Traverse 652 User manual

652: Dual-Channel Vacuum Tube

Preamplifier

User Manual

I. WARRANTY & DISCLAIMER

During the warranty period of 2 years from original date of purchase, with proof of purchase,

Traverse Analogue will at no additional cost, repair or replace defective parts with new parts. This

warranty does not extend to any unit that has been damaged or rendered defective because of

accident, misuse, or abuse; by unauthorized modification or repair of the 652.

Vacuum tubes are not included in this warranty but are warranted from manufacturer defect for 90

days from original date of purchase, with proof of purchase.

This manual provides general information, preparation for use, installation, and operating

instructions for the 652. The information contained in this manual is subject to change without

notice. Traverse Analogue makes no warranties, expressed or implied, regarding this manual,

including, but not limited to, the implied warranties of merchantability and fitness for a particular

purpose.

Traverse Analogue shall not be liable for errors contained herein or direct, indirect, special,

incidental, or consequential damages associated with the furnishing, performance, or use of this

material.

This manual and any associated artwork, product designs, and design concepts are subject to

copyright protection. No part of this document may be reproduced, in any form, without prior

written permission from Traverse Analogue.

II. SAFETY PRECAUTIONS

Before using this unit, be sure to carefully read the applicable items of these operating instructions

and the safety precautions. Afterwards, keep them handy for future reference. Take care to follow

the warnings indicated on the unit, as well as in the operating instructions.

1. Water and Moisture –Do not use the unit near any source of water or in excessively moist

environments.

2. Object and Liquid Entry –Care should be taken so that objects do not fall, and liquids are not

spilled, into the enclosure through openings.

3. Ventilation –When installing the unit in a rack or any other location, be sure there is adequate

ventilation over, below, and beside the unit. Improper ventilation can cause overheating and

damage the unit. It is recommended that at least 1RU of space be left atop and below the unit.

4. Heat –The unit should be situated away from heat sources, or other equipment that produce

heat.

5. Power Sources –The unit should be connected to a power supply only of the type described in the

operating instructions, or as marked on the unit.

6. Power Cord Protection –AC power supply cords should be routed so that they are not likely to be

walked on or pinched by items placed upon or against them. Pay attention to cords at plugs,

receptacles, and the point where they exit from the unit. Never take hold of the plug or cord if your

hand is wet. Always grasp the plug body when connecting or disconnecting it; do not pull from the

cable.

7. Grounding of the Plug –This unit is equipped with a 3-wire grounding type plug, having a third

grounding pin. This plug will only fit into a grounding-type power outlet. This is a safety feature. If

you are unable to insert the plug into the outlet, contact your electrician to replace your obsolete

outlet, or correct facility wiring. Do not cut or remove the third pin.

8. Cleaning –The unit should be cleaned only as recommended by the manufacturer. A slightly

damp cloth should be used for the front panel. There is no need to clean the inside of the unit,

unless performed by an appropriate technician.

9. Damage Requiring Service –The unit should be serviced by qualified service personnel, as

suggested by the manufacturer.

10. Servicing –The user should not attempt to service the unit beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel, as

suggested by the manufacturer.

III. TABLE OF CONTENTS

THE 652: AN OVERVIEW 1

SPECIFICATIONS 2

OPERATION & CONTROLS 3 - 4

POWER REQUIREMENTS & MAINTENANCE 5

THE 652: AN OVERVIEW

Introducing the all new dual-channel vacuum tube preamplifier with mic, line, and instrument

inputs: the 652!

The unique circuit provides up to 60 dB of gain using the vacuum tube input stage, followed by a

master attenuation control in the discrete output buffer stage. Want a clean yet musical replication

of the source? How about the creamy saturation of an esoteric vintage preamplifier?

The 652's gentle drive characteristics allow for a broad tonal palette, depending on the gain

selection and how hard you hit it with signal. It can be used with all types of microphones (including

ribbons) and the line level input pad allows you to add warmth and coloration to any track from a

digital audio workstation. The switched ¼” DI jack on the front is perfect for the direct recording of

unbalanced instruments.

Vintage sound, feel, and vibe. Hand-soldered and crafted with passion. The ultimate stereo tube

preamp for the modern studio.

1

SPECIFICATIONS

Input Impedance

300 ohms, 1200 ohms (Mic)

15K ohms (Line)

4.7 Meg ohms (1/4” DI)

Maximum Input Level

+6 dBu (XLR, 1200R)

-8 dBu (1/4” DI)

Maximum Output Level

+18 dBu

XLR Output Impedance

< 65 ohms

Recommended Minimum Load

300 ohms

Frequency Response

18Hz - 50kHz (-3 dB)

High Pass Filter Characteristics

-3 dB @ 80Hz, 20 dB/decade

Maximum Gain

60 dB (XLR, 1200R)

EIN Noise

-126 dBu (20Hz - 30kHz)

-128 dBu (A-weighting)

Noise Factor

5 dB ref 150 ohms (20Hz - 20kHz)

THD+N

+2 dBu to +18 dBu, 0.03% to 2%

VU Meter Calibration

0 VU = +4 dBu

Tube Per Channel

1x 12AX7

Phantom Power

+48V DC Regulated

Power Sequencing

Soft start for +/-12V DC supply

Soft start for +260V DC supply

30s turn-on delay for output relays

Output relays mute immediately at power-

down

Power Requirements

110-120VAC/220-240VAC, 50/60Hz, 33VA max

Power Consumption

24 Watts

Dimensions

19” W x 3.5” H x 12.25” D (2U)

Weight

16 lbs.

2

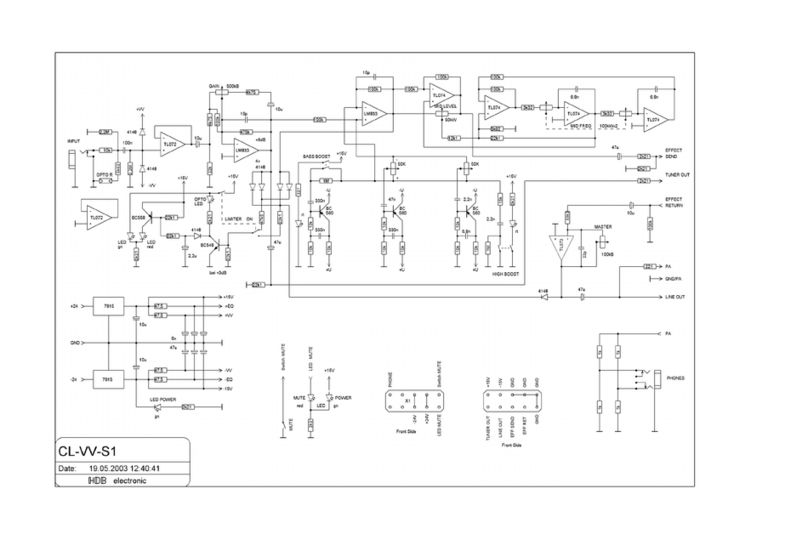

OPERATION & CONTROLS

The toggle switches are in their default setting when positioned “down” as shown.

GAIN (dB) - A 12-position rotary switch controls the gain. With the MASTER control at maximum, the

net gain will be adjustable from 5dB –60dB in 5 dB steps (XLR, 1200R).

VU METER - A Sifam VU meter allows for traditional monitoring of the signal.

MASTER -A potentiometer in the output stage attenuates the signal, from the specified gain on the

GAIN (dB) switch, to zero.

INPUT Z - The XLR input impedance can be switched between 300 ohms and 1200 ohms.

SOURCE - The XLR inputs can be switched for use with microphone or line level signals.

1/4" JACK -The switched DI jack is a high impedance, unbalanced input for instruments.

PHASE -The output signal polarity can be flipped 180 degrees by selecting REV.

HPF -The high pass filter may be engaged by selecting 80Hz.

3

The center portion of the front panel is divided between both channels. The two left-hand toggle

switches are for the left channel, and the two right-hand switches are for the right channel. The

toggle switches are in their default setting when positioned “down” as shown.

POWER -This switch turns the preamplifier on and off. The power LED and VU meters will illuminate

when the unit is in operation.

PHANTOM -Regulated +48V is available on the rear XLR inputs by engaging the front panel switch.

To prevent possible microphone damage, always ensure the switch is in the “OFF” position before

making connections. Phantom power is not available on the XLR inputs when the source switch is

set to LINE.

METER -Allows you switch the meter in and out of circuit.

REAR PANEL I/O - The rear panel of the preamplifier simply consists of input and output XLR jacks

for each channel and the AC IEC power receptacle.

4

POWER REQUIREMENTS &

MAINTENANCE

WARNING: Lethal voltages are stored inside the 652 and remain for some time after the power

has been disconnected. Refer all servicing to qualified personnel.

AC RECEPTACLE –This unit is equipped with an IEC power-entry connector on the rear panel and

accepts 120VAC and 240VAC. Ensure the correct AC voltage is applied (and set internally) before

applying power. A fuse is located inside the rear IEC receptacle and must only be replaced with a 5 x

20MM 250VAC 1A Slow-Blow. If this occurs, please check with a qualified technician.

NOTE: The 652 utilizes various control circuitry, including a gradual ramp of the supply rails and an

output-muting relay. It is normal for the 652 to take approximately 30 seconds of warm up time

before any signal can pass.

Your 652 comes out of the box calibrated and characterized for best performance. The only user

maintenance that generally needs to be carried out is tube replacement from time to time. Traverse

Analogue supplies each unit with a pair of 12AX7s (selected for low noise and microphonics). Tubes

can last for thousands of hours, but if you notice the preamplifier is becoming excessively noisy after

prolonged use, they may need to be replaced.

Please contact your dealer for tube options or contact Traverse Analogue to purchase a set of

replacements.

To replace the tubes:

Ensure the 652 is unplugged and unscrew the top cover.

Gently rock the tubes in a circular motion while pulling outwards to release them from the

sockets.

Replace the tubes in the reverse manner, taking caution not to stress the circuit board, and

then replace the top cover.

WARNING: Do NOT attempt to substitute other tube types. 12AX7/ECC83/7025 only.

If you experience a technical issue, please contact your dealer or Traverse Analogue directly for

customer support.

5

Traverse Analogue

28 Mainsail Drive

Conception Bay South, NL

A1W 2G4, Canada

info@traverseanalogue.com

Copyright © 2020 Traverse Analogue. All Rights Reserved.