Trac Vac 858-RH Product guide

10/10/2018

Model 858-RH

Operating and

Assembly

Manual

Midwest Equipment Mfg.

5225 Serum Plant Road

Thorntown, IN 46071

1

SAFETY RULES

Remember, any power equipment can cause injury if operated improperly or if the user does not understand how to

operate the equipment. Exercise caution at all times when using power equipment.

This symbol means Attention!!!!! It is used to point out safety precautions.

▪ Read and follow all instructions in this manual before assembly or operation of this equipment. Failure

to comply with these instructions may result in personal injury. Keep this manual for future

reference and for ordering replacement parts.

▪Read this instruction manual carefully. Become familiar with the controls and proper use of this

equipment.

▪Read the engine owners manual and safe operation rules before using this equipment.

▪Never allow children less than 16 years of age to operate the Trac-Vac. Children 16 years and older

should operate only under close parental supervision.

▪Do not allow anyone to operate this equipment without proper instruction.

▪Do not allow passengers to ride on the Trac-Vac or on the towing vehicle.

▪Keep children and pets out of area of operation.

▪Check fuel before starting engine. Do Not fill fuel tank indoors, or while engine is running or hot.

Wipe off any spilled fuel before starting engine.

▪Engine and muffler get HOT! Do Not touch! Keep debris from accumulating on or around engine and

muffler to avoid fire hazard.

▪Allow engine to cool before storing in any enclosed area. Never store Trac-Vac with fuel in tank.

▪Do not operate engine if air cleaner or cover is removed, except for adjustments. Removal of the part

could create a fire hazard.

▪Keep hands, feet, face, long hair and clothing out of inlet and discharge areas. There are ROTATING

BLADES inside these openings.

▪Make certain that all moving parts come to a complete stop before cleaning, repairing or inspection.

Disconnect spark plug wire and keep away from plug to prevent accidental starting.

▪If Trac-Vac should become clogged with debris, SHUT OFF ALL ENGINES and wait until impeller

comes to a complete stop before attempting to remove obstruction. Disconnect spark plug wire to prevent

accidental starting.

▪If excessive vibration occurs while operating your Trac-Vac, stop the engine immediately, disconnect

the spark plug wire and allow all moving parts to stop completely before taking the following steps.

A. Inspect for damage.

B. Repair or replace any damaged parts.

C. Check for loose parts and tighten to assure continued safe operation.

▪Check all hardware periodically to insure safe operation.

▪Check cart cover periodically for wear and replace if worn or damaged.

▪Never operate Trac-Vac without intake hose and exhaust hose attached in proper place.

▪Do Not remove exhaust hose or attempt to empty contents of cart while engine in running.

▪Keep all shields and guards in place and securely attached.

▪Always wear eye protection (safety glasses or goggles) when operating this equipment.

▪Do Not stand behind cart in exhaust discharge area while engine is running.

▪Do Not operate this equipment while intoxicated or while taking medications that could impair reactions or

senses.

▪Operate this equipment at reduced ground speed on rough terrain, along creeks and ditches and on slopes to

prevent tipping or loss of control.

▪Vehicle stability and braking are affected by the addition of this unit. Do not fill the Trac-Vac to its

full capacity without checking the capability of the towing vehicle to safely pull and stop with the unit

attached.

▪Do Not operate on slopes in excess of 10 degrees. STAY OFF OF STEEP SLOPES!

▪Follow the maintenance instructions outlined in this manual.

2

2

3

4

25

23

22

21

Model 858 Trac-Vac Parts List

11-19-14

25

25

1

17 19

20

32

30

25

27

33

28

43

16

29

11

5

14

13

7

9

8

810

12

6

15

24

26

DRAWBAR KIT

PART NO. 10620

18

27

34

35

36

37

38

41

38

39

40

31

42

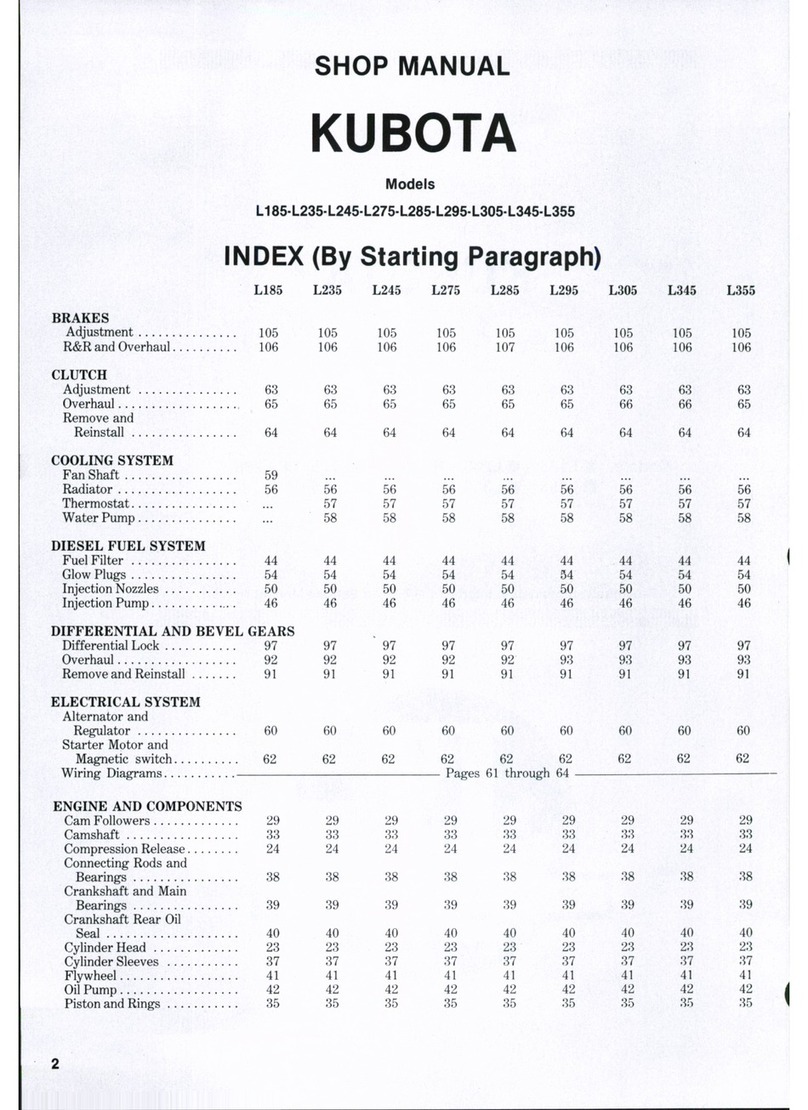

3

Model 858 Trac-Vac Parts List

Key Part No. Description Qty.

1 85810 Frame, 854-RH 1

2 18030 Turbine Housing, RH 1

3 86040 Turbine 1

4 18050 8" Inlet 1

5 85001 Gearbox 1

6 85023 PTO Shaft 1

7 85016 Pulley, MA 55 x 3/4" 1

8 85009 Bearing, 3/4" Pillow Block 2

9 85028 Bearing, 1" Flange 1

10 85029 Bearing, 1" Pillow Block 1

11 85027 Pulley, 8400 x 1" 1

12 85015 Pulley, 8400 x 3/4" 1

13 18104 Shaft, 3/4" 1

14 18109 Shaft, 1" 1

15 85101 Belt, AX25 1

16 85102 Belt, AX40 1

17 85032 Belt Guard, RH 1

18 85812 Guard Mount Tab 1

19 85020 Belt Guard, Outer, RH 1

20 85008 U-Joint Guard 1

21 86101 Exhaust Hose, 8" x 60" 1

22 86060 Hose Connector 1

23 18070 Cart Connector 1

24 88101 Intake Hose, 8" x 90" 1

25 18119 8" Hose Clamp 4

26 58104 Hitch Pin 1

27 85019 Bearing Support 2

28 85026 Support, Belt Guard 1

29 85014 Pulley, AK74 x 1" 1

30 85811 Support Arm, 858 1

31 18125 Support Arm Extension 1

32 18118 8" Hose Support Strap 1

33 85034 Bearing Support, 1" Pillow Block 1

34 10606 Drawbar 1

35 10605 Drawbar, Step-up 1

36 58061 Cart Latch 1

37 3750238 3/8”-24 x 3/8” Set Screw, Turbine 1

38 2501716 1/4” Square Key Stock x 2 1/2” 2

39 1871714 3/16” Square Key Stock x 1 3/4” 2

40 2501712 1/4" Square Key Stock x 1 1/2" 2

41 3121875 5/16”-18 x 3/4" Sq. Head Set 1

42 858** Mount Kit 858 (Tractor Specific) 1

43 ***-8 8" Deck Chute Assembly 1

85888 Hardware Bag, 858 1

45131 Decal, 2" x 8" Trac-Vac white 1

45133 Decal, Warning Stop Engine 1

4

GENERAL INSTRUCTIONS

Your Model 858 Trac-Vac is designed to mount to the drawbar and center link of your compact

tractor. It does not require the use of the lower arms of the 3-point hitch to mount.

Each unit requires a tractor specific mount kit that will need to be installed to the drawbar of

your tractor. Once the kit is installed the frame on the Model 858 bolts to the mount kit via two

1/2" x 1 1/4” hex bolts and locknuts included in the hardware package of the Model 858 Trac-

Vac.

Please refer to instructions in the mount kit in conjunction with this manual to install your Model

858 Trac-Vac.

Once installed be sure that the lower arms of the 3-point hitch are free to move through their full

range of motion as this is usually how the mid-mount deck achieves its movement up and down.

5

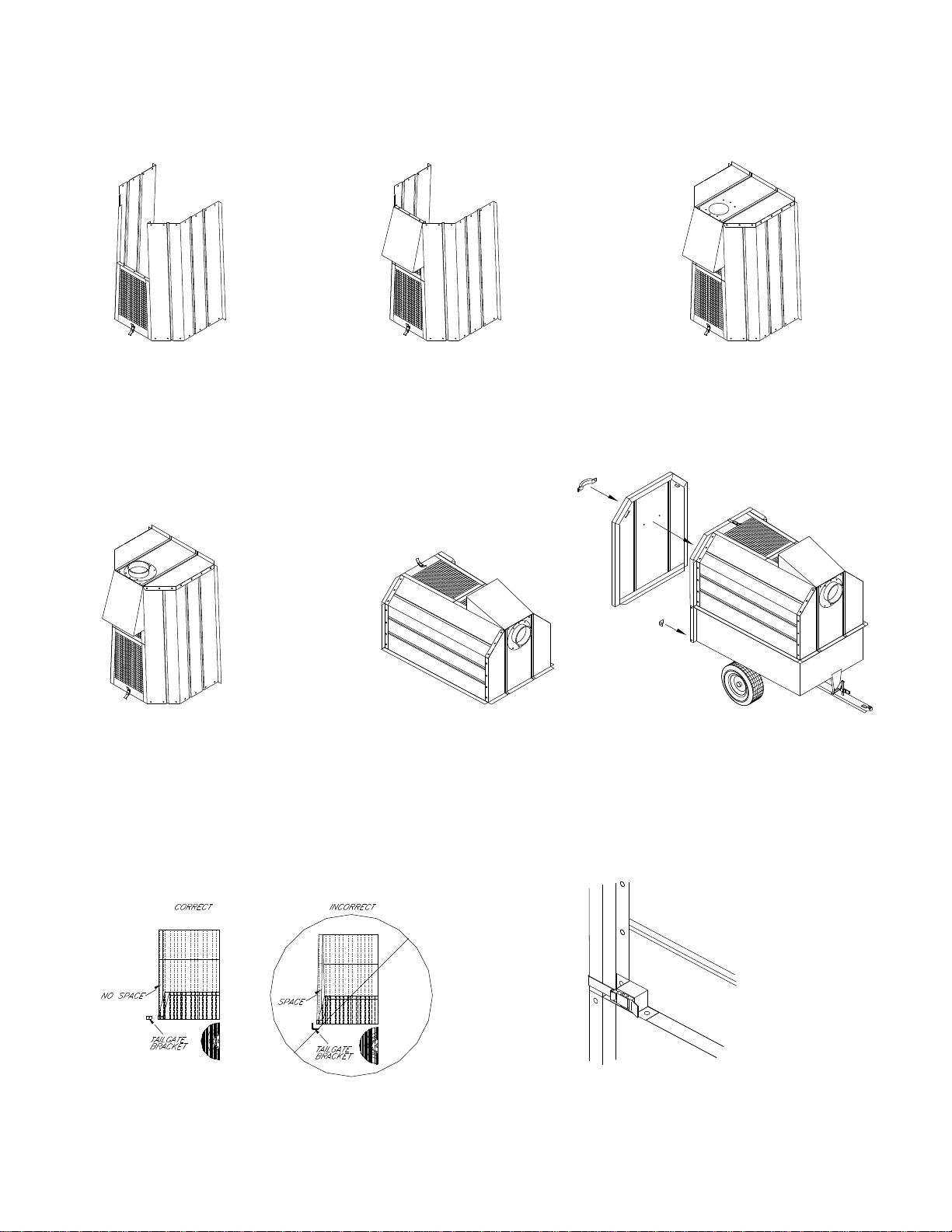

Place side panels on end with decal

outward and about a foot apart at

top. Place screen with latch, ( rear

screen), on end between sides with

latch outward and to the floor.

Attach to sides with 1/4 x 1/2 bolts.

Place screen without latch, (front

screen), on top of rear screen and

between sides. Secure to rear

screen with 1/4 x 1/2 bolts. Slip

deflector between sides and front

screen with tapered end up.

Secure with 1/4 x 1/2 bolts.

Place front on sides with flanges on

outside . Start corner bolts in sides

and screen before tightening. Start

bolts at top & bottom of side panels

and work your way toward center,

with truss head, round, to the outside.

Place cover flat on floor and attach angles

to side panels at rear of cover with angles

on the outside of cover. Secure with 1/4 x

1/2 bolts. Start at the top and second hole

from the bottom, (latch uses bottom hole),

then work towards the center of the panels.

Bolts truss, (round), head should be to the

inside of cart.

Attach handle to tailgate on smooth

side. Place cover on cart. Make sure

the two lower black angle brackets

have been installed on the lower rear

of the cart. Fit tailgate to the cover

using the top latch and lower brackets

only.

Place latch on each side of cart with

tongue of latch to rear. Attach to

side panel and cart with 1/4 x 1/2 bolts.

Place connector, (packed in with vac),

on outside of front with the lip to the

outside. Attach with 1/4 x 1/2 bolts.

Model 280 Cart Cover Assembly Instructions

Gently move cover to the rear to insure

contact between the tailgate and cover,

(along entire contacting surface). Center

1/4 x 1/2 bolts.

drill 9/32" holes. Attach cover with

front on cart. Mark hole locations, and

NOTE: Do not tighten any bolts until the end of construction.

Tighten all hardware.

6

4

2

3

15

6

79

10

12 11 8

Model 280/348L Cart Cover Model 280/368L Cart Cover

Key Part No. Description

1

2

3

4

5

6

7

8

9

10

11

12

28047

28030

28236

28232

28242

28243

28100

28101

28102

28103

28105

28104

Side Panel

Front Panel

Tailgate

Deflector

Front Screen

Rear Screen

Rear Angle RH

Rear Angle LH

Latch Ass'y RH

Latch Ass'y LH

Top Latch

Handle

DescriptionPart No.Key Side Panel

28100

728101

28102

28103

28105

28104

10

12

11

8

9

28059

28035

28238

28235

28240

28241

4

5

6

2

3

1

Rear Angle RH

Latch Ass'y LH

Latch Ass'y RH

Rear Angle LH

Handle

Top Latch

Rear Screen

Front Screen

Front Panel

Deflector

Tailgate

Model 348/368L Cart Covers

1

28156

13 Latch Ass'y LH

14

28157

14 Latch Ass'y RH

13

7

CAUTION!!!!

SPINNING BLADE

MAINTENANCE SCHEDULE

Check engine oil level

Check tire pressure

Check all hardware for tightness

Check cover for wear

Lubricate

Clean

Maintain engine per engine manual

Before each use

After each use

Every season

Before Stoarage

Service Dates

X

X

X

X

X

X

X

MAINTENANCE

DANGER: The Trac-Vac 858 was built to be operated according to the rules for safe

operation as outlined in this manual. Carelessness or error on the part of the operator can

result in serious injury. This unit is capable of amputating fingers or hands and throwing

objects. Failure to comply with the safety instructions could result in serious injury or death.

BEFORE EACH USE

CHECK FOR LOOSE HARDWARE

▪Make a thorough visual check of the unit for any bolts and nuts which may have become loose.

Retighten any loose nuts and bolts

CHECK TIRE PRESSURE

▪Check tire pressure regularly. The recommended tire pressure is printed on the tire.

CHECK ENGINE OIL LEVEL

▪Check oil level before each use. Maintain engine oil as instructed in engine manual.

LUBRICATION

▪Use a light machine oil to lubricate the axle where the hitch tongue pivots and the latch and pivot bolt at

the beginning of each season.

▪Grease or oil wheel bearings, using automotive wheel bearing grease at least once every season.

WARNING: Always stop engine and disconnect spark plug wire before

lubricating, cleaning or before maintenance or repairs.

ENGINE MAINTENANCE

▪Check oil level before each use, maintain engine oil according to the engine manual

▪Service air cleaner after every 25 hours of normal conditions. Under extremely dusty conditions,

clean every few hours. Poor engine performance usually indicates that the air cleaner needs to be

serviced.

▪Clean spark plug and reset gap once every season. It is recommended that the spark plug be

replaced at the start of each season. Check the engine manual for the correct spark plug and gap

specifications.

CLEANING

▪Clean the cart & top after each use. Grass clippings and leaves can mildew and cause damage if

not properly cleaned.

▪Clean the engine regularly with a cloth or brush. Remove all dirt and debris from muffler area.

8

CAUTION!!!!

SPINNING BLADE

Operation

The Model 858 Trac-Vac is designed to operate at a 540 RPM PTO speed. Poor performance will

result if ran much below recommended speed.

1. Inspect area to be vacuumed and pick up all harmful objects and litter. Rocks and other

harmful debris can do serious damage to vacuum assembly and cause bodily injury.

2. For best vacuuming results operate tractor at manufacturers’ recommended speed for best

cutting. If grass is high, reduce ground speed to prevent overloading mower and vacuum.

If grass is wet, wait until dry for best results.

3. When mowing, keep discharge chute to the outside of the cutting area for better cut of

grass and efficient pickup of grass clippings and leaves.

4. Do not overload cart. When it is filled shut off vacuum, disconnect hose at snap

disconnect, remove tailgate and dump.

5. When operating tractor on slope or grade, exercise much caution. Do not cut across grade

or slope. Mow directly up or down hill.

6. Periodically tighten all bolts.

7. Listen for unusual vibration of air turbine. If excessive vibration is present, STOP

vacuum and check for damaged blade.

8. Always shut off tractor engine before servicing vacuum.

9. Replace deflector shield when discharge chute is removed.

10. When removing clogs, SHUT OFF ALL engines.

Maintenance

•Your 858 Trac-Vac has been serviced at the factory for initial operation.

•Bearings should be greased and gearbox oil checked. Gearbox oil level should be to the bottom of

the cross shaft bearing. Overfilling will cause oil to be forced out though the vent. Fill with 90

weight gear lube.

•Check belt tension after the first hour of operation and every ten hours thereafter.

•Adjust inboard belt first by moving jack shaft bearing to the rear, then adjust outboard belt by

moving gearbox forward.

TRAC VAC WARRANTY POLICY

Midwest Equipment Mfg. will repair or replace, free of charge, any part, or parts that are

defective in material or workmanship or both for a period of one year residential use, and 90

day’s for commercial and rental use. The purchaser will pay transportation charges on parts

submitted for replacement under warranty. For warranty service, contact your local dealer from

whom the unit was purchased. There are no other express or implied warranties. Some states do

not allow limitations on how long an implied warranty lasts, and some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation and

exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights, which vary from state to state.

MIDWEST EQUIPMENT MFG.

5225 Serum Plant Rd.,Thorntown, IN 46071

Phone: 1-800-Trac-Vac

Web Page: www.trac-vac.com E-Mail: sales@midmfg.com

Table of contents