4 18-CD32D1-3

Installer’s Guide

9. The furnace may be used for temporary heating of

buildings or structures under construction only when

the following conditions have been met:

a. The furnace venting system must be complete and

installed per manufacturer’s instructions.

b. The furnace is controlled only by a room thermostat

(no field jumpers).

c. The furnace return air duct must be complete and

sealed to the furnace and clean air filters are in

place.

d. The furnace input rate and temperature rise must

be verified to be within nameplate marking.

e. 100% of the furnace combustion air require-

ment must come from outside the structure.

f. The furnace return air temperature range is be-

tween 55 and 80 degrees Fahrenheit.

g. Clean the furnace, duct work, and components upon

substantial completion of the construction process,

and verify furnace operating conditions including

ignition, input rate, temperature rise and venting,

according to the manufacturer’s instructions.

10. This product must be gas piped by a Licensed Plumber

or Gas Fitter in the Commonwealth of Massachusetts.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result

in serious injury, death or property damage. Improper ser-

vicing could result in dangerous operation, serious injury,

death, or property damage.

GENERAL INSTALLATION INSTRUCTIONS

The manufacturer assumes no responsibility for equipment

installed in violation of any code or regulation.

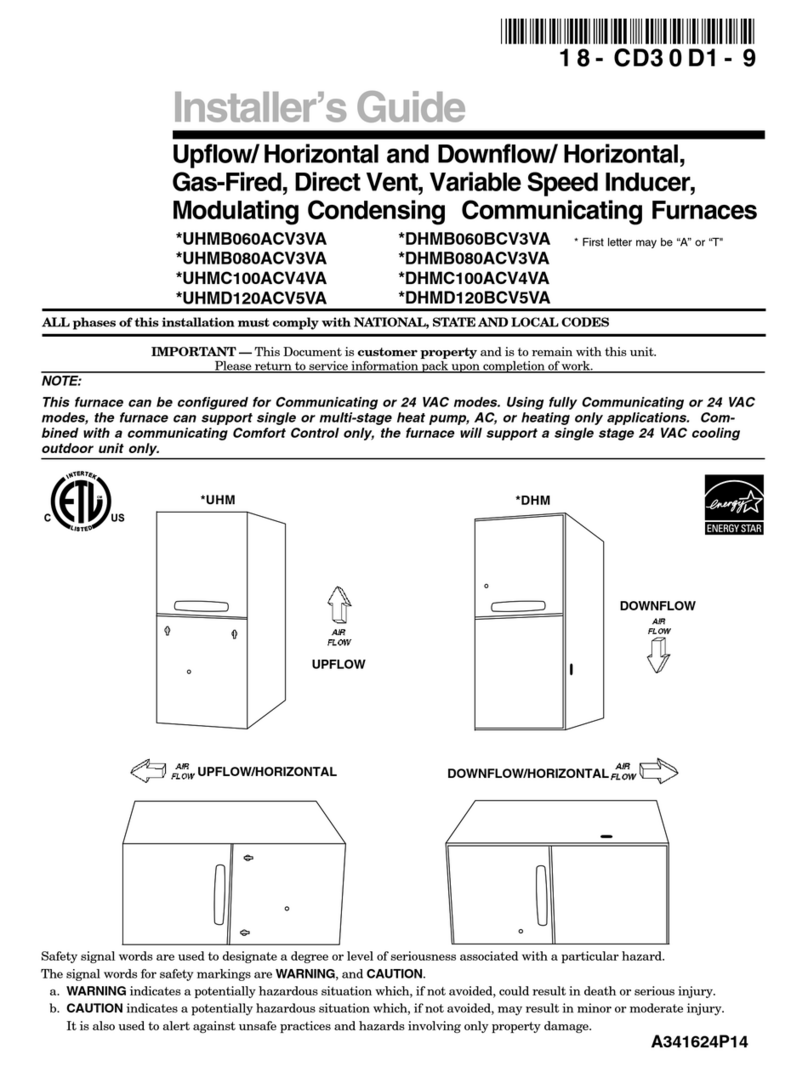

This furnace can be configured for Communicating

or 24 VAC modes. Using fully Communicating or 24

VAC modes, the furnace can support single or multi

stage heat pump, AC, or heating only applications.

Combined with a communicating Comfort Control

only, the furnace will support a single stage 24 VAC

cooling outdoor unit only.

It is recommended that Manual J of the Air Conditioning

Contractors Association (ACCA) or A.R.I. 230 be followed

in estimating heating requirements. When estimating

heating requirements for installation at Altitudes above

2000 ft., remember the gas input must be reduced (See GAS

INPUT ADJUSTMENT).

Material in this shipment has been inspected at the

factory and released to the transportation agency

without known damage. Inspect exterior of carton

for evidence of rough handling in shipment. Unpack

carefully after moving equipment to approximate

location. If damage to contents is found, report the

damage immediately to the delivering agency.

Codes and local utility requirements governing the instal-

lation of gas fired equipment, wiring, plumbing, and flue

connections must be adhered to. In the absence of local

codes, the installation must conform with latest edition of

the National Fuel Gas Code ANSI Z223.1 • National Instal-

lation Code, CAN/CGA B149.1. The latest code may be

obtained from the American Gas Association Laboratories,

400 N. Capitol St. NW, Washington D.C. 20001.

1-800-699-9277 or www.aga.org

These furnaces have been classified as Fan Assisted Com-

bustion system CATEGORY I furnaces as required by

ANSI Z21.47 “latest edition” and CAN/CGA 2.3. Therefore

they do not require any special provisions for venting other

than what is indicated in these instructions. (Category I

defined on page 15).

SAFETY HAZARD

These furnaces are not approved or intended for installa-

tion in manufactured (mobile) housing, trailers, or rec-

reational vehicles. Failure to follow this warning could

result in property damage, personal injury, or death.

LOCATION AND CLEARANCES

The location of the furnace is normally selected by the

architect, the builder, or the installer. However, before the

furnace is moved into place, be sure to consider the follow-

ing requirements:

1. Is the location selected as near the chimney or vent and

as centralized for heat distribution as practical?

2. Do all clearances between the furnace and enclosure

equal or exceed the minimums stated in Clearance

Table on the Outline Drawings.

3. Is there sufficient space for servicing the furnace and

other equipment? A minimum of 24 inches front acces-

sibility to the furnace must be provided. Any access

door or panel must permit removal of the largest com-

ponent.

4. Are there at least 3 inches of clearance between the

furnace combustion air openings in the front panel and

any closed panel or door provided?

5. Are the ventilation and combustion air openings large

enough and will they remain unobstructed? If outside

air is used, are the openings set above the highest snow

accumulation level? (See the Air for Combustion and

Ventilation section.)

6. Allow sufficient height in supply plenum above the

furnace to provide for cooling coil installation, if the

cooling coil is not installed at the time of this furnace

installation.

7. A furnace shall be installed so electrical components

are protected from water.

8. If the furnace is installed in a residential garage, it

must be installed so that the burners, and the ignition

source are located not less than 18 inches above the

floor and the furnace must be located or protected to

avoid physical damage from vehicles.