Treetech TM1 User manual

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 2

Temperature Monitor

Table of contents

1FOREWORD.................................................................................................................................................... 6

1.1 LEGAL INFORMATION................................................................................................................................................ 6

1.2 PRESENTATION........................................................................................................................................................ 6

1.3 TYPOGRAPHICAL CONVENTIONS.................................................................................................................................. 6

1.4 GENERAL AND SAFETY INFORMATION........................................................................................................................... 6

Safety Symbols ..................................................................................................................................................... 7

General Symbols................................................................................................................................................... 7

Minimum profile recommended for the TM1/TM2 operator and maintainer ..................................................... 7

Environmental and voltage conditions required for installation and operation .................................................. 8

Instructions for test and installation .................................................................................................................... 8

Cleaning and decontamination instructions......................................................................................................... 9

Inspection and Maintenance instructions ............................................................................................................ 9

1.5 TECHNICAL ASSISTANCE .......................................................................................................................................... 10

1.6 WARRANTY TERM .................................................................................................................................................. 11

1.7 REVISION CONTROL................................................................................................................................................ 12

2INTRODUCTION.............................................................................................................................................13

2.1 MAIN FEATURES.................................................................................................................................................... 13

2.2 OPTIONAL FEATURES .............................................................................................................................................. 15

2.3 OPERATION PHILOSOPHY......................................................................................................................................... 16

3OPERATION...................................................................................................................................................19

3.1 INITIAL SETTINGS ................................................................................................................................................... 19

3.2 FUNCTION OF KEYS ................................................................................................................................................ 21

3.3 CONSULTATION SCREENS......................................................................................................................................... 21

TM1 Consultation Screens.................................................................................................................................. 21

Consultation Screen TM2 ................................................................................................................................... 23

3.4 COMMANDS ......................................................................................................................................................... 24

4PROJECT AND INSTALLATION ........................................................................................................................26

4.1 SYSTEM TOPOLOGY ................................................................................................................................................ 26

4.2 INPUTS AND OUTPUTS ............................................................................................................................................ 26

4.3 PROJECT AND INSTALLATION .................................................................................................................................... 28

RTD Temperature Sensors .................................................................................................................................. 29

Serial Communication Ports RS485 .................................................................................................................... 30

Analogic Outputs................................................................................................................................................ 31

Current Transformers ......................................................................................................................................... 31

Forced Cooling Control ....................................................................................................................................... 33

4.4 TYPICAL APPLICATION DIAGRAMS ............................................................................................................................. 41

4.5 MECHANICAL INSTALLATION .................................................................................................................................... 46

5PARAMETERIZATION.....................................................................................................................................47

5.1 PROGRAMMING .................................................................................................................................................... 47

5.2 ACCESS TO THE PROGRAMMING MENU...................................................................................................................... 48

5.3 ACCESS TO SUBMENUS ............................................................................................................................................ 49

Submenu LNG ..................................................................................................................................................... 50

Submenu CLK...................................................................................................................................................... 50

Submenu ALM .................................................................................................................................................... 51

Submenu CNF ..................................................................................................................................................... 53

Submenu TRF...................................................................................................................................................... 61

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 3

Temperature Monitor

Submenu FAN ..................................................................................................................................................... 65

Submenu LTC ...................................................................................................................................................... 69

Submenu LOG..................................................................................................................................................... 71

5.4 TYPICAL ADJUSTS ................................................................................................................................................... 73

6START-UP PROCEDURE FOR PUTTIN EQUIPMENT IN OPERATION .................................................................74

7TROUBLESHOOTING......................................................................................................................................80

7.1 THE DEVICE DISPLAYS SELF-DIAGNOSIS MESSAGES ON THE DISPLAY ................................................................................... 80

7.2 TM1/TM2 READS INCORRECT VALUES FOR TEMPERATURES........................................................................................... 87

7.3 TM1/TM2 READS INCORRECTLY VALUES FOR LOAD CURRENTS ....................................................................................... 88

7.4 TM1/TM2 INDICATES INCORRECT VALUES FOR WINDING TEMPERATURES ........................................................................ 88

7.5 TM1 DOES NOT COMMUNICATE WITH THE DATA ACQUISITION SYSTEM............................................................................. 88

7.6 REMOTE READING THROUGH ANALOG OUTPUT INCORRECT............................................................................................. 89

7.7 TM1/TM2 DOES NOT CORRECTLY ACTIVATE THE FORCED COOLING ................................................................................. 89

8ATTACHMENTS .............................................................................................................................................90

8.1 ATTACHMENT A .................................................................................................................................................... 90

8.2 ATTACHMENT B..................................................................................................................................................... 91

8.3 ATTACHMENT C..................................................................................................................................................... 92

8.4 ATTACHMENT D .................................................................................................................................................... 93

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 4

Temperature Monitor

List of figures

FIGURE 1–TEMPERATURE MONITORS TM1 AND TM2 ............................................................................................................... 14

FIGURE 2–TEMPERATURE MEASUREMENTS OF LTC, TRANSFORMER AND TEMPERATURE DIFFERENTIAL ................................................. 17

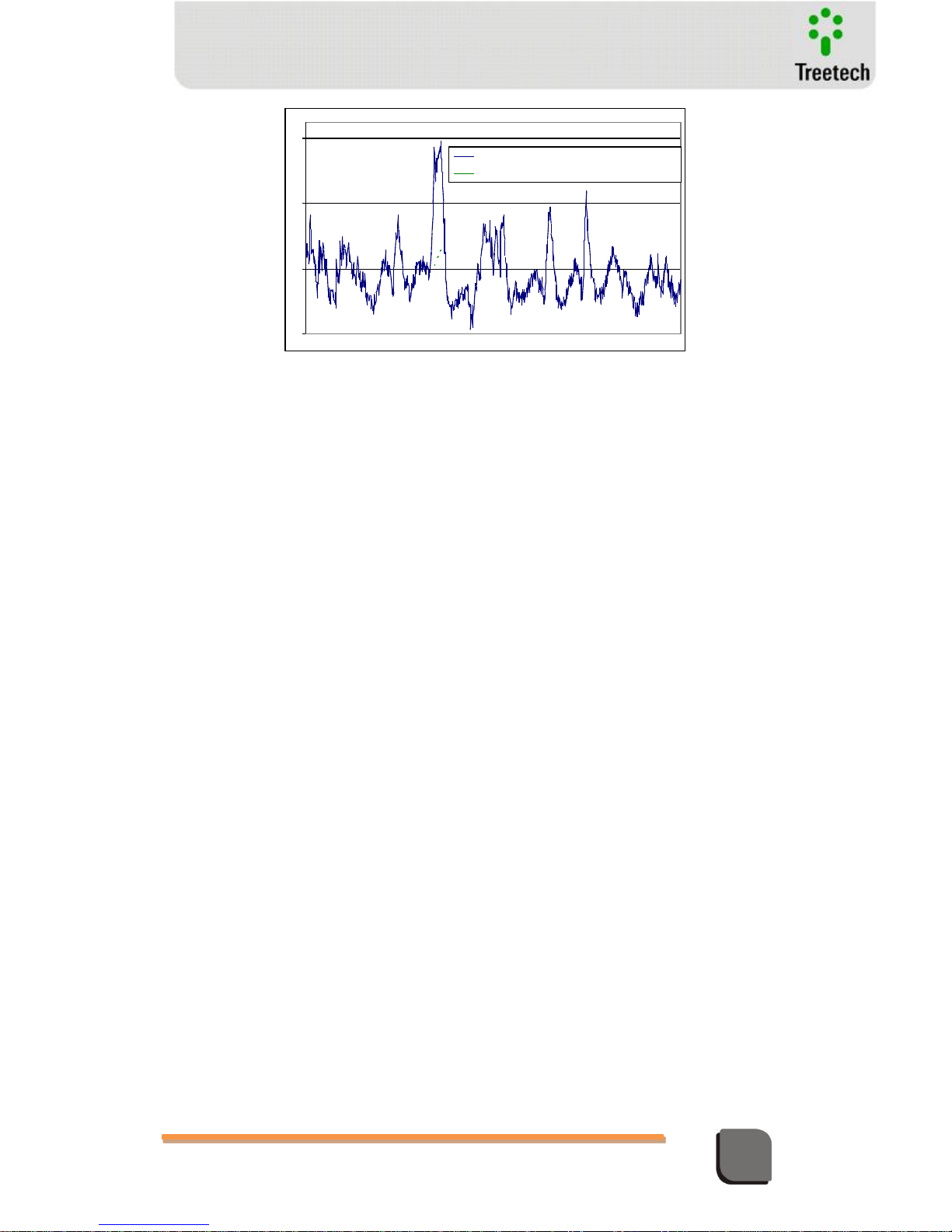

FIGURE 3-INSTANTANEOUS AND FILTERED TEMPERATURE DIFFERENTIALS ....................................................................................... 18

FIGURE 4–TEMPERATURE INDICATIONS .................................................................................................................................... 19

FIGURE 5–SIGNALING LEDS ON TEMPERATURE MONITOR TM1 ................................................................................................... 20

FIGURE 6–SIGNALING LEDS ON TEMPERATURE MONITOR TM2 ................................................................................................... 20

FIGURE 7–SELF-DIAGNOSTIC INDICATIONS ................................................................................................................................ 21

FIGURE 8–BLOCK DIAGRAM................................................................................................................................................... 26

FIGURE 9–DETAIL SHIELD CONNECTION OF RTD SENSOR ............................................................................................................ 30

FIGURE 10 –SHIELD CONNECTION OF SERIAL COMMUNICATION...................................................................................................... 31

FIGURE 11 –CONNECTION DETAILS OF CURRENT TRANSFORMERS DIRECTLY TEMPERATURE MONITORS .................................................. 32

FIGURE 12 –CONNECTION DETAILS OF CURRENT TRANSFORMERS TO TEMPERATURE MONITORS PREPARED FOR EXTERNAL CILIP-ON CTS...... 33

FIGURE 13 –COMMAND OF 4EQUAL FORCED COOLING GROUPS SHIFTING THE OPERATION OF GROUPS ................................................. 35

FIGURE 14 –COMMAND OF 1FORCED COOLING GROUP WITH PUMPS AND 3EQUAL GROUPS WITH FANS SHIFTING THE OPERATION OF FAN

GROPS ........................................................................................................................................................................ 36

FIGURE 15 –COMMAN OF 2EQUAL FORCED COOLING GROUPS WITH PUMPS AND 2EQUAL GROUPS WITH FANS,WITH INDEPENDENTE SHIFTING

FOR THE OPERATION OF THE PUMP GROUPS AND THE FAN GROUPS.......................................................................................... 37

FIGURE 16 –COMMAND OF 4EQUAL FORCED COOLING GROUPS IN 2TEMPERATURE STAGES,WITH TIMER FOR MOTORS START AND SHIFTING

THE GROUPS ................................................................................................................................................................ 39

FIGURE 17 –COMMAND OF 2EQUAL FORCED COOLING GROUPS WITH COMMAND REDUNDANCY ......................................................... 40

FIGURE 18 –OPTION 1–2RTDS WITH 3WIRES......................................................................................................................... 41

FIGURE 19 -OPTION 2–1RTD WITH 4WIRES .......................................................................................................................... 42

FIGURE 20 –OPTION 3–1RTD WITH 3WIRES,RTD A............................................................................................................... 43

FIGURE 21 –OPTION 4–1RTD WITH 3WIRES,RTD B............................................................................................................... 43

FIGURE 22 –CONNECTION TM1/TM2..................................................................................................................................... 44

FIGURE 23 –CONNECTION TM1 /MT2 ................................................................................................................................... 44

FIGURE 24 –CONNECTION MT1 /TM2 ................................................................................................................................... 45

FIGURE 25 –CONNECTION TM1 /SYNCHRONISM SIGNAL IRIG-B .................................................................................................. 45

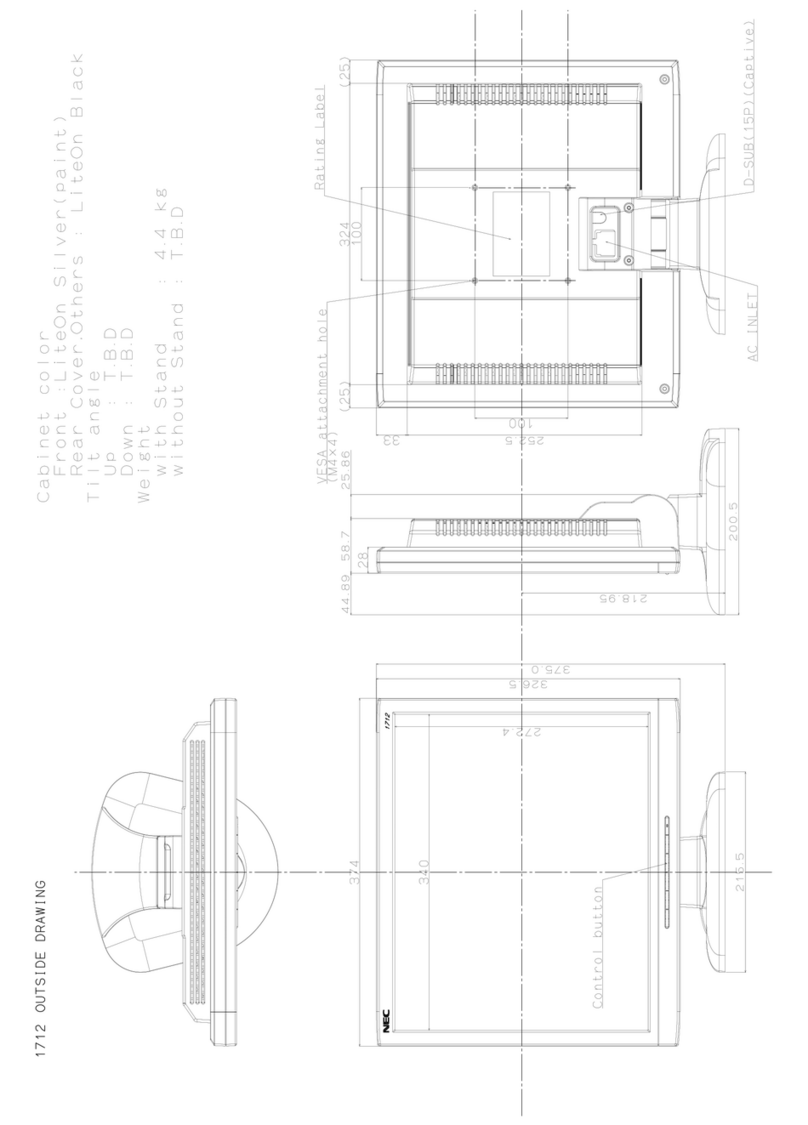

FIGURE 26 –DIMENSIONS OF TM1 AND TM2 ........................................................................................................................... 46

FIGURE 27 –SELF-DIAGNOSTIC INDICATIONS .............................................................................................................................. 80

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 5

Temperature Monitor

List of Tables

TABLE 1–OPERATING CONDITIONS ............................................................................................................................................ 8

TABLE 2–REVISION CONTROL ................................................................................................................................................. 12

TABLE 3–TM1/TM2 INPUTS................................................................................................................................................. 27

TABLE 4-TM1/TM2 OUTPUTS............................................................................................................................................... 28

TABLE 6–DIGIT 1FAILURES .................................................................................................................................................... 81

TABLE 7–DIGIT 2FAILURES.................................................................................................................................................... 82

TABLE 8–DIGIT 3FAILURES.................................................................................................................................................... 84

TABLE 9–DIGIT 4FAILURES .................................................................................................................................................... 86

TABLE 10 –INCORRECT READING OF VALUES FOR TEMPERATURES ................................................................................................... 87

TABLE 11 –INCORRECTLY VALUES FOR LOAD CURRENTS ................................................................................................................ 88

TABLE 12 –INCORRECT VALUES FOR WINDING TEMPERATURES....................................................................................................... 88

TABLE 13 –NO COMMUNICATION BETWEEN TM1 AND DATA ACQUISITION SYSTEM.......................................................................... 88

TABLE 14 –REMOTE READING THROUGH ANALOG OUTPUT INCORRECT ............................................................................................ 89

TABLE 15 -INCORRECT ACTIVATE THE FORCED COOLING ................................................................................................................ 89

TABLE 16 –COMPATIBILITY BETWEEN FIRMWARES....................................................................................................................... 93

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 6

Temperature Monitor

1Foreword

1.1 Legal Information

The information contained in this document is subject to changes without prior notice.

This document belongs to Treetech Sistemas Digitais Ltda. and may neither be copied,

transferred to third parties nor used without express authorization, in terms of law 9.610/98.

Disclaimer:

Treetech Sistemas Digitais reserves the right to make changes without prior notice in all

products, circuits and functionalities described herein with the aim of improving their

reliability, function or design. Treetech Sistemas Digitais does not assume any liability resulting

from application or use of any product or circuit described herein, and does not transmit any

licenses or patents under its rights, not even third party rights.

Treetech Sistemas Digitais Ltda. may own patent or other types of registrations and intellectual

property rights described in the content of this document. Possession of this document by any

person or entity does not give such person or entity any right over these patents or

registrations.

1.2 Presentation

This manual presents all the recommendations and instructions for installation, operation and

maintenance of the Temperature Monitor –TM1/TM2.

1.3 Typographical Conventions

Throughout this text, the following typographical conventions were adopted:

Bold: Symbols, terms and words that are in bold have greater contextual importance.

Therefore, pay attention to these terms.

Italics: Terms in foreign language, alternative or with their use outside the formal situation are

written in italics.

1.4 General and Safety Information

This section presents relevant aspects of safety, installation and maintenance of the TM1/TM2.

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 7

Temperature Monitor

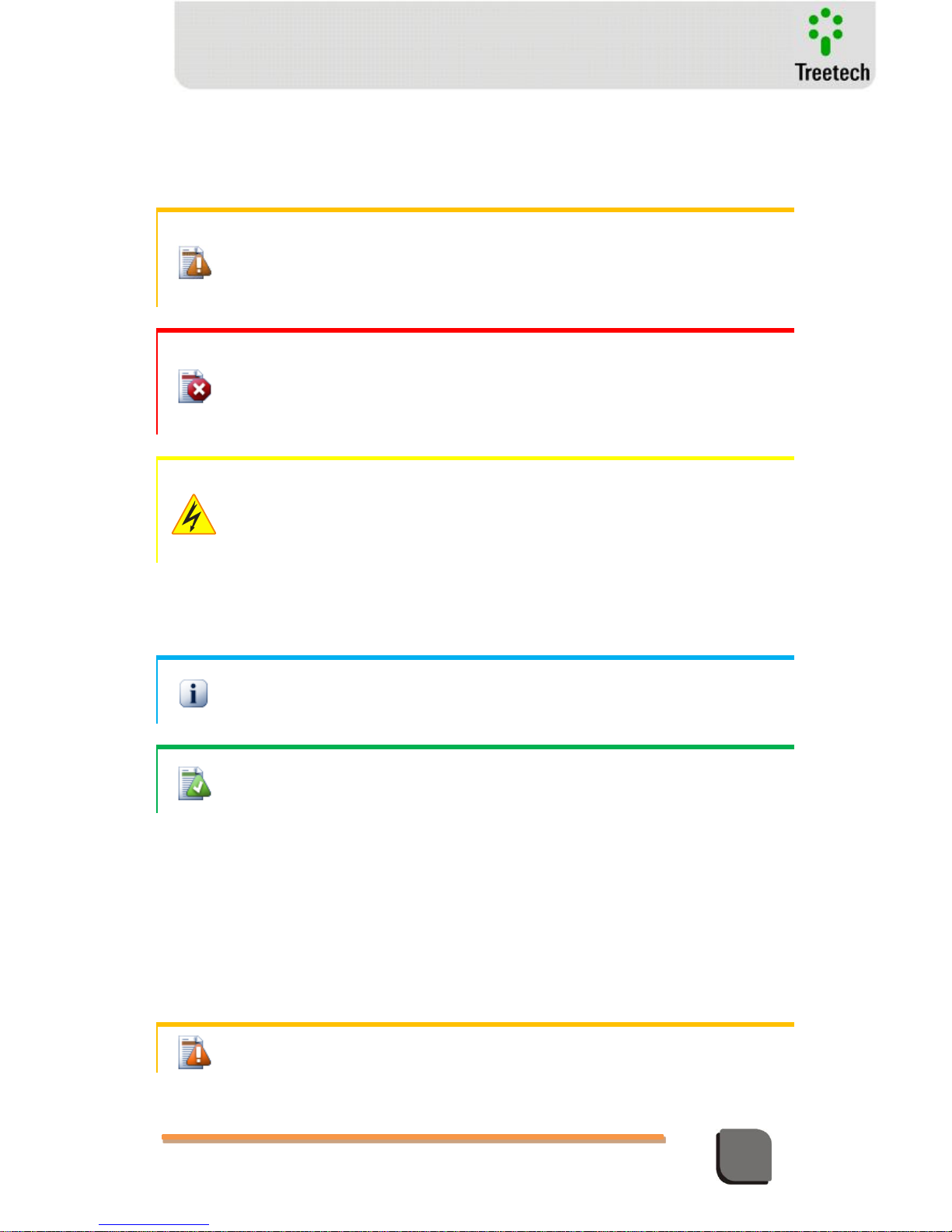

Safety Symbols

This manual uses three types of risk classification, as shown below:

Caution

The Caution symbol is used to alert the user of a potentially hazardous operating or maintenance

procedure that demands greater caution in its conduction. There may be minor or moderate injuries, as

well as damages to the equipment.

Warning

The Warning symbol is used to alert the user of a potentially hazardous operating or maintenance

procedure in which extreme caution must be taken. There may be serious injuries or death. Possible

damages to the equipment are irreparable.

Electric Shock Hazard

The Electric Shock Hazard symbol is used to alert the user of an operating or maintenance procedure

that may result in electric shock if not strictly observed. There may be minor, moderate, serious injuries

or death.

General Symbols

This manual uses the following general symbols:

Important

The Important symbol is used to highlight relevant information.

Tip:

The Tip symbol represents instructions that facilitate use and access of functions in the TM1/TM2.

Minimum profile recommended for the TM1/TM2 operator and maintainer

Installation, maintenance and operation of equipment in electric power substations require

special cares and, therefore, all recommendations of this manual, applicable standards, safety

procedures, safe work practices and good judgment must be used during all handling stages of

the Temperature Monitor (TM1 and TM2).

For use of this manual, an authorized and trained person has knowledge of the inherent risks –

both electrical and environmental –involved in handling the TM1 and TM2.

Only authorized and trained personnel –operators and maintainers –should handle this equipment.

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 8

Temperature Monitor

a) The operator or maintainer must be trained and authorized to operate,

ground, turn on and turn off the TM1/TM2, following maintenance procedures

according to the safety practices established, under the sole responsibility of the

TM1/TM2 operator and maintainer;

b) Be trained in the use of IPEs, CPEs and first-aid;

c) Trained in the working principles of the TM1 and TM2, as well as its

configuration.

d) Follow regulatory recommendations regarding interventions in any type of

equipment included in an Electric Power System.

Environmental and voltage conditions required for installation and operation

The table below lists important information on the environmental and voltage requirements:

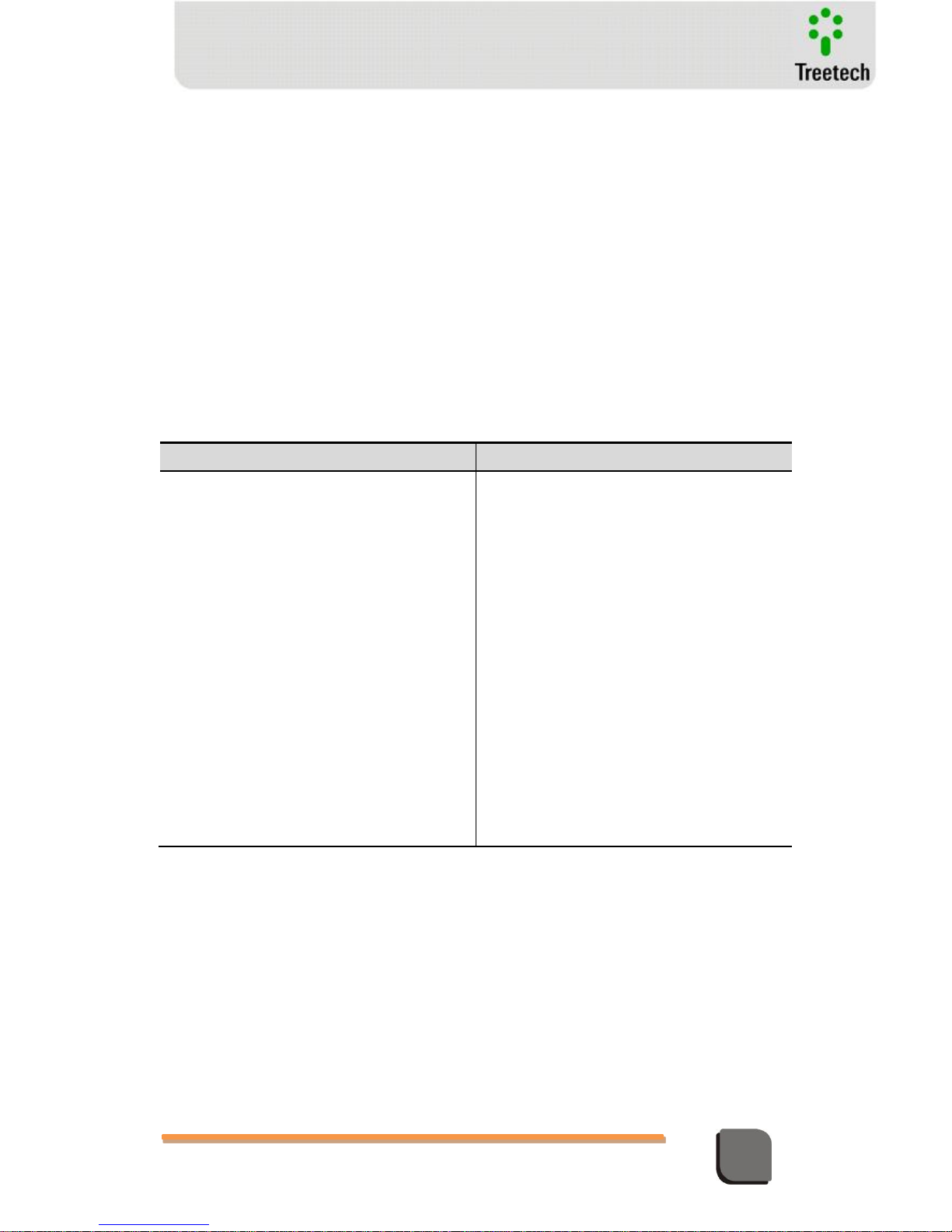

Table 1 –Operating Conditions

Condition

Interval/Description

Application

Equipment for sheltered use in substations, industrial

environments and similar.

Internal/External Use

Internal Use

Degree of Protection (IEC 60529)

IP 20

Altitude* (IEC EN 61010-1)

Up to 2000 m

Temperature (IEC EN 61010-1)

Operation

-40 °C to +85 °C

Storage

-50 °C to +95 °C

Relative Humidity (IEC EN 61010-1)

Operation

5% to 95% –Uncondensed

Storage

3% to 98% –Uncondensed

MAINS Supply Voltage Fluctuation (IEC EN 61010-1)

Up to ±10% of the Rated voltage

Overvoltage (IEC EN 61010-1)

Category II

Level of Pollution (IEC EN 61010-1)

Level 2

Atmospheric Pressure** (IEC EN 61010-1)

80 kPa to 110 kPa

* Altitudes greater than 2000 m already have successful applications.

* Pressures of less than 80 kPa already have successful applications.

Instructions for test and installation

This manual must be available to those responsible for installation, maintenance and users

of the Temperature Monitor –TM1/TM2.

To guarantee user safety, equipment protection and correct operation, the following minimum

cares must be followed during the TM1/TM2 installation and maintenance:

1. Read this manual carefully before installation, operation and maintenance of

the TM1/TM2. Errors in installation, maintenance or adjustments of the TM1/TM2

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 9

Temperature Monitor

can cause undue operations of the tap changer in load, unsatisfactory voltage

regulation, undue alarms or pertinent alarms may also fail to be emitted.

2. The installation, adjustments and operation of the TM1/TM2 must be done by

personnel trained and acquainted with the electric motors, power transformers,

tap changers on load or voltage regulators, control devices and control circuits of

substation equipment.

3. Special attention must be paid to installation of the TM1/TM2, including the

type and size of the cables and terminal strips used, as well as the procedures

for commissioning, including correct parameterization of the equipment.

The TM1/TM2 must be installed in a sheltered environment (a panel without doors in a control room or

in a closed panel, in cases of outdoor installation) where the temperature and humidity specified for the

equipment are not exceeded.

Do not install the TM1/TM2 near sources of heat like heat resistors, incandescent lamps and devices

with high power or with heat dissipaters. Its installation near ventilation orifices or where it can be

affected by forced air flow, like outlet or inlet of cooling fans or forced ventilation ducts, is not

recommended.

On conducting dielectric strength tests on the wiring (applied voltage), the ground cables connected to

terminal 17 of the TM1/TM2 must be disconnected in order to prevent destruction of the protections

against overvoltage existing inside the device due to application of high voltages for a long period (e.g.:

2 kV for 1 minute).

Cleaning and decontamination instructions

Take care when cleaning the TM1/TM2. Use ONLY a cloth wet with soap or detergent diluted

in water to clean the cabinet, front plate or any other part of the equipment. Do not use

abrasive materials, polishers or aggressive chemical solvents (like alcohol or acetone) on any of

its surfaces.

Turn off and unplug the equipment before cleaning any of its parts.

Inspection and Maintenance instructions

The following observations must be followed for inspection and maintenance of the TM1/TM2:

If the panel where the TM1 / TM2 was installed has a window , use a G20 film - or higher - to avoid

direct incidence of sunlight ( UV ) at the equipment . Even if the glass of this window is dark, such

procedure is necessary.

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 10

Temperature Monitor

Do not open the equipment. In it, there are no parts reparable by the user. This should be done by the

Treetech technical assistance, or by technicians accredited by it.

This equipment is completely maintenance-free, being that visual and operational inspections,

periodical or not, may be conducted by the user. These inspections are not mandatory.

Opening of the TM1/TM2 at any time will imply in loss of the product warranty. In cases of undue

opening of the equipment, Treetech will also not be able to warrant its correct functioning, regardless of

the warranty period having expired or not.

All parts of this equipment must be supplied by Treetech, or by one of its accredited suppliers,

according to its specifications. If the user wishes to purchase it otherwise, he must strictly follow

Treetech’s recommendations for this. This way, the performance and safety for the user and the

equipment will not be compromised. If these specifications are not followed, the user and the

equipment may be exposed to unforeseen and unnecessary risks.

1.5 Technical Assistance

To obtain technical assistance for the TM1/TM2 or any other Treetech product, contact us

through the address below:

Treetech Sistemas Digitais Ltda. –Assistência Técnica

Rua José Alvim, 100 –Salas 03 e 04 –Centro

Atibaia –São Paulo –Brazil

Zip Code: 12940-800

CNPJ [Corporate taxpayer's roll]: 74.211.970/0002-53

IE [State Tax ID]: 190.159.742.110

PHONE: +55 (11) 2410-1190 x201

FAX: +55 (11) 2410-1190 x702

Email: suporte.tecnico@treetech.com.br

Site: http://www.treetech.com.br

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 11

Temperature Monitor

1.6 Warranty term

The Temperature Monitor is guaranteed by Treetech for the term of 2 (two) years, counted

from the date of purchase, exclusively against eventual manufacture defects or quality vices

that render the equipment unfit for use.

The warranty will not cover damages sustained by the product, as a consequence of accidents,

improper handling, incorrect installation and use, inadequate tests or in case the warranty seal

has been breached.

The eventual need for technical assistance must be informed to TREETECH, or to a technical

assistance service appointed by the same, with the equipment being delivered together with

the purchase invoice.

Treetech does not supply, nor is liable to, any other warranty, express or understood, in

addition to the ones mentioned above. Treetech does not supply any guarantee of suitability

of the TM1/TM2 to any specific application.

The dealer is not liable to any claims for damage to property, nor any other form of losses that

might occur, in connection to or stemming from the acquisition of the equipment, of the

performance of the equipment or of any other service possibly supplied together with the

TM1/TM2.

Under no circumstances will the dealer be made responsible for any losses incurred, included

but not limited to: loss of profit or revenue, impossibility in using the TM1/TM2 or any other

associated item of equipment, costs of capital, costs of energy acquired, costs of replacement

equipment, facilities or services, costs of outages, complaints from clients or employees of the

buyer, regardless of whether said damages, complaints or losses are based on contracts,

warranties, negligence, felony or any other reason.

Under no circumstances can the dealer be made liable for any personal damage of any sort.

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 12

Temperature Monitor

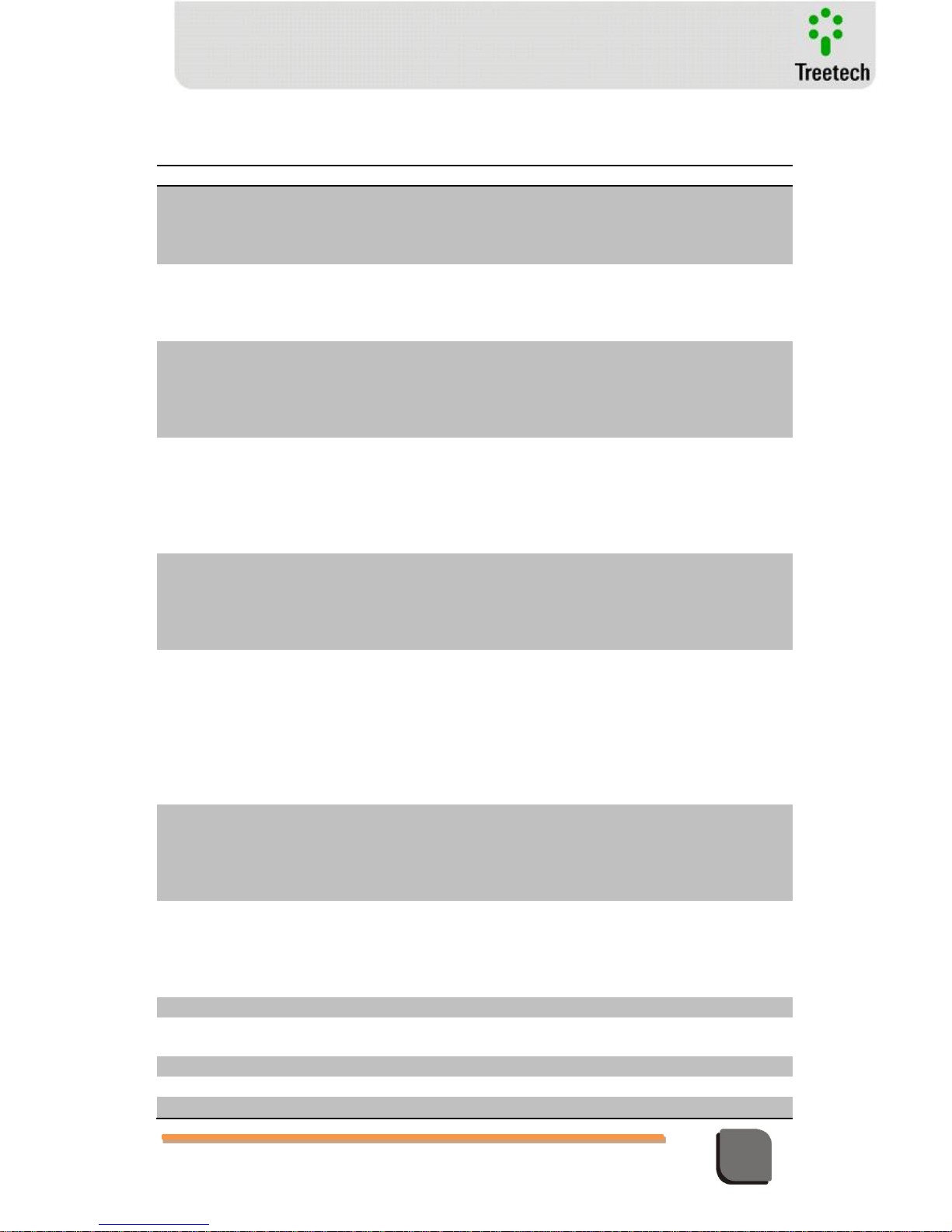

1.7 Revision Control

Table 2 –Revision Control

Revision

Issued

Description

Author

2

2004-11-11

Add submenu PRT (serial communication protocol selection)

and review control page. General text revision.

Note: This manual version is applied just for Temperature

Monitor with firmware V2.0.2

Fco

3

2004-12-08

Included optional functions of forced cooling, clock and

calendar, DNP3.0 information.

Note: This manual version is applied just for Temperature

Monitor with firmware V2.0.4

Fco

4

2005-07-15

Setting range of TRC parameter changed (chapters 5.3.4.1

and 5.3.4.2). Added Modbus registers 67...72.

Note: This manual version is applicable only to Temperature

Monitor with firmware V2.0.7 and higher (unless a specific

manual version is available)

Marcos

5

2006-10-31

Recommendations for insulation tests and parameter sheets

included. Revised temperature scale, register maps and

troubleshooting. General text revision.

Note: This manual version is applicable only to Temperature

Monitor with firmware V3.0.0 and higher (unless a specific

manual version is available)

Marcos

6

2007-06-01

Optional functions Mass Memory and LTC Temperature

Differential included.

Note: This manual version is applicable only to Temperature

Monitor with firmware V4.0.0 and higher (unless a specific

manual version is available)

Marcos

7

2008-04-14

Revised DNP3.0 Device Profile –Analog Inputs 42-49 and

Binary Inputs 64-71 included.

Revised Modbus Register Map –registers 1025-1031, 1505

and 1506 included. Added figures 4.4.and 4.5.

Note: This manual version is applicable only to Temperature

Monitor with firmware V4.0.3 and higher (unless a specific

manual version is available)

Marcos

8

2008-07-15

Revised Forced Cooling control, chapters 2.2, 3.1, 3.4, 4.1,

4.2, 4.2.4, 4.3, 5.3, 5.3.5, 5.3.5.1, 5.3.5.2, 7.7 and Apendix D.

Note: This manual version is applicable only to Temperature

Monitor with firmware V4.0.5 and higher (unless a specific

manual version is available)

Marcos

9

2013-01-15

Aditional functions PBT, SCT, BG1...BG4 included.

Some menus were divided in submenus.

Note: This manual version is applicable only to Temperature

Monitor with firmware V5.0.0 and higher (unless a specific

manual version is available)

William Botelho

10

2015-05-21

International Representatives updated

João V. Miranda

11

2015-07-06

New design; parameterization updated; compatible with 4.16

firmware.

João V. Miranda

12

2015-09-17

Procedure for film installation added

João V. Miranda

13

2016-01-20

Figure 26 (Dimensions) Updated

João V. Miranda

14

2016-03-21

Connection Diagram Updated

João V. Miranda

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 13

Temperature Monitor

2Introduction

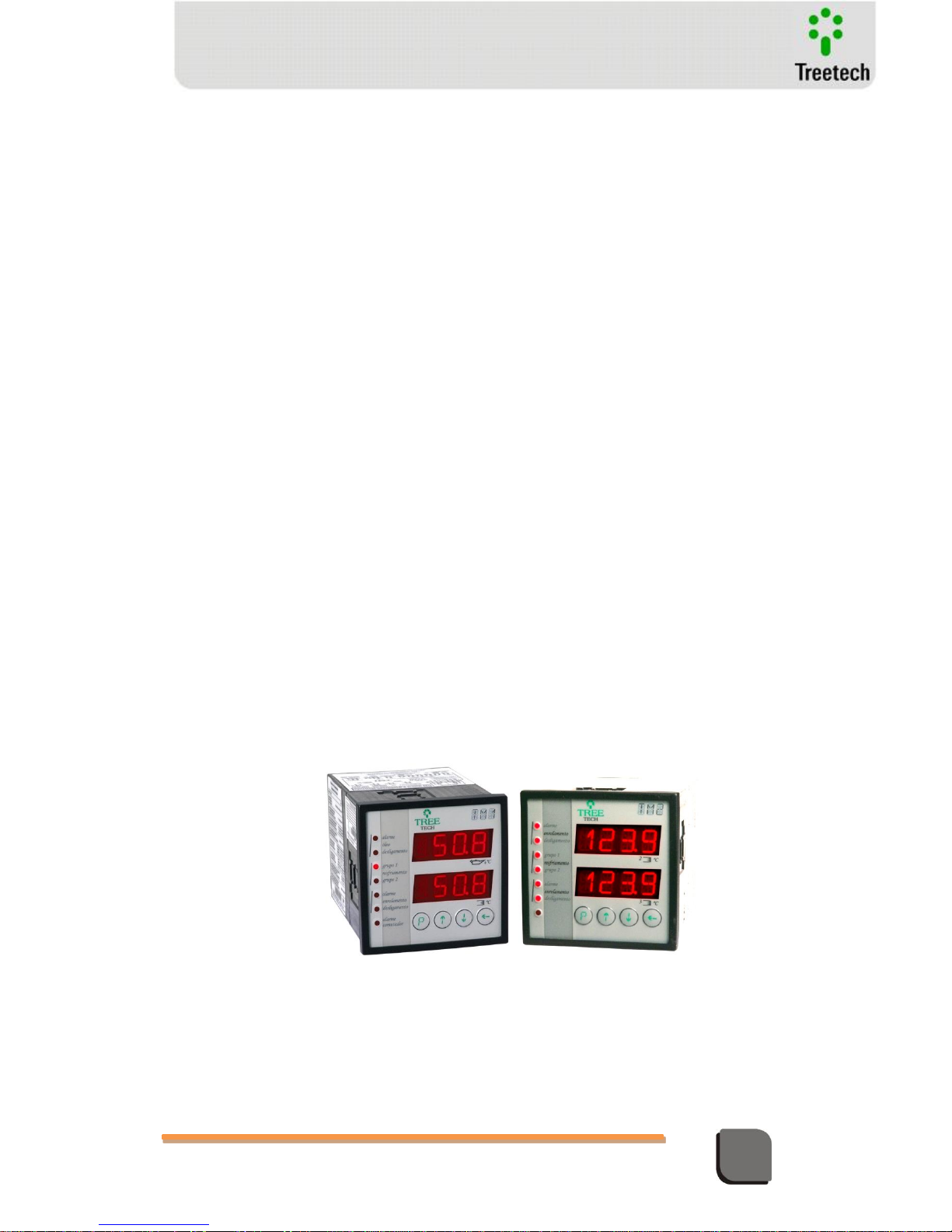

The Treetech's TM Temperature Monitors form a complete Temperature Monitoring system

for transformers and reactors immersed in oil. Designed as a modular system, it can be used in

simple, low cost applications, as well as in complete monitoring systems. The system is

comprised of modules TM1 and TM2:

TM1 monitors the temperature of the oil and one winding. The device is equipped

with:

-Configurable input for one 4-lead RTD sensor, for oil temperature, or two 3-lead

sensors - redundant reading of oil temperature or simple reading for oil

temperature and one additional temperature (e.g.: ambient or LTC);

- One load current measuring input, for calculating temperature of the winding.

TM2, applied as complement to TM1, monitors the temperature of one or two

additional windings. It is equipped with:

- Two current measuring inputs, for calculating the temperature of two additional

windings;

- Configurable input for one 4-lead RTD sensor, one 3-lead RTD sensor in input A,

one 3-lead RTD sensor in input B or two 3-lead sensors in inputs A and B for

reading additional temperatures (e.g.: ambient, LTCs or others).

Além destas funções básicas, estão disponíveis nos monitores TM1 e TM2 diversos opcionais.

Vide Funções Opcionais adiante.

2.1 Main Features

Input for Pt100 ohms at 0ºC sensors with self-calibration, precision of 0.2% of the end of

scale and high level of stability in a broad range of ambient temperatures.

Oil temperature measurement using one three-wire Pt100 sensor, one four wire Pt100

or two three-wire Pt100 (redundant temperature measurement and validation of the

reading);

Universal AC current inputs True RMS from 0 to 10A, precision 0.5% of full scale for load

measurement and calculation of temperature in the winding through the thermal image

process. Optional clip-on current transformers;

High luminosity, LED type displays for easy visualization, indicating oil, winding and

other user selected temperatures;

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 14

Temperature Monitor

Calculation of forecast for final oil-winding temperature gradient for current load

condition;

Current outputs for remote temperature readings, with selection of output range

(0...1mA, 0...5mA, 0...10mA, 0...20mA or 4...20mA);

Selectable cooling system operation via front panel on Automatic or Manual. Automatic

alternation in operation of forced cooling groups in pre-programmed stages, based on

their operation times , affording uniform use of fans or pumps;

Optional Pre-cooling function for reducing insulation loss of life due to elevated loads;

Optional Fan Exercise function for prevention of failures in cooling fans or pumps;

NO contacts (NC or combinations upon request) for oil or winding temperature alarms;

NO contacts (NC or combinations upon request) for tripping due to oil and/or winding

temperatures with double activation safety (simultaneous order from the 2 micro-

controllers for the operation). Adjustable timing between 0 and 20 min with countdown

on display;

NC contacts for activation of forced cooling groups with timer between start up for

groups (even with lack of feed for TM1 or TM2) and forced operation resulting from self-

diagnosis routines in case of failure or absence of voltage (power outage);

NC contacts for indication of internal failure or lack of voltage detected in self-diagnosis;

NO contacts for indication of count down mode for trip activation or alarm by LTC

temperature differential;

Modbus-RTU (standard) or DNP 3.0 (optional) serial communication protocols.

Protocol DNP-3.0 (optional) with time stamp with 1ms resolution for events like alarms

and trips, based on synchronicity by GPS signal clock on standard IRIG-B (only for TM1)

or synchronicity by the protocol DNP3.0;

Non volatile mass memory for storage of temperature readings, alarm or trip events and

forced cooling operation;

Internal clock with settings maintained for 48h in case of failure of power supply. No

batteries are used - maintenance-free device.

Figure 1 –Temperature Monitors TM1 and TM2

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 15

Temperature Monitor

2.2 Optional Features

According to the order, the TM1/TM2 can be supplied with one or more of the optional

features listed below:

Optional 1 –DNP 3.0 protocol:

User selectable communication protocol: Modbus RTU or DNP3.0 level 1. DNP3.0 protocol with

support for 1ms resolution time-stamp.

Optional 2 –Pre-Cooling:

Pre-cooling can extend the insulation useful life of transformers subject to overloading by

activating cooling groups when user selected load levels are reached. Taking advantage of the

large thermal inertia of the oil, the forced cooling systems are activated even before the

temperature rises, thus increasing the time required to reach high temperature levels, which

would cause accelerated shortening of insulation life cycle. The following parameters are

programmed by users:

Loading percentages for individual activation of up to four cooling stages;

Hysteresis for shut off of forced cooling stages in case of load reduction.

Optional 3 –Fan and Pump Exercise:

The fan exercise function keeps fans and / or pumps from remaining inactive for prolonged

periods of time in transformers operating under low load conditions or during periods of low

ambient temperatures. This avoids axle blocking due to accumulation of dirt, grease dry out or

bird nesting. Fans are switched on every day, based on the equipment's internal clock and

depending on selections made by users:

Hour and minute for start up of fans and/or pumps;

Total daily fan and/or pump operation time, from 0 to 999 minutes.

Optional 4 –Temperature Differential for the Load Tap Changer:

Load Tap Changers are one of the main sources of transformer failure. Measuring the

temperature difference between the LTC oil and transformer oil may give an indication of a

thermal failure event in the equipment before reaching a level of severity that could lead to a

major failure. Since this difference is subject to the influence of external variables, monitoring

is carried out in two different ways, in order to increase efficiency of diagnosis and avoid false

alarms:

Monitoring of instant difference triggers fast response alarms, in case of high intensity

defects, even in case of short duration events;

Monitoring of difference with long term filter triggers alarms sensitive to permanent

defects, even in case of low intensity, with longer detection times.

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 16

Temperature Monitor

In three-phase transformers using three single-phase tap changers in separate oil chambers

the three temperature differences can be monitored separately.

Optional 5 –Mass Memory:

Nonvolatile memory for storage of temperature readings and alarm events. Users select

variable groups to store and save to memory. Recording operation can be started by:

Time interval between storage of readings selected by user; or

Variation of temperature higher than any dead band selected by the user, in ºC; or

Change of state in any output relay (control of cooling, alarms, trips or self-diagnostic).

2.3 Operation Philosophy

OIL AND WINDING TEMPERATURES

Based on the readings obtained for the top oil temperature and the load current on the

transformer, the temperature monitor calculates the winding temperature by way of the

algorithm implemented in its firmware (thermal image). Other data items are part of this

algorithm. These other items are programmed in the device by the user, thus adapting the

model to each transformer’s characteristics.

transformer load current measurement is carried out through the secondary of one or more

current transformers (CTs) connected directly to the TM1 and TM2 or through external clip-on

CTs (optional delivery).

FORCED COOLING CONTROL

Temperature Monitors TM1 and TM2 can command up to 4 forced cooling groups, either in

manual or automatic mode. In automatic mode, the control of forced cooling groups is always

accomplished based in the higher value measured among oil and 1, 2, and 3 winding

temperatures. If the optional pre-cooling function is available, forced cooling can also be

commanded based on percentage load of windings, considering the highest measured load.

Due to oil and windings thermal inertia, pre-cooling function causes the cooling groups to be

activated before transformer achieve the temperature levels preset in automatic command

settings, thus reducing the average transformer operating temperature.

Optional function of cooling equipment exercise allows daily activation of fans and/or oil

circulation pumps in order to prevent mechanical failures caused by long periods out of

service, with user-defined starting time and duration.

LTC TEMPERATURE DIFERENTIAL

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 17

Temperature Monitor

The Load Tap Changer (LTC) is one of the principal sources of failure in power transformers,

arising mainly from the existence of moving parts that conduct and interrupt high currents

while submitted to high electrical potentials.

Some of the most common of these tap changer failure modes are related to the contact

deterioration or mechanical wear and tear that give rise to increase in the contact resistance

and which in turn raises the temperature significantly and then tends to increase even more

the resistance, a cascading effect that leads to complete, severe failure.

Under normal operating conditions, the LTC is a small source of heat compared to the heat

generated by the losses of the transformer, in the way that oil temperature in the LTC tank is

influenced principally by the transformer’s oil temperature. Illustration below, elaborated by

real measurements in the field, exemplifies this situation. In it we can observe, as well as the

individual transformer and tap changer temperatures, the difference between the LTC

temperatures minus the transformer’s, which is monitored to detect the faults mentioned

above.

Figure 2 –Temperature measurements of LTC, transformer and temperature differential

As the temperature differential is subject to the influence of external variables, such as the

action of forced cooling, rapid variations in atmospheric conditions and others, monitoring is

carried out by two distinct modes, illustrated in next figure, in order to increase diagnostic

efficiency and avoid false alarms:

Instantaneous Differential Monitoring - the Instantaneous Temperature Differential

monitoring triggers alarms with a rapid response in case there are large-scale faults,

even if they have short duration.

Monitoring of Filtered Differential - the Filtered Temperature Differential is obtained

by submitting the Instantaneous Differential to a low-pass filter with user adjustable

time-constant. Its monitoring enables the detection of the evolutionary trend of a

differential which indicates small permanent defects, over a longer period of

detection.

-10

0

10

20

30

40

50

60

28/8/2002

00:00:00 30/8/2002

00:00:00 1/9/2002

00:00:00 3/9/2002

00:00:00 5/9/2002

00:00:00 7/9/2002

00:00:00

TRANSFORMER OIL (ºC)

LTC OIL (ºC)

DIFFERENCE LTC-TRANSFORMER (ºC)

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 18

Temperature Monitor

Figure 3 - Instantaneous and Filtered Temperature Differentials

The alarm settings to the monitoring of the Instantaneous and Filtered differentials can be

automatically determined by the Temperature Monitor, through a learning period about the

normal behavior of the LTC. The automatic alarm settings can be manually changed by user.

The duration of the learning period can be programmed by user. Typical value is one week.

During this period the Temperature Monitor will register the peak values for the Instantaneous

and Filtered Differentials. After that the alarm settings for both temperature differentials are

obtained by summing the peak values to a programmed tolerance margin.

If the measured temperature differentials, either Instantaneous or Filtered, exceed their

respective alarm settings the Temperature Monitor will trigger an alarm. This alarm is

indicated by a LED lamp on the device’s front panel and can operate the output contact A1-A2

on TM1 and/or TM2, provided these contacts are programmed by user in this way.

The measurements of transformer top oil temperature and load tap changer oil temperature

are performed by Pt100Ω@0ºC sensors, which are connected to the inputs available on

Temperature Monitors TM1 and TM2. TM1 has 2 temperature sensor inputs; at least one of

them must be used for transformer top oil temperature, the other one can be used for

redundant top oil measurement or for LTC, ambient or other temperatures. TM2 has 2

additional inputs available for LTC temperature, ambient temperature or others.

-8

-4

0

4

INSTANTANEOUS DIFFERENTIAL (ºC)

FILTERED DIFFERENTIAL (ºC)

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 19

Temperature Monitor

3Operation

All operations on the Temperature Monitors TM1 and TM2 are performed through the

keyboard on the front panel, without the need for any external selector switches. The

temperature of the oil, winding (or windings) and Load Tap Changer are shown on the displays,

and the alarm status, trips and forced cooling commands are indicated by the signal LEDs.

3.1 Initial Settings

During normal work mode, the Temperature Monitor will display the temperatures of the

oil and winding (or windings) connected to the equipment.

When the value programmed for an event is reached, the corresponding signal LED will light

up, and activate the output contact for this event.

Winding 1

Temperature

Teclas de operação e

programação

Signaling

Leds

Oil

Temperature

Operation and

programming buttons

Winding 2

Temperature

Winding 3

Temperature

Figure 4 –Temperature Indications

Technical Manual –TM1/TM2 | MA-010| 2016-03-21 | Ver.: 6.30 20

Temperature Monitor

Figure 5 –Signaling LEDs on Temperature Monitor TM1

Figure 6 –Signaling LEDs on Temperature Monitor TM2

In case any abnormality occurs, the corresponding self-diagnostic code will be shown on the

displays.

If selected the PTA or PTB option in the DSP parameter of TM2, the LED indicating the presentation of

this temperature instead of winding temperature 3 - which is the standard indication - lights on the front

of TM2. This is the signal for the display mode of the lower display, DSP parameter TM2.

Oil Temperature

Alarm / Trip

Status of forced cooling groups 1

and 2

Load Tap Changer

Temperature Differential

Alarm (optional)

Winding 1 Temperature

Alarm / Trip

Winding 3 Temperature

Alarm / Trip

Winding 2 Temperature

Alarm / Trip

Forced Cooling Groups 1 and 2

(redundant) or 3 and 4 status

Status

Indication mode of lower display: ambient

temperature (LED lit) or winding 3 temperature

(LED unlit)

This manual suits for next models

1

Table of contents

Other Treetech Monitor manuals