Toyo SOT-MQ82 Series User manual

DS4-2731C

- 1 -

CC-Link Space Optical Repeater

SOT-MQ82/162 series

Operation Manual

TOYO ELECTRIC CORPORATION

DS4-2731C

- 2 -

TABLE OF CONTENTS

1. Introduction 3

2. Outline 3

3. Construction 3

3-1. Model number 3

3-2. Combination 3

4. Major specifications 4

5. Constituent parts and their functions 5

6. Data linking procedure 6

6-1. Procedure 6

6-2. Setting the switches 7

6-3. Installation 8

6-4. Electric connections 11

6-5. Beam path adjustment 14

6-6. Monitoring function 14

7. External output circuit 16

8. Inspection and maintenance 17

9. Caution in use 17

10. External dimensions 18

11. Warranty 19

12. Contact 19

13. Revision history 20

DS4-2731C

- 3 -

1. Introduction

Thank you for choosing our SOT-MQ82/162 series, CC-Link space optical repeater.

To ensure the correct use, please thoroughly read this manual before use.

2. Outline

The SOT-MQ82/162 is a high-speed space optical transmitter using infrared rays.

(1) It optically transmits CC-Link data.

The CC-Link cable can be replaced with space optical communication.

(2) The optical reception status can be communicated to the master station and used for

maintenance or another purpose.

(3) The data transfer rates of 156 kbps, 625 kbps, 2.5 Mbps are supported.

(4) Dip switch allows to switch the channel to the one having different carrier frequency and to

communicate with up to two opposite directions in series or parallel without interference.

3. Construction

3.1 Model number

SOT - MQ 16 2

Optional specification No code: No specification

CH1 CH2

Carrier wave frequency A: 14.5MHz 21.5MHz

B: 18.0MHz 25.0MHz

Transmission distance 16: 0.2 to 160m

8: 0.2 to 80m

Series name MQ: 2.5Mbps CC-Link

3-2. Combination

(1) Use a type A carrier wave unit and a type B one as a pair.

A pair consisting of two type A units or two type B units does not work.

(2) The SOT-MQ82/162 series are not compatible with other space optical transmission

units.

Type A Type B

Power supply

Auxiliary outputs

CC-Link

Auxiliary outputs

Power supply

CC-Link

DS4-2731C

- 4 -

4. Major specifications

Item Specifications

Model SOT-MQ162A/B SOT-MQ82A/B

Operating environment CC-Link Ver.1.10/Ver.2.00

Data transfer rate 156k, 625k, 2.5Mbps

Supply voltage Rated voltage: 24VDC, 10% or less ripples

Operating voltage: 18-30VDC, 30V or less at peak including ripples

Current consumption Less than 150mA

Interface RS485 compliant

Transmission mode Semi-duplex, bi-directional

Communication control

mode

Bit forward

# of occupied stations When using the monitoring function: 1

When not using the monitoring function: 0

Transmission distance 0.2-160m 0.2-80m

Detection angle 1° (horizontal and vertical) 1° (horizontal and vertical)

Modulation mode FSK

Projector element Near infrared light emitting diode (870nm in wavelength)

Receiver element Photo diode

Auxiliary outputs CDO: On when data is received.

ALM: Off when the reception level is low.

A photo-coupler insulated, NPN open collector output

Rated output level: 30VDC, 50mA max.

Electric connections For CC-Link signals: 4-pin connector terminal block

(PHOENIX MSTB 2,5/4-GF-5,08)

For power supply and auxiliary outputs:5-pin connector terminal block

(PHONEIX MSTB 2,5/5-GF-5,08)

Check terminals Applies an output DC voltage corresponding to the reception level.

(Use the DC voltage range of a 10kΩ/V or higher tester.)

Operating ambient

illumination

Sunlight : 10,000 lx or less

Fluorescent or candescent lamps : 3,000 lx or less

No ambient light shall directly enter the receiver.

Operating ambient

temperature

-10-55°C No frozen parts allowed.

Operating ambient

humidity

10-85% RH No condensation allowed.

External dimensions

(weight)

See “External dimensions” (approx. 350g).

Accessories A set of fittings, mounting screws (4),

signal plug (1), power/auxiliary output plug (1),

110Ωterminal resistors (2) and 130Ωterminal resistors (2)

DS4-2731C

- 5 -

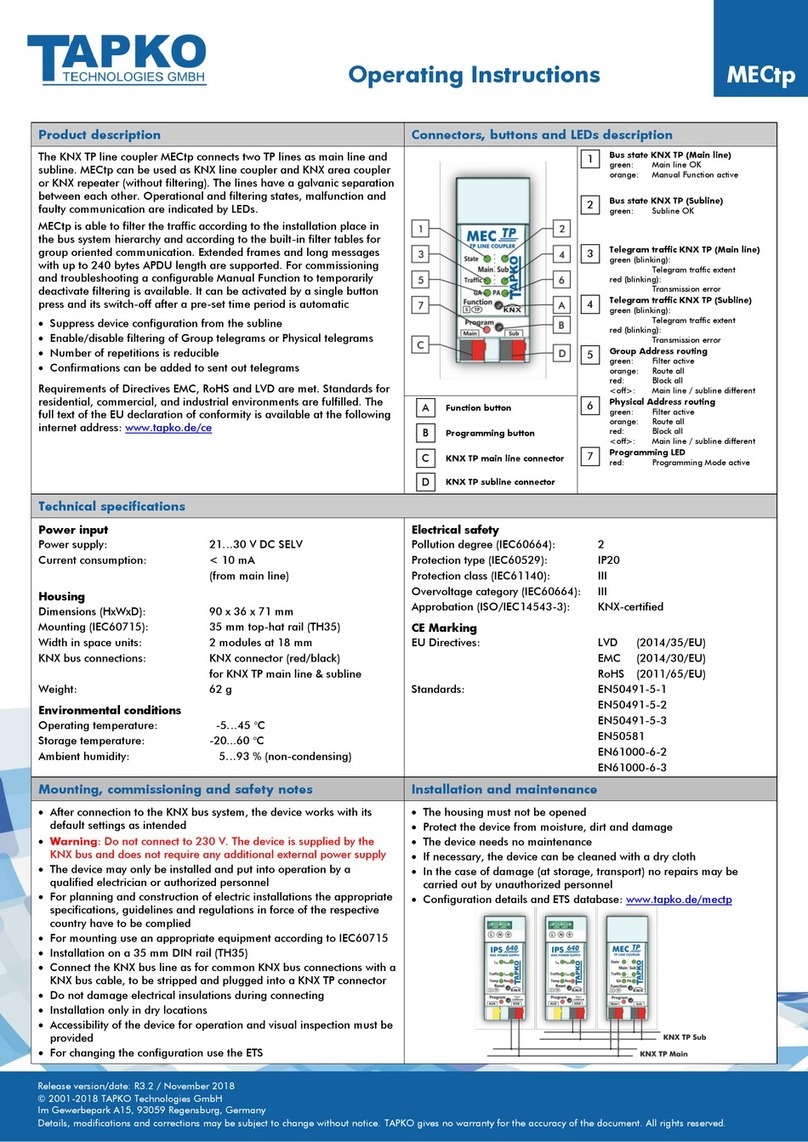

5. Constituent parts and their functions

(1) Power indicator (POW): Shows red when the power supply in on.

(2) Clear data indicator (↓CD): Shows red when the reception level at the station

is sufficient for communication.

(3) Reception level indicator (↓1 to 4): Shows green to indicate the reception level at the

station.

(4) Monitor running indicator (LRUN): Shows green during normal communication using

the monitoring function.

Remains off when the monitoring function is not

used.

(5) Monitor error indicator (LERR): Shows red during faulty communication using the

monitoring function.

Remains off during normal communication using

the monitoring function or when the monitoring

function is not used.

(6) Communication error indicator (ERR): Shows red during faulty CC-Link communication.

(7) Sent data to cable indicator (SD1): Shows red when data is transmitted to the cable.

(8) Sent data to optical unit indicator (SD2): Shows red when data is transmitted to the optical

unit.

(9) Received data from cable indicator (RD1): Shows green when data is received from the cable.

(10) Received from optical unit indicator (RD2): Shows green when data is received from the

optical unit.

(11) Channel indicator (CH) Remains off when choosing CH1.

Shows red when choosing CH2.

(12) Opposite station data clear indicator (↑CD): Shows red when the monitoring function is used

and the reception level at the opposite station is

sufficient for communication.

(13) Opposite station reception level indicator (↑1 to 4): Shows green to indicate the reception level at the

opposite station when the monitoring function is

used.

(14) + check terminal (red): Applies an output DC voltage corresponding to the

reception level. (Use the DC voltage range of a

10kΩ/V or higher tester).

(15) – check terminal (black)

(16) Setting switches: Used to select the data transfer rate and to switch

carrier frequency.

(17) Station number setting switches: Used to select the data transfer rate and carrier

frequency.

(18) Power/auxiliary output plug: FKCT 2.5/5-STF-5.08, Phoenix Contact

(19) Signal plug: FKC 2.5/4-STF-5.08, Phoenix Contact

(20) FG terminal: For connecting external FG, M3 threaded

1

2

8 7

3

4 613 12

10 9 5

11

19

14

15

17

18

16

20

DS4-2731C

- 6 -

6. Data linking procedure

6-1. Procedure

Start

↓

Setting the switches

Set to the SOT station number and data

transfer rate.

See subsection 6-2.

↓

Installation

Install the SOT units on the equipment. See subsection 6-3.

↓

Wiring the cables

Wire the power and dedicated CC-Link cables. See subsection 6-4.

↓

Beam path adjustment

Adjust the beam path while checking the CD

and level indicators on each SOT unit. See subsection 6-5.

↓

Setting the master unit

Set up the master unit.

↓

Circuit check

Check the CC-Link circuit.

↓

Creating a monitoring program

Create a PLC program to control the

monitoring function.

See subsection 6-6.

↓

End

is the step recommended to see the User’s Manuals for the CC-Link master and local units.

DS4-2731C

- 7 -

6-2. Setting the switches

6-2-1. Setting switches

(1) Detail of settings

Detail of settings

SW1 Used to select the data transfer

rate

SW2

SW3 Not used (used when off)

SW4 Used to switch channels

(2) Data transfer rate selection (SW1, 2)

SW1 SW2 Data transfer rate

OFF OFF 156k

ON OFF

625k

OFF ON 2.5M

ON ON Not valid

The switches have been factory-set to “156 kbps.”

(3)Channel select switch (SW4)

SW4 Carrier frequency

OFF CH1 selected

ON CH2 selected

The switches have been factory-set to “CH1 selected.”

6-2-2. Station number setting switches

(1) Detail of settings

(2)

Detail of settings

×10 ×1

x10: Set to the first-digit value of the

station number.

X1: Set to the second-digit value of the

station number.

Set to 00 when using the monitoring

function.

01 to 64: Specifies the station number

when using the monitoring function.

65 to 99: Not valid

The switches have been factory-set to “00.”

(2) When using the monitoring function, set the station number to “01” if there is no preceding

station.

If there is any preceding station, set to the “preceding station number + the number of

stations occupied by the preceding station unit.”

Example: If the previous station number is “01” and two stations are occupied by the unit,

the current station number will be “03.”

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

DS4-2731C

- 8 -

6-3. Installation

6-3-1. Drilling dimensions for mounting holes

6-3-2. Caution about the place for installation

In order not to spoil the transmitter performance, the transmitter shall not be installed in a place

where:

(1) it may be directly exposed to splashes of water, oil, dust and/or chemical,

(2) optical signals may be dampened by aqueous vapor, smoke, corrosive gas or the like (the

projector and receiver ports are made of resin and shall not be cleaned with paint thinner

based solvent),

(3) the transmitter may be exposed to temperatures, humidity, vibration and/or impact

exceeding the ratings (the transmitter shall be protected when it is continuously exposed to

vibration or impact even not exceeding the rating),

(4) a device generating a strong magnetic field, e.g. magnet or motor, or a device or power

wire generating strong noises, e.g. inverter, is used nearby,

(5) the sunlight or incandescent light containing strong infrared rays directly enters the receiver

within 10 degrees from the center of the beam path (the transmitter shall be used indoors),

(6) the beam path between the receiver and projector may be interrupted by a passing person

or obstacle or optical signals may be dampened by aqueous vapor or smoke

(communication may be suspended when the beam path is interrupted)

(7) a reflective object or beams coming from another photoelectric switch that may optically

interfere with the transmitter is located above the beam path, or

(8) the beam path to a moving unit, if used, will be inclined by 1 degree or more when the

moving unit is making a zigzag, vibrating or given an impact.

Beam

direction

M4 screw mounting hole

DS4-2731C

- 9 -

6-3-3. Intervals between adjacent pairs

When installing two or more pairs of SOT units or using a one near another photoelectric

sensor, reserve a sufficient space between them to prevent optical interferences.

Example 1

*1. This setup does not interfere with data transfer but will affect the reception level

indicated on each unit. (When adjusting the beam path or checking the

reception level, turn off the other pair of units.)

Example 2

*2. This setup does not cause interferences unless disturbed by any reflective object.

Example 3

*3. Same condition is applicable as Example 1 when the channel is different.

Caution

Note that the severity of optical interferences depends on the beam path adjustment and

misalignment factors such as vibration or impact. When installing a unit on a moving cart

or the like, adjust the beam path according to 6-5 “Beam path adjustment” and check the

performance before use to ensure normal communication throughout the whole

communication area.

Type A

Type B

Type B

Type A

0.5m or

more

Type AType B

Type BType A

*2

Type AType B

3m or more

*3

Type AType B

DS4-2731C

- 10 -

6-3-4. Installing directions

Install the SOT units in the opposite directions as shown in (1) below.

They do not work if rotated as shown in (2) or (3).

DS4-2731C

- 11 -

6-4. Electric connections

6-4-1. Power/auxiliary output connector

Signal name Code Terminal

number

24V 1

Power supply GND 2

CDO 4

ALM 5

Auxiliary

outputs COM 3

Arrangement of cable connecting terminals

(1) Applicable connector (enclosed)

Plug, FKCT 2.5/5-STF-5.08 (1902330), Phoenix Contact or equivalent

(2) Recommended cable

Use a 0.3mm2or thicker cable for power supply and auxiliary outputs.

(Check the voltage drop across the cable and use it within a length not exceeding 50m.)

6-4-2. Signal connector

Signal name Code Terminal

number

Signal A DA 1

Signal B DB 2

Signal ground DG 3

Shielded SLD 4

Arrangement of cable connecting terminals

(1) Applicable connector (enclosed)

Plug, FKC 2.5/4-STF-5.08 (1873223), Phoenix Contact or equivalent

(2) Recommended cable

Use a dedicated CC-Link cable.

The CC-Link system performance cannot be guaranteed if used with a cable other than

dedicated for CC-Link.

For specifications and other details of the dedicated CC-Link cable, see:

CC-Link Partner Association’s homepage: http://www.cc-link.org/

DS4-2731C

- 12 -

6-4-3. Connecting the dedicated CC-Link cables

(1) Use dedicated CC-Link cables of the same type in each segment. Using different types of

cables together does not guarantee normal data transfer.

(2) The intervals required between adjacent dedicated CC-Link cables and the maximum

extension length depend on the data transfer rate and the construction of the equipment

used. For detail, see the User’s Manual for the master unit.

(3) For the units at either ends of each segment, always connect the terminal resistor between

DA and DB. The SOT units themselves contain no terminal resistor.

Use compatible ones of the attached terminal resistors (110Ωand 130Ω) with the cable.

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

Dedicated CC-Link

cable

Master unit

SOT-MQ82/162

Remote unit

SOT-MQ82/162

Remote unit

Terminal

resisto

r

Terminal

resistor

Terminal

resistor

Terminal

resistor

Dedicated CC-Link

cable

Dedicated CC-Link

cable

Space optical

transmission

DS4-2731C

- 13 -

6-4-4. Measures to be taken to comply with the EMC Directive

The measures to be taken to ensure conformity of this optical transmission device with the EMC

Directive are described below.

To ensure conformity of the entire CC-Link system with the EMC Directive, it is necessary to take

all the necessary measures for the peripheral devices, such as the slave unit and power supply,

referring to the appropriate hardware manuals for the sequencer CPU.

(1) Attaching a ferrite core to the CC-Link cable

Attach a ferrite core to the CC-Link cable in the vicinity of the optical transmission device.

This ferrite core must have attenuation characteristics equivalent to those of the TDK

ZCAT3035-1330 ferrite core.

Please note that the measures described above are deemed as the best method based on the

information on the regulatory requirements and standards that is currently available to us.

However, use of the entire system incorporating this optical transmission device after completion

of these measures does not always ensure conformance to the EMC Directive.

It is the responsibility of the system manufacturer to specify the method for ensuring conformity

of the entire system with the EMC Directive and make a final decision on its compliance.

Ferrite core

DS4-2731C

- 14 -

6-5. Beam path adjustment

A data link error occurs during beam path adjustment.

Before starting, remove the cable from the connector or check that no trouble will be caused if a

data link error occurs.

(1) After ensuring correct wiring, turn on the SOT units.

The power indicator (POW) on each unit shows red.

(2) Loosen the unit and fitting mounting screws and move the unit in every direction until the

clear data indicator (CD) on the opposite unit shows red.

Note: The opposite station reception level indicator on the unit only lights when the

monitoring function is used and the reception level at the station is CD or higher.

First, adjust while checking the reception level indicated on the opposite unit.

(3) Finely adjust until the reception level indicator on the opposite unit shows green at level 3 or

higher. The accurate reception level can be measured with a tester connected to the check

terminals on the opposite unit.

Use the DC voltage range of a tester with an input resistance of 10kΩ/V around 10V.

Insert φ2 tester probes into the (+) and (-) check terminals.

(4) The maximum voltage at the check terminals shall be 4.2V.

As a guide, the voltage shall be 2.2V or higher at the maximum transmission distance and

fixed nearly around the maximum level.

(5) Adjust the opposite unit in the same manner.

(6) When installing a unit on a moving object such as stacker crane, check that the reception

level indicators on both the moving and fixed units show green at level 3 or higher

throughout the entire region of motion.

(7) The communication error indicator (ERR) shows red when disturbed by reflected or ambient

light. When installing a unit on a moving object such as stacker crane, check that the

communication error indicators on both the fixed and moving units will not show or blink red

throughout the entire region of motion.

6-6. Monitoring function

The monitoring function communicates the reception status of each SOT unit to the master

station.

When using the monitoring function, it is necessary to specify the station number and set

parameters as remote I/O station.

6-6-1.Master unit input/output signals

(1) Input signals (SOT-MQ to master unit)

Device No. Signal name Description

RXn0 Local CD Input station’s CD signal

RXn1 Local ALM Input station’s ALM signal

RXn2 LocalL1 Input station’s L1 signal

RXn3 LocalL2 Input station’s L2 signal

RXn4-RX(n+1) Reserve Reserved

* The reserved signals cannot be used.

(2) Output signals (master unit to SOT-MQ)

Device No. Signal name Description

RYn0-RYnF Reserve Reserved

RY(n+1)0 Remote CD

Opposite station’s CD signal

RY(n+1)1 Remote ALM

Opposite station’s ALM

signal

RY(n+1)2 RemoteL1

Opposite station’s L1 signal

RY(n+1)3 RemoteL2

Opposite station’s L2 signal

RY(n+1)4-RY(n+1)F Reserve Reserved

DS4-2731C

- 15 -

* The reserved signals cannot be used.

6-6-2. Correspondence between input/output signals and indicators

The correspondence between the input/output signal on/off statuses and the indicator

statuses is shown below:

Signal Indicator

LEVEL

CD ALM L1 L2 CD 1 2 3 4

OFF OFF OFF OFF × × × × ×

ON OFF OFF OFF

{× × × ×

ON ON OFF OFF

{{× × ×

ON ON ON OFF

{{{× ×

ON ON OFF ON {{{{×

ON ON ON ON {{{{{

6-6-3. Example of program

(1) Example of system construction

In this example, the QCPU, QJ61BT11N and SOT-MS are set up as shown below for explanation.

1. Insert the QJ61BT11N into slot 0.

2. Set the station number of SOT-MS162A

to “1” and that of SOT-MS162B to “2.”

3. Program the automatic refreshing.

RX refreshing device: X1000

RY refreshing device: Y1000

4. Set parameters

Station type: Remote I/O

# of occupied stations: 1

* For detail of parameter settings, see

the User’s Manual for the master unit.

(2) Monitoring program

With this monitoring program, the reception level at the opposite station can be determined with

the indicator and used for fine adjustment and maintenance.

× : Off

{: On

Slot 0

Power unit

162A, station

number “1”

162B, station

number “2”

Send reception level at

station 1 to station 2

Send reception level at

station 2 to station 1

Reception level at station 1

decreased when M0 is off

Reception level at station 2

decreased when M1 is off

DS4-2731C

- 16 -

7.External output circuit

( 1 ) DA

( 2 ) DB

( 3 ) DG

( 4 ) SLD

( 4 )

Terminal No. Abbrev.

CDO

( 5 ) ALM

( 2 ) GND

FG

( 1 ) 24V

( 3 ) COM

Signal connector

Power/auxiliary output connector

Terminal No. Abbrev.

DS4-2731C

- 17 -

8. Inspection and maintenance

(1) Periodically check the front cover for contamination.

The product optically transmits data and may malfunction if the front cover is

contaminated. If it is heavily contaminated, wipe it clean with a dry cloth or the like.

The projector and receiver ports are made of resin and must not be cleaned with toluene

based solvent.

(2) Check for loose or chattering mounting screws and tighten, if any.

9. Caution in use

(1) Caution about voltage ripples

Use a power supply that meets power specifications for the product.

When supplying from the power unit of a PLC (sequencer), check that the product will

normally function.

(2) Caution about the power reset

Data cannot be transmitted for about two seconds after power-up.

(3) Beam path adjustment

When installing the SOT units, never fail to adjust the beam path.

Data can be transmitted when the clear data indicator (CD) lights and the clear data

output signal (CDO) is on.

When the reception level indicator (level 1) does not light, the low reception level output

(ALM) signal is issued (off).

(4) Power wiring

The power cable length shall not exceed 50m.

Electric noises in various forms are induced into the power cable from electric

appliances on the power circuit and power cables coming from other equipment. They

may cause the units to malfunction even if the power cable is shorter than 50m.

In case the power cable wiring circuit has such disturbing factors:

(1) install the power unit nearby,

(2) shorten or separately wire the power cable, or

(3) use a cable shielded from electromagnetic fields.

DS4-2731C

- 18 -

10. External dimensions

As removed from bracket

5 x 12

oblong hole

Receiver

port

Projector

port

5 x 12

oblong hole

DS4-2731C

- 19 -

11. Warranty

(1) Warranty period

A year after delivery to the specified location.

(2) Scope of Warranty

If the product is found to have a fault attributable to us within the Warranty period

specified above, the faulty part will be replaced or repaired at our cost. This does not

apply to the faults resulting from:

(1) incorrect handling or abuse by the user,

(2) causes not related with the product,

(3) alternation or repair made by a party other than us, or

(4) natural disasters and accidents beyond our control.

Note that the Warranty only applies to the product itself and does not cover secondary

damages arising from a failure of the product.

12. Contact

For detail of the product, please contact the nearest sales office or the Kagiya Factory.

TOYO ELECTRIC CORPORATION

Kagiya Factory

Head office

/Kagiya Factory

1-39 Aza-hikizawa, Kagiya-cho, Kasugai City, Aichi Prefecture, 480-0393

Tel <0568>88-1181 (Rep.) Fax <0568>88-3086

Tokyo office Uchikanda Tosei building 3F, 1-18-12 Uchikanda, Chiyoda Ward, Tokyo,

101-0047

Tel <03>5282-3308 Fax <03>5282-3309

Nagoya office 2-156 Ajiyoshi-cho, Kasugai City, Aichi Prefecture, 486-8585

Tel <0568>35-3456 Fax <0568>34-4666

Osaka office Asahi seimei doushu-machi building 5F, 1-5-18 Doushu-machi, Chuo Ward,

Osaka City, 541-0045

Tel <06>6221-5361 Fax <06>6221-5363

Homepage: URL http://www.toyo-elec.co.jp

* The specifications and external dimensions shown herein may be revised to reflect

future improvements without notice.

DS4-2731C

- 20 -

13. Revision history

Date Contents of revision Remarks

2010.03.31 Newly issued Development 1

2010.04.09 CC-Link version added Development 1

2010.07.26 Editorial errors with addresses in 12 “Contact” corrected Development 1

2011.04.22

Page 1, CE mark added.

Page 13, 6-4-4. Measures to be taken to comply with the

EMC Directive, added.

Page 19, Department names changed due to change of

organization in 12. Contact.

Development 1

Blank

This manual suits for next models

3

Table of contents

Popular Repeater manuals by other brands

Pyramid

Pyramid SVR-200 Service manual

MST

MST ImPact owner's manual

Digital Antenna

Digital Antenna DA4000SBR Installation and operation manual

O2Line

O2Line TRIO2SYS 10020113 Installation and operating manual

HAMTRONICS

HAMTRONICS REP-200 Installation, maintenance & operation guide

Campbell

Campbell AL205R product manual