Tricel Puraflo Series User manual

1

125 Rev 4 Jan 2019

Tricel®Puraflo 1-50

Wastewater Treatment Plants

Engineering a green future

2

Contents

Contents......................................................................................................................................................... 2

1 Health & Safety Precautions ................................................................................................................... 6

1.1 General ......................................................................................................................................... 6

1.2

Electrical/Maintenance

............................................................................................................. 7

1.3 Installation:................................................................................................................................... 7

2Introduction: Tricel Puraflo ................................................................................................................... 8

2.1 How a Tricel Puraflo Plant works: ................................................................................................. 9

2.2

Tricel Puraflo: Typical Layout

........................................................................................................ 10

2.2.1

Plan view of Typical Tricel Puraflo Secondary System

........................................................ 10

2.2.2

Plan view of Typical Tricel Puraflo Tertiary System

............................................................ 10

2.3 Tricel Puraflo Applications.......................................................................................................... 11

2.3.1 Secondary Treatment.............................................................................................................. 11

2.3.2 Tertiary Treatment.................................................................................................................. 11

3Tricel Puraflo Range ................................................................................................................................ 12

3.1 System Specifications................................................................................................................. 12

3.2 System Components ................................................................................................................... 12

3.2.1 Tricel Puraflo Module.............................................................................................................. 12

3.2.2 Effluent Filter (secondary treatment only) ............................................................................. 13

3.2.3 Pump ....................................................................................................................................... 13

3.2.4 Pipework ................................................................................................................................. 14

3.3 System Layout Drawings:................................................................................................................. 14

4Transportation & Lifting........................................................................................................................... 16

5Installation............................................................................................................................................. 16

6Commissioning ....................................................................................................................................... 16

7Disposal of Treated Water ....................................................................................................................... 17

8Maintenance.......................................................................................................................................... 17

8.1 Regular Maintenance...................................................................................................................... 17

8.1.1 Septic Tank (If applicable)....................................................................................................... 17

8.1.2

Wastewater Treatment Plant (If applicable)

.................................................................... 17

8.1.3 Effluent Filter (If applicable)................................................................................................... 18

8.1.4 Pump Chamber (If applicable)................................................................................................. 18

8.1.5 Control Panel .......................................................................................................................... 19

8.2 Annual Service(Available from your supplier) ..................................................................................... 20

8.3 De-sludging ................................................................................................................................... 20

3

9Operating Conditions .............................................................................................................................. 21

9.1 Conditions: .................................................................................................................................... 21

10 Troubleshooting ..................................................................................................................................... 23

10.1 Plant Operation........................................................................................................................... 23

10.2 Odours ........................................................................................................................................ 24

11 Certification ........................................................................................................................................... 25

11.1 Declaration of Performance - Tricel Puraflo with Tricel Fortis ............................................................... 25

11.2 Declaration of Performance – Tricel Puraflo with Tricel Vento................................................... 28

4

5

6

1 Health & Safety Precautions

This manual contains basic information on the installation, operation and maintenance of the Tricel

Puraflo wastewater treatment system. For this reason, it is essential that these instructions are

carefully read and understood before installation or commissioning by both the installation crew as

well as those responsible for the operation and maintenance of the system. This manual should be

readilyavailableatthelocationofthesystem.Itistheresponsibility ofthe homeowner toensurethat the

wastewater treatment system is operated and maintained correctly and in a safe manner at all times.

As safety and security are of vital importance, the following aspects are critical:

1.1 General

•

Ensure that all the information contained in this manual is adhered to at all times.

•

Treatedwastewateris notsuitablefor humanconsumption

. It is unhealthy for humans, pets, and

wildlife to drink or come in contact with surface or ground water contaminated with sewage.

•

It is importantthatlocksare fitted to the lid to preventaccidentalaccess.

•

Neverenteratank,unless qualifiedtodoso.

•

Nakedflamesshall not be used in the vicinityof the tank due tothedangerof combustion.

•

The manhole covers shall never be left off an unattended tank. Always lock the covers of the

plant whenwork is completed.

•

Sewage and sewage effluent can carry micro-organisms and gases harmful to human health.

•

Any person carrying out work on the

wastewater treatment system

must be appropriately

trained.

•

Suitable protective clothing; including waterproof/abrasion-resistantgloves,

overalls,

safety

footwear, eye, ear and respiratory protection, goggles (face visors are particularly effective

againstsplashes) should be worn at all times. All protective clothing must bein goodcondition

and befit for its intended purpose.

•

Always remove contaminated clothing and protective equipment after working with

wastewater treatment plants.Wash hands and face prior toeating,drinkingorsmoking.

•

Wastewater treatment plants contain very low levels of oxygen. Hydrogen sulphide, methane,

carbon dioxide and other

life-threatening gases are also present. Tanks have manholes

covers to provide access to the tank only in times of cleaning and inspecting the tank from

outside.The manhole covers must always be in place and secure.

•

Keep vehicles and other heavy equipment away from the wastewater treatment plant and

percolation area.

•

Erect a safety barrier around open manholes to prevent anyone from accidently falling down

the manholes.

•

Keepchildrenawayfromthesepticsystemwhenitisbeing workedon.

•

Donot smoke near wastewater treatment plants. Combustible gases could be present and cause

an explosion.

•

Contact a plumber or other qualified person if you smell 'sewer gases'. They can identify the

sourceand correctit immediately.

•

The sewage treatment process uses many beneficial microorganisms, like bacteria, in the

treatment process.

However, the plant also contains harmful bacteria, viruses and disease-

organisms.

Liquid and solid contents of the septic system are capable of causing infectious

diseases.

7

1.2

Electrical/Maintenance

•All electrical work to be carried out by competent persons using suitable materials for the

application.

•Do not open the Tricel Puraflo alarm cover without firstly isolating the mains power.

All power

isolation switches should be turned off [Follow Lock-out/Tag-Out Procedure] before any

maintenance/inspection work is done at the wastewater treatment plant.

•Never use electrical lights, appliances or power tools in or close to water or wet ground near the

septic tank or percolation area. This can result in electrical shock or explosion.

•Electrical work must be carried out strictly to the manufacturer’s instructions and to the relevant

national rules for electrical installations.

All connections to the control panel should only be

made by competent qualified personnel. If a cable is damaged, it should be replaced

immediately to prevent electrical shock or damage to the electrical equipment. All electrical

connections are completed on site.

•When working with machinery/electrical equipment, proximity of water shall be noted. Electrical

equipment shall not be wet when working with it.

•

There is potentialdanger whende-sludgingand thereforethis shall neverbe done alone.

•

A wastewater treatment system that fails to fully treat sewage due to poor maintenance or

overloading may allow excess nutrients (phosphorus and nitrogen) to reach nearby lakes and

streams, promoting algae and plant growth. Algal blooms and abundant weeds may make lakes

unpleasant for swimming, boating, and other water-based activities. This plant growth can also

affect water quality for fish and wildlife habitat. As plants die and settle to the bottom, they are

brokendown bybacteria that use upoxygenthatfishneedtosurvive.

•

Itistheresponsibilityoftheownertoensurethatthewastewatertreatmentplantisoperatedand

maintained correctly at all times.

•

It is advised that the owner enters into a yearly Service Agreement to ensure the correct

operationoftheirwastewater treatmentplant.

1.3 Installation:

•

Excavationwork shouldbe plannedwith dueregardto healthandsafetyrequirements.

•

Septic tank should also be properly vented in accordance with the tank manufacturer’s

guidelines.

•

Excavated material should either beshoredor batteredbacktoa“safe”angle.

•

Use appropriate liftingequipment.

•

Careshouldbetakenaroundgroundsworkmachinery.

•

Keepproper footing and balance at all time.

•

Tricel Puraflo modules are supplied with ropes for lifting purposes. The modules are designed

for a single lift when placing them in position.

8

2Introduction: Tricel Puraflo

Tricel Puraflo is a modular wastewater treatment system which can cater for large or small populations.

It is

a flexible system which can treat effluent from one-off domestic houses, small communities and light

commercial applications through the implementation of additional Puraflo modules.

The Tricel Puraflo system uses peat fibre to break down the effluent making this type of treatment system

popular, using little to no energy. The Tricel Puraflo system works in conjunction with your septic tank or

wastewater treatment plant.

The wastewater is distributed evenly over the top of the peat filter, using a

specially designed pipe network, to ensure optimum performance. Through a combination of biological,

chemical and physical processes the peat treats the wastewater as it filters through.

The Tricel Puraflo is

designed such that maintenance requirements are minimised whileatthesametimeeffectivelytreating

effluent.

The Tricel Puraflo can be implemented as secondary or tertiary treatment as part of a complete

wastewater treatment system.

9

2.1 How a Tricel Puraflo Plant works:

Typical Tricel Puraflo System

Stage 1

Liquid effluent is pumped, by submersible pump, intermittently on- demand to the Puraflo modules.

Stage 2

Effluent is distributed evenly onto the peat filter via a distribution grid at the top of each Puraflo

module.

Stage 3

Liquid effluent undergoes treatment as it filters through the bio-fibrous peat in the Puraflo modules.

Stage 4

Highly treated effluent can be sampled at the in-built sample chamber.

Stage 5

Treated wastewater flows from the outlet of the sampling chamber and is discharged to a percolation

area/polishing filter.

10

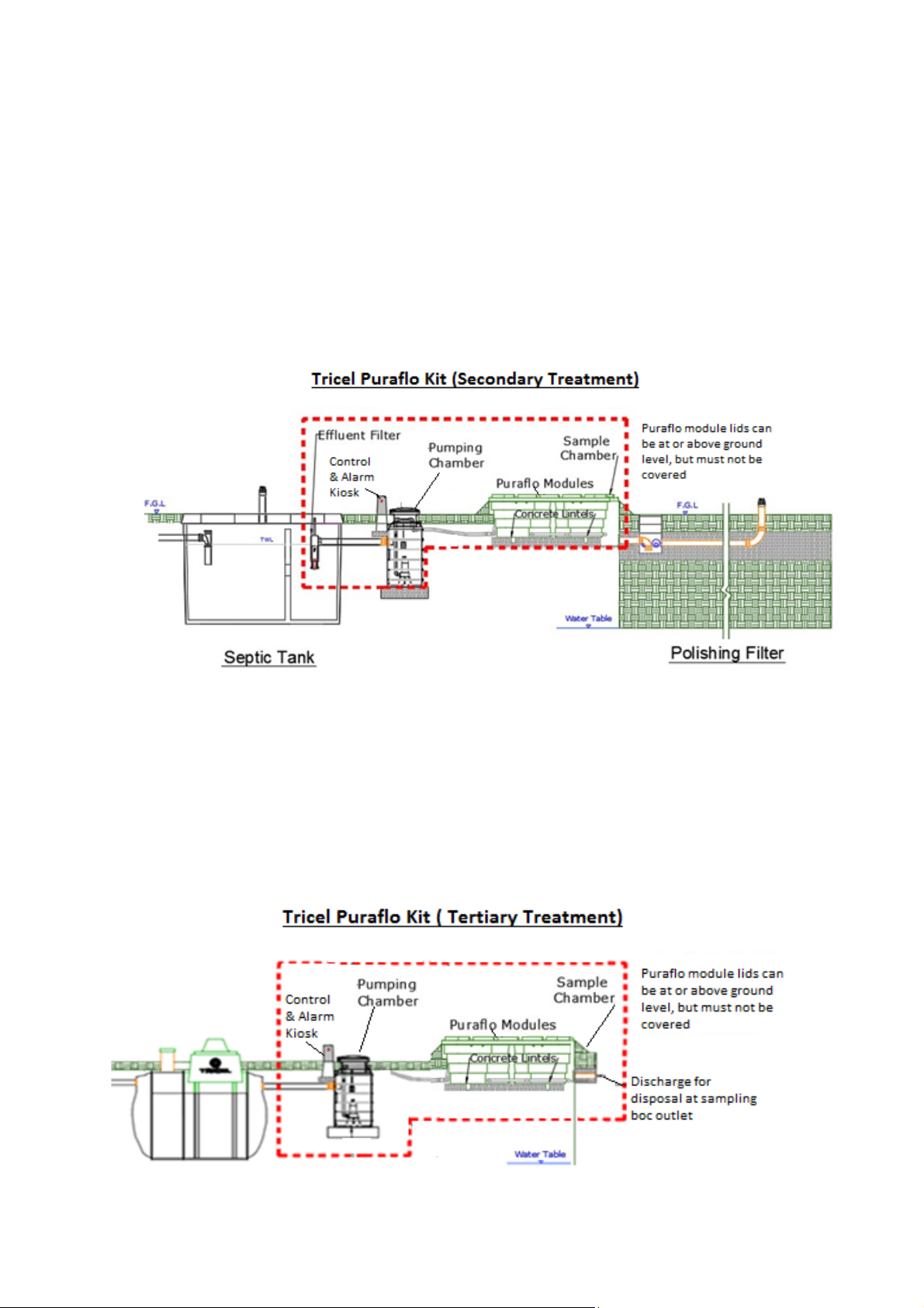

2.2

Tricel Puraflo: Typical Layout

2.2.1

Plan view of Typical Tricel Puraflo Secondary System

1

Manhole Cover – Inlet to Septic Tank (access to inlet tee)

2

SepticTankVentPipe withCowl.Vents mayvarydependingonseptictank.

3

Manhole Cover – Outlet from Septic Tank (access to filter) *

4

TricelPuraflo Kiosk (contains control panel & alarm)

5

Manhole Cover – Tricel Puraflo Pump Chamber

6

Tricel Puraflo Modules – Number of modules depend on loadings

7

Sampling Chamber

8

DistributionBox– Flowing topercolationarea/pumpchamberto discharge treated liquid.

* Some septic tanks may only have one manhole cover.

2.2.2

Plan view of Typical Tricel Puraflo Tertiary System

1

Manhole Cover – Inlet to wastewater treatment plant (access to inlet tee)

2

Manhole Cover – Outlet from wastewater treatment plant *

3

Tricel Puraflo Modules – Number of modules depend on loadings

4

Sampling Chamber

5

DistributionBox– Flowing topercolationarea/pumpchamber to discharge treated liquid.

* Some wastewater treatment systems may only have one manhole cover.

11

2.3 Tricel Puraflo Applications

Tricel Puraflo modules can be used in secondary and tertiary treatment applications. The appropriate

treatment depends on the level of treatment required, the flow rates and the area available on site for the

installation.

2.3.1 Secondary Treatment

•

For secondary treatment, the Tricel Puraflo is used in conjunction with a septic tank.

•

A Tricel Puraflo secondary treatment kit comprises of an effluent filter (must be fitted

to the septic tank) a pumping chamber with control & alarm kiosk as well as the Puraflo

modules with a sampling chamber.

2.3.2 Tertiary Treatment

•Environmentally sensitive sites or sites that are restricted in terms of space, often require a higher

level of treatment. This is achieved by passing the secondary treated wastewater through the Tricel

Puraflo modules, within which the wastewater is treated to a higher treatment level this is known as

tertiary treatment. Tertiary treatment will achieve very high-level pathogen and nutrient reduction.

•A Tricel Puraflo tertiary treatment kit consists of a pump with control and alarm kiosk, the Puraflo

modules as well as a sampling chamber.

12

3Tricel Puraflo Range

3.1 System Specifications

Tricel Puraflo is a flexible system for treating wastewater. Tricel Puraflo systems are implemented in zones

and each zone contains multiple modules, as outlined in the table below.

In systems comprising of multiple zones, the wastewater is pumped to each zone sequentially ensuring equal

dispersion and optimum treatment.

PE

No. Zones

Per System

No. Modules

Per Zone

Total No.

Modules

1-6

1

2

2

7-9

1

3

3

10-11

1

4

4

12-15

3

2

6

16-21

4

2

8

22-24

3

3

9

25-27

5

2

10

28-33

6

2

12

34-42

5

3

15

43-45

4

4

16

46-50

6

3

18

3.2 System Components

3.2.1 Tricel Puraflo Module

Dimension

Unit

Value

A

mm

760

B

mm

1185

C mm 1400

D

mm

1935

E

mm

2150

Height of Peat in Module

mm

750

Vol. of Peat in Module

m³

2

Warning

Itis imperative thatthe treatment systemis not overloaded hydraulically or organically. The number of

modules thatare required to treat the wastewater has been designed inaccordancewiththeEPACoP.If

the owner feels that the modules are being overloaded, please contact Tricel, as it is possible to add

modulestoaccommodateanyextraloadings.

13

3.2.2 Effluent Filter (secondary treatment only)

•

Secondary treatment Tricel Puraflo systems require an effluent filter be

installed at the outlet of the septic tank to retain solids in the septic tank so

that the Tricel Puraflo modules are not overloaded.

•It is important the filter is cleaned regularly to ensure the correct operation of

the system and reduce the chance for sewerage backing up. It is recommended

that the effluent filter is cleaned bi-annually using a garden hose over the

septic tank.

3.2.3 Pump

•

The submersible pump and float switch is fitted with a thermal overload protection.

•

Effluent from the septic tank or waste water treatment is pumped via a 1.5inch pipe to the Tricel

Puraflo modules.

•

The standard pump can cater for a total head of up to 5 metres. For systems that are subject to a

total head greater than 5m, alternative pumps can be sourced. All pumps are single phase 220

–

240volt50-Hz motorswithenclosures toIP68.

•

Ahigh-level alarm is fittedanda visual warning light is located in the kiosk to alert the owner to

pump malfunctions.

•

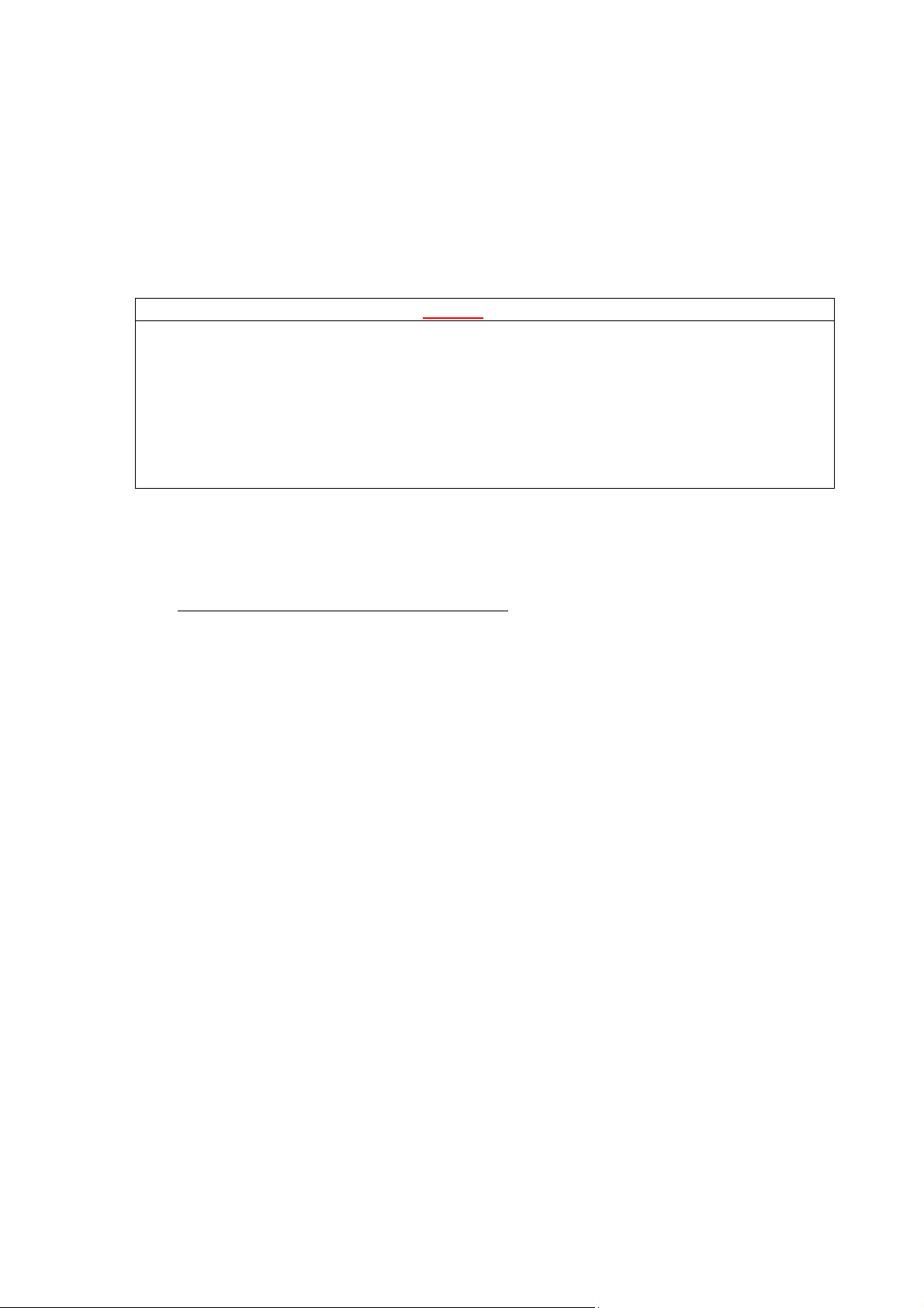

If a pump chamber is required, the dimensions of the pump chamber are outlined in the

following diagram:

14

3.2.4 Pipework

The pipework supplied with the Tricel Puraflo modules to collect the treated wastewater from the

Puraflo modules, and the pipeworkusedforthedispersion of wastewater on top of the peat inside

the Puraflo modules, is in accordancewithBS3505:1986*

*

Specification for unplasticized polyvinyl chloride (PVC-U) pressure pipes for cold potable water.

3.3 System Layout Drawings:

15

Important

If you required drawings for larger Tricel Puraflo systems from 12 to 50PE, please visit

http://ie.tricel.eu/downloads/.

16

4Transportation & Lifting

•Tanks must be held down during transportation using nylon straps, do not use cables or chains to

secure the modules.

•Do not over tighten straps that can result in deformation of the module shell.

•Do not drop or roll modules from the truck.

•Move modules only by lifting and setting, do not drag or roll.

•Always set the module(s) on flat smooth ground clear of debris etc.

•Modules are best lifted by a machine and webbing lifting straps – do not use chains or wire ropes in

contact with the modules.

•Care is needed to control the lift to ensure the modules are not damaged.

•

The modules are designed for a single lift when placing them in position.

Always lift modules

from above using the four lifting ropes attached to the tanks, as shown the following

images.

Figure 1 - Lifting Puraflo Module

Figure 2 - Setting Puraflo Module in position

5Installation

Important

The installation of a Tricel Puraflo system must only be done by a Tricel-authorised distributer or a

Tricel service technician.

6Commissioning

Important

The commissioning of a Tricel Puraflo system must only be done by a Tricel-authorised distributer or

a Tricel service technician.

17

7Disposal of Treated Water

The treated wastewater from the Tricel Puraflo systemshould be disposed of as per guidelines from the

planning regulations issued by your local authority.

8Maintenance

Warning

When working on the Tricel Puraflo system during routine maintenance & servicing, please

follow all national health and safety regulations. Sewage and sewage effluent can carry

micro-organisms and gases harmful to human health. Any person carrying out maintenance

on the system must be appropriately trained. Suitable protection equipment including

gloves, goggles etc., should be worn at all times. Always remove contaminated clothing and

protective equipment after completion of work. Wash hands and face prior to eating,

drinking or smoking. Refer to section.

The Tricel Puraflo system is designed with the best of quality and performance in mind to meet your

specificwastewater treatmentrequirementsandtoprovideyearsoftrouble-freeuse. However, a certain

amount of system maintenance is required on an on-going basis to ensure that the system is working

correctly. This is the responsibility of the homeowner.

Failure to maintain your system could also result in reduced effectiveness and increased maintenance

and/orreplacementcostsinthelong-term.

8.1 Regular Maintenance

8.1.1 Septic Tank (If applicable)

•

Theseptictankshouldbede-sludgedwhenrequired.InaccordancewithEPAguidelines,the

septic

tank should be de-sludged a minimum of once a year. Consult the manufacturer’s

guidelines.

•

De-sludging of the septic tank should prevent any solids carryover from the septic tank into the

TricelPuraflo moduleswhichwoulddecreasetheperformanceofthetreatmentsystem.

•

The inlet and outlet should be inspected and rodded to remove any blockages if necessary.

•

Ensure that no storm or surface water enters the system.

•

Ensure that the effluent filter is not blocked or matured (clogged naturally over time). Blockages

will result in backups in the septic tank which will back-up towards the house if the problem is

not resolved.

8.1.2

Wastewater Treatment Plant (If applicable)

•

The

wastewater treatment plant

should be inspected a minimum of once a year and be de-

sludgedwhenrequired. The sludge level should never be more than 50% of the depth of the

liquid.

•

The vent around the base of the blower housing guarantees a fresh supply of air to the air

blower. All vents should be checked to make sure they are not blocked or obscured.

•The vent under the de-sludging cover allows gas to escape and stops the tank from becoming

pressurised.

18

•

Ensurethe air blower is workingbylisteningfor a gentle hum whenstandingbeside theplant.

•

The inlet and outlet should be inspected and rodded to remove any blockages if necessary.

•

Ensure that no storm or surface water enters the system.

•

The

wastewater treatment plant should be serviced once a year or as per the manufacturer’s

instructions.

8.1.3 Effluent Filter (If applicable)

•

The filter should be inspected and cleaned bi-annually.

•

Do not use plumbing whencleaning filter.

•

Pull the filter out of the housing when cleaning.

•

Hose off the filter over the septic tank, ensuring that all solids fall back into the septic tank.

•

Insert the filter cartridge back into the housing ensuring that the filter is properly aligned and

inserted correctly.

8.1.4 Pump Chamber (If applicable)

•

The pump chamber should be inspected annually and the following checks andprocedures should

be followed.

•

Removethemanholecoverandde-sludgetankifnecessary.

•

Turn up the high-level alarm float switch and check that the alarm light flashes in the control

panel.

•

Clean the high-level alarm float switch ifnecessary.

•

Ensure thatthehigh-level alarm float switch is positionedcorrectly to ensure correct operation.

•

Check the position of the pump to ensure that the control float has free movement within the

pumpchamber.

19

8.1.5 Control Panel

Familiarise yourself with the location of the electrical control panel:

•

Secondary treatment systems: The control panel is located inside the kiosk supplied.

o

There is a red light located on the side of the kiosk to signal a fault has occurred in

relation to the pump.

o

Intheeventofan electrical storm or power failure,thecircuit-breakerswitchesoff

the electrical lines feedingthe pump. The pump/alarmshould be checkedtosee if

they tripped to the off position. If a circuit breaker switch is tripped, the power

supply tothealarm/pump should be restoredassoonas possible.

•

Tertiary treatment systems:

o

The control panel is located in the wastewater treatment plant.

Respond to alarm conditions promptly.

Kiosk

Tricel Puraflo Control Panel

20

8.2 Annual Service(Available from your supplier)

•

The

Tricel Puraflo system

will require a full service (available from your supplier) once a year to

guarantee the efficiency of the system is maintained.Service personnel must be accommodated

with clearaccess to thesystem.

•

During routine servicing, the following items are checked if applicable:

Checks

Procedures

The general condition of the pump chamber is

good.

The vents in the sampling chamber are

cleared.

The pipework inside the pump chamber is

secure.

The electrical control panel and alarm

system are tested.

The pipework in the sampling chamber is

secure.

The pump and float switch are tested.

The lid of the sampling chamber is in good

condition.

The distribution outlets in the modules are

cleared of any blockages.

Condition of the media is inspected.

The level of the sludge in the septic

tank/primary storage chamber is measured.

The system is inspected for any obvious non-

wastewater infiltration into any compartment

(at the time of inspection).

The effluent filter in the septic tank is checked

and cleared of any blockages if required (only

applies to secondary system).

General appearance and condition of the

treatment system and the surrounding ground

area is good.

8.3 De-sludging

To ensure that the Tricel Puraflo system performs effectively, the septic tank/wastewater treatment plant

must receive regularly maintenance.

•The de-sludging must be performed by qualified personnel.

De-sludging is done with a vacuum

tanker (we recommend the use of a licensed company).

•Please remove all floating and settled sludge from the septic tank/ primary chamber of the

wastewater treatment plant during de-sludging.

•

During the de-sludging, the effluent filter at the outlet of the septic tank should be removed

from its housing and hosed down to remove any materials which may result in blockage

(secondary treatment only).

This manual suits for next models

22

Table of contents

Popular Water Dispenser manuals by other brands

Elkay

Elkay EFHA8 2C Series Installation, care & use manual

CASO DESIGN

CASO DESIGN HW 500 Touch Original operating manual

Pentair

Pentair FLECK 5800 SXT Installation

Wells

Wells WM-TR II Operation manual

Elkay

Elkay EWTLA16*1E Series Installation, care & use manual

Elkay

Elkay EZ Series Installation, care & use manual

Watts

Watts PWS15 Series Installation, operation and maintenance manual

Hellenbrand

Hellenbrand ProMate Series owner's manual

Follett

Follett EU155N Series Installation, operation and service manual

Excalibur Water Systems

Excalibur Water Systems EWS S12530 Installation and user guide

Plumbline

Plumbline 3000 Series owner's manual

Judo

Judo PROMI Installation and operating instructions