (or its authorized representative)

for inspection. RWI shall, at its option, repair or replace the applicable part(s) of the Equipment and (RWI) shall,

at its expense, return the Equipment to Customer in the same or equivalent manner that the Equipment was

delivered to RWI. Part(s) replaced during this Limited Hardware Warranty period, as applicable, will be covered

for the remaining term of such period. Such replacement parts may, at RWI’s option, be new or equivalent to

new.

This warranty shall be void if Customer fails to use or maintain the Hardware in accordance with RWI’s

specifications or instructions, or if the Hardware or any part thereof have been subject to any unauthorized

modifications, improper operation, user negligence, service by unauthorized person, company, association, use

with any unauthorized attachment, device or feature, accidental neglect, misuse, tampering, acts of God, or

any event other than ordinary use. Do not immerse in water.

Export Law Regulations

You agree that you will not export, either directly or indirectly, any RWI Product, material or data provided in

the course of receiving Standard Limited Hardware Warranty services without first obtaining any required

license or other approval from the Canadian Department of Consumer and Corporate Affairs or any other

agency or department of the Government of Canada. In the event that You export any RWI Product from

Canada, or re-export it from a foreign destination, You agree to ensure that the distribution and export/re-

export or import of the RWI Product is in compliance with all laws, regulations, orders, or other restrictions of

Canadian Export Controls Legislation Regulations and the appropriate foreign government. You agree that

neither You nor any of Your subsidiaries will export/ re-export any RWI Product, material or data provided in

the course of receiving Standard Limited Hardware Warranty, directly or indirectly, to any country for which

the Government of Canada or any agency thereof or the foreign government from where it is shipping required

and export license, or other governmental approval, without first obtaining such license or approval

30" SHARK

Owner’s Manual

3

30" SHARK Operations and Maintenance

The 30" SHARK is a horizontal shaft type, directly driven, rotary forestry mulching

attachment designed for use in conjunction with boom-equipped carriers. The unit is

comprised of a cutting frame and cutting drum driven by a hydraulic motor equipped with

protective valves and associated hydraulic fittings and conductors. The unit is fitted with

guarding to limit access to the cutting drum and designed to limit flying debris that may be

ejected during clearing operations.

The unit is designed for use in the safe and efficient reduction (to chips/mulch) of all types of

vegetation up to diameter of 180mm and is to be used only in applications where personnel,

property and roadways are greater than 100 meters from where the mulching equipment is

being operated.

Audience

This user guide is written for operators who use and maintain the Torrent 30” SHARK

Forestry Mulching Attachment during vegetation clearing activities.

Precautions

Failure to follow and respect the following WARNINGS can result in damage to the mulcher,

the carrier, other property or injury or death of operation personnel or pedestrians. This unit

must not be used within 100 meters of objects, other machinery, livestock, pedestrians, or

personnel (other than the operator)

WARNING: This machine must be operated only by qualified equipment operators with

thorough knowledge and understanding of the contents of this manual. RWI accepts no

responsibility for damage or injury resulting from inappropriate or misuse of its products.

WARNING: Before starting the supply of hydraulic oil to the mulcher the operator must

verify that equipment, personnel, property, and roadways are greater than 100 meters from

where the mulching equipment is being operated. As well, the operator must be inside the

operator’s compartment of the machine with the doors and windows closed.

WARNING: The 30” SHARK must not be approached by persons (including the operator) or

by other equipment while the cutting drum is turning. Because of the risk of entanglement

or debris that may be ejected from the unit, the 30” SHARK must be in a ZERO ENERGY

STATE (that is, the drum is stationary, the cutting frame is squarely on the ground and

excavator engine is shut down) before being approached for inspection or maintenance.

WARNING: The 30” SHARK must not be used in water.

30" SHARK

Owner’s Manual

4

WARNING: Because of the nature of the hydraulic motor protective valving supplied on the

mulching unit, the cutting drum will continue to rotate after the unit is shut down until all

inertial energy is expended from the cutting drum. Always allow the unit at least two

minutes to “run-down” after the carrier has been shut down before approaching the unit for

any reason.

WARNING: This machine must be installed according to the product technical specifications

contained herein by qualified technical personnel only. RWI Ltd. accepts no responsibility for

damage or injury resulting from inadequate or improper installation of its products.

WARNING: When servicing cutters, the cutting drum must be mechanically prevented from

turning (that is, wedged or blocked) to minimize the risk of injury to the maintainer.

WARNING: The 30” SHARK is manufactured from metal components and, as such, is a highly

efficient electrical conductor. Extreme caution must be used when working around electric

power transmission lines whether above or belowground!

WARNING: This machine must be installed and used in observance of all laws, rules and

regulations as laid out by local regulatory bodies in the country/region in which it is being

used.

30" SHARK

Owner’s Manual

5

Operation

Clearing operations should be carried out only by a competent equipment operator familiar with

the safe operation of the 30” SHARK when installed to the applicable carrier. The operator must

understand the contents of this manual.

Before starting the supply of hydraulic oil to the mulcher the operator must verify that

equipment, personnel, property, livestock and roadways are greater than 100 meters from

where the mulching equipment is being operated. The operator must always remain inside the

operator’s compartment while the mulcher drum is turning.

For lighter growth, such as bush and smaller trees up to 2" (50mm), material is most efficiently

reduced by approaching the work from the left, such that material is introduced into the “feed

side” or left side of the mulcher. This allows the cutting drum assembly to pull the material in to

be reduced and then ejected downward from the discharge side of the mulcher.

Figure 1. Discharge Side

30" SHARK

Owner’s Manual

6

Vegetation 2" (50 mm) and larger in diameter, often require that the top be cut off and mulched

separately on the ground. In addition, with respect to larger growth it is faster and more efficient to

chip/mulch as much of the tree as possible while it is standing (still on the stump). For efficient

mulching of larger trees, the steps to remember are as follows:

1. Reach as high as safely possible (that is, boom highest position with mulching head

horizontal) toward the right side of the tree.

2. Using the left or “discharge” side of the mulching drum, slowly cut into the right portion of

the treetop being careful not to cut the top off completely.

3. As the top weakens, apply increasing left swing pressure until the combination of cutting

and swing forces cause the top to fall .

4. Using slight down pressure, trees 3” (75mm) and smaller may me reduced using the guard

to direct the stem into cutting drum continuing to mulch the stem down to grade.

5. Swinging from left to right introduce any material on ground into the feed side, to be

reduced and ejected from the unit

Figure 2. Feed Side

30" SHARK

Owner’s Manual

7

Maintenance Schedule

Checks & Services

Daily

Weekly

(50 Hours)

Check hydraulic conductors for

leaks or damage

x

Lubricate drum shaft bearings

with FAG Arcanol Multitop

rolling bearing grease

(1 shot each)

x

Lubricate drive coupling with

multipurpose EP grease

(2 shots)

x

Inspect cutters for excessive

wear or breakage

x

Inspect tool Holders for

excessive wear or damage

x

Inspect bearings for excessive

radial clearance or end play

x

Verify cutter fasteners torqued

to 55 ft-lb (75nm)

x

Inspect hydraulic motor,

protective valves and hydraulic

hoses and fittings for leaks

x

30" SHARK

Owner’s Manual

8

Lubrication

WARNING: 33 percent of premature bearing failures are caused by incorrect specification

and inadequate application of the lubricant.

Use of FAG Arcanol Multitop Rolling Bearing Lubricant is recommended for use in the

lubrication of all Torrent Shark series drum shaft bearings. Use of multipurpose extreme

pressure grease is recommended for lubrication of drive coupling components

30" SHARK

Owner’s Manual

9

30"SHARK Technical Specifications

Operating weight (Standard) 680 lb/330 Kg

Cutting width 30 inches

Rotational speed (RPM) 2800 (minimum) 3200 (max. continuous)

Carrier power requirement 40 Hp or 28 Kw (minimum)

Cutter type Fixed round or square

Cutter quantity 24

Drive type Direct

Power transmission type Hydraulic fluid power

Hydraulic motor type Fixed axial piston

Maximum hydraulic system pressure 5000 psi/345 bar (max. continuous)

Hydraulic oil flow requirement 20 usgpm/75 lpm (minimum)

30" SHARK

Owner’s Manual

10

Preventive Maintenance Instructions

This section provides the information necessary to ensure safe and effective maintenance of

the 30” SHARK forestry mulching attachment. Periodic checks and lubrication requirements

are described in detail.

DAILY

Check Hydraulic Conductors for Leaks or Damage

The hydraulic hose assemblies connecting the mulching unit to the boom of the carrier are

exposed to impact and abrasion as a normal course of operation.

Hydraulic hoses and fittings must be checked regularly in order to avoid any soil

contamination due to leakage of hydraulic fluid and to maintain the proper level of oil in the

hydraulic system. Restrictions in the hydraulic conductors can adversely affect the

performance of the mulcher and, in some cases, cause damage to the hydraulic motor.

30" SHARK

Owner’s Manual

11

Grease Drum Shaft Bearings

Lubricate main shaft bearings twice daily with one shots of special purpose grease suitable

for operating conditions (see “Recommended Rolling Bearing Lubricant Specifications” for

lubricant requirements).

Idler End Bearing

Grease Point

4 Shots Twice Daily

30" SHARK

Owner’s Manual

12

Grease Drive Coupling

With the unit squarely on the ground, or other flat solid surface, and with the carrier in a

ZERO ENERGY STATE, apply two shots of multipurpose (ie. Pin and bushing grease to the

grease fitting into the side of the cutting drum toward the drive end of the unit (see

illustration below).

30" SHARK

Owner’s Manual

13

Inspect Cutters for Excessive Wear or Breakage

As cutters wear, they become less efficient. Rotate cutters as required.

To rotate, a cutter perform the following steps:

1. Remove cutter fastener and lock washer.

2. Turn 90 degrees, or as required, to expose a new cutting edge. –if no new edges

remain, replace the cutter with a new one.

3. Torque to 75 Nm.

Do not use an impact wrench to tighten the cutters. Remove/replace a cutter as follows:

1. Remove cutter bolt and lock washer.

2. Remove cutter from tool holder.

3. Replace exhausted cutter with a new one.

4. Reinstall cutter bolt and lock washer and torque to 55 ft-lb (75 Nm).

30" SHARK

Owner’s Manual

14

WEEKLY –Every 50 Hours of Operation

Inspect Tool Holders for Excessive Wear or Damage

In cases of severe damage to cutters involving loss of the entire cutting head, the tool holder

tool face may be exposed to impact with potential for damage to the machined surface. Any

damage to the machined surface must be corrected. In cases of severe damage, a new tool

holder must be installed.

Check Bearings for Excessive Radial clearance or Endplay

With the unit squarely on the ground, or other flat solid surface, and with the carrier in a

ZERO ENERGY STATE, slide a pry bar under the drum ting. Check for excessive radial

clearance. Readily visible movement while moving the pry bar up and down, may indicate

worn or damaged bearings.

Excessive endplay may be detected by placing a pry bar between the cutting frame and

either end of the cutting drum. A small amount of end-play (approximately 1/16” (1.5mm) is

built into the bearing. If total axial play (in excess of 1/16”) is detected, bearings may have

be replaced and further inspection is required.

Verify Cutter Fastener Torque

Using a torque wrench, check that all cutter bolts are tightened to a value of 55 ft-lb (75Nm).

Inspect Hydraulic Motor, Valving and Hydraulic Hose Connections for Leaks

Place the unit squarely on the ground, or other flat solid surface, and ensure that the carrier

is in a ZERO ENERGY STATE. Allow the unit to cool to ambient temperature. Remove the

drive end cover and inspect the hydraulic motor and anti-cavitation valve assembly hose

connections for leaks or seepage of hydraulic oil and correct as necessary.

30" SHARK

Owner’s Manual

15

30" SHARK Installation

Installation of the 30” SHARK must be carried out by a factory trained technician or with

extensive experience in hydraulic fluid power systems and components. The technician must

possess knowledge and/or documentation specific to the excavator brand, model and model

year to which the unit is to be installed and should commence installation of the 30” SHARK

only after having read and understood the contents of this manual.

Warning: All installation and any other maintenance or mechanical procedures

to be carried out on the 30” SHARK must be performed with the unit resting

squarely on the ground or other flat solid surface, and with the carrier in a ZERO

ENERGY STATE.

The 30” SHARK is a hydraulically driven, rotary mulching attachment driven by a fixed

displacement axial piston hydraulic motor rated for a maximum continuous operating

pressure of 5000 psi (345 bar). The hydraulic motor is fitted with case overpressure

protection and anti-cavitation valves.

The 30” SHARK cutting drum shaft is supported at either end by flanged cartridge roller

bearing assembly. Maximum continuous rotor speed is not to exceed is 3200 rpm. Higher

intermittent speeds may be permissible after consultation with RWI/Torrent technical suppoert.

30" SHARK

Owner’s Manual

16

Mounting

The 30” SHARK is designed with an 8-bolt

pattern for the purpose of anchoring a

quick coupler to match that of recipient

excavator. The dimensions of the deck

plate and the bolting pattern are supplied

in the following diagram of the 30” SHARK

as viewed from the top of the unit.

30" SHARK

Owner’s Manual

17

30" SHARK

Owner’s Manual

18

Hydraulic Connections

Pressure Oil

The circuit relief setting of the pressure oil supply should be no less than 3000 psi (207 bar)

to maximum of 5000 psi (345 bar). Motor torque is directly proportional to the value of the

supplied pressure and so higher supplied pressure translates into increased performance

and reduced time required to bring the rotor from dead stop to full speed. The minimum

recommended pressure supply line size is ¾” (19mm) inside diameter and capable of

withstanding pressure established by the circuit relief setting.

Main Return Oil

Main return oil may pass back to tank through the directional control valve section from

which the pressure oil is supplied. A more efficient configuration is to have the return oil

circumvent the control valve directly back to tank thereby avoiding back pressure and heat

generated due to throttling losses encountered in the directional control valve.

30" SHARK

Owner’s Manual

19

Table of contents

Other Torrent Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

HORNEET

HORNEET CK2A Instruction for operation and maintenance

Volpi

Volpi Olytech Dualcomb 255SP Operation and maintenance manual

AL-KO

AL-KO 4000 VB manual

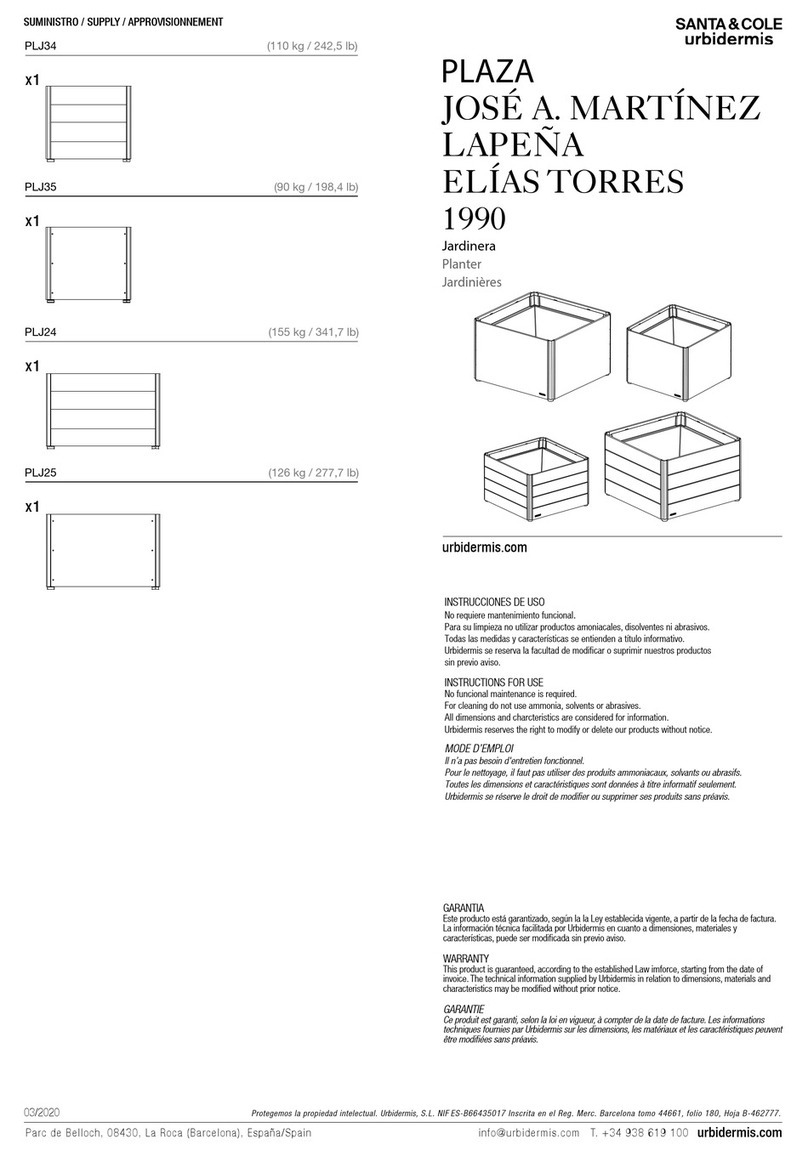

urbidermis

urbidermis Plaza 1990 Assembly instructions

Westfalia

Westfalia GartenMeister Spitzbergen XL Original instructions

Black & Decker

Black & Decker GT26 user guide