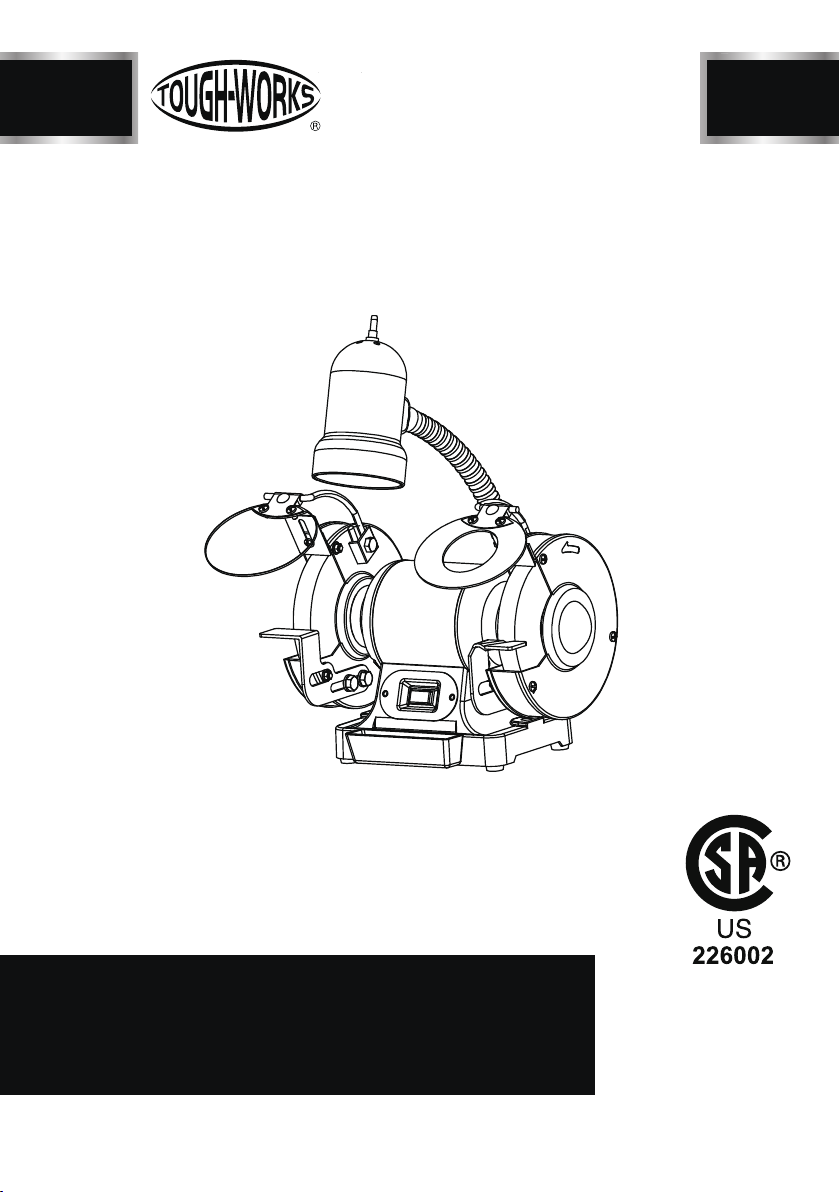

TOUGH-WORKS TDS-200CL User manual

8 IN. BENCH GRINDER

WITH FIEXIBLE WORKLIGHT

INSTRUCTION

MANUAL

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

TDS-200CL

2

TABLE OF CONTENTS

SPECIFICATIONS

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................

2

SAFETY GUIDELINES ................................................................................................

5

PACKAGE CONTENTS ..............................................................................................

6

KEY PARTS DIAGRAN

..................................................................................................

7

ASSEMBLY/MOUNTING

........................................................................................

8

OPERATION .................................................................................................................

9

MAINTENANCE ............................................................................................................

10

TROUBLESHOOTING GUIDE .....................................................................................

12

EXPLONED VIEW .........................................................................................................

13

PARTS LIST ..................................................................................................................

14

WARRANTY ..................................................................................................................

15

TDS-200CL

SPECIFICATIONS .......................................................................................................

2

Motor:120 V AC, 60 Hz, 4.8A, 3/4 HP

Wheel Size:8 x 1" (20.3 x 2.5 cm) with 5/8"

(1.6 cm) arbour

Speed:3450 RPM (no-load)

Wheels: 36- and 60-grit

Weight: 29 lb 2 oz (13.2 kg)

SAFETY GUIDELINES

3TDS-200CL

• Always wear safety glasses complying with

OSHA/ANSI requirements Z87.1.

• Wear a mask or respirator when dust is

generated.

• Keep bystanders out of the work area while

operating the tool.

• Always ensure that the work area is clear of

any flammable materials, liquids or gasses,

because the use of this tool may create sparks.

•Wheel guards and eye shields must be properly

adjusted and tightened.

• During each start-up, stand to one side of

the grinder and switch it on. Let the grinder

operate at full speed for approximately one

minute so that any undetected flaws or cracks

will become apparent.

• Use only 40 W (max.) bulbs on the work light.

• Use only 8” wheels suitable for 3450 RPM

or over.

• Keep guards in place and working properly.

• Keep hands clear of grinding wheels.

•Always make sure wheels are properly mounted.

• Secure the tool when working to prevent

unexpected movement.

• Never reach behind or beneath the grinding

wheels.

• Unplug from power supply before adjusting

or servicing. The grinding wheels continue

to rotate after the tool is switched off. Always

allow wheels to stop before adjusting or

servicing.

• To avoid electric shock, DO NOT use in damp

conditions or expose to rain.

Failure to observe any of the following

instructions could result in severe

personal injury to tool user and bystanders

or cause damage to tool and property!

Read, understand and observe all

instructions in this manual before

using or operating the tool for which

it is written and supplied. Ensure that

anyone who is to use the tool has read

and understood the instructionsprovided.

•When fitting a new grinding wheel, always

check that the stated maximum RPM meets

or exceeds that stated on the grinder. Also

check the new wheel for damage, such as

flaws or cracks. If the wheel appears

satisfactory, fit it to the grinder.

• When a new grinding wheel has been

fitted, stand to one side of the grinder and

switch it on.

Let the grinder operate at full speed for

approximately one minute so that any

undetected flaws or cracks will become

apparent.

• Use only accessories that are recommended

by the manufacturer for your model.

•DO NOT attempt to cut anything with the

grinding wheel.

• Grounded tools must be plugged into an outlet

that has been properly installed and grounded

in accordance with all local codes and ordinances.

Never remove the grounding prong from the plug

or modify it in any way. Do not use adaptor plugs.

If in doubt as to whether the outlet is properly

grounded, consult a qualified electrician.

• Do not use the tool when tired or under the

influence of drugs, alcohol or medication.

• Do not wear gloves, neckties, jewellery or loose

clothing when using tool. Keep hair tied back.

• Ensure the power switch is off prior to plugging

in the tool.

Replace cracked grinding wheels

immediately.

• Do not overtighten spindle nuts.

• Spacing between tool rests and wheels should

be set to 1/8” or less; hold workpiece firmly

against tool rest.

• Service on thesetools should only be performed

by an authorized, qualified technician.

• Failure to comply with these warnings may

result in serious personal injury.

• There is a risk of injury due to accidental starting;

do not use this tool in an area where children

may be present.

4

TDS-200CL

General Tool Safety Warnings

Read all safety warnings and instructions.

Failure to follow the warnings and

instructions may result in electric shock,

fire and/or serious injury.

Save all warnings and instructions for

future reference.

9.

USE PROPER EXTENSION CORD.

Make sure your extension cord is in good

condition. When using an extension cord,

be sure to use one heavyenough to carry

the current your product will

draw.

An

undersized cord will cause a drop in

line voltage resulting in loss of power and

Table A shows the correct size to use

depending on cord length and nameplate

ampere

rating.

10.WEAR PROPER APPAREL.

Do not wear

loose

clothing, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended.

Wear protective hair covering to contain

long hair.

11.ALWAYS USE SAFETY GLASSES.

Alsouse face ordust mask if cutting operation

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety

12.SECURE WORK.

Use clamps or a vise to hold

work when

practical. It’s safer than using your hand

and it frees both hands to operate tool.

13.DON’T OVERREACH.

Keep proper footing and balance at all

times.

1. KEEP GUARDS IN PLACE and in

working order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES.

Form habit of checking to see that keys

and adjusting wrenches are removed

from tool before turning it on.

3. KEEP WORK AREA CLEAN.

Cluttered areas and

benches invite

4. DON’T USE IN DANGEROUS

ENVIRONMENT.

Don’t use power tools in damp or wet

locations, or

expose them to rain. Keep

5. KEEP CHILDREN AWAY.

All visitors should be kept safe distance

6. MAKE WORKSHOP KID PROOF with

padlocks, master switches, or by

7. DON’T FORCE TOOL.

It will do the job better

and safer at the

8. USE RIGHT TOOL.

Don’t force tool or attachment to do a

job for which it was not designed.

accidents.

work area well lighted.

from work area.

removing starter keys.

rate for which it was designed.

overheating.

is dusty.

glasses.

14.MAINTAIN TOOLS WITH CARE.

Keep toolssharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

15.DISCONNECT TOOLS

Before servicing;

when changing accessories,

such as blades, bits, cutters, and the like.

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING.

Make sure switch is in

off position before

plugging in.

17.USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended

accessories. The use of improper

SAFETY GUIDELINES

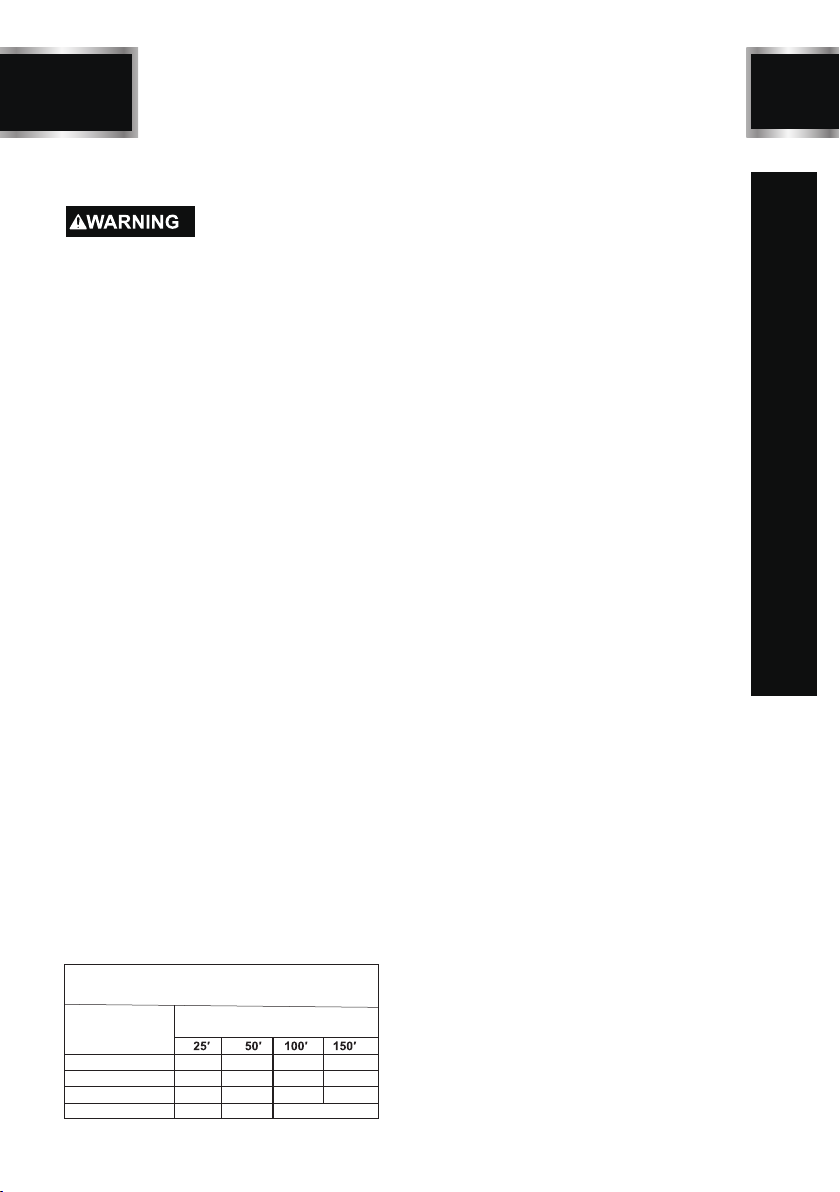

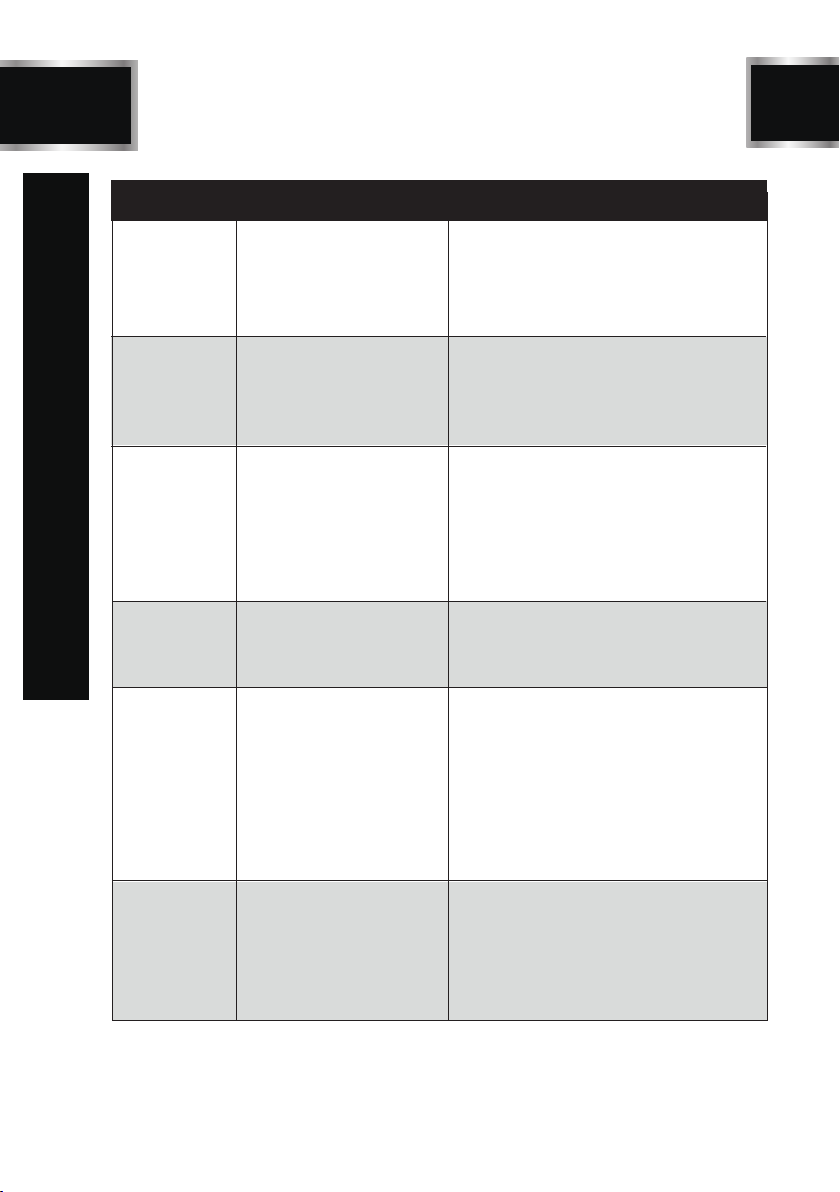

TableA: RECOMMENDED MINIMUM WIRE GAUGE

FOR EXTENSIONCORDS

(

120VOLT)

NAMEPLATE

AMPERES

(at full load)

EXTENSION CORD

0 – 6 18 16 16 14

6.1 – 10 18 16 14 12

10.1 – 12 16 16 14 12

12.1 – 16 14 12 Do not use.

5TDS-200CL

Before You Start – Electrical

• Always wear eye protection that complies

with a recognized standard (CSA or ANSI;

for example: ANSI Z87.1)

• Wear a mask or respirator when dust is

generated.

• Keep bystanders out of the work area

while operating the tool.

• Always ensure that the work

area is clear of any flammable materials,

liquids or gases,because the use of this tool

may create sparks.

• Do not wear loose clothing or jewellery.

Keep hair tied back.

• Replace cracked grinding

wheels immediately..

• Do not overtighten spindle nuts.

• Adjust tool rests whenever necessary to

maintain a distance of 1/8” (3.2 mm) from

the grinding wheel.

• NEVER grind on the side of the wheel.

Grind on the face of the wheel only.

• NEVER apply pressure to the workpiece

when the grinding wheel is cold. Allow the

wheel to warm up by applying the workpiece

gradually.

• NEVER use the grinder without the wheel

guards. Keep thumbs andfingers away

from the wheel.

Before You Start - Safety

In the event of a malfunction or short circuit,

grounding provides the path of least resistance

for electrical current, and reduces the risk of

electric shock for the operator. This tool is

equipped with an electric cord that has an

equipment grounding conductor and a grounding

plug. The plug must be plugged into a matching

outlet that is properly installed and grounded

in accordance with all local codes and or

dinances.

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit the outlet, have the proper outlet

installed by an electrician.

IMPROPER CONNECTION of the equipment

grounding conductor can result in increased

risk of electric shock. The conductor with the

green insulation (with or without yellow stripes)

is the equipment grounding conductor. If repair

or replacement of the electric cord or plug is

necessary, DO NOT connect the equipment

grounding conductor to a live terminal.

CHECK with a qualified electrician or service

personnel if you do not completely understand

the grounding instructions, or if you are not

sure if the tool is properly grounded.

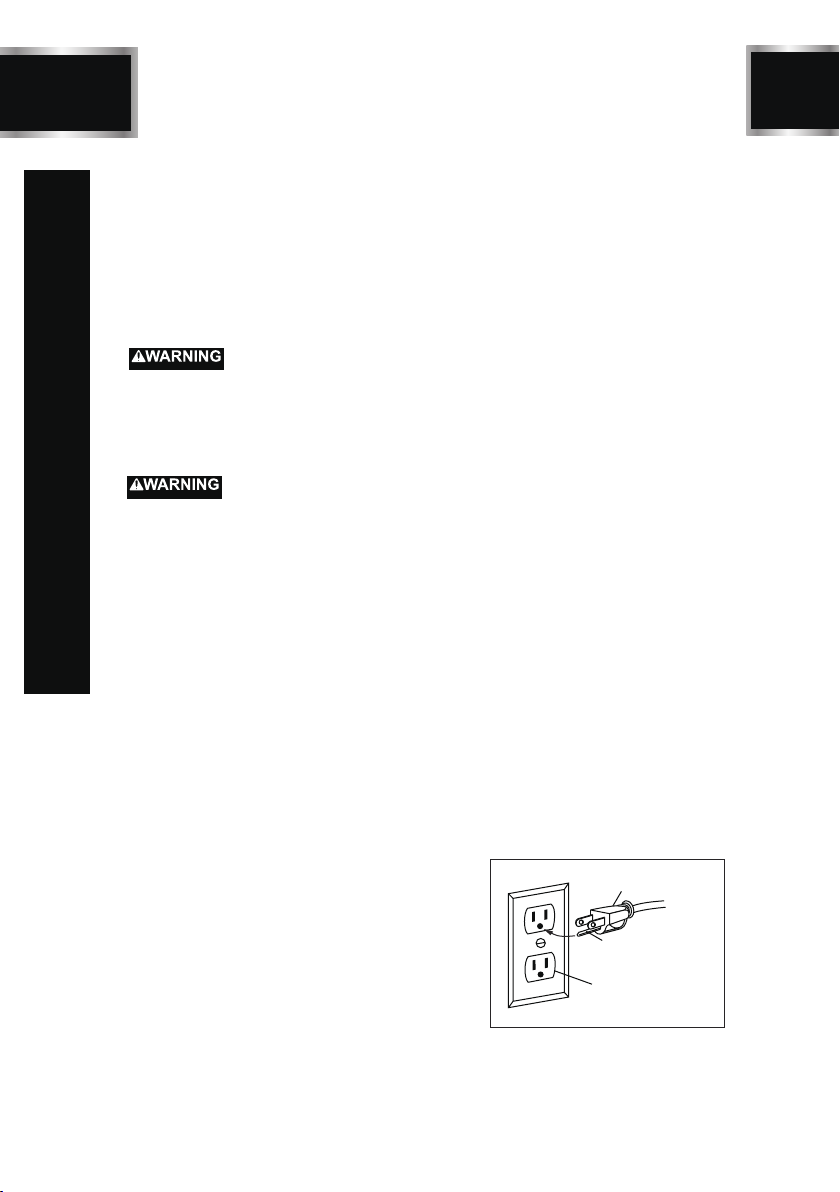

3-Pronged Plug

Properly Grounded

3-Hole Receptacle

Grounding Prong

This tool is intended for use on a circuit

that has align outlet that looks like the one

illustrated. The original tool has a grounding

plug that looks like the plug illustrated.

ELECTRICAL SAFETY

SAFETY GUIDELINES

6

TDS-200CL

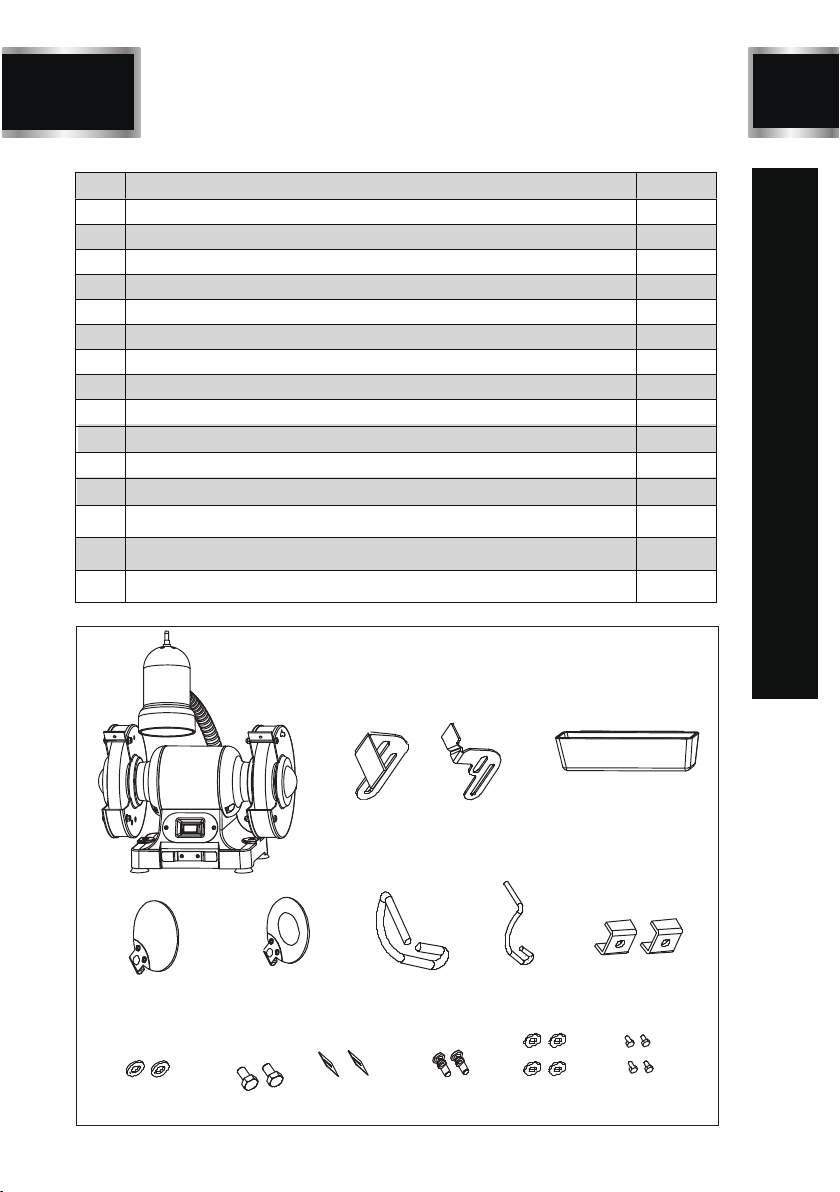

C

PACKAGE CONTENTS

No. Description Qty.

1

2

3

4

5

6

7

8

Bench grinder

Left work rest

Right work rest

Coolant tray

Plain eye shield assembly

Magnify eye shield

Left eye shield support

Right eye shield support

Bracket

Flat washer D6

Hex bolt M6X14

Spark deflector

Star-head screw+flat washer M5X10

Flat washer D8

Hex bolt M8X8

1

1

1

1

1

1

1

1

2

2

2

2

2

4

4

9

10

11

12

13

14

15

1

2 3 4

56789

10 11 12 13 14 15

BD4603

7TDS-200CL

KEY PARTS DIAGRAN

Lamp on/off switch

Lamp

Spark deflector

Plain

eye shield

Grinding

wheel 36#

Left

work rest

Switch

Magnify

eye shield

Grinding

wheel 60#

Right

work rest

Base Water tray

8

TDS-200CL

ASSEMBLY/ MOUNTING

Before attempting to use this grinder,

it must be properly mounted to a workbench

or grinding stand.

Using two long bolts, washers, lock-washers

and nuts, as shown (not supplied), secure the

grinder to the workbench.(Figure A)

Work bench

Flat washer

Hex nut

Bolt

Flat

washer

Fit the eye shield to the mount rod. Mount

the left and right shield rods to the inside of

the wheel guards using hex bolts.(Figure B)

Figure A

Figure B

Attach the left eye shield mounting rod

to the bench grinder using the bracket,

flat washer and bolt supplied.(Figure C)

Figure C

BD4603

9TDS-200CL

OPERATION

Bench grinders vibrate. Grinder movement

during high-speed rotation may cause

injury or damage to the workpiece or operator.

Mount the grinder securely to a sturdy

workbench or grinding stand.

The eye shield should move freely when

being adjusted, but stay in place when

the screw is tightened.

8INCH Bench Grinder is ideal for use in sharpening

chisels, axes and other woodcutting tools. It is also

useful for repairing tips on screwdrivers and drill

bits or for removing excess metal burrs from pieces

of cut metal.

With the proper accessories, this tool can be used

for cleaning metal surfaces using a wire brush or

for buffing and polishing using a cloth wheel.

The rocker I/O power switch is located on the front

of the grinder.

START-UP

Press the side marked “I” to turn the grinder on.

SHUT-DOWN

Press the side marked “O” to turn the grinder off.

10

TDS-200CL

MAINTENANCE

• Always keep the workpiece moving across the

face of the grinding wheel. Grinding continuously

on the same spot on the wheel will cause grooves

to be worn into the wheel. The wheel may crack

or become damaged more easily, and grinding of

other objects will be difficult.

• If the workpiece becomes hot, dip it into water or

oil to cool it.

• Always grind on the face of the wheel (around the

diameter), NEVER on the sides. Side pressure on

grinding wheels can cause cracking and damage.

• If the face of the grinding wheel is worn unevenly,

becomes grooved, or is no longer smooth and

flat, the wheel should be reshaped with a dressing

tool (not supplied).

• If the diameter of the grinding wheel is no longer

round, the wheel should be reshaped with a dre-

ssing tool or replaced.

• If the surface of the wheel becomes loaded and

dull with workpiece material, the wheel should be

cleaned with a dressing tool.

• After reshaping, always readjust the tool rests and

spark arrestors.

Installing or Changing the Wheel

When grinding, metal objects become heated

quickly. It is important to keep moving the object

back and forth across the face of the grinding

wheel and to cool the object frequently using the

coolant tray.

Work-light Bulb Replacement

When the light bulb is worn out and will no longer

work, purchase a replacement bulb. To replace,

gently push the light bulb into the socket and

turn clockwise. Uses Max 40 W anti-vibration

light bulb.

Installing or Changing the Wheel

1. Use a screwdriver to loosen the wheel cover

screws and push counter-clockwise to remove

the wheel cover.

2. Fit an appropriately sized wrench on the

spindle hex nut.

3. Loosen the wheel nut in a clockwise dire-

ction for the left side and a counter-clock

wise direction for the right side.

4. Remove the outer flange and grinding wheel.

To remove the hex nut, turn the wrench

and nut until the wrench is resting on the

workbench behind the tool.

5. Inspect the new wheel carefully to ensure

there are no cracks, chips or other damage.

6. Wipe the flange surfaces clean, and install

the new wheel, flange and the spindle hex

nut.

7. To install a new grinding wheel, reverse the

above procedure.

8. Be sure the grinding wheel and outer flange

are properly seated on the spindle shaft.

9. Replace the wheel cover and reposition the

tool rest.

BD4603

11 TDS-200CL

Problem Likely Solutions

Motor will

not start.

1. Low voltage.

2. Open circuit in motor or loose

connections.

3. Blown fuse or breaker.

Problem Possible Causes Likely Solutions

TROUBLESHOOTING

Motor will not

start-fuses or circuit

breakers tripping or

blowing.

Wheel dulls

quickly, grit

falls off.

1. Feed rate is too aggressive.

2. Wheel is soft.

3. Wheel diameter too small.

4. Bad wheel dressing.

5. Defective wheel bonding.

1. Decrease feed rate of workpiece into

grinding wheel.

2. Select a grinding wheel with a harder bond

of material.

3. Replace wheel.

4. Dress the wheel.

5. DO NOT USE – return wheel to point of

purchase.

1. Check power source for proper voltage.

2. Inspect all lead connections on motor for

loose or open connections.

(Send for servicing)

3. Change fuse or reset breaker.

(send for servicing)

1. Short circuit in line, cord or

plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit

breakers in power line.

1. Inspect cord or plug for damaged

insulation and shorted wires.

2. Inspect all connections on motor for loose

or shorted terminals and/or worn insulation.

3. Install correct fuses or circuit breakers or

switch tool to an appropriately sized circuit.

Motor overheats.

1. Motor overloaded.

2. Extension cord too long and of

insufficient gauge (weight).

1. Reduce load on motor.

2. Utilize an extension cord of appropriate

gauge and length or plug tool directly into

outlet.

Motor stalls

(resulting in blown

fuses or tripped

circuit).

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit

breakers in power line.

4. Motor overload.

1. Inspect connections on motor for loose or

shorted terminals or worn insulation.

(Send for servicing)

2. Correct low voltage conditions (for example:

improper extension cord length and/or

gauge).

3. Install correct fuses or circuit breakers or

plug tool into an appropriate circuit, matched

to an appropriate fuse or breaker.

4. Reduce the load on the motor.

Wavy condition

on surface of

workpiece.

1. Machine vibrating.

2. Workpiece not being held

firmly.

3. Wheel face uneven.

4. Wheel is too hard.

1. Ensure machine is securely mounted on a

solid surface.

2. Use a holding device to firmly retain the

workpiece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the feed rate.

12

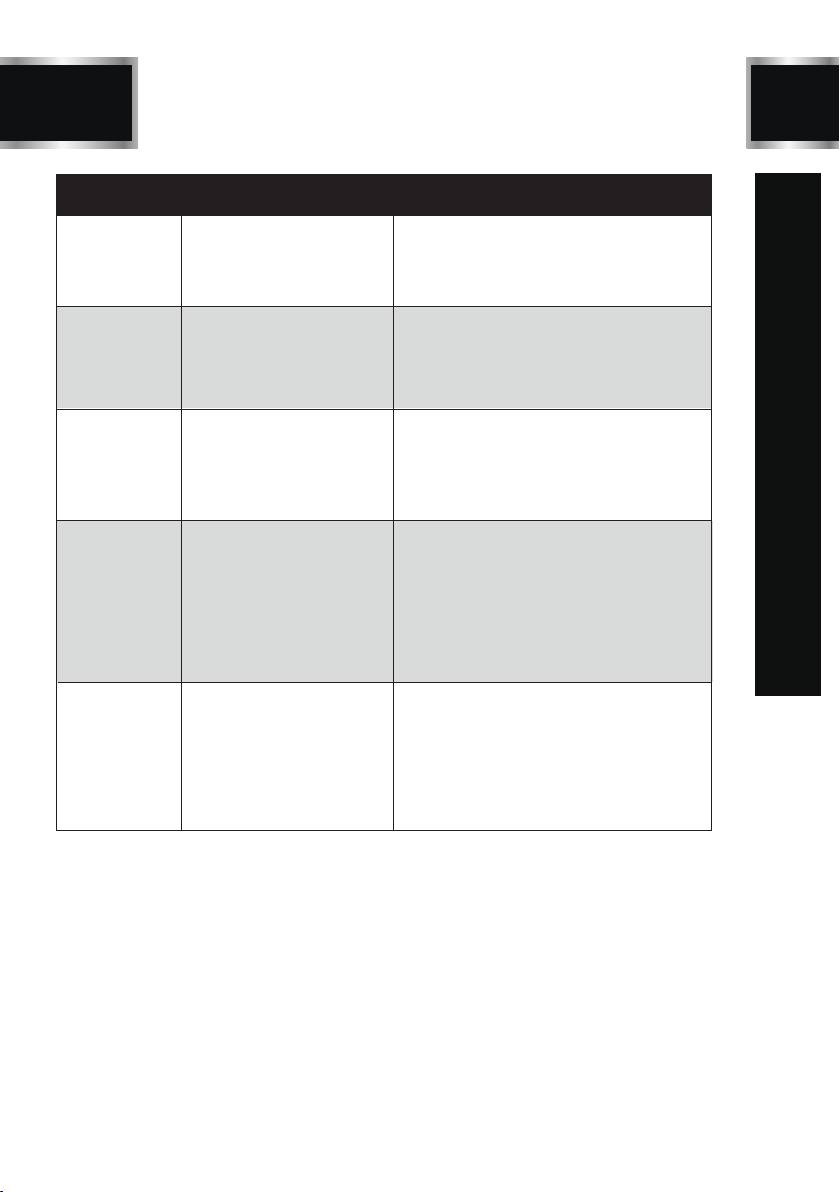

BD4603 TDS-200CL

Problem Likely Solutions

Problem Possible Causes Likely Solutions

Machine slows

when operating. 1. Feed rate too great.

1. Reduce the rate at which the workpiece is

fed into the working area of the tool

(grinding wheel).

Lines on surface

of workpiece.

Burning spots or

cracks in the

workpiece.

1. Impurity on surface of wheel.

2. Workpiece not being held

tightly.

1. Improper type of grinding

wheel.

2. Improper feed rate.

3. Coolant required.

1. Dress the grinding wheel.

2. Use a holding device to more firmly retain

the workpiece.

1. Try wheels with softer bond or coarser grit.

2. Slow down the rate at which the workpiece

is fed into the wheel.

3. Introduce coolant.

Wheel dulls

quickly, grit

falls off.

Wheel clogs and

workpiece shows

burn marks.

1. Feed rate is too aggressive.

2. Wheel is soft.

3. Wheel diameter too small.

4. Bad wheel dressing.

5. Defective wheel bonding.

1. Wheel is too hard.

2. Feed rate is too slow.

3. Bad wheel dressing.

4. Coolant required.

1. Decrease feed rate of workpiece into

grinding wheel.

2. Select a grinding wheel with a harder bond

of material.

3. Replace wheel.

4. Dress the wheel.

5. DO NOT USE – return wheel to point of

purchase.

1. Select a grinding wheel with a softer bond

of material.

2. Increase the feed rate of the workpiece into

the grinding wheel.

3. Dress the wheel.

4. Introduce coolant.

TROUBLESHOOTING

BD4603

13 TDS-200CL

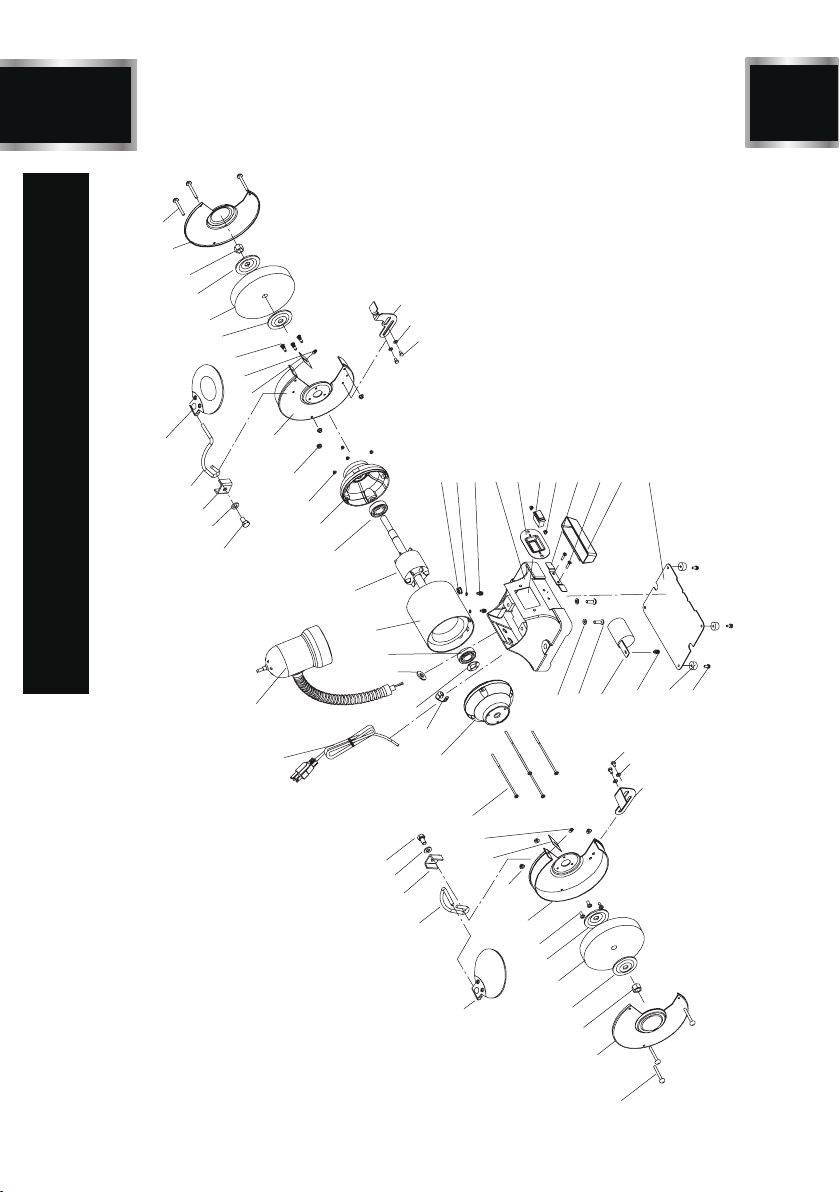

EXPLODED VIEW

51

32

31

4

4

6

30

15

50

34

35

41 42 38 43 44 45 46 46 48 49

403938

35

34

33

37

36

52

47

14

29

28

11

12

13

27

8

26

17

23

25

24

21 19

18

17

16

15

14

13

12

11

10

8

7

6

9

4

5

4

3

2

1

20

23

22

14

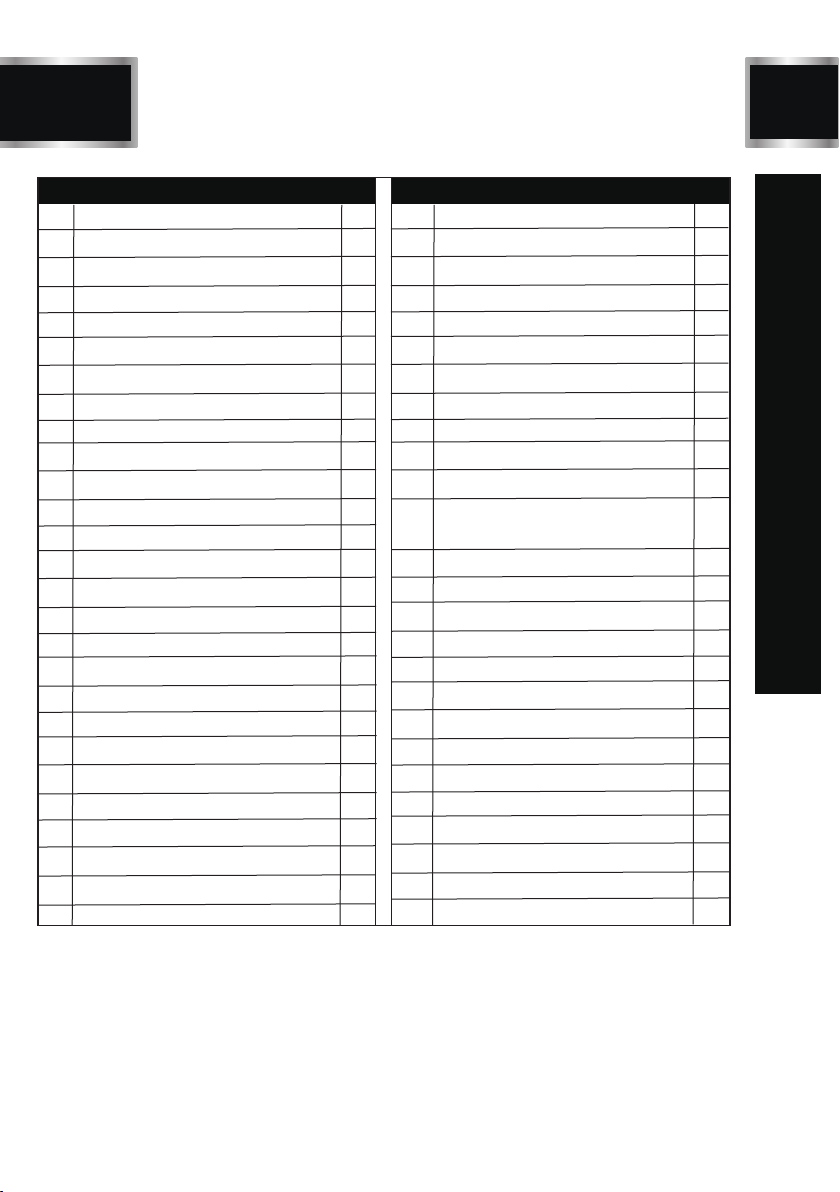

TDS-200CL

PARTS LIST

No. Qty.Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Star-head screw M5X48

Left wheel guard cover

Hex nut, I type M16 left

Wheel flange

Grinding wheel 36#

Star-head screw+spring washer M5X10

Left wheel guard plate

Hex flange nut M5

Plain eye shield assy.

Left eye shield support

Bracket

Flat washer D6

Hex bolt M6X14

Spark deflector

Star-head screw+flat washer M5X10

Star-head screw+flat washer M5X155

End cap

Strain relief 6P4

Wave spring retainer D40

Cord & plug

Lamp assy

Flat washer D12

Bearing

Stator

Rotor

Hex flange nut M5

No. Qty.Description

3

1

1

4

1

6

1

6

1

1

2

2

2

2

2

4

2

1

2

1

1

1

2

1

1

4

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Right wheel guard plate

Right eye shield support

Magnify eye shield assy.

Grinding wheel 60#

Hex nut, I type M16

Right wheel guard cover

Left work rest

Flat washer D8

Hex bolt M8X8

Hex bolt M8X20

Capacitor

Star-head screw+flat washer+

spring washer M4X8

Rubber washer

Star-head screw+ big flat washer M5X1

6

Cord bushing

Toothed lock washer D4

Base

Switch plate

Switch

Star-head screw M4X8

Coolant tray clip

Coolant tray

Base cover

Right work rest

Star-head screw M5X51

Spring washer D8

1

1

1

1

1

1

1

4

4

2

1

3

4

4

1

2

1

1

1

4

1

1

1

1

3

2

BD4603

15 TDS-200CL

WARRANTY

Having Problems ?

Give us a chance to help you before returning this product

Email :

After the phone:(844) 866-5687

ONE-YEAR LIMITED WARRANTY

Table of contents

Other TOUGH-WORKS Grinder manuals