TRENCHERPRO 26-183 User manual

TRENCHER PRO

Mini-Trencher

Operator’s Manual

26-183: 16” Trencher

26-184: 20” Trencher

26-185: 27” Trencher

Product registration form attached to the back of this booklet. Mail your registration within 2

weeks of date of purchase.

Parts and Design

Power Head *

* 16” & 20” con gurations sold with

Husqvarna K770 power head; 27” sold

with Husqvarna K970.

Welcome!

Thanks for buying a TrencherPro! We design our products to meet the high demands

of our industrial and commercial clients, with ease-of-use that’s aimed at homeowners

and do-it-yourselfers. That means that our products are tough enough to meet rigorous

industry standards, but designed for non-professionals to learn to use. We warranty all

TrencherPro parts for one year from purchase date. Register your product today.

If you have feedback or questions, we want to know!

Mini-Trencher

TRENCHER PRO

This user guide/manual covers assembly, use, basic service and troubleshooting information for Tren-

cherPro parts (“digging-head drive adaptor”), including:

• mounting and installing the digging chain and chain guard;

• assembling the trenching cart;

• instructions for basic operation.

For more information about use and maintenance of the power head refer to operator’s manual pro-

vided.

WARNING!

WEAR PERSONAL

PROTECTIVE EQUIPMENT

Failure to follow warnings, cautions, or assembly

and operation instructions in this manual may

result in serious injury or death.

Read this operator’s manual before operation!

●Do not permit children to operate this

equipment at any time. Do not permit others

that have not read and understood this

manual to operate the mini-trencher.

●Keep all people and pets a minimum of

10 feet away from the work area when

operating the mini-trencher. Only the

operator should be near the mini-trencher

during use.

●Do not operate this device when under the

inuence of alcohol, drugs or medication.

●Do not allow a person who is tired, not

completely alert, or otherwise impaired to

operate the mini-trencher.

●Always check with authorities for

underground utilities before digging

trenches. Serious injury or death could

result from contact with gas or electric lines.

●Read the power head operation manual

concerning the use and maintenance of

power head.

●Make sure that all safety guards are in

place and securely fastened. Do not operate

if any guards are missing.

●Make sure that the digging chain is

correctly installed, oriented, and in good

working condition prior to use.

We recommend operating this minitrencher with

the cart.

Death or serious injury can result from

entanglement with moving parts.

GENERAL SAFETY

KEY TO SYMBOLS

Notice:

Tip

Indicates the possibility of death

or serious injury.

Indicates the possibility of injury

to self or damage to equipment.

Indicates additional information.

3

Important Safety Information

Read and thoroughly understand all instructions

and safety information before assembling or

operating this mini-trencher. Failure to do so

may result in serious injury or death. Do not

allow anyone who has not read this manual to

operate the device. As with all power equipment, a

trencher can be dangerous if assembled or used

improperly. Do not operate if you have doubts or

questions concerning safe operation.

Call our customer service department at 720-

437-7640, or email us at customerservice@

tooltuffdirect.com if you have questions or

concerns about the safe operation of this

equipment.

When operating this minitrencher it is essential

that you wear safety gear including safety

glasses, steel toe shoes, well-tted gloves

(no loose cuffs or draw strings), and hearing

protection. We also recommend a face guard,

especially for hand-held applications.

Do not wear loose clothing or jewelry that can be

caught by moving parts. Keep clothing and hair

away from all moving parts while operating.

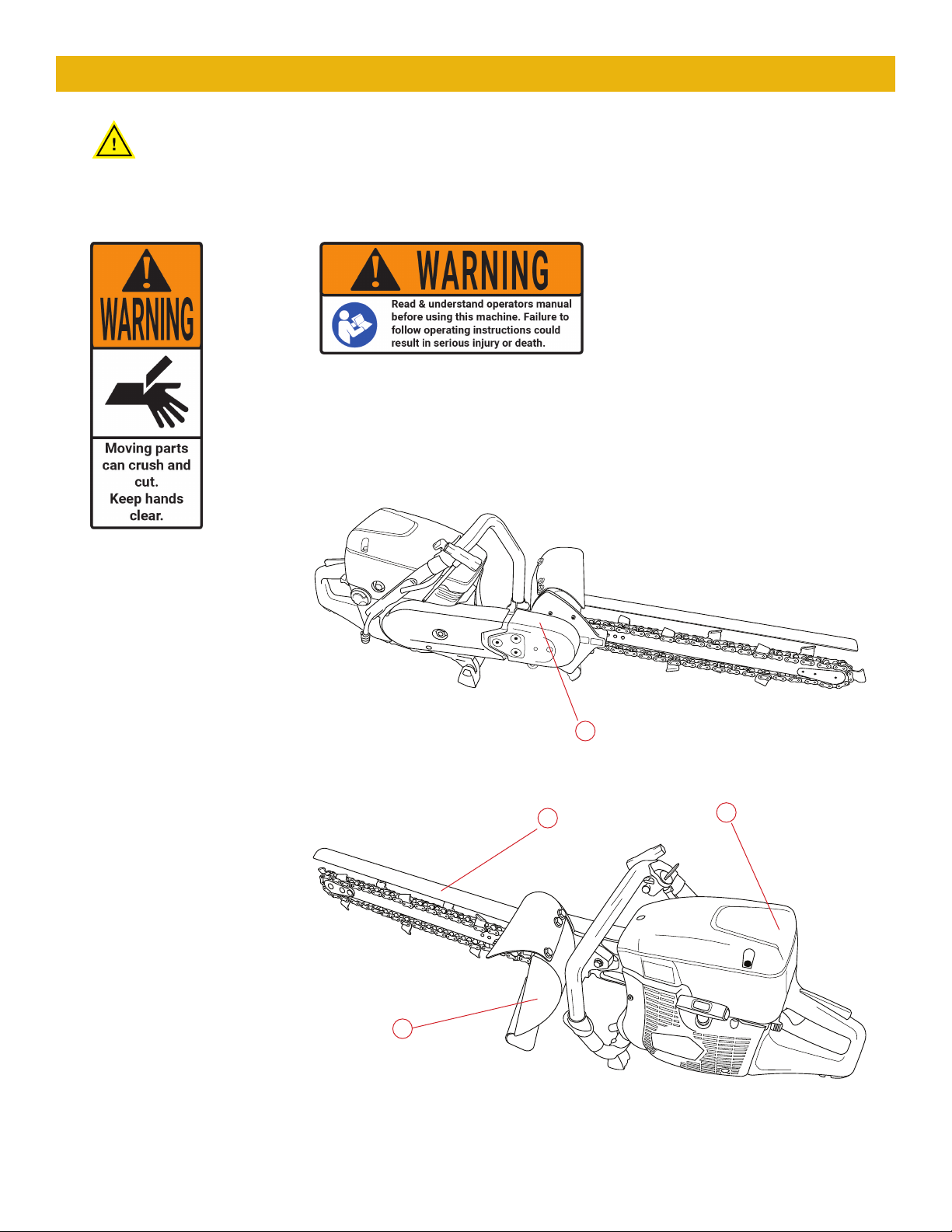

Safety Decals

Make sure all safety warning decals are attached and in readable condition. Replace

missing or defaced decals. Call 720-437-7640 for replacement decals.

1) Part # 29-036

2) Part # 29-037

1

1

1

2

4

Important Safety Information

INTENDED USE REASONABLY FORESEEABLE

MISUSE

5

General Use Guidelines

This device is designed and tested for use

digging narrow (2-3”) trenches from 16-27” in

depth (depending on conguration) in most soil

types. It is not intended to cut solid surfaces

such as tarmac or concrete. Excessively rocky

soil types, soil with large heavy rocks, or soil with

roots measuring more than 2” in diameter can

damage the chain, drive adapter, or powerhead.

It is recommended for laying sprinkler lines,

drainage pipes, cables, root barriers, and related

applications. Do not use the mini-trencher for

any purpose other than digging trenches in the

suitable soil. Any other use is unauthorized and

may result in serious injury or death.

We recommend that you use the cart when

digging trenches. It reduces fatigue and keeps

you at a safe working distance from moving

parts and debris. However, it is possible to use

the trencher without the cart if the situation

demands.

Use common sense and stay safe!

The following constitutes improper use

and voids any warranty:

Notice:

Always check with authorities for

underground utilities before digging

trenches!

Serious injury or death could result from

contact with gas or electric lines.

• Attempting to cut wood or trim hedges

• Attempting to cut concrete, asphalt or tarmac,

or any solid surface

• Attempting to cut solid stone or rock

• Use in extremely rocky soil

In the course of digging a trench, the mini-

trencher may come into contact with unforeseen

objects such as large tree roots, large heavy

rocks, unmarked obstacles, etc. We consider this

reasonably foreseeable misuse and will work with

you to keep your mini-trencher operational.

Please contact our service department at:

customerservice@tooltuffdirect.com

or

720-437-7640

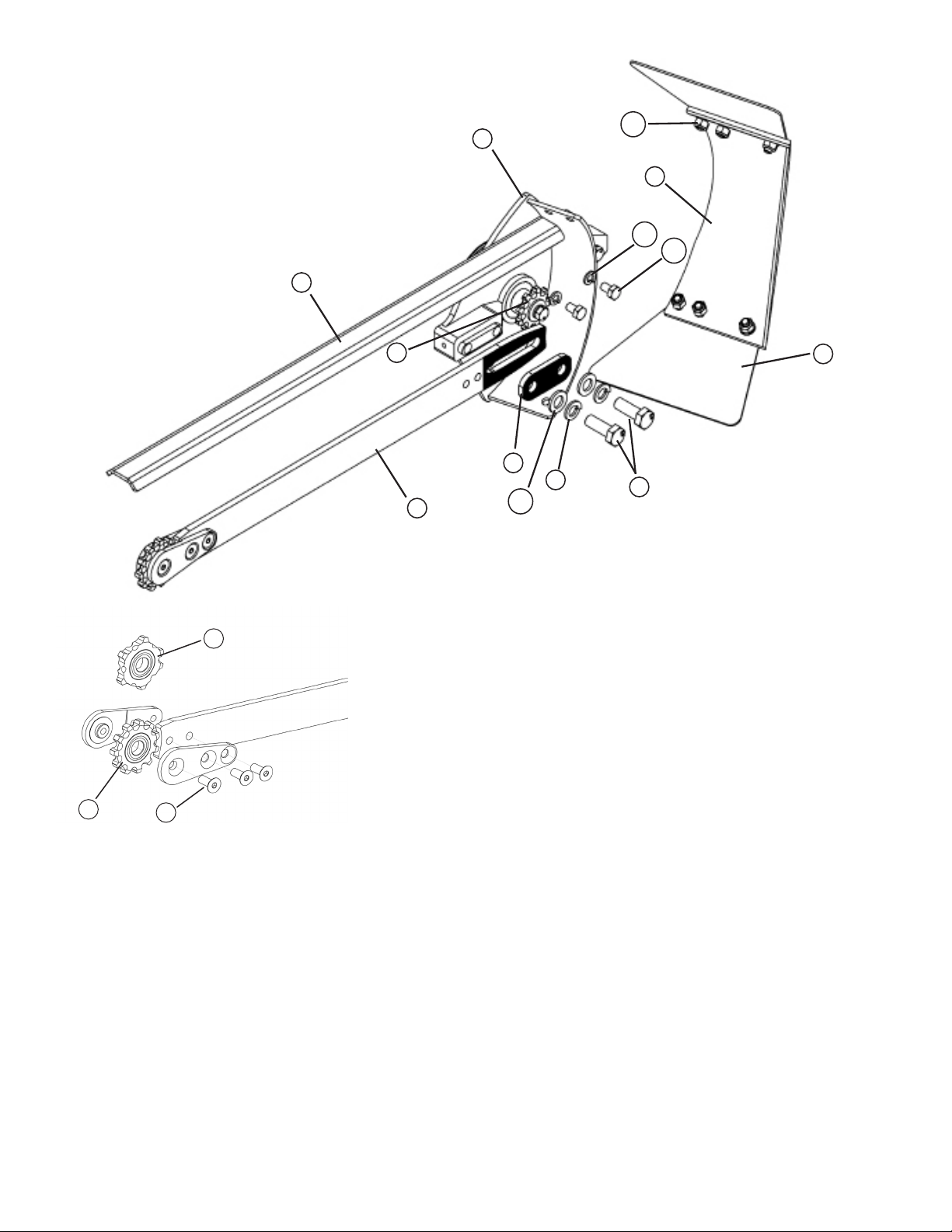

TRENCHER PRO

10

3

1

2

4

5

6

7

8

9

11

12

13

15

14 16

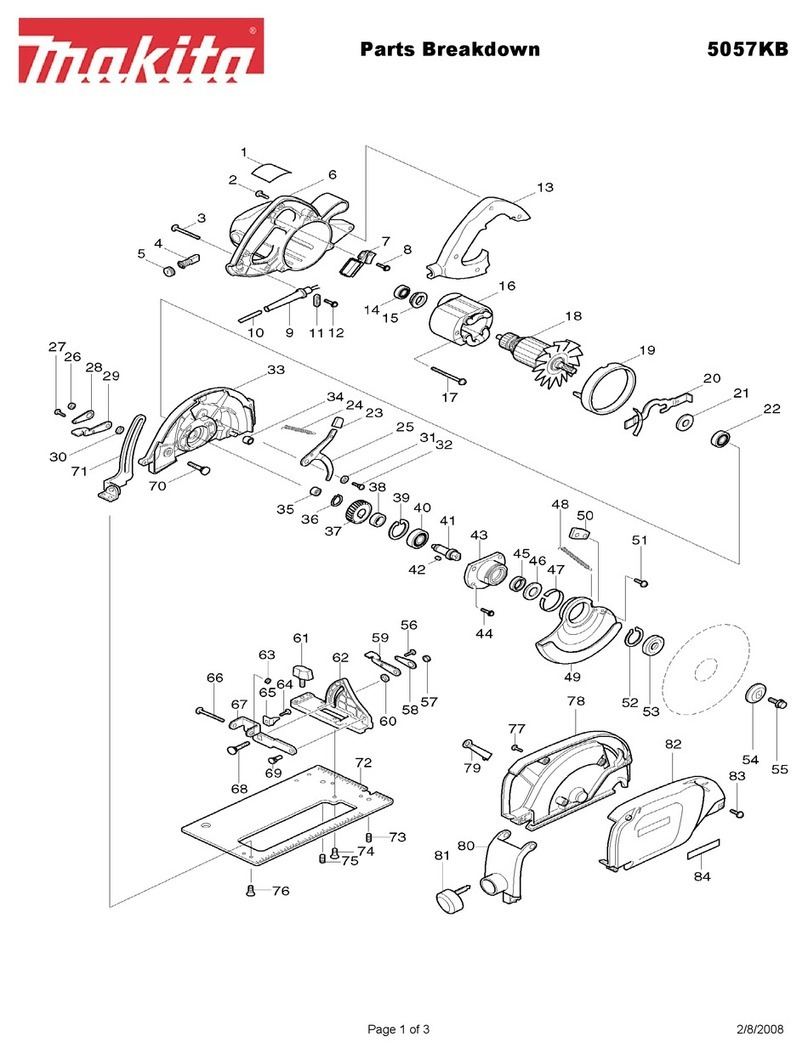

ref. # description part #

1 Main mount 26-114

2 Heavy-duty digging bar 26-115 / 26-179 / 26-180

3 (Chain bar) mounting plate 26-118

4 Chain guard 26-146

5 Drive sprocket 26-140

6 Plastic guard 26-147

7Rubber guard ap (x 2) 26-137

8M12 bolt (x 2); (1.25mm X 35mm)

9M12 lock washer (x 2)

10 M12 washer (x 2)

11 M8 bolt (x 2); (1.25mm X 14mm)

12 M8 lock washer (x 2)

13 M8 nylock nut (x 6)

Inset

14 Nose sprocket A (11 teeth) 26-170

15 Nose sprocket B (6 teeth) 26-120

16 M8 screw (x 3); (1.25mm X 20mm)

6

Mini-Trencher Parts Guide:

Digging-head drive adapter

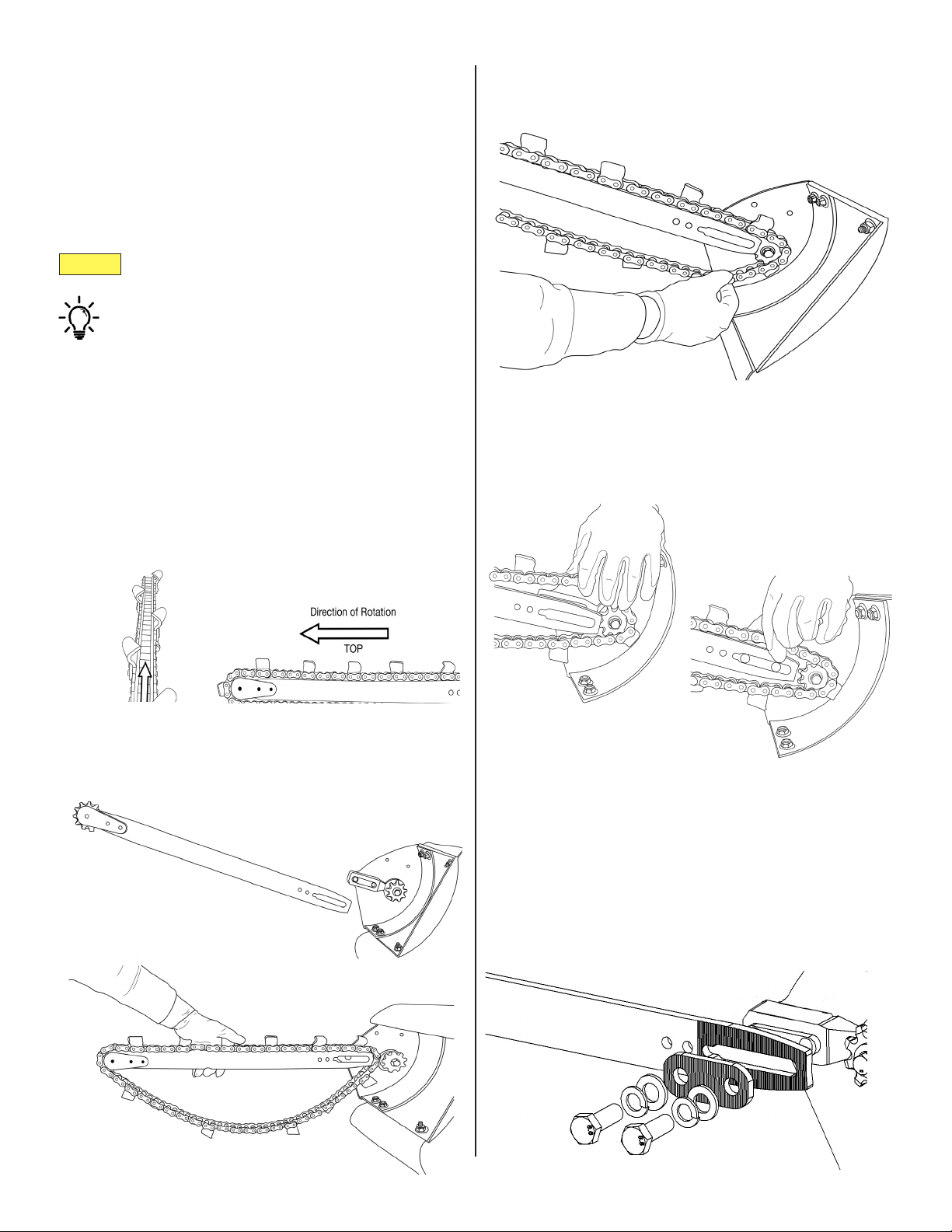

Tip

Notice:

7

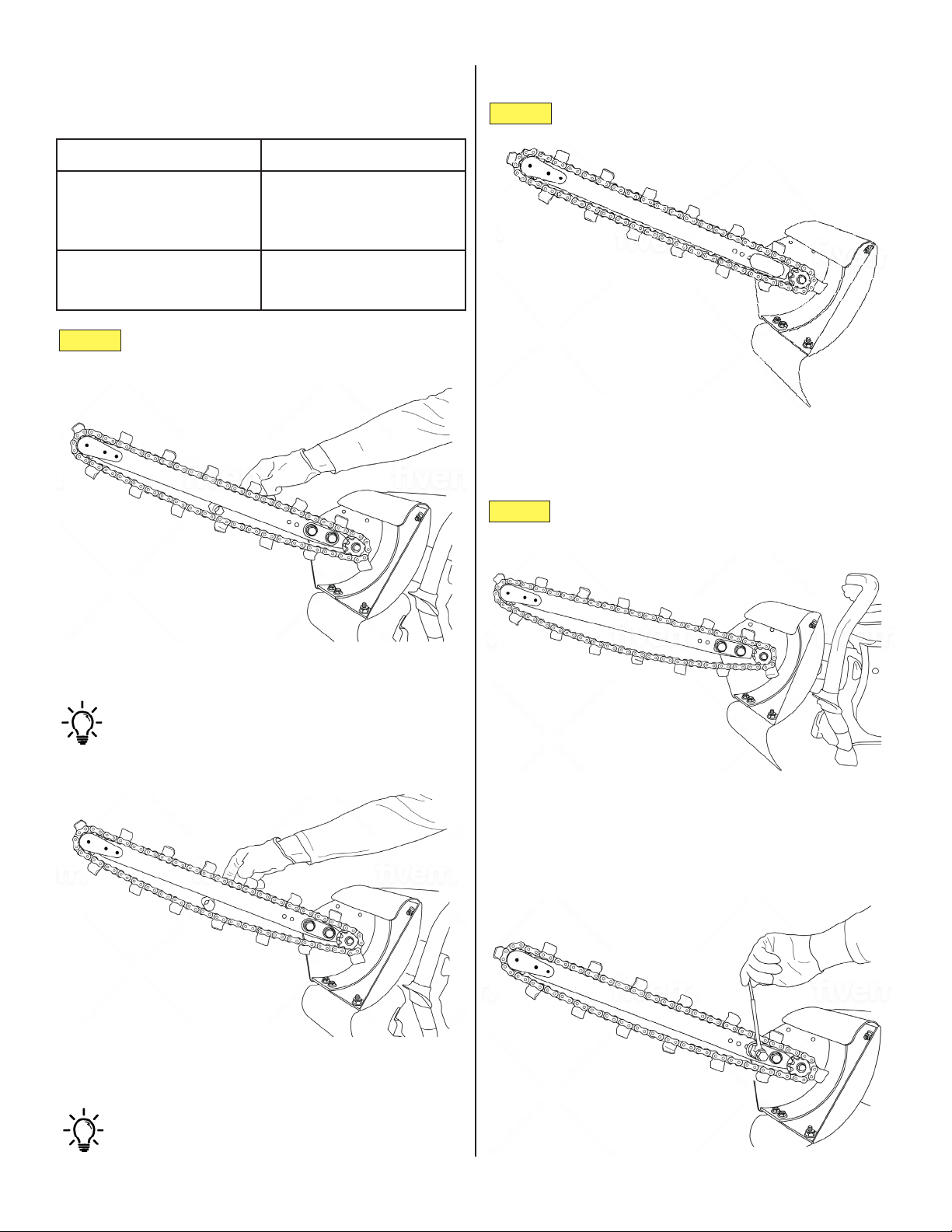

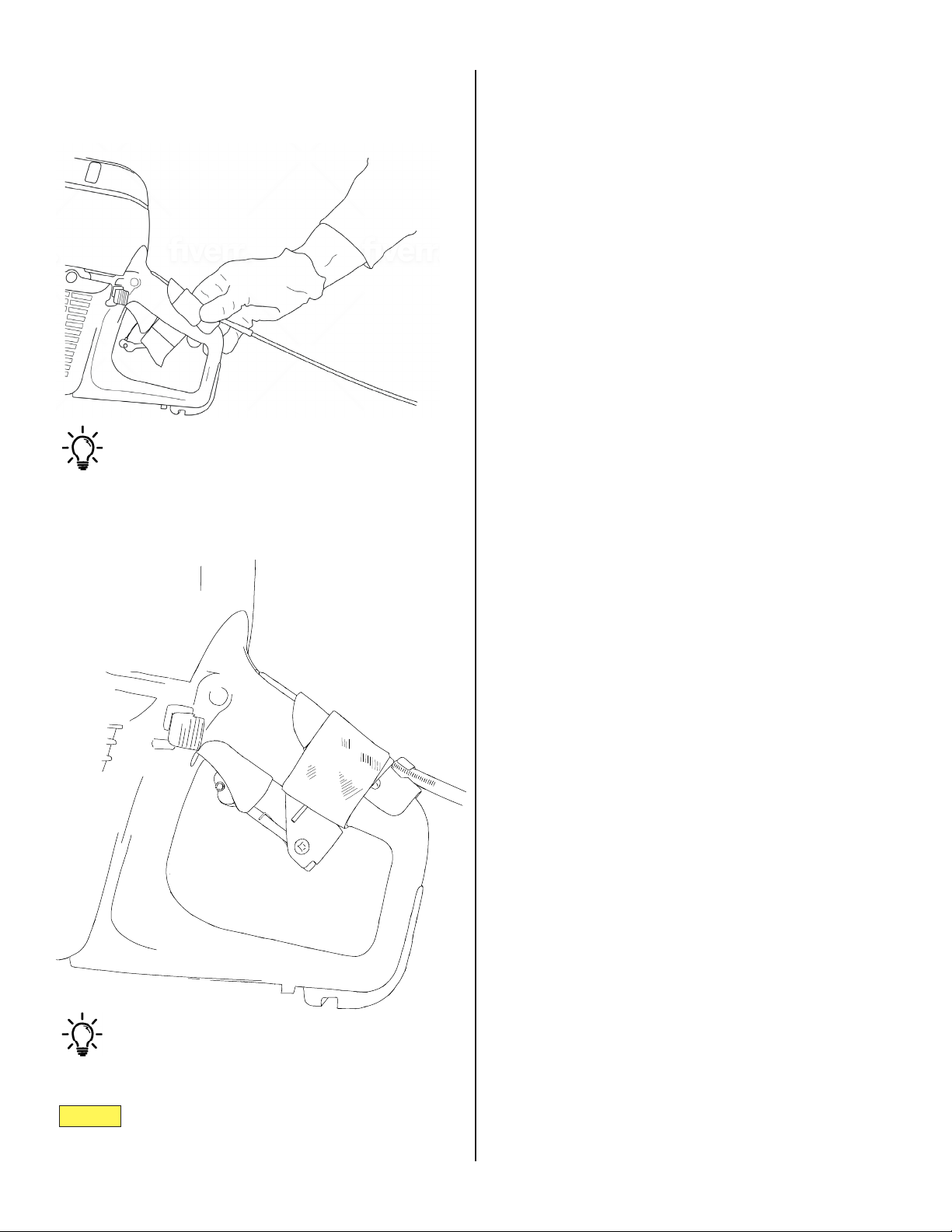

Step 1: Installing the Digging Bar

and Chain

The heavy-duty digging bar [2] and chain are

disassembled for shipping. Before operating the

mini-trencher, you must install the digging bar

and chain, then tension the chain for the type of

material you will be working with.

1. Orient the digging chain correctly.

During operation, the chain rotates away from the

powerhead on the top side and returns on the bot-

tom, pulling loose material with it. e chain must be

oriented correctly, with the teeth opening towards the

loose material.

2. Mount the chain and chain bar.

A. Get the bar in position. Drape the digging

chain over the bar.

B. Seat the chain on both the nose sprocket

[14/15] and drive sprocket [5] as you mount

the bar.

C. Slide the slot into place. It should t snugly.

Use the M12 bolts [8], washers [10] and lock washers

[9] to attach the mounting plate [3], and tighten loose-

ly.

• Don’t tighten rmly until you tension the

chain.

Before you begin, locate the mounting plate [3],

M12 bolts [8], washers [10] and lock washers [9].

Read and understand the chain-tensioning

guide before operation.

3. Attach the mounting plate.

Notice:

Tip

Tip

8

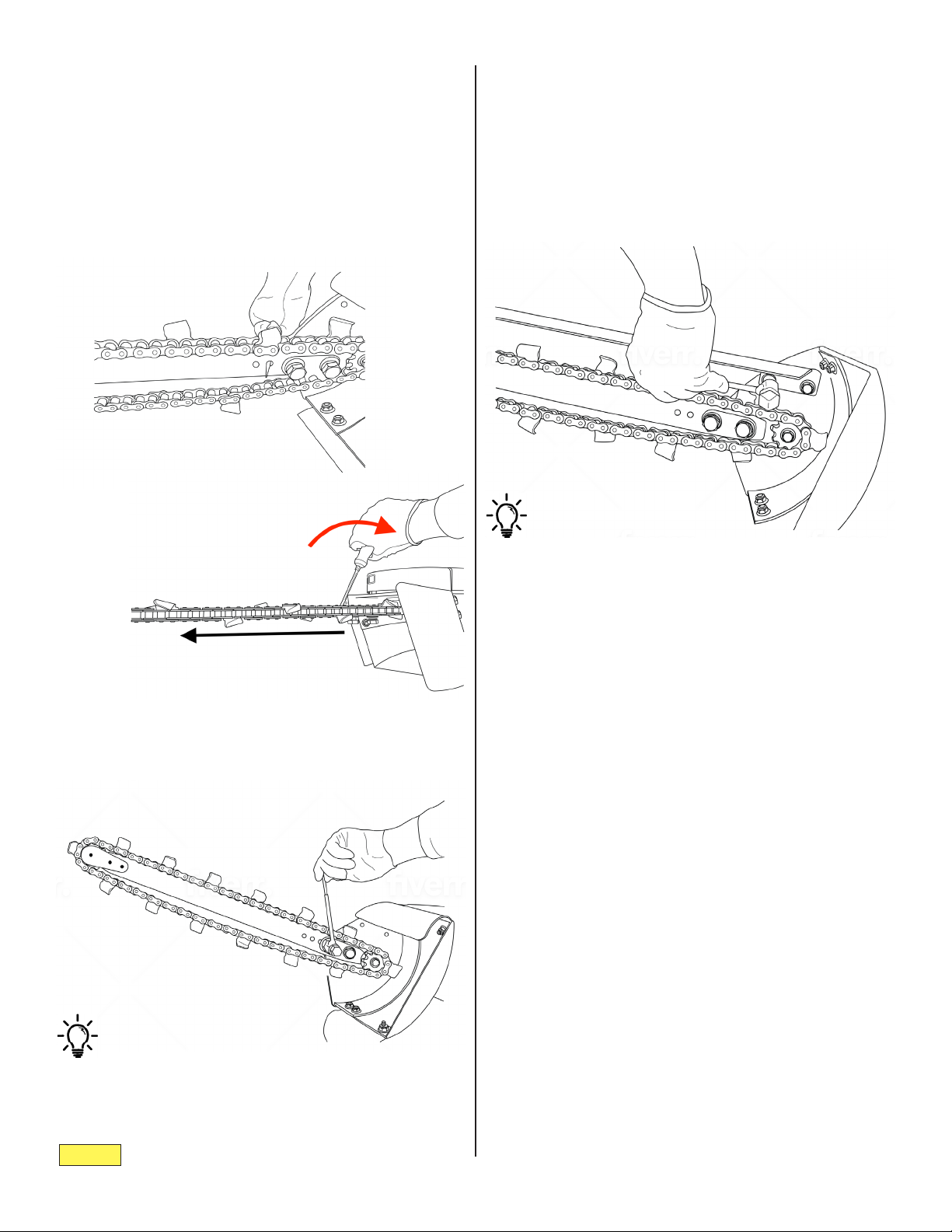

Step 1, Continued:

4. Tension the chain.

Insert a athead screwdriver into the tensioning hole

in the chain bar. Force the bar out, away from the pow-

er head, until you reach the desired chain tension.

You may need to tap the bar back and start again if the

chain becomes too tight.

5. Attach the chain guard.

Use a socket wrench (not included) or impact driver to

rmly tighten the bolts.

Once the desired chain tension is reached, securely fas-

ten the mounting plate [3]. (See the Chain Tensioning

Guide for more details.)

Use a socket wrench (not included) or impact driver to

rmly tighten the bolts.

Review the chain-tensioning guide (next page)

carefully before operation.

Use the M8 bolts [11] and lock washers [12] to attach

the chain guard [4] onto the main mount [1].

e bolt holes are located above the drive sprocket [5].

Notice:

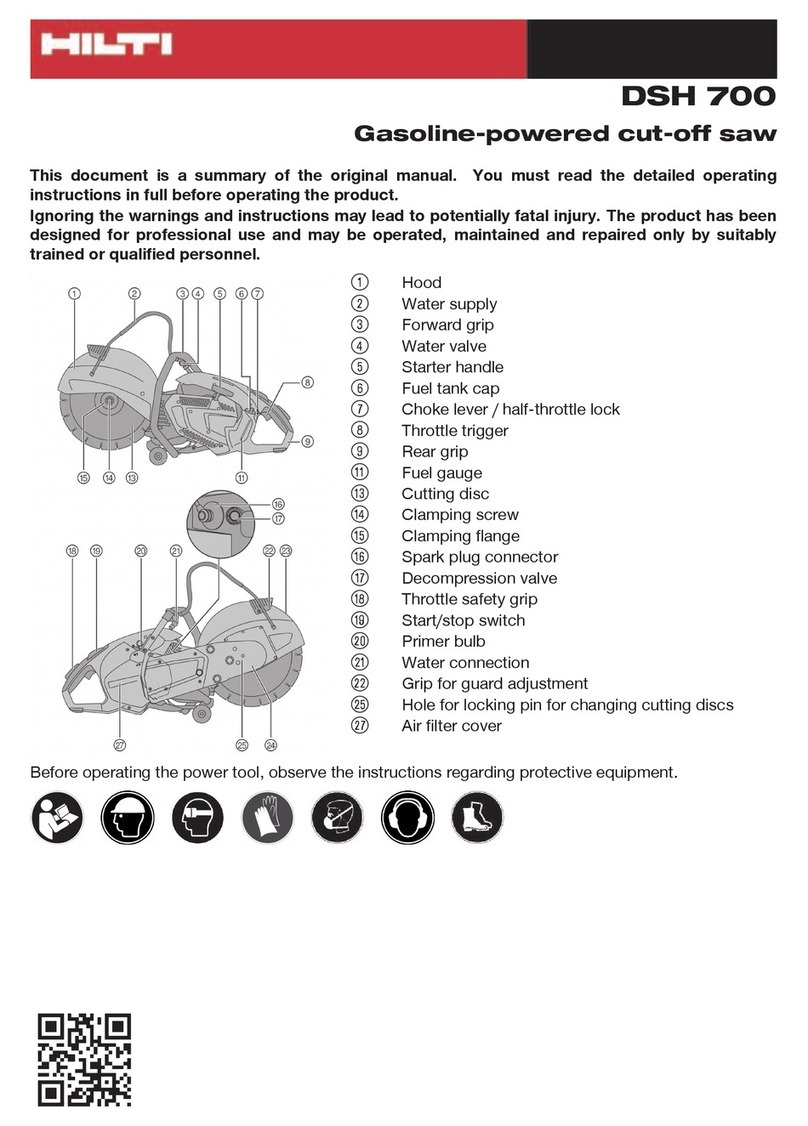

Soil type Chain tension

loose top soil;

hard, compacted soil;

clay

1”

between bottom of digging bar and inside

of digging chain

moderately rocky soil;

sandy, coarse soil

1 ½”

between bottom of digging bar and inside

of digging chain

Notice:

Notice:

Tip

Tip

9

Chain Tensioning Guide

Above: Chain is tensioned to 1” for normal top

soil.

Use the small end of the combination wrench

tool to measure approximate spacing between

bottom of digging bar and inside of digging

chain.

1”

Check chain tension occasionally during

operation!

• Chain tension can slip and may require

adjustment!

The chain tension must be adjusted according to

soil type.

1 ½”

Above: Chain is tensioned to 1 ½” for coarse

soil.

Use the large end of the combination wrench

tool to measure approximate spacing.

Tighten the bolts [8] rmly before use.

• We recommend using a socket wrench (not in-

cluded) or impact driver to make sure bolts are

tight.

too tight!

too loose!

Too much slack in the chain causes excessive

wear to external parts and may damage the

main mount and guards.

Over-tightening the chain may cause binding

and excess wear to the drive belt and/or clutch.

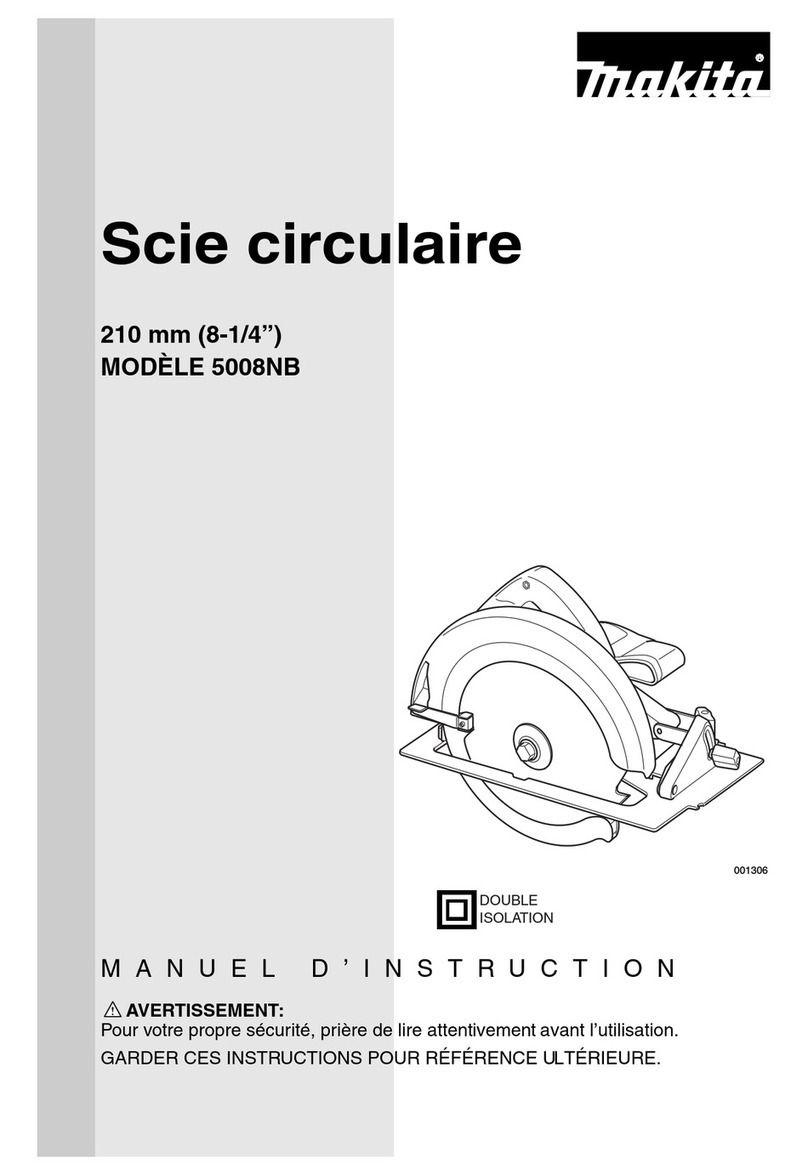

1

2

10

3

4

5

6

7

8

11

12

13

14

15

16

17

9b

9a

10

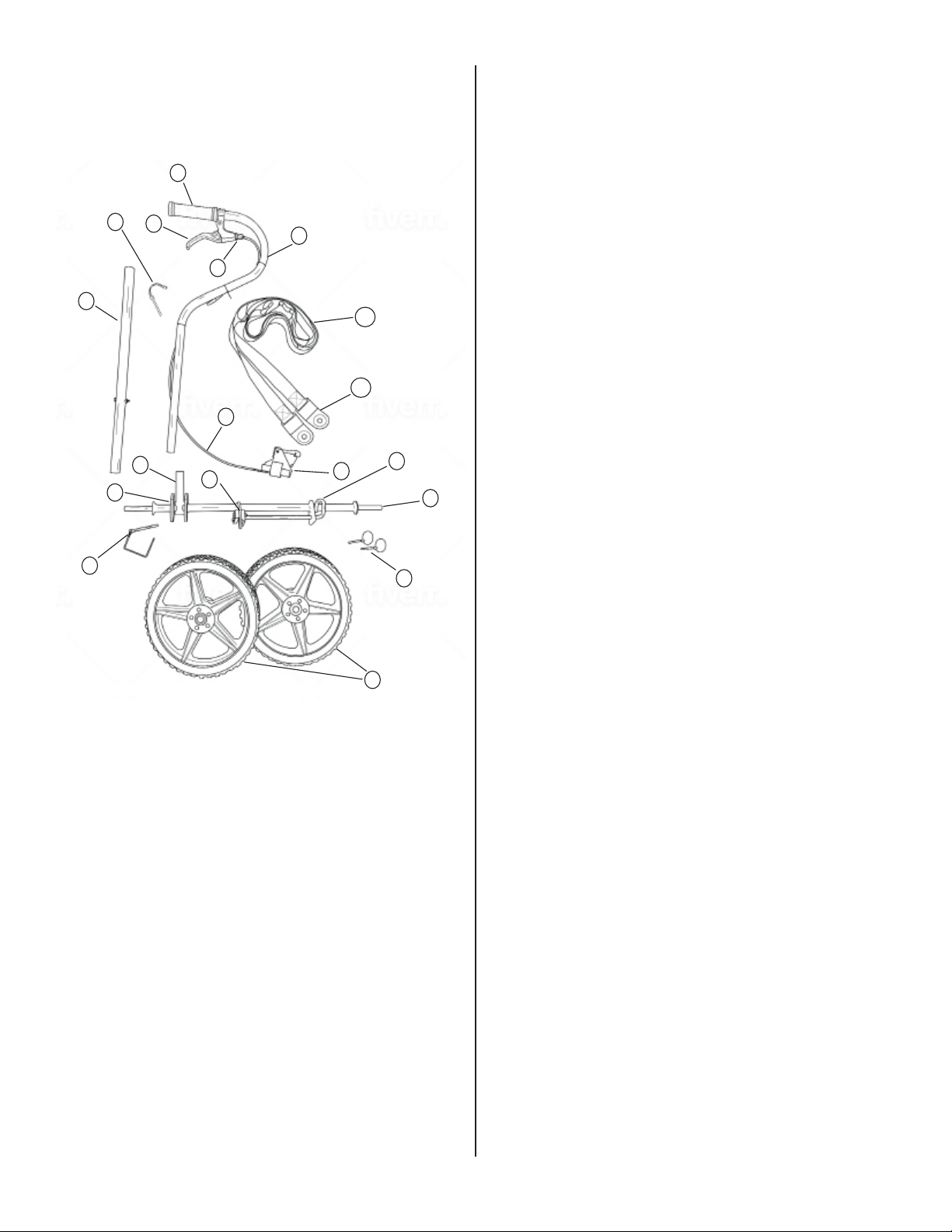

Step 2: Assembling the Cart

Lay out all the parts in an area where you have

plenty of space to assemble the cart. Locate the

axle [10C].

Cart Parts

ref. # description part #

1C grip 26-173

2C (throttle) lever 26-172

3C cable-tension adjuster

4C throttle cable 26-148

5C trigger-extension accessory

6C throttle-extension arm 26-129

7C pivot arm (spring-loaded

end faces axle) 26-133

8C shaft-locking pin

9C-a strap 26-131

9C-b strap plates (x 2)

10C axle

26-135

11C mounting lock

12C mounting guide

13C handle-mount bar

14C pivot plate

15C clevis pin

16C lynch pins (x 2)

17C wheels (x 2) 26-174

}

}

}

}

Tip

Tip

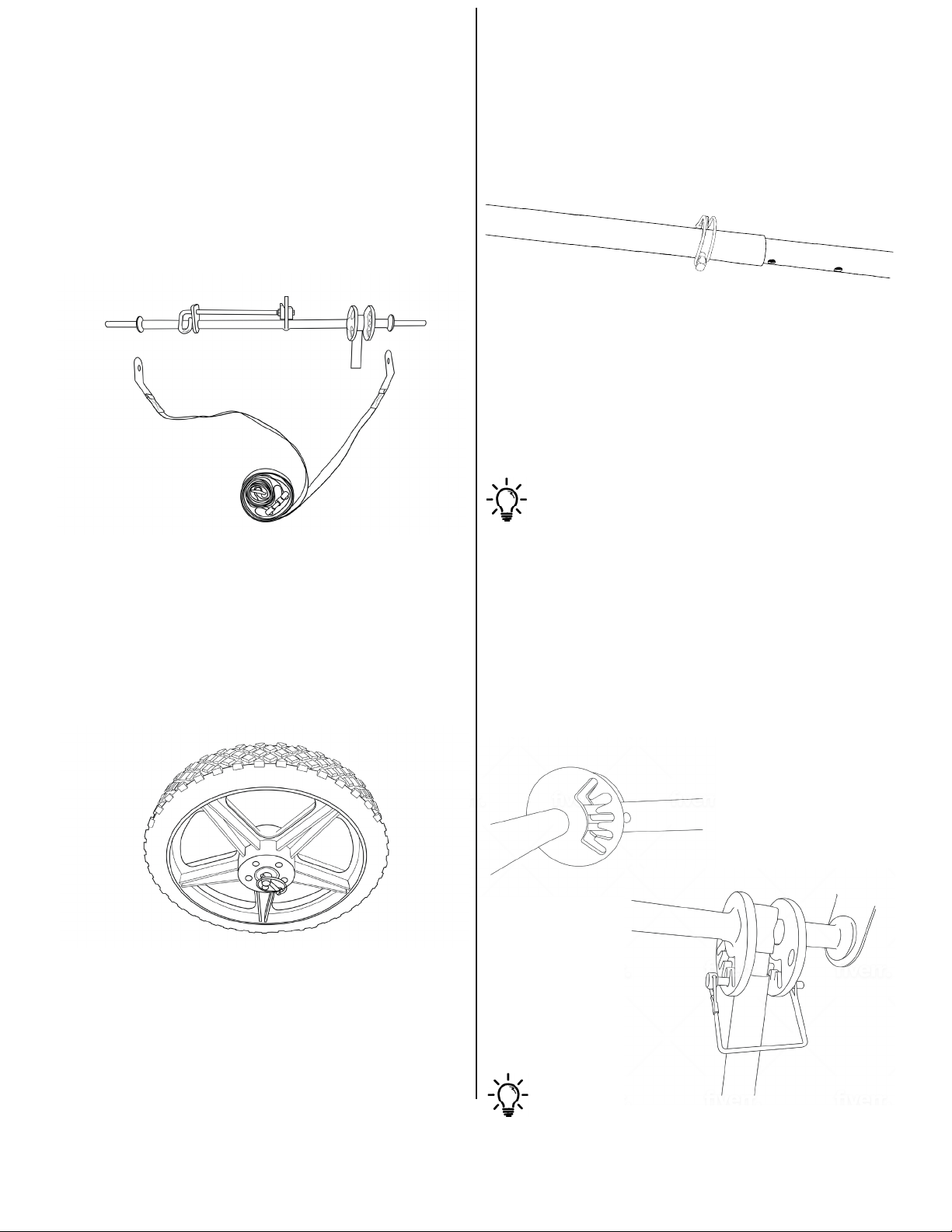

11

1. Put the metal strap plates over either

end of the axle.

e strap [9C-a] is used to pull the cart along as you

work.

Angle the plates [9C-b] inward when mounting them

on the axle [10C] as shown, and don’t twist the strap.

Put the wheels [17C] on either end of the axle [10c].

Insert the lynch pins [16c] and ip them into the locked

position.

e pivot arm [7C] is unidirectional, with a

spring-loaded end that mounts towards the cart’s axle

[10C]. Check that the spring is facing the opposite

direction before you insert the throttle extension arm.

2. Put the wheels on the axle and insert

the lynch pins.

3. Put the throttle-extension arm and

pivot arm together, and set the

locking pin.

e throttle-extension [6C]/pivot arm [7C] is adjust-

able in length: set the pin [8C] accordingly.

4. Mount the pivot/throttle-extension

arm onto the axle.

When using the mini-trencher, the pivot/throttle-ex-

tension arm [6C + 7C] is used to push the nose of the

trencher down, into the ground, while driving the en-

gine.

Locate the clevis pin [15C] before you begin.

A. Push the pivot arm [7C] in, depressing the

spring, to set the clevis pin [15C].

B. Set clevis pin by passing it thru both sides

of the pivot plate [14C], thru the slot in the

pivot arm [7C], and thru the handle mount

bar [13C], while the spring is depressed.

is may take a couple tries.

Don’t worry which slot in the pivot plate the pin passes

through; more about that in Adjusting the Cart Arm,

below.

Step 2, Continued:

DO NOT attempt to operate without mounting

lock engaged!

locked position

open position

tab

throttle cable

cable-tension

adjuster

trigger lever

velcro strap

12

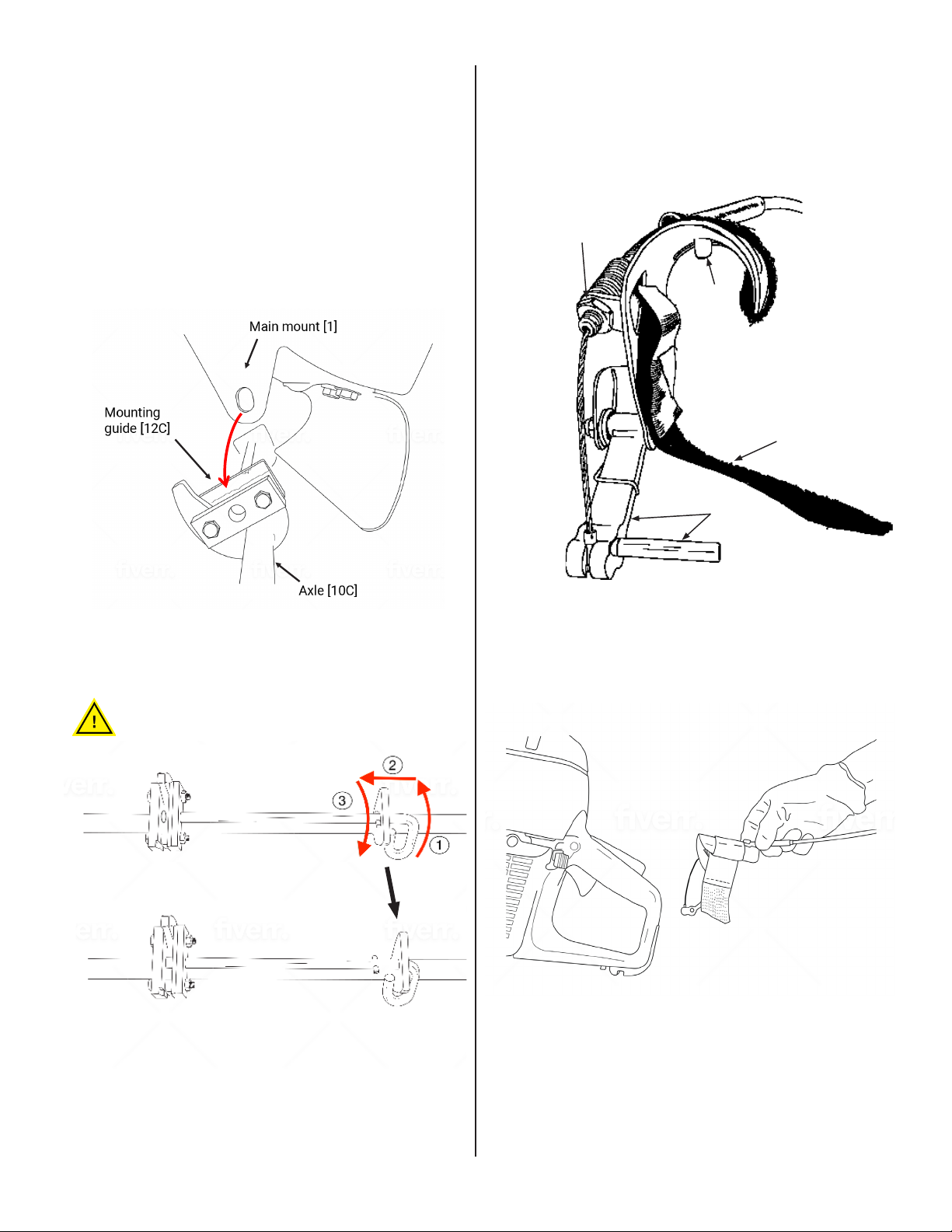

Step 3: Mounting the Mini-trencher

on the Cart

1. Seat the mini-trencher on the cart.

With the chain mounted and the cart assembled,

you’re ready mount the mini-trencher on the cart.

2. Slide the mount lock into place.

3. Mount the trigger-extension

accessory:

Locate mounting lock [11C] and guide [12C]. Make

sure the lock is open. Li the mini-trencher by the han-

dle, align the ange with the guide, and set the trencher

onto the cart.

A. Orient the throttle accessory so that it’s fac-

ing the right direction, and open the velcro

strap.

Tip

Tip

Notice:

13

C. Fasten the velcro strap securely.

D. Adjust the trigger lever so that it sits snugly

on the throttle trigger.

Step 3, Continued:

B. Set the accessory over handle, as shown,

depressing the safety (a.k.a. throttle-trigger

lockout).

During and after starting the engine, you

may need to readjust the trigger-extension

assembly. If the throttle lever doesn’t work, the

cable may have become loose or disconnected.

Use the cable-tension adjusters as needed.

There’s one tension adjuster on the accessory

and another on the throttle-extension arm.

The tab on the inside surface of the accessory

ts into the space behind the safety lockout.

Notice:

14

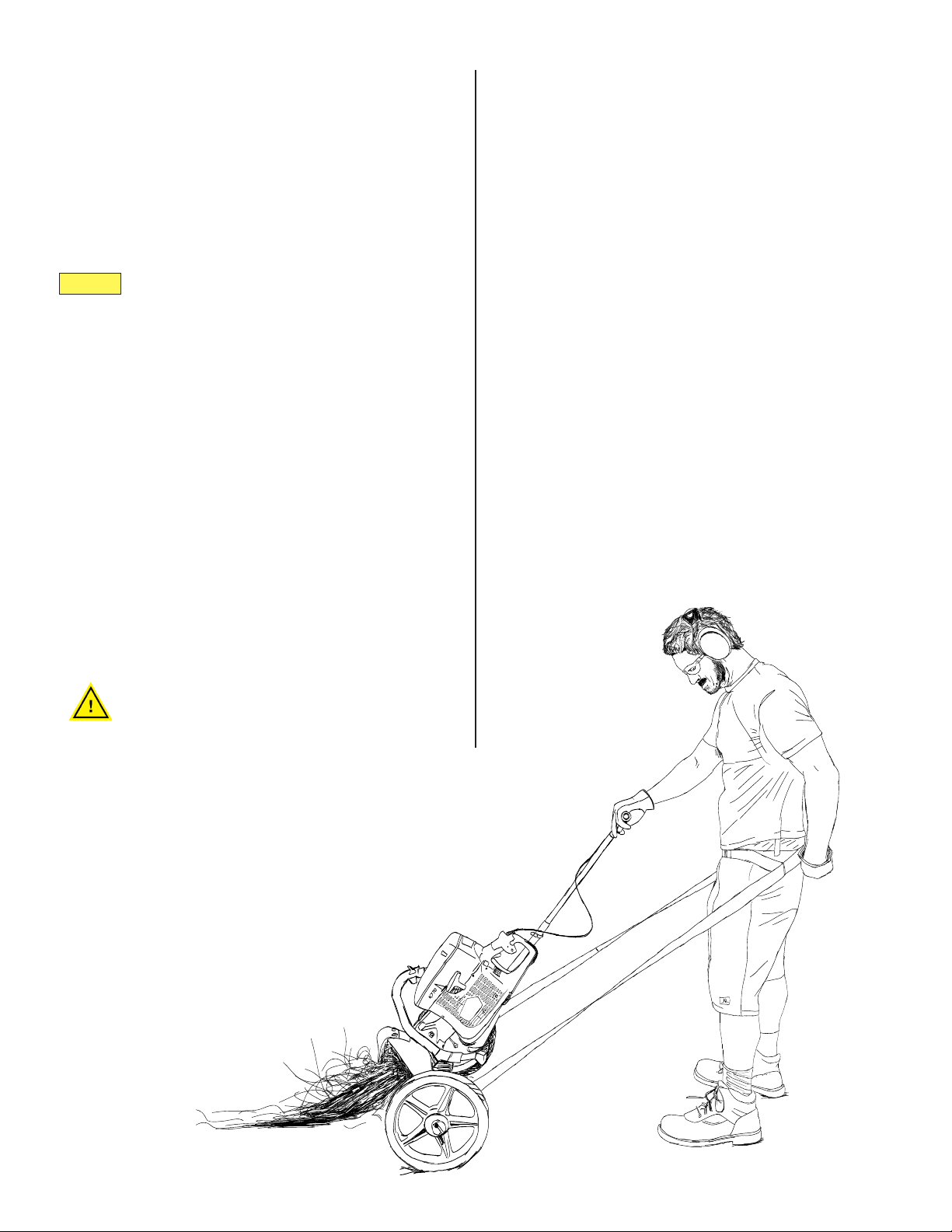

Digging a Trench

In general, the process is the following:

1. Assemble the mini-trencher and mount it

on the cart.

2. Get the mini-trencher into position over

It takes a little practice to get procient with the

mini-trencher. Read on for a few tips and strate-

gies for success.

the area you want to dig, and strap on the

belt.

3. Start the engine (we use the trigger on the

power head to get it started, then adjust the

tension on the throttle cable as needed),

and then move up to the throttle-extension

arm [6C] to power the engine.

4. Get the chain rotating at a moderate speed

(50-75%) before you bring it into contact

with the ground. Too high a speed risks

throwing projectiles and too low can cause

a stall.

5. Work the nose of the mini-trencher into the

ground to desired depth, up to 90 degrees.

e angle of the digging chain determines

the depth of trench.

Before beginning, strap on belt to avoid

entanglement.

6. Adjust the pivot arm as needed. We recom-

mend holding the rear handle of the power

head when adjusting.

7. Use the belt to pull the weight of the tren-

cher towards you, in the direction you want

to dig the trench.

8. Use a rocking motion to get to get past

compacted soil and minor obstacles.

9. If you strike large rocks, thick tree roots,

Never operate on the downhill side of the

machine!

• If operating on a slope, operator should stay

on the uphill-side of the machine.

Adjusting the cart arm

e cart arm (throttle-extension/pivot arm) allows

you to exert downward pressure on the nose of the

mini-trencher and control depth. Adjust it as needed.

1. Hold the rear handle of the power head, de-

press the clevis pin [15C] inward to disen-

gage from the pivot plate [14C], and pivot

the throttle-extension arm up or down.

2. Once adjusted, release inward pressure to

re-engage the pivot plate.

Notice:

Notice:

15

MaintenanceandTroubleshooting

Proper care and maintenance of the power head

improves overall function of TrencherPro parts.

The power head includes a clutch, drive belt, and

belt tensioning system. Review the power head

manual and understand how these systems work

before operating the machine.

See power head manual for detailed information

about servicing and maintaining the drive belt,

carburetor, starter, fuel system, air lter, clutch,

and general troubleshooting.

Never run the engine in a conned or poorly

ventilated space.

Always stop engine and allow parts to cool

down before servicing.

Periodically check chain for damage and lodged

debris.

Aer each use, take a sti brush and clean debris o of

the digging chain. Lightly spray with oil. For long-term

storage, remove chain and place in oil bath.

Maintaining the digging chain

e heavy-duty digging chain and drive belt are parts

designed to wear over time. Check, tension, and re-

place these parts regularly for best results.

• To extend chain life, adjust the chain ten-

sion to t the soil type.

• e working life of a digging chain is great-

ly impacted by soil type.

Parts designed to wear

Never attempt to operate device with a

damaged, heavily rusted, or otherwise faulty

chain.

For detailed instructions on how and when to ten-

sion or replace the drive belt, see power head manual:

Drive belt tension and replacement

Solution: Correctly tension drive belt.

1. Turn o engine. Allow to cool.

2. Remove cover guard. Inspect drive belt and

tensioner visually and check belt tension.

3. See power head manual for instruction on

tensioning drive belt.

Common problems and solutions

Problem: Engine is revving but chain isn’t

rotating

Solution: Adjust tension of digging chain.

1. Turn o engine. Allow engine and chain to

cool.

Problem: Chain is binding, possibly

causing engine to stall

The chain tends to tighten itself with use

and needs periodic adjustment. Rocks stuck

between the digging chain and bar also tighten

chain tension. The mini-trencher performs best

with a certain amount of slack in the chain.

Stop and check the chain tension.

Problem: Pivot arm not engaged

Solution: Make sure that the clevis pin [15C] is en-

gaged in the pivot plate [14C]. See ‘Adjusting the cart

arm’ above.

e pivot arm should be used to adjust the downward

pressure on the nose of the trencher, not to push or

pull the cart forward or backward. Use the strap to pull

the cart in the direction of your trench.

Problem: Throttle lever not working.

Solution: Trigger-extension cable is disengaged.

Check the throttle extension accessory [5C] and throt-

tle lever [2] to make sure the cable is engaged properly

tensioned.

Problem: Rock stuck in digging chain/

bar.

Solution: Remove rock and re-tension digging chain.

1. Turn o engine. Allow engine and chain to

cool.

2. Once cool, rotate chain reverse of operating

direction to dislodge rock.

Problem: Rocks continually stuck in

digging chain/bar.

Solution: Change the nose sprocket.

1. Turn o engine. Allow engine and chain to

cool.

2. 2. See ‘Changing the nose sprocket’ below.

16

Changing the nose sprocket: 6 tooth vs.

11 tooth.

See fuel specications in power head manual for your

specic model.

Use minimum of 87 octane unleaded fuel, with the

correct mixture (1:50 or 2%) of two-stroke oil for

air-cooled engines. Never use two-stroke oil intended

for water-cooled engines. Never use oil intended for

four-stroke engines. Mix the fuel and oil in a clear con-

tainer intended for gasoline. Do not start the engine if

fuel has been spilled nearby as sparks may cause a re.

Transport and store the machine upright so that there

is no risk of fuel leakage. For long-term storage, drain

the fuel mixture from the machine.

Fuel and two-stroke oil:

MaintenanceandTroubleshooting

Continued:

Solution: See Husqvarna manual for detailed informa-

tion about “Starting and Stopping,” (pp 24-26).

Problem: Engine won’t start, or starts

with difculty

Changing the sprocket is fairly straightforward. To

change the nose sprocket:

1. Heat the screws to loosen the locking com-

pound.

2. Remove the M8 screws [16] using an im-

pact driver.

3. Remove the plates and swap out the sprock-

et.

4. Add a locking compound to the screws

before reinstalling.

5. Tighten the screws to 33Nm.

Failure to add locking compound when

reinstalling sprocket could result in injury or

damage to equipment!

e 6-tooth nose sprocket is designed to clear rocks

from the chain, but has less chain engagement. e

sprocket is ideal for moderately rocky soil, sandy and

coarse soil.

e 11-tooth nose sprocket is ideal for loose top soil,

clay, hard and compacted soil.

TRENCHER PRO

Warranty Information

IMPORTANT NOTICE

We, the manufacturer, reserve the right to change the product and/or specications in this manual

without notication. The manual is for information use only and the pictures and drawings depicted

herein are for reference only.

Warranty Repair and Service

Do not return this product to the store for warranty issues or repair. Call our customer service

department at 720-437-7640 for the location of the nearest service center.

Record the information below for future reference.

Model No. ____________________________________________________________________________

Serial No. ____________________________________________________________

Date of Purchase ______________________________________________________________________

Place of Purchase _____________________________________________________________________

For Service or Questions:

Call 720-437-7640

Registration

Acceptance of responsibility:

I (purchaser) have read the User Guide & Manual and Limited Warranty or someone has read and

explained all instructions to me. I understand this warranty does not cover any labor and that all

disputes will be settled by binding arbitration. Warranty void if any attempt to repair or replace defective

parts has been made by unauthorized personnel. The mark next to each item below conrms my

acceptance of responsibility for the use and maintenance of this mini-trencher. I understand that I

alone am responsible for the proper maintenance, care, and safe operation of this mini-trencher.

Received, read, and understand this User Guide & Manual

Understand the safety warnings

Specications accepted

Operations understood

Maintenance requirements understood

I (purchaser) understand that persons who have not read and understood the operator’s manual should

not be allowed to use the machinery. Children should not operate or be near the equipment. Anyone

operating the mini-trencher must have rst read the general safety and use guidelines sections of the

manual.

Is this mini-trencher used by a business?

Yes, business type: _____________________________________________________

No

Owner / Purchaser Signature: ________________________________________________________

The warranty may be refused if the registration is not completed, signed, and legible. It is the

responsibility of the purchaser to assure that the registration form is returned to us, post-marked within

two weeks of date of purchase.

TrencherPro product warranty offers one year warranty against defects in workmanship.

The warranty gives the consumer certain and specic rights which may vary from state to state.

Warranty does not cover normal wear, misuse, neglect, abuse, improper maintenance, overload beyond

rated capacity, accidents, cosmetic defects, consumables, non-authorized replacement parts or

accessories, operation with inadequate supply of gear box oil, improper uid types, or unauthorized

adjustments.

TRENCHER PRO

WARRANTY VOID IF REGISTRATION IS NOT POST MARKED WITHIN 15 DAYS OF PURCHASE.

Mail to:

ToolTuff

15000 West 44th Ave, Suite B

Golden, CO 80403

Serial #: _________________________________________________________Purchase Date: _______________________

Purchased From: ______________________________________________________________________________________

Purchaser: ___________________________________________________________________________________________

Purchaser’s Street Address: ___________________________________________________________________________

City: ___________________________________________________________________________________________________

State: ______________________________________________________ Zip Code: _________________________________

Phone:__________________________________________________________

Email: _________________________________________________________

Attach a copy of receipt or proof of purchase.

To complete registration electronically, ll out and scan the Registration pages and email them to:

customerservice@tooltuffdirect.com

For Service or Questions:

Call 720-437-7640

This manual suits for next models

2

Table of contents