EN

ES

FR

IT

DE

PT

PL

CZ

RU

CR

HU

TR

NL

GR

SV

FI

NO

DK

RO

BG

EE

LV

SK

SI

1

PRECAUTIONS FOR SAFETY

WARNING

• Never modify this unit by removing any of the safety guards or bypassing any of the safety interlock switches.

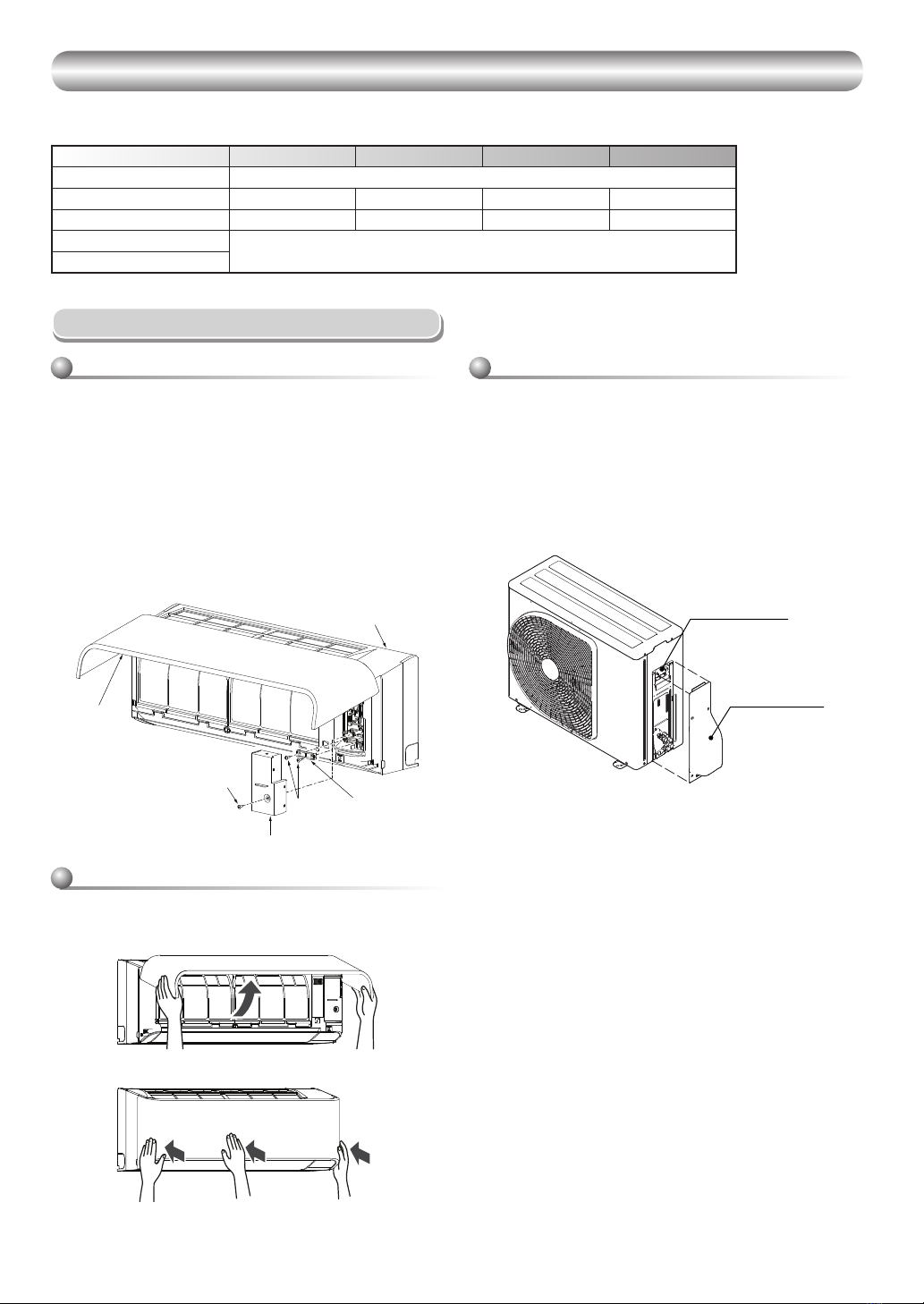

• Do not install in a place which cannot bear the weight of the unit.

Personal injury and property damage can result if the unit falls.

• Before doing the electrical work, attach an approved plug to the power supply cord.

Also, make sure the equipment is properly earthed.

• Appliance shall be installed in accordance with national wiring regulations.

If you detect any damage, do not install the unit. Contact your dealer immediately.

• Do not use any refrigerant different from the one specified for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a failure or explosion of the product or an injury to your

body.

DANGER

• FOR USE BY QUALIFIED PERSONS ONLY.

• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE ALL POWER SWITCHES ARE OFF.

FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

• CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED WRONGLY, ELECTRIC PARTS MAY BE

DAMAGED.

• CHECK THE EARTH WIRE THAT IT IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.

• DO NOT INSTALL NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS.

FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

• TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNIT WELL AWAY (MORE THAN 2 M) FROM

HEAT SOURCES SUCH AS RADIATORS, HEATERS, FURNACE, STOVES, ETC.

• WHEN MOVING THE AIR CONDITIONER FOR INSTALLING IT IN ANOTHER PLACE AGAIN, BE VERY CAREFUL NOT TO GET THE SPECIFIED

REFRIGERANT (R410A) WITH ANY OTHER GASEOUS BODY INTO THE REFRIGERATION CYCLE. IF AIR OR ANY OTHER GAS IS MIXED IN THE

REFRIGERANT, THE GAS PRESSURE IN THE REFRIGERATION CYCLE BECOMES ABNORMALLY HIGH AND IT RESULTINGLY CAUSES BURST

OF THE PIPE AND INJURIES ON PERSONS.

• IN THE EVENT THAT THE REFRIGERANT GAS LEAKS OUT OF THE PIPE DURING THE INSTALLATION WORK, IMMEDIATELY LET FRESH AIR

INTO THE ROOM. IF THE REFRIGERANT GAS IS HEATED BY FIRE OR SOMETHING ELSE, IT CAUSES GENERATION OF POISONOUS GAS.

CAUTION

• Exposure of unit to water or other moisture before installation could result in electric shock.

Do not store it in a wet basement or expose to rain or water.

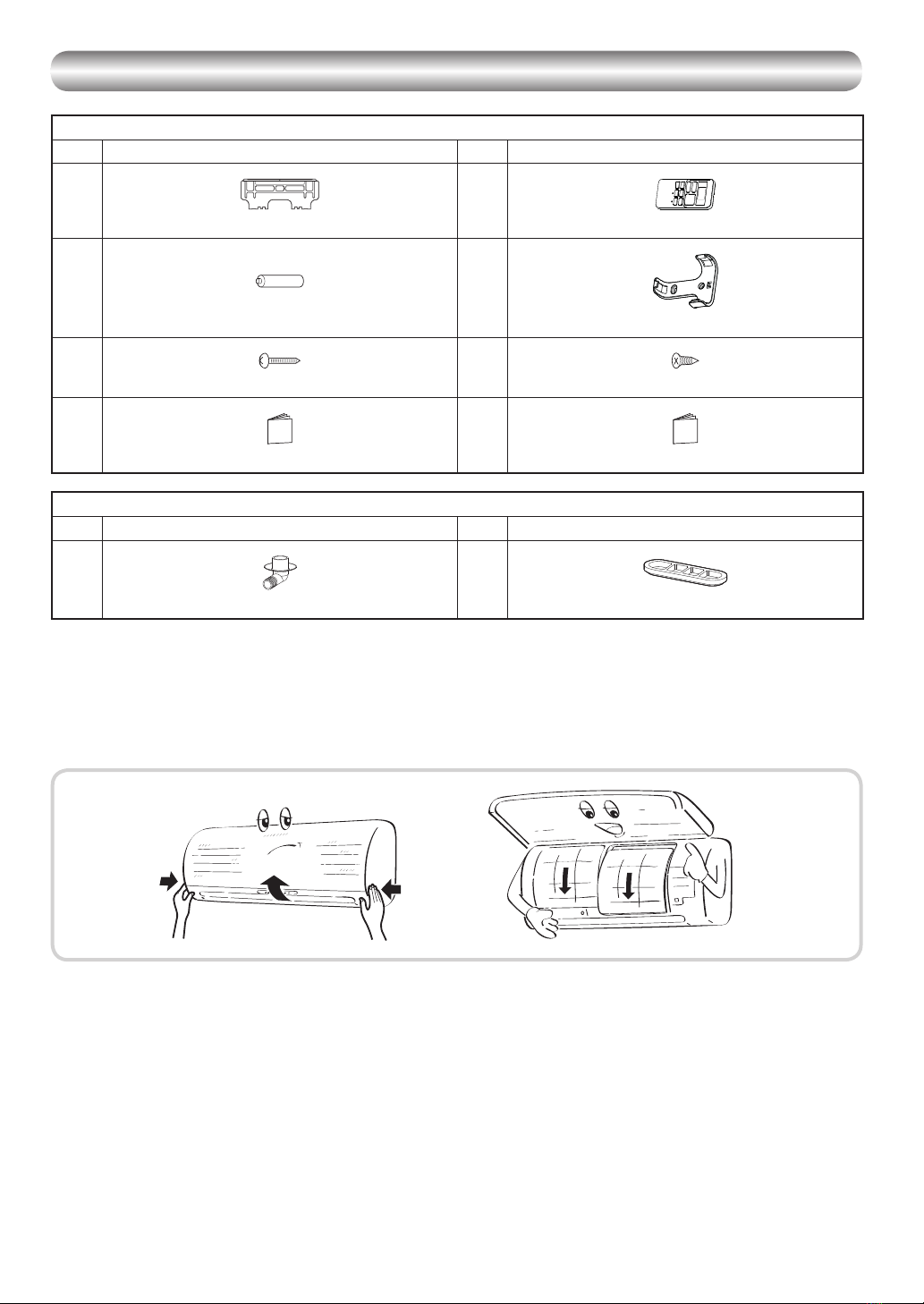

• After unpacking the unit, examine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the noise level of the unit or where noise and

discharged air might disturb neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read this installation manual carefully before installing the unit. It contains further important instructions for proper installation.

• The manufacturer shall not assume any liability for the damage caused by not observing the description of this manual.

• Before installation, please read these precautions for safety carefully.

• Be sure to follow the precautions provided here to avoid safety risks. The symbols and their meanings are shown below.

WARNING : It indicates that incorrect use of this unit may cause severe injury or death.

CAUTION : It indicates that incorrect use of this unit may cause personal injury (*1), or property damage (*2).

*1: Personal injury means a slight accident, burn, or electrical shock which does not require admission or repeated hospital treatment.

*2: Property damage means greater damage which affects assets or resources.

For general public use

Power supply cord and connecting cable of appliance use shall be at least polychloroprene sheathed flexible cord (design H07RN-F) or cord designation

60245 IEC66. (Shall be installed in accordance with national wiring regulations.)

This appliance must be connected to the main power supply by means of a circuit breaker or a switch with a contact separation of at least 3 mm in all poles.

CAUTION To disconnect the appliance from the main power supply

New refrigerant air conditioner installation

CAUTION

• THIS AIR CONDITIONER USES THE NEW HFC REFRIGERANT (R410A), WHICH DOES NOT DESTROY THE OZONE LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membranes, and oils because the pressure of R410A refrigerant is approx.

1.6 times of refrigerant R22. As well as the adoption of this new refrigerant, refrigerating machine oil has also been changed. Therefore, during installation

work, be sure that water, dust, former refrigerant, or refrigerating machine oil does not enter the refrigeration cycle of a new-refrigerant air conditioner.

To avoid mixing refrigerant and refrigerating machine oil, the sizes of charging port connecting sections on the main unit are different from those for the

conventional refrigerant, and different size tools are also required. For connecting pipes, use new and clean piping materials with high pressure withstand

capabilities, designed for R410A only, and ensure that water or dust does not enter. Moreover, do not use any existing piping as its pressure withstand

may be insufficient and may contain impurities.

REQUIREMENT OF REPORT TO THE LOCAL POWER SUPPLIER

Please make absolutely sure that the installation of this appliance is reported to the local power supplier before installation. If you experience any problems

or if the installation is not accepted by the supplier, the service agency will take adequate countermeasures.