Trac-Rite 944 User manual

ROLLING CURTAIN DOOR MANUAL

INSTALLATION • MAINTENANCE • PARTS

Model 944

PHONE 800 448 8979

FAX 800 236 8722

WEBSITE www.tracrite.com

EMAIL [email protected]

ADDRESS 314 Wilburn Road

Sun Prairie, WI 53590

This manual MUST be left with the owner

944_Manual_522000revH_818 color.indd 1 9/10/2018 1:36:45 PM

www.tracrite.com

TRAC-RITE

Thank you for purchasing Trac-Rite’s model 944 door. The following is an

instructional guide to take you through the steps of installing your new door. Be

sure to read and understand this entire installation manual including the warnings,

cautions, and notes before starting the installation of your new Trac-Rite door.

The following terms are defined as:

WARNING - serious personal injury or death can result from failure to follow instructions.

CAUTION - minor injury or property damage can result from failure to follow instructions.

NOTE - special attention should be given.

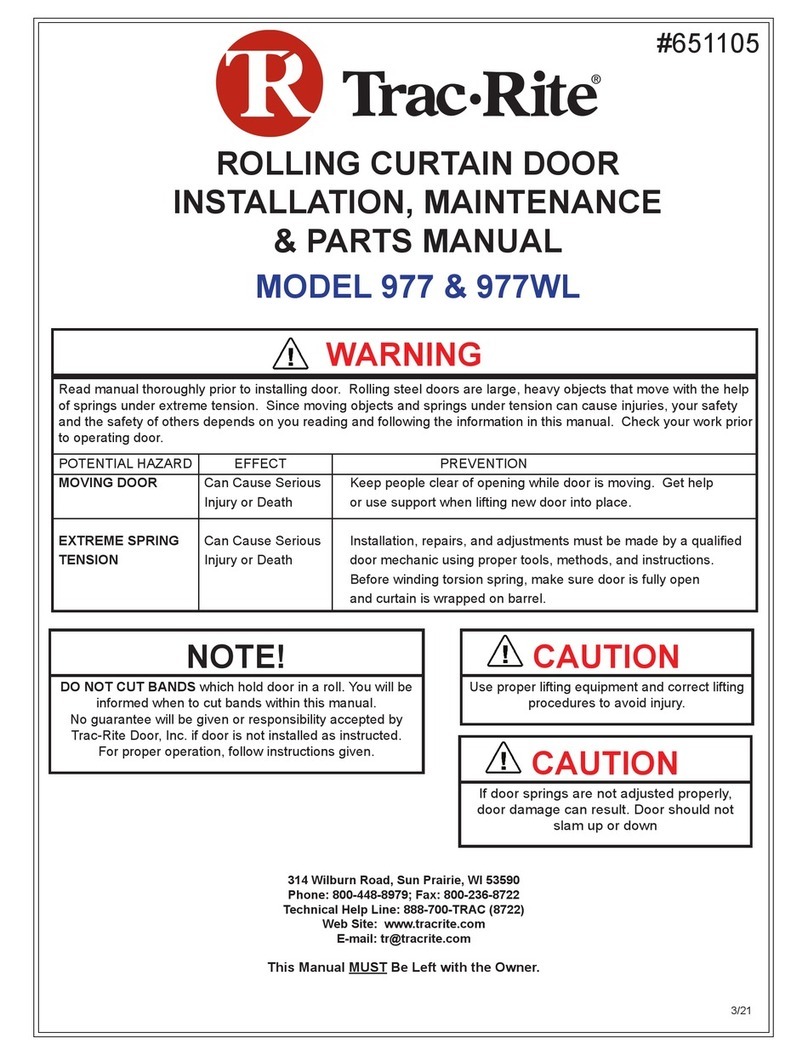

WARNING

!

Improper installation of anchoring devices or installation into unsound material may result in premature product

wear, product failure, property damage or serious personal injury.

Rolling steel doors are large, heavy objects that move with the help of springs under extreme tension. Since moving

objects and springs under tension can cause injuries, your safety and the safety of others depends on you reading

and following the instructions in this manual. Check your work prior to operating door.

WARNING

!

POTENTIAL HAZARD EFFECT PREVENTION

MOVING DOOR Can Cause Serious

Injury or Death

Keep people clear of opening while door is moving. Get

help or use support when lifting new door into place.

EXTREME SPRING

TENSION

Can Cause Serious

Injury or Death

Installation, repairs, and adjustments must be made by

a qualied door mechanic using proper tools, methods,

and instructions. Before winding torsion spring, make

sure door is fully open and curtain is wrapped on barrel.

Components under extreme spring tension can cause SERIOUS INJURY or DEATH. Adjustments and repairs must

be made by a qualied door mechanic using proper tools and instructions. Do NOT attempt to adjust door tension

unless the door is in the “UP” position. Winding bar should be solid steel 1/2” diameter rod or 3/8” x 1/2” at.

WARNING

!

1

CAUTION

!

Spring Tension is Critical: Improper tensioning of the spring(s) can result in door damage and reduce the life of your

door. The door should not slam up or down during operation. Please refer to Page 8; Fig. 12. No warranty claims will

be honored due to damage caused by improperly tensioned spring(s).

944_Manual_522000revH_818 color.indd 2 9/10/2018 1:36:45 PM

800-448-8979

TRAC-RITE

Proprietary Notice

Information contained in this document is copyrighted

by Trac-Rite and may not be duplicated in full or part

by any person without prior written approval of Trac-

Rite. Its purpose is to provide the user with adequate

detailed documentation to efficiently install a model

944 rolling curtain door.

For Customer Support regarding:

Parts orders

Technical help

Emergency support

Installation questions

Damage

Shortages

Please Call: 1-800-448-8979

1. INSPECTION:

Door and Hardware: Upon receiving the door

shipment, immediately inspect the door and

hardware for damage. Verify the product received

with the packing list. Damage and/or shortages should

be reported immediately to Trac-Rite customer service

at 800-448-8979. Please have your bill of lading and

packing list to reference when reporting shortages

or damage. Do not install damaged material without

authorization from Trac-Rite.

2. PREPARATION:

Clean the work area. Remove all debris and sharp

objects from the area where the door will be

placed on the floor. Sweep the area clean. It is also

recommended that the door curtain assembly be

placed on a piece of cloth or cardboard to help

ensure that the finished door surfaces will not be

damaged while the door is being prepared for

installation.

Recommended tools for assembly:

• Wrenches or sockets 7/16” and 1/2” sizes

• Drill or screw gun

• 3/8” and 7/16” hex drivers (wood mounting)

• 5/16” hex driver and 3/8” drill bit (steel

mounting)

• 5/16” and 7/16” hex drivers and 5/16”

masonry bit (concrete or masonry mounting)

• C-clamps or vise grips

• Safety glasses

• Work gloves

• Pliers

Door Opening Inspection (See Figure 1):

• Is the framed opening width and height the same

size as the door ordered? (A x B)

• Are the door jambs plumb and square?

• Is the floor level and square with the door jambs?

• Is there adequate jamb side clearance? (E)

• Is there adequate clearance above the door

curtain roll? (G)

•

Is there adequate clearance in front of the roll? (F)

• Are the jambs structurally and/or dimensionally

adequate to accept door brackets and guides?

2

SIDE VIEW FRONT VIEW

Figure 1

A - FRAMED OPENING WIDTH

B - FRAMED OPENING HEIGHT

C - MINIMUM BRACKET MOUNTING WIDTH:

4”[10cm] FOR METAL OR WOOD;

6”[15.2cm] FOR MASONRY

D - MINIMUM HEADER HEIGHT:

7-1/2”[19cm]

E - MINIMUM JAMB WIDTH:

2”[5cm] FOR METAL OR WOOD;

4”[10cm] FOR MASONRY

F - BACK ROOM:

18”[46cm]*

G - HEAD ROOM:

15”[38cm]* DOORS UP TO 7’0”

16”[41cm]* DOORS 7’1” TO 10’4”

18” [46cm] DOORS 10’5” TO 12’

H - SIDE ROOM:

4”[10cm] FOR METAL OR WOOD;

(9”[23cm] ON A SIDE WITH A CHAIN

HOIST)

* ADD 1”[25mm] FOR INSULATED DOORS

DO NOT CUT BANDS which hold door in a roll until

instructed to do so. Trac-Rite will not guarantee

or accept responsibility if door is not installed as

instructed.

NOTE!

944_Manual_522000revH_818 color.indd 3 9/10/2018 1:36:45 PM

www.tracrite.com

TRAC-RITE

3. BRACKET AND GUIDE ASSEMBLY

3.1 Position the guides and brackets inside the

building on the floor near their mounting location.

3.2 Place the guides on the ground with the mounting

holes facing the ground and the bent curtain lead-in

up and toward the door opening (See Figure 2 for

example of right hand guide).

3.3 Now place each bracket with the correct guide.

Each bracket is labeled left or right (See Figure 1A).

3.4 Attach a bracket to each guide with one (1) 5/16”

flat head track bolt and one (1) whiz-nut as shown

in Figure 2. Nuts go to outside of guide. MAKE

SURE THE BACK OF THE BRACKET AND GUIDE

ARE FLUSH WHEN DONE MOUNTING BOTH

BRACKETS (See Figure 4).

3.5 Place a protective material on the floor of the

work area to protect door nest while on the floor.

3.6 With enough room between the guides for the

door nest, bring the nest in and lay it between the

guides on the floor. Orient the door nest in the

opening as shown in Figure 3.

3.7 Slide the door bracket over the door axle, through

the bearing. If needed, rotate the tension wheel to

allow the adjustment wheel to slide past the tension

adjustment pawl.

3.8 Install a steel washer onto the axle and secure

with cotter pin through axle’s hole. If the washer

blocks the cotter pin hole, don’t use the washer.

3.9 Using pliers, bend both ends of the cotter pin

back to secure it.

Repeat steps 3.7 - 3.9 for other side of door.

LEFT

BRACKET

DOOR OPENING

RIGHT

BRACKET

RIGHT GUIDELEFT GUIDE

GENERAL ASSEMBLY LAYOUT

WALL

WALL

INSIDE

OUTSIDE

3

Figure 3

Figure 1A

DOOR NEST

WHIZ-NUT & 5/16”

TRACK BOLT

RIGHT HAND DOOR

BRACKET

DOOR GUIDE

BENT CURTAIN LEAD IN

Figure 2

INSIDE OPENING LOOKING OUT

NOTE DIRECTION AND POSITION

OF BOTTOM SEAL

DOOR NEST

TENSION PAWL

944_Manual_522000revH_818 color.indd 4 9/10/2018 1:36:45 PM

800-448-8979

TRAC-RITE

4. Door Mounting

4.1 With one person on each end of the door nest, lift

it and the attached brackets/guides into position.

4.2 Temporarily secure door assembly to jamb with

C-clamps, vise grips, or bar clamps.

4.3 Center the door in the opening with the door

brackets perpendicular to the mounting surface.

NOTE!

The door brackets will are away from the opening to

allow for the use of the tension system.

CAUTION

!

Use proper lifting equipment and correct lifting

procedures to avoid injury.

Figure 4

NOTE!

DO NOT LIFT BY THE GUIDES! They will bend and

become unusable. For larger doors, a third person or

lifting equipment may be required.

44

Steel jambs

4.4s Position the door

assembly in the opening as

shown in Figure 4, and drill

a 3/8” hole in the jamb to

match up with the upper

hole in the bracket if one is

not there already.

4.5s Using the supplied

rounded head 5/16” carriage

bolts, attach both door

brackets to jambs. Drive a

tek screw into the lowest

small hole through the

bracket and into the jamb.

4.6 After both door brackets are secured to the jambs,

remove temporary clamping devices.

Wood/masonry jambs

4.4w Drill through both

slots. Hole sizes for

masonry or wood may

vary, depending on the

type of fastener required.

Verify the fastener size

before drilling (See

Figure 4).

4.5w Using the supplied

hardware, bolt both

door brackets to jambs.

Use two (2) fasteners

appropriate for your

jamb construction.

ALTERNATIVE FASTENERS

2) WOOD FASTENERS PER BRACKET

5/16” X 1 5/8” LAG BOLT (P/N 502860)

2) MASONRY ANCHORS PER BRACKET

5/16” X 1 1/2” ANCHOR (P/N 508330)

DOOR JAMB (STEEL OR WOOD)

DRILL HOLES

INTO DOOR JAMB

FOR WOOD AND

MASONRY

DOOR NEST

5/16” CARRIAGE BOLT/NUT WITH

TEK-SCREW FOR METAL JAMB

DOOR GUIDE

METAL JAMBS

5/16”-18 CARR.

BOLT & NUT

2 PER BRACKET

WOOD JAMBS

SCREW, HWH,

5/16” X 1 1/8”

2 PER BRACKET

METAL JAMBS

SCREW, HWH SELF-

DRILLING 1/4”-14 X 7/8”

WOOD JAMBS

SCREW, HWH, #14 X 1 1/2”

MOUNTING BRACKET

944_Manual_522000revH_818 color.indd 5 9/10/2018 1:36:46 PM

www.tracrite.com

TRAC-RITE

NOTE!

When installing multiple doors of the same size,

conrm the rst door is operates correctly and is

properly tensioned and apply the same tensioning

method to all doors.

WARNING

!

Care must be taken to secure door so it does not spin

around free, as this may cause personal injuries and

damage to door curtain. Door is free to spin until door

stops and keepers are installed.

5. DOOR TENSIONING:

5.1 Determine the proper number of nest rotations

needed to tension the door, based on the door size

(See Figure 5). Rotate the nest towards the door

opening the appropriate number of turns to tension

the system (See Figure 6).

5.2 Hold the door tightly to prevent unwinding.

Remove the stretch wrap and cardboard strips

wrapped around the door curtain and discard.

NOTE!

DO NOT REMOVE WHITE FELT TAPE on the inside of

the door curtain. It is a door component, NOT packing

material.

5.3 Guide the door curtain carefully into the door

guides and pull it down to approximately waist level.

5.4 Hold the door in position until the door stops

and keepers are installed.

Figure 6

5

up to: 7' 0" 10' 4"

3' 0"

3' 11"

4' 6"

5' 0" 4

5' 1"

7' 11"

8' 0"

9' 0"

10' 8" 2

WIDTH

HEIGHT

3

2

33

Spring Tension (Number of turns)

Figure 5

DOOR

CURTAIN

STRETCH

WRAP & CARDBOARD

STRIPS

ROTATION DIRECTION

TOWARDS WALL

944_Manual_522000revH_818 color.indd 6 9/10/2018 1:36:46 PM

800-448-8979

TRAC-RITE

7. SECURING THE GUIDES

7.1 Pull the door down to within 6” of the floor (See Figure

8). Adjust the door guides so there is 1/8” to 1/4” of play side

to side. If the clearance is too small the door will be hard to

operate. Too much clearance will allow the door to move

side to side excessively and may cause the door to bind.

7.2 Attach the guides to the jambs as follows:

7.2a For steel jambs, secure with supplied Tek screws, using

one fastener per mounting hole.

7.2b For wood jambs, secure with supplied lag bolts, using

one fastener per mounting hole.

7.2c For masonry jambs, install masonry clips along the

guide height, using one clip located next to each mounting

hole on the guide. Make sure the clips are flush with the

back of the guide. Attach each clip to the guide with two (2)

small (#12-14 x 3/4”) supplied Tek screws (See Figure 8).

Drill a hole in the masonry and fasten the clip in place using

supplied anchors.

WARNING

!

Immediately install keepers and door stops. These

devices will prevent the door from rolling up out of the

guides and possibly causing injury.

!CAUTION

Excessive force in operation may cause damage to

the door. If the door binds, adjust guides to allow

appropriate movement.

Figure 7

6. KEEPER AND TOP STOP ASSEMBLY

6.1 Remove whiz nut from each side of door bottom bar

(See Figure 7).

6.2 Attach one keeper to the bottom interior edge of each

side of the door with one (1) 1/4” carriage bolt and whiz nut

that was just removed. On doors with two handles, install

one of the handles as you install the left side keeper (See

Figure 10).

6.3 Tighten whiz nuts to fasten keepers.

6.4 Slide the stops up into position so that the hook tab

mates with the upper hole on the stop (See Figure 7). Fasten

each door stop to each bracket as shown using one (1) 5/16”

track bolt and nut through the lower hole of the stop.

6

BENT CURTAIN LEAD IN

DOOR BRACKET

DOOR STOP

5/16” TRACK BOLT & NUT

DOOR GUIDE

KEEPER

1/4” CARRIAGE BOLT & NUT

BOTTOM OF

DOOR CURTAIN

DOOR AXLE ASSEMBLY NOT SHOWN FOR CLARITY

Figure 8

NON-MASONRY

FASTENING HOLES

MASONRY ANCHOR

MASONRY CLIP

TEK SCREWS #12-14 x 3/4”

MAINTAIN 1/8 TO 1/4” GAP (3-6MM)

BETWEEN GUIDE AND WEAR GUARD

DOOR CURTAIN

DOOR GUIDE

BLOCK JAMB

944_Manual_522000revH_818 color.indd 7 9/10/2018 1:36:46 PM

www.tracrite.com

TRAC-RITE

Figure 11

8.3 Attach the guide warning label (See Figure 11)

to wall next to the guide at eye level. If mounting to

an unfinished surface such as bare masonry or wood,

attach the label to a nonporous surface and use

mechanical fasteners to mount on wall.

8. FINAL ASSEMBLY

8.1 Pull rope handle: Tie a knot in one end of the

rope. Slide the plastic handle onto the rope and pull

the knot up into the handle. Pass the other end of

the rope through the hole in the center of the bottom

edge of the door and tie another knot in the end to

keep the rope from pulling through (See Figure 9).

Figure 10

8.2 Exterior handle: Attach the handle(s) to the bottom

exterior edge of the door with two (2) 1/4” carriage

bolts and whiz nuts provided (See Figure 10). Doors

8’ wide and larger will have two handles.

Figure 9

7

PULL ROPE

HANDLE

EXTERIOR

HANDLE

BOTTOM

ASSEMBLY

944_Manual_522000revH_818 color.indd 8 9/10/2018 1:36:47 PM

800-448-8979

TRAC-RITE 8

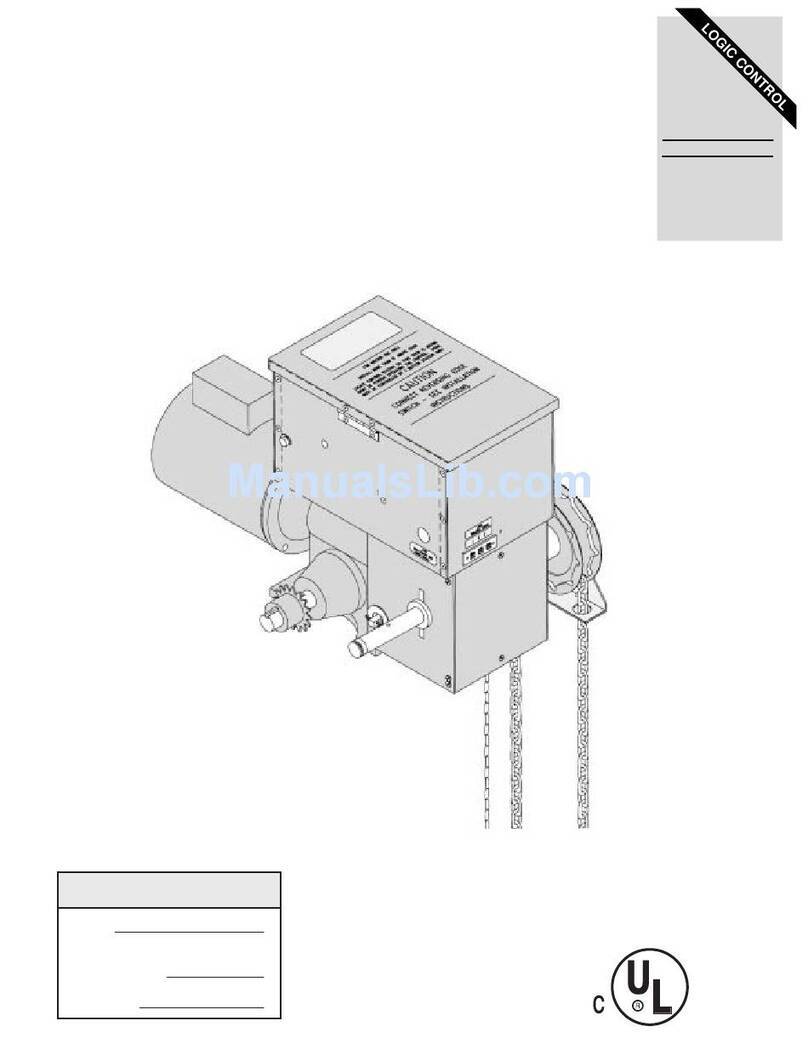

9. OPERATORS:

9.1 Direct-drive operator -- Direct drive chain hoists

can be installed on either side of the door, prior to or

after the door is hung (although there may be clearance

limitations). Please reference Figure 12 for specifics.

9.2 Reduced-drive operator — 4:1 chain hoist

installation as shown in Figure 13.

9.2.1 Align hole in shaft extension with axle hole and

fasten with 1/4" shoulder screw and nylon insert stop

nut.

9.2.2 Assemble onto shaft extension as shown, making

certain 41B36 sprocket is aligned with the sprocket

on the hoist body and the 1/4" x 1/4" key is in place.

Tighten all set screws.

SLIDE INTO DOOR AXLE

HOIST RETAINING

COLLAR WITH

SQUARE HEAD SET

SCREW (SCREW

INTO KEYWAY)

ALIGN WITH AXLE

HOLE AND FASTEN

WITH 1/4"

SHOULDER SCREW

AND NYLON INSERT

STOP NUT

POCKET WHEEL

1/4" SQUARE KEY SHAFT EXTENSION

CHAIN RETAINER

HAND CHAIN NOT

SHOWN FOR

DRAWING CLARITY

Figure 13.

FOR DRAWING CLARITY

HAND CHAIN NOT SHOWN

41B36 SPROCKET

ROLLER CHAIN

MAIN HOIST BODY

WALL "L" BRACKET

SHAFT COLLAR

SHAFT EXTENSION

AXLE

Figure 14.

9.2.3 Attach wall “L” bracket to main hoist body using

either supplied self tapping screw or bolt and nut

supplied using an existing hole in the case. This will

hold the hoist level and keep it from swinging during

operation. Secure “L” bracket to wall.

Components under extreme spring tension

can cause SERIOUS INJURY or DEATH.

Adjustments and repairs must be made by a

qualied door mechanic using proper tools and

instructions. Do NOT attempt to adjust door

tension unless the door is in the “UP” position

and “LOCKED” in place. Winding bar should be

solid steel 1/2” dia. rod or

3/8” X 1/2” at

WARNING

9.2.4 Feed hand chain through and around pocket

wheel. Shorten chain so it does not lay on the floor,

(1' to 3' off floor is ideal). Close chain, making certain

there are no twists in the chain.

9.2.5 Install roller chain around sprockets with

connecting link provided.

9.2.6 Attach chain keeper clip to wall (4' to 5' above

floor).

Figure 12

Figure 13

944_Manual_522000revH_818 color.indd 9 9/10/2018 1:36:47 PM

www.tracrite.com

TRAC-RITE

9

10. ADJUSTING DOOR SPRING TENSION

10.1 A properly tensioned door should be balanced

(does not fall closed or spring open) when opened to

waist level. Step on the handle to close door fully.

10.2 To add tension, insert winding bar in the

rectangular hole in the tension wheel and pull down

until ratchet clicks. Move up slightly until ratchet locks

in place (See Figure 14). If more tension is needed,

move winding bar to the next hole in the tension

wheel and repeat as necessary.

10.3 To remove tension, insert winding bar into

tension wheel and move down 1” to unlock ratchet.

Push the tension lock pin toward wall and raise

winding bar 2”. Release tension lock pin. Move up 1/8

turn until the ratchet locks in place.

10.4 If door has two tensioners be sure to equally add

or remove tension to each side of door.

11. OPTIONAL FIELD INSTALLED

DRAFT STOP OR BRUSH SEAL

11.1 Close the door before installing the draft stop.

Note that with the door down, the curtain may “bow”

slightly near the top; this bowing is normal. For the

draft stop to be effective, it should follow the “bow” in

the door curtain so that it stays in contact across the

entire width of the door curtain. Starting at one end,

attach to header every 9” with appropriate fasteners. If

necessary, trim excess at other end.

11.2 Close the door before installing the brush seal.

Position brush seal so it just touches the flat portion of

the inside of the curtain (See Figure 15). Fasten brush

seal to jamb every 12” with appropriate fasteners.

Figure 15

Components under extreme spring tension can cause SERIOUS INJURY or DEATH. Adjustments and repairs must

be made by a qualied door mechanic using proper tools and instructions. Do NOT attempt to adjust door tension

unless the door is in the “UP” position. Winding bar should be solid steel 1/2” diameter rod or 3/8” x 1/2” at.

WARNING

!

TENSION

LOCK PIN

WINDING

BAR

MORE

TENSION

LESS

TENSION

TENSION

WHEEL

DOOR JAMB

BRUSH SEAL

CURTAIN

DOOR GUIDE

Figure 14

CAUTION

!

Spring Tension is Critical: Improper tensioning of the

spring(s) can result in door damage and reduce the

life of your door. The door should not slam up or down

during operation. No warranty claims will be honored

due to damage caused by improperly tensioned

spring(s).

944_Manual_522000revH_818 color.indd 10 9/10/2018 1:36:47 PM

800-448-8979

TRAC-RITE

12. OPTIONAL INTERIOR LOCK INSTALLATION

12.1 Position door at waist level.

12.2 Assemble components as shown in Figure 16,

noting that two (2) high collar lock washers are placed

over each 1/4” one-way screw to allow the lock bar to

slide freely.

12.3 As the 1/4” screws are being tightened, move the

lock bar to assure that the high collar lock washers

are inside the slots in the lock bar.

13. MAINTENANCE INSPECTION:

Visually inspect the entire door monthly for general

cleanliness and ease of operation.

• Inspect the guides and curtain for wear and/or

accidental damage.

• Inspect all fasteners and anchor bolts for loose,

damaged, or missing parts.

• If door is equipped with a chain hoist

mechanism, inspect it for missing or loose parts.

Cleaning: No specific cleaning procedures are

absolutely required. Clean all parts of the door and

guides as needed.

LUBRICATION: Lubricate the following every six

months. When operating in dusty or wet enviroments

lubrication may be required more often.

• Guides: Open the door. Spray silicone spray or

Zep 45™ onto the door guide runners and inside

the guide.

• Latch: Spray the slide latch with silicone spray to

promote smooth latch operation.

• Chain Hoist Parts: Apply a small amount of oil to

roller chain.

• Spring: To ease friction and prevent squeaking

apply silicone spray or Zep 45™ across the

spring.

10

Figure 16

DOOR CURTAIN

ASSEMBLY

LEFT DOOR GUIDE

CARRIAGE

BOLTS

INT. LOCK STRIKE

HEX NUTS

NUT

LOCK WASHER

SLIDE BAR

ONE-WAY

SCREWS

LOCK COVER

944_Manual_522000revH_818 color.indd 11 9/10/2018 1:36:47 PM

PHONE 800 448 8979

FAX 800 236 8722

WEBSITE www.tracrite.com

ADDRESS 314 Wilburn Road

Sun Prairie, WI 53590 522000 rev H (08/18)

© Trac-Rite

Proprietary Notice

Information contained in this document is copyrighted by Trac-Rite and may not be duplicated in full or part by any person

without prior written approval of Trac-Rite. Its purpose is to provide the user with adequate detailed documentation to

efficiently install a model 944 rolling curtain door.

Door Assembly - Parts Layout

944_Manual_522000revH_818 color.indd 12 9/10/2018 1:36:49 PM

Table of contents

Other Trac-Rite Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Craftsman

Craftsman 139.18458DM owner's manual

Keyautomation

Keyautomation TURBO 250 Instructions and warnings for installation and use

GiBiDi

GiBiDi PASS 6 Instructions for installation

Chamberlain

Chamberlain Security+ 2110 owner's manual

Zap

Zap 8825-R4 installation instructions

Raynor

Raynor Aviator II PREMIUM Series repair parts

Chamberlain

Chamberlain 8550W owner's manual

Chamberlain

Chamberlain LM55 Assembly and operating instructions

Chamberlain

Chamberlain CD 10 instructions

CAME

CAME BK-2200T installation manual

Chamberlain

Chamberlain GH owner's manual

Garage Door Systems

Garage Door Systems ThermaRoll 77 installation instructions