2

Table of contents

1. Health and safety precautions: ...................................................................................................................... 3

1.1 General: ..................................................................................................................................................................................3

1.2 Electrical/Maintenance:......................................................................................................................................................3

1.3 Installation:............................................................................................................................................................................4

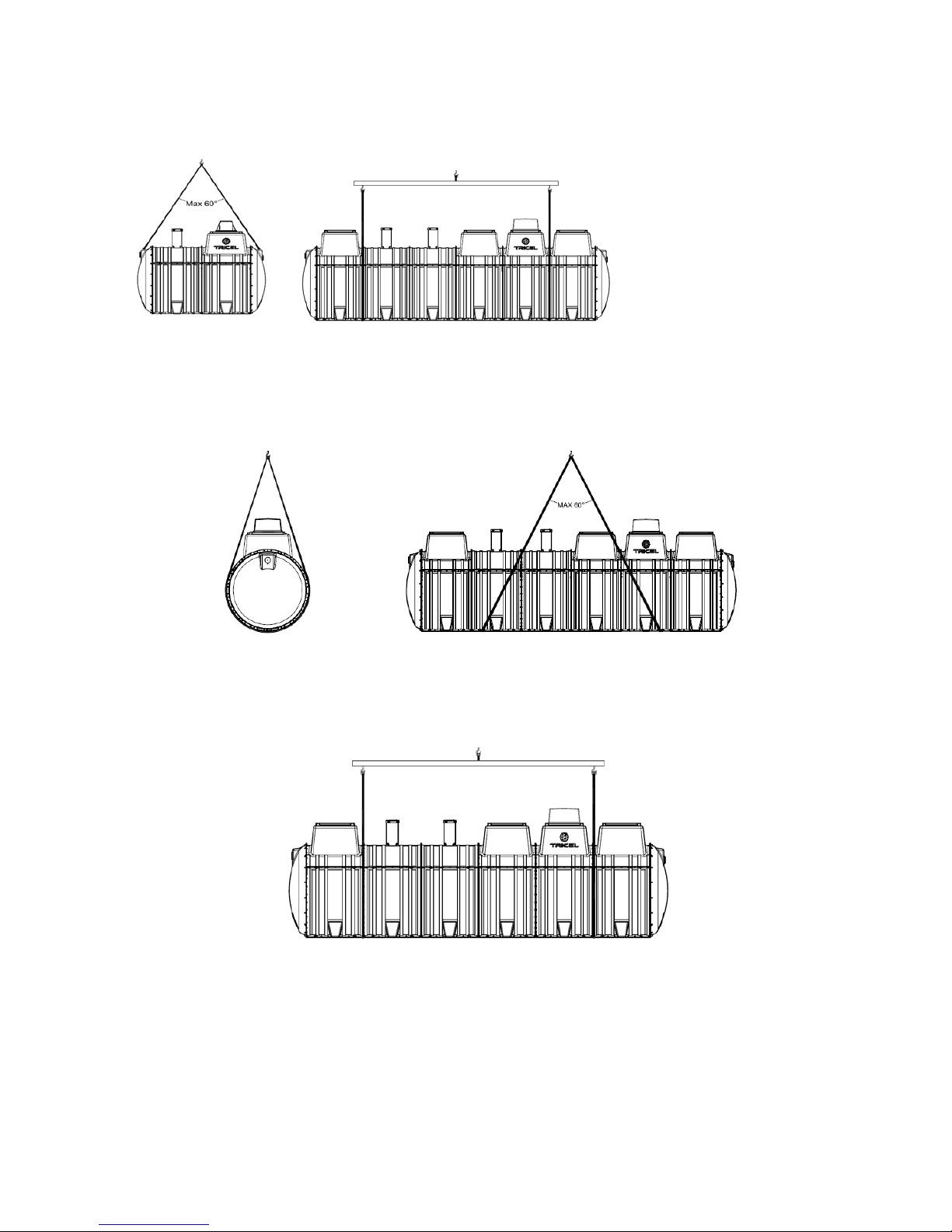

2. Transportation, unloading and storage of tanks: ........................................................................................... 4

3. Introduction:.................................................................................................................................................. 6

4. The wastewater purification process:............................................................................................................ 7

4.1 Stage 1: Primary settlement chamber:............................................................................................................................7

4.2 Stage 2: Aeration (treatment) chamber: .........................................................................................................................7

4.3 Stage 3: Final settlement chamber: .................................................................................................................................7

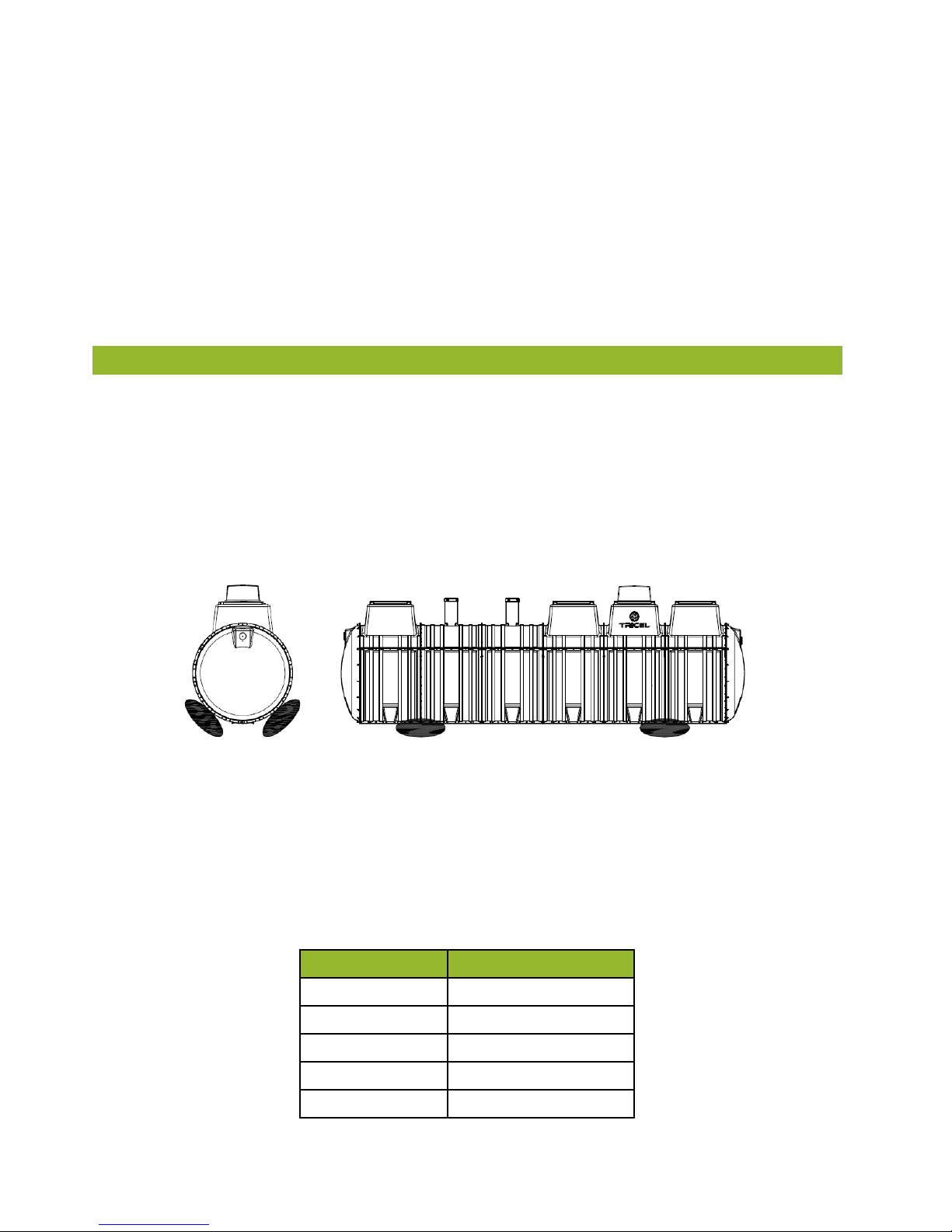

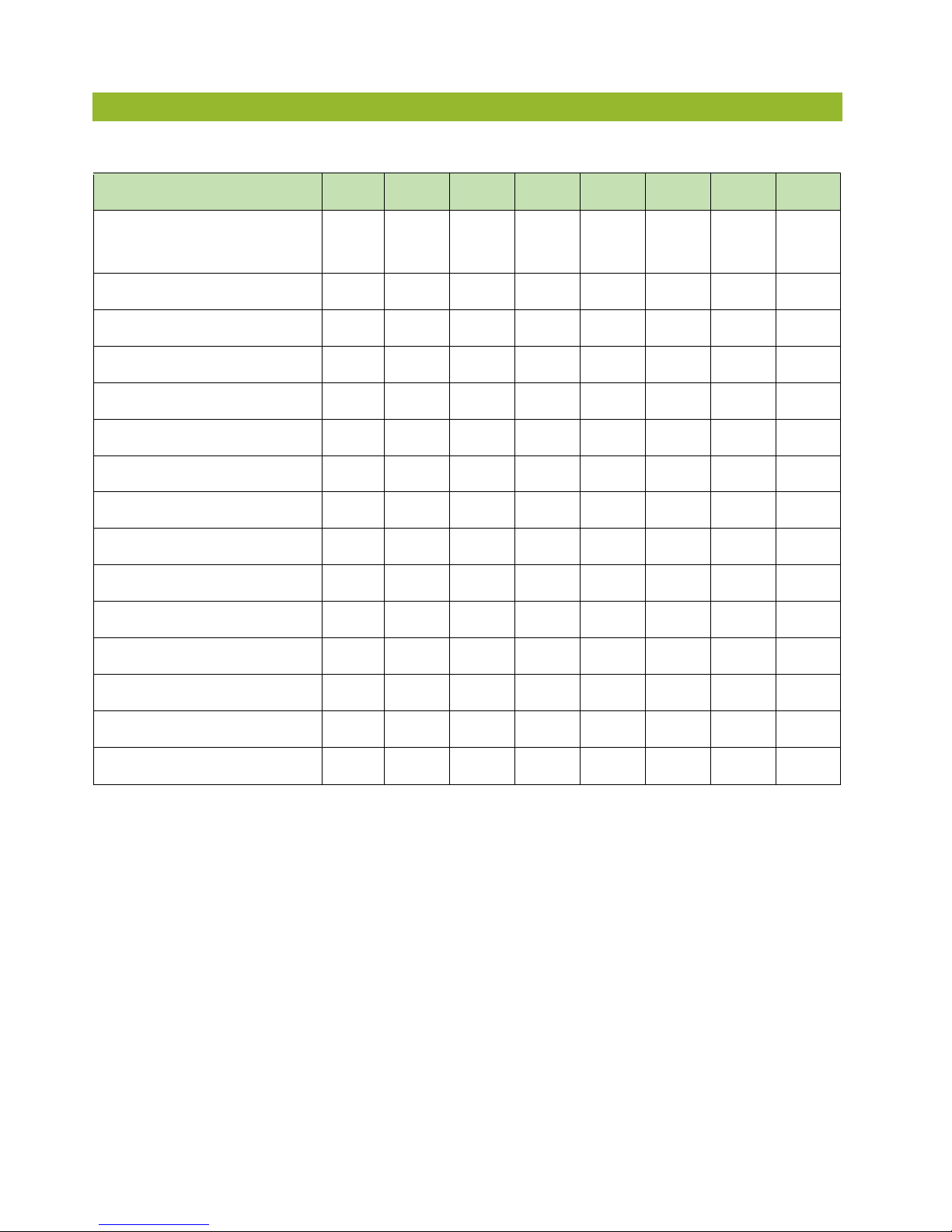

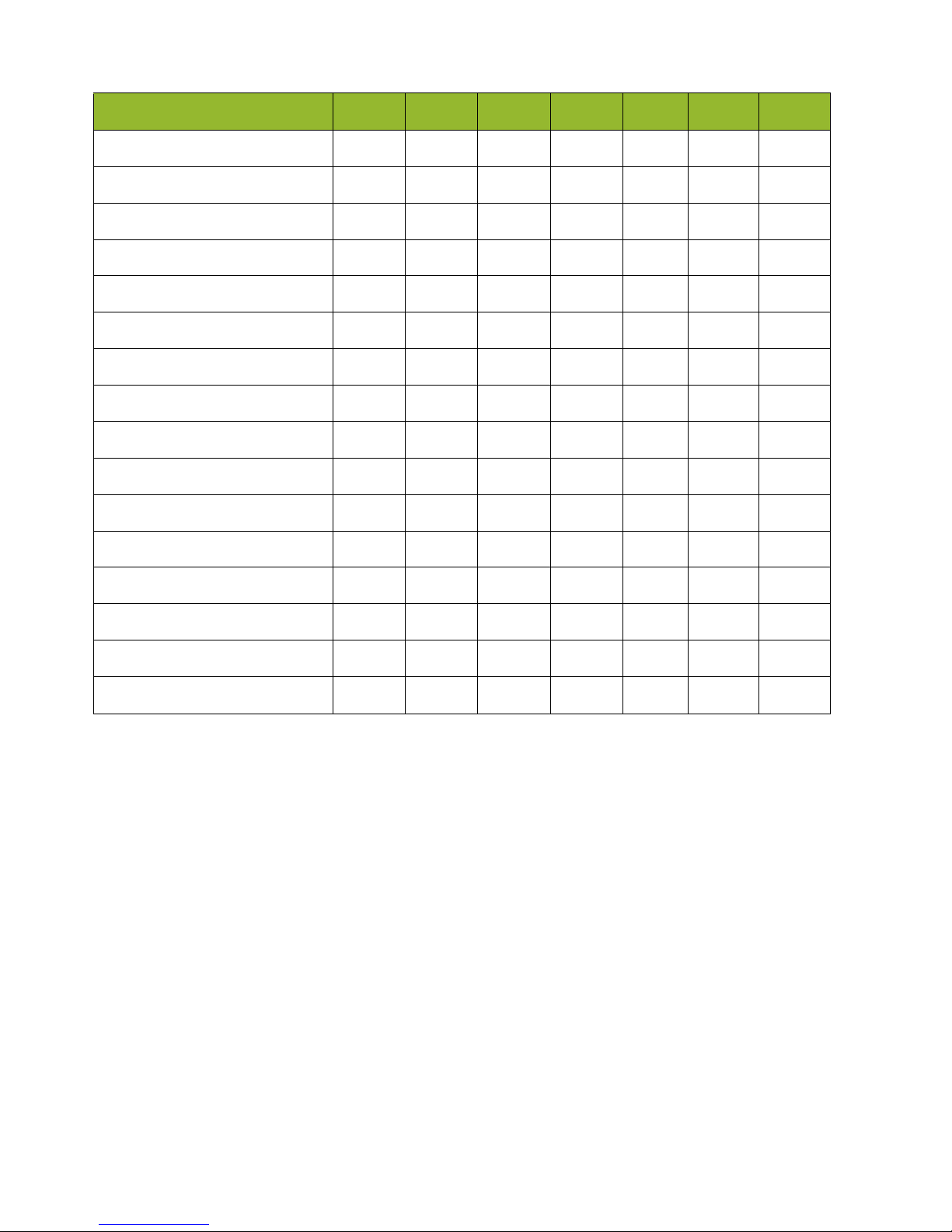

5. Plant Dimensions:.......................................................................................................................................... 8

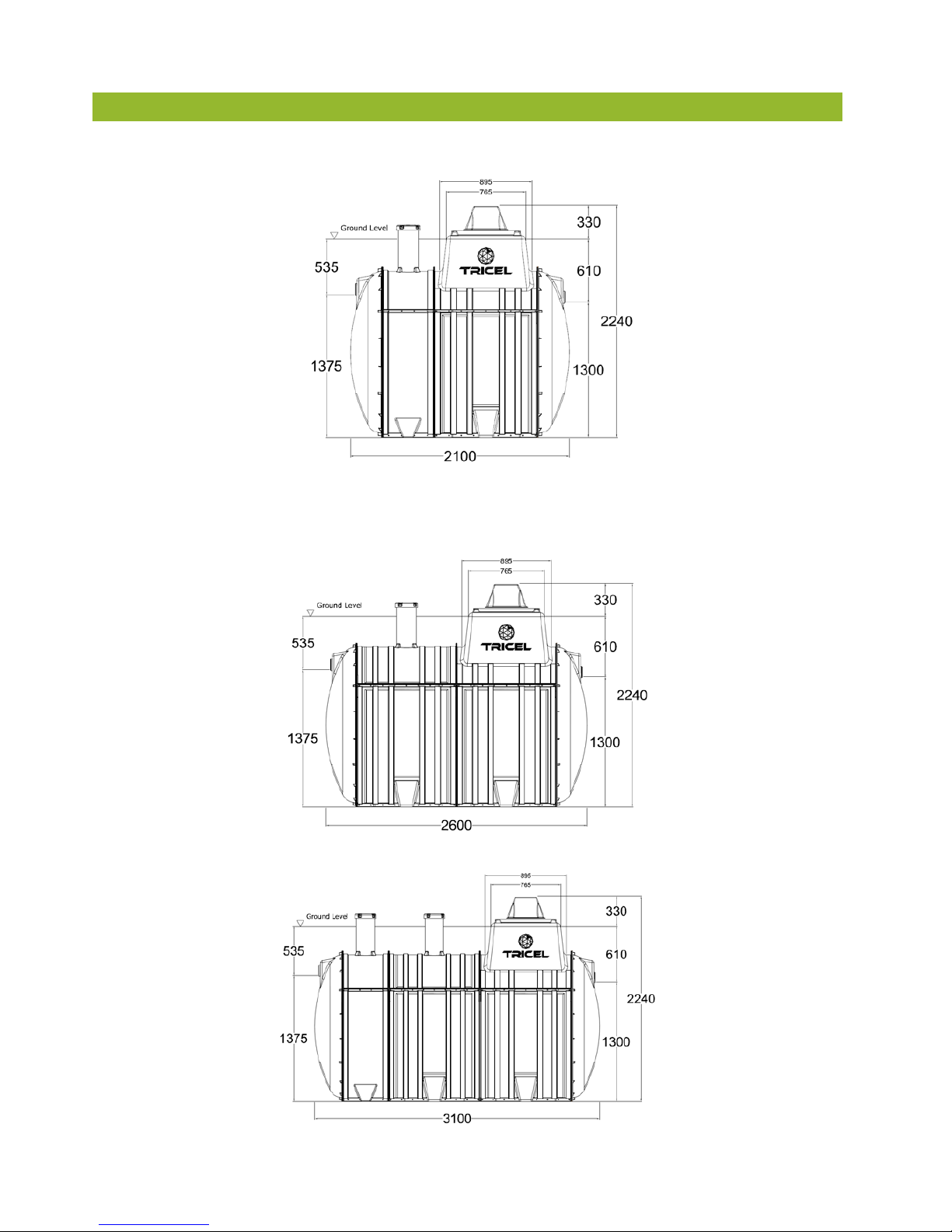

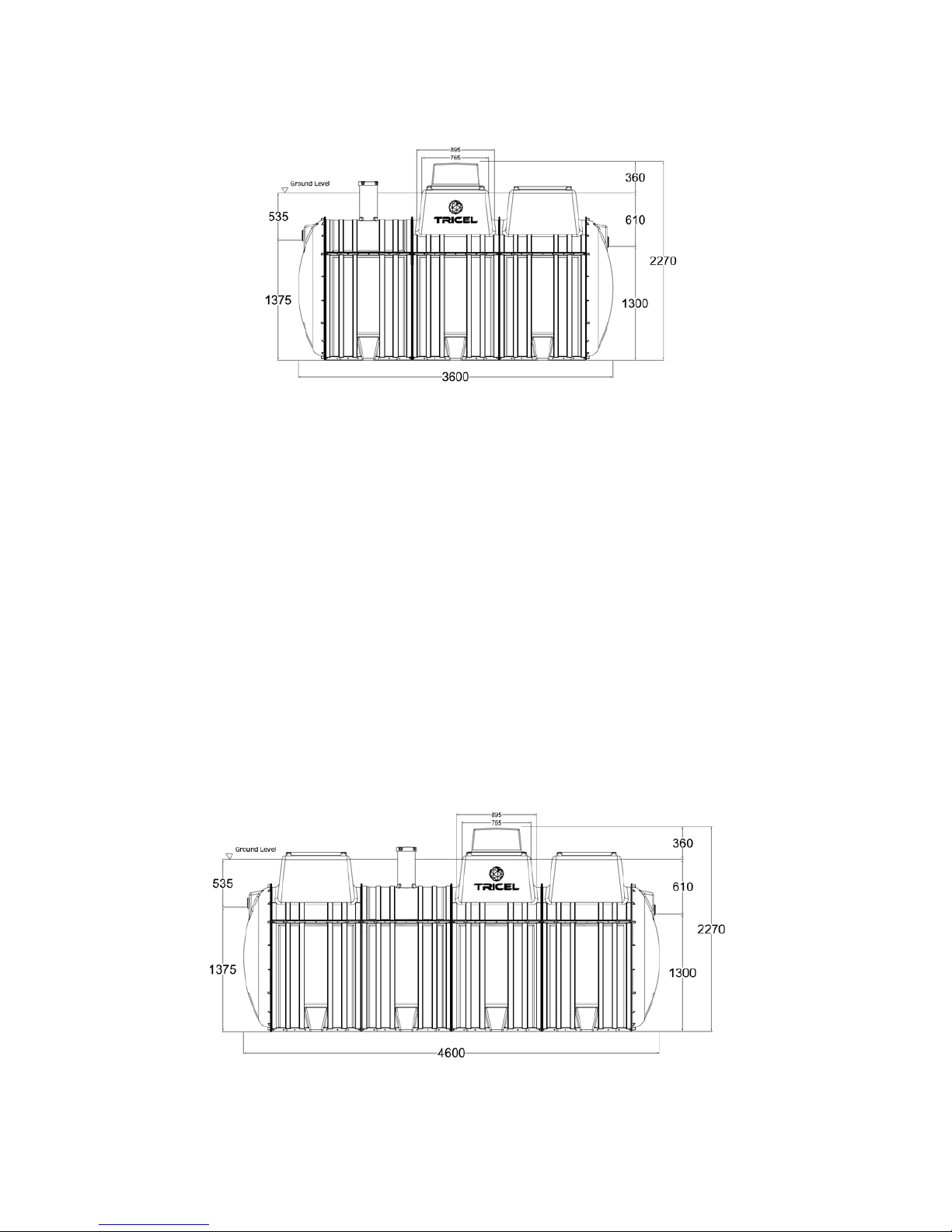

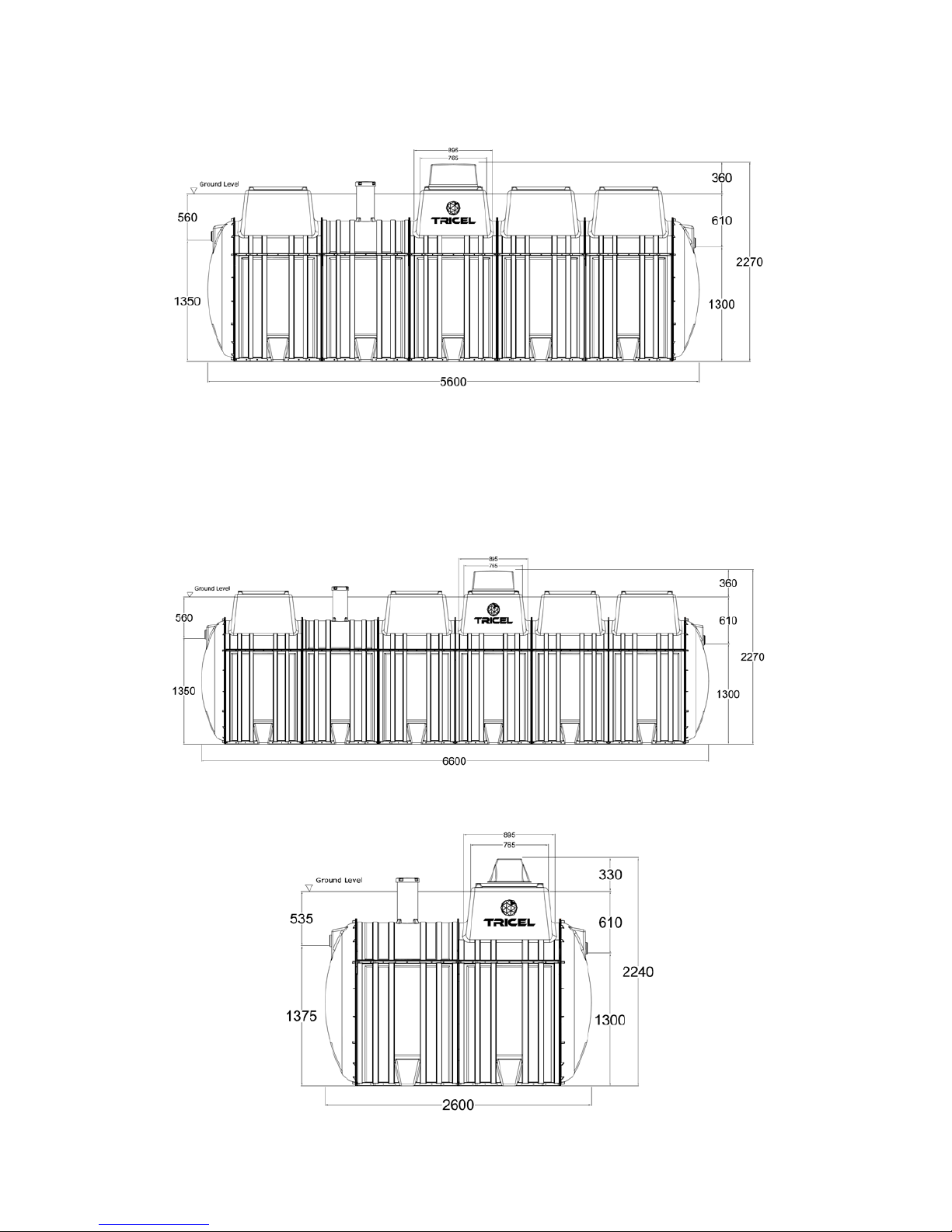

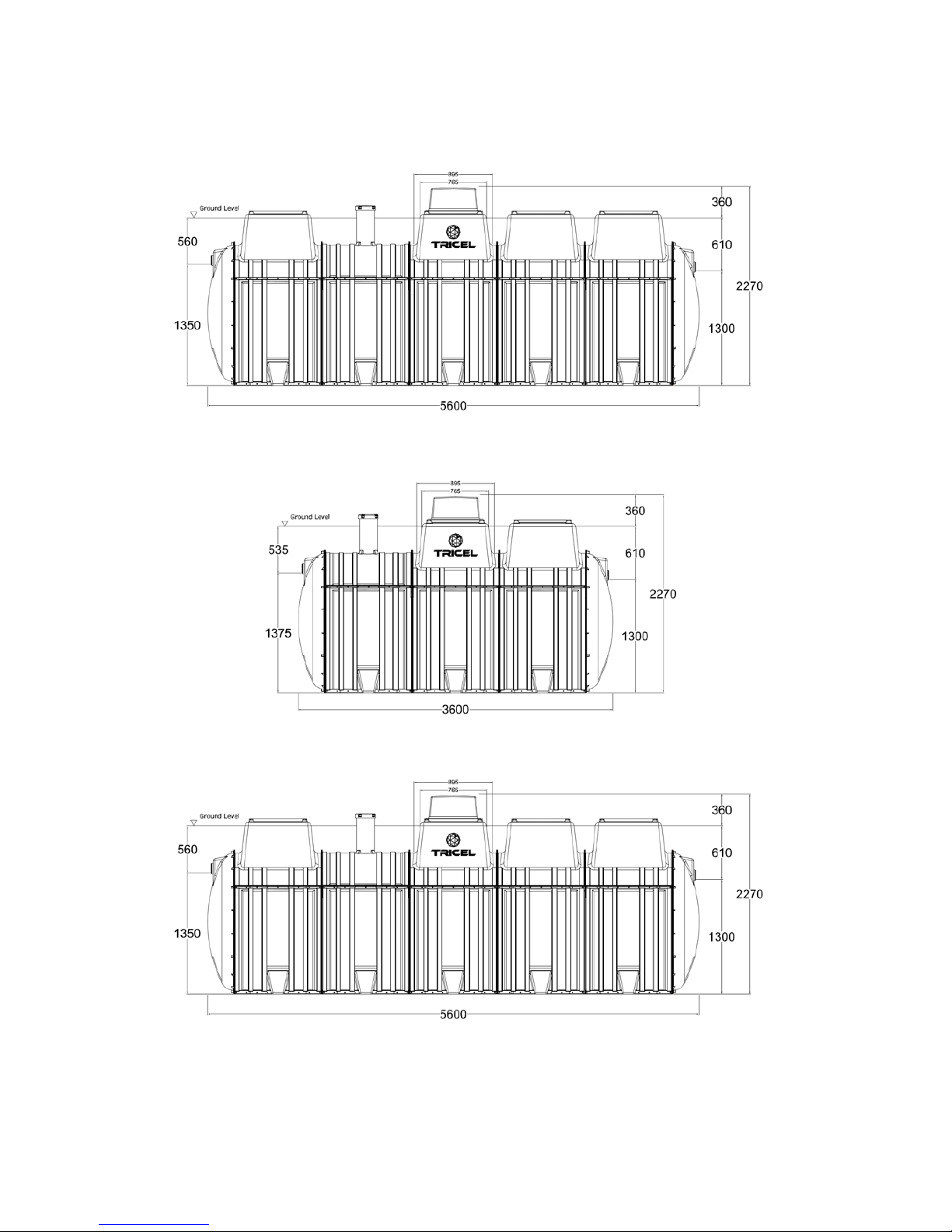

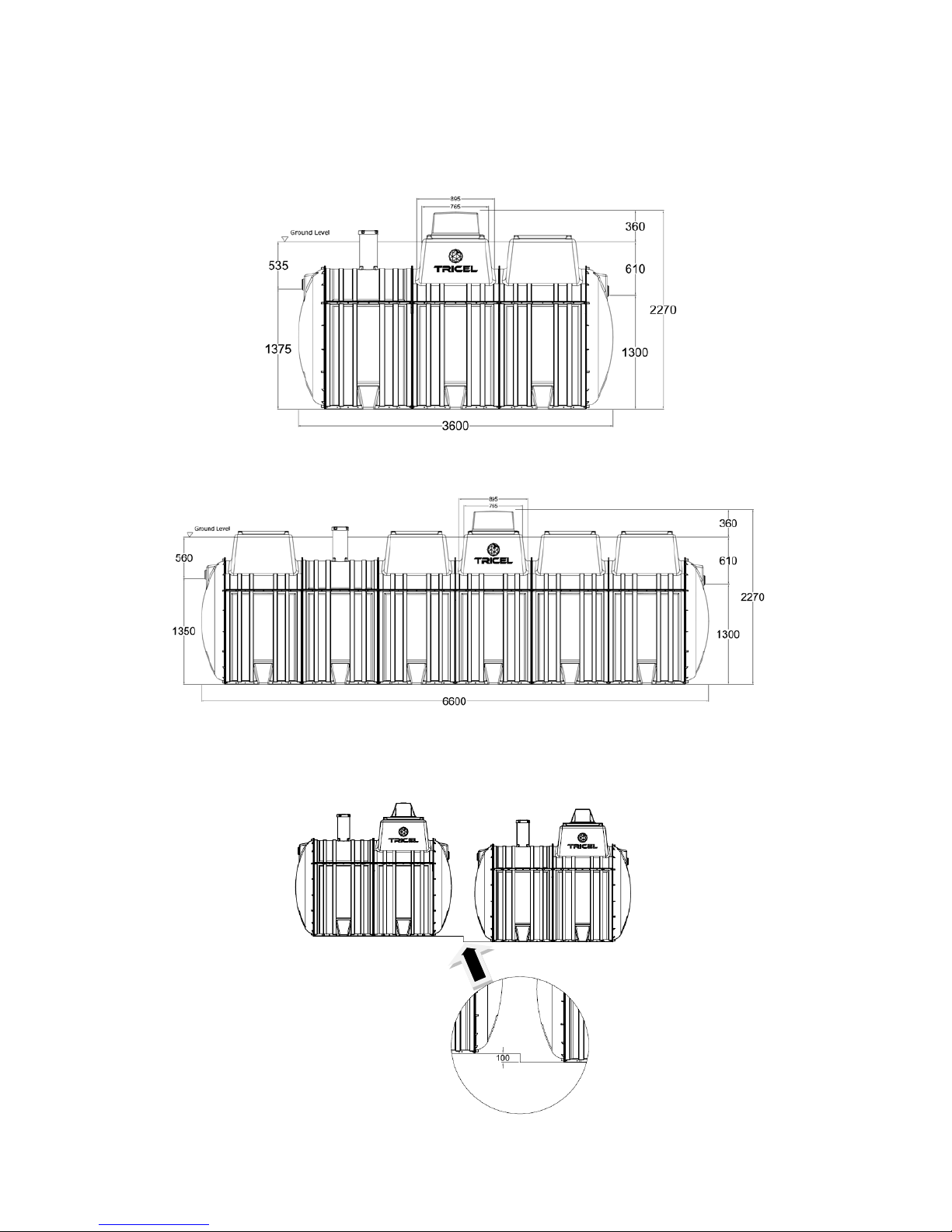

6. Plant Drawings:............................................................................................................................................ 10

7. Technical drawing of Tricel pumped plant: ................................................................................................. 15

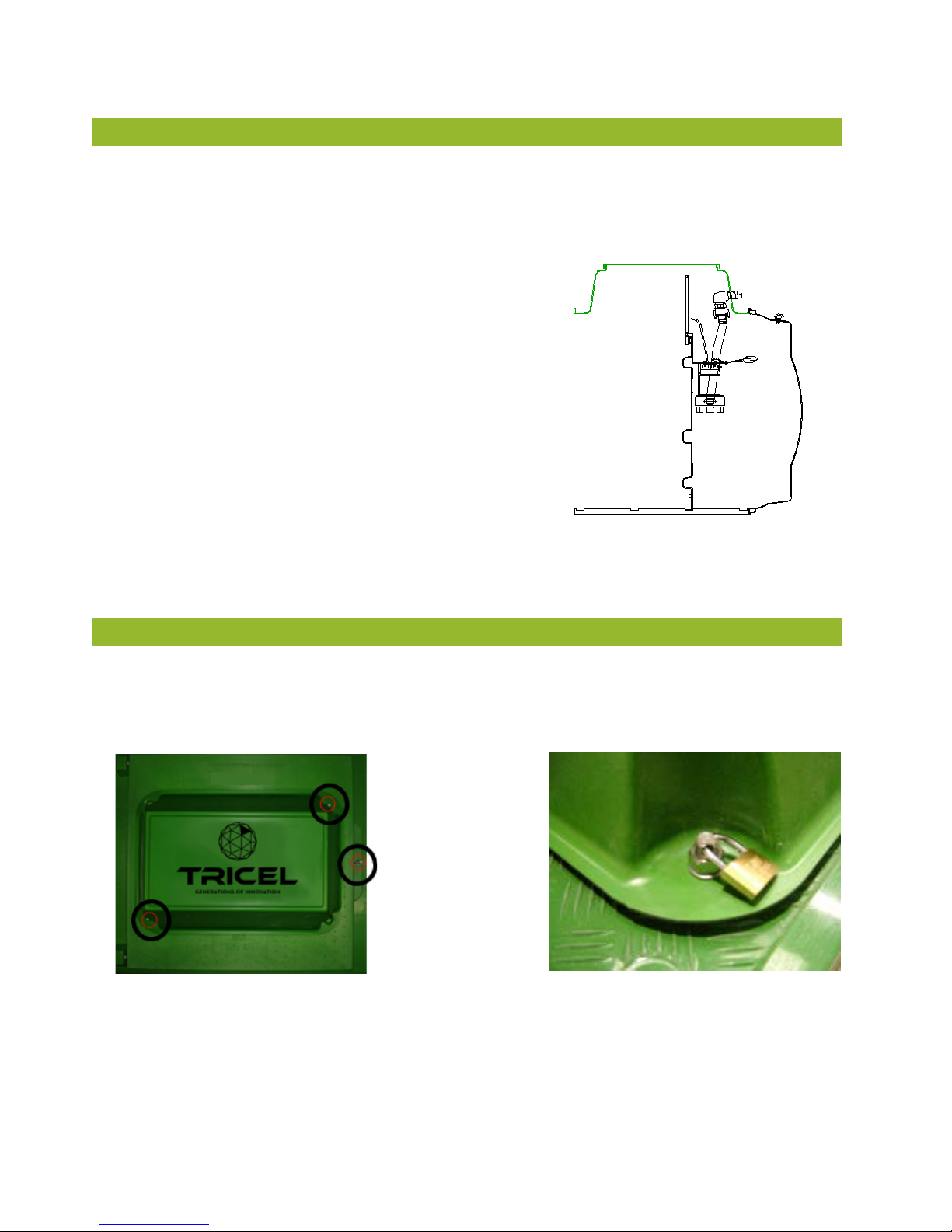

8. Lid locking points:........................................................................................................................................ 15

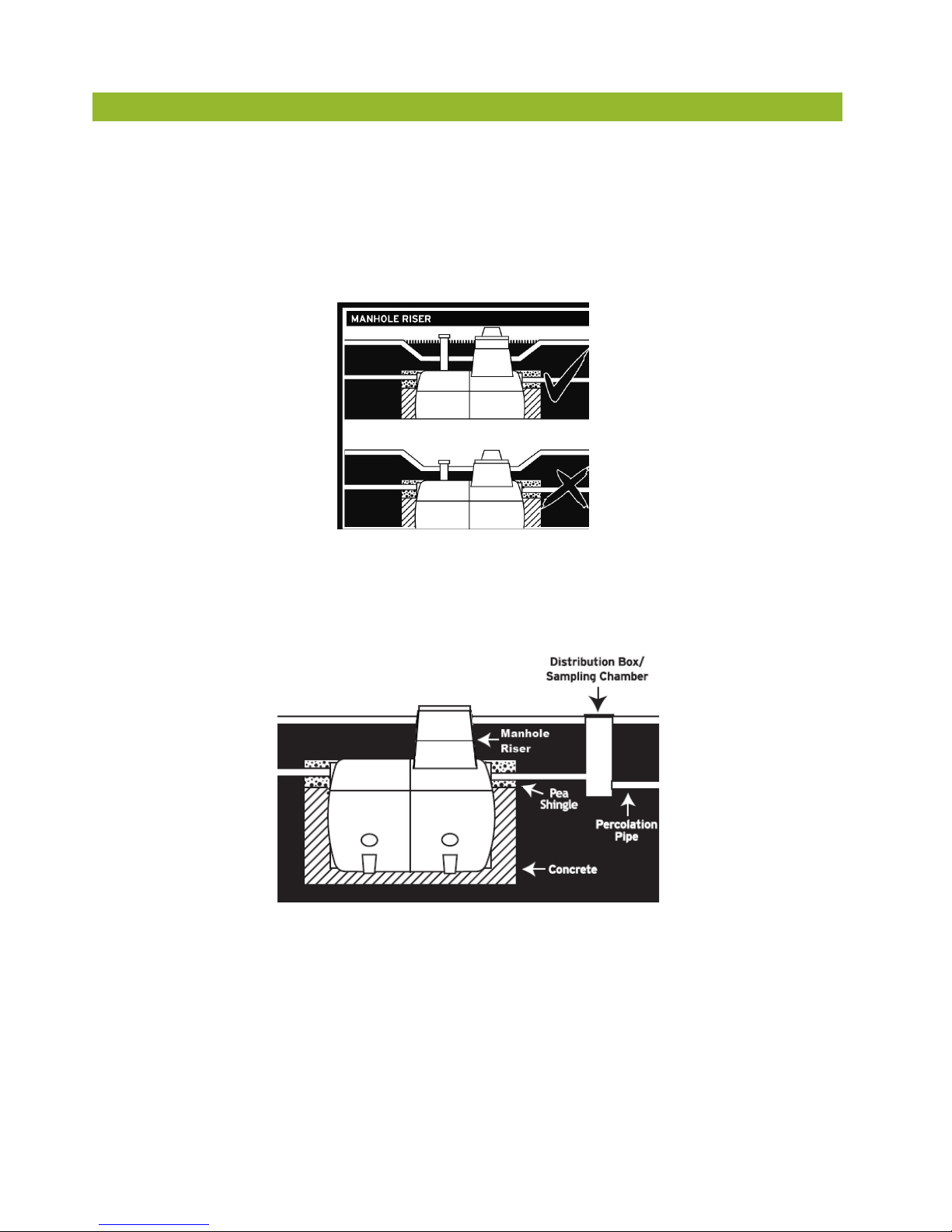

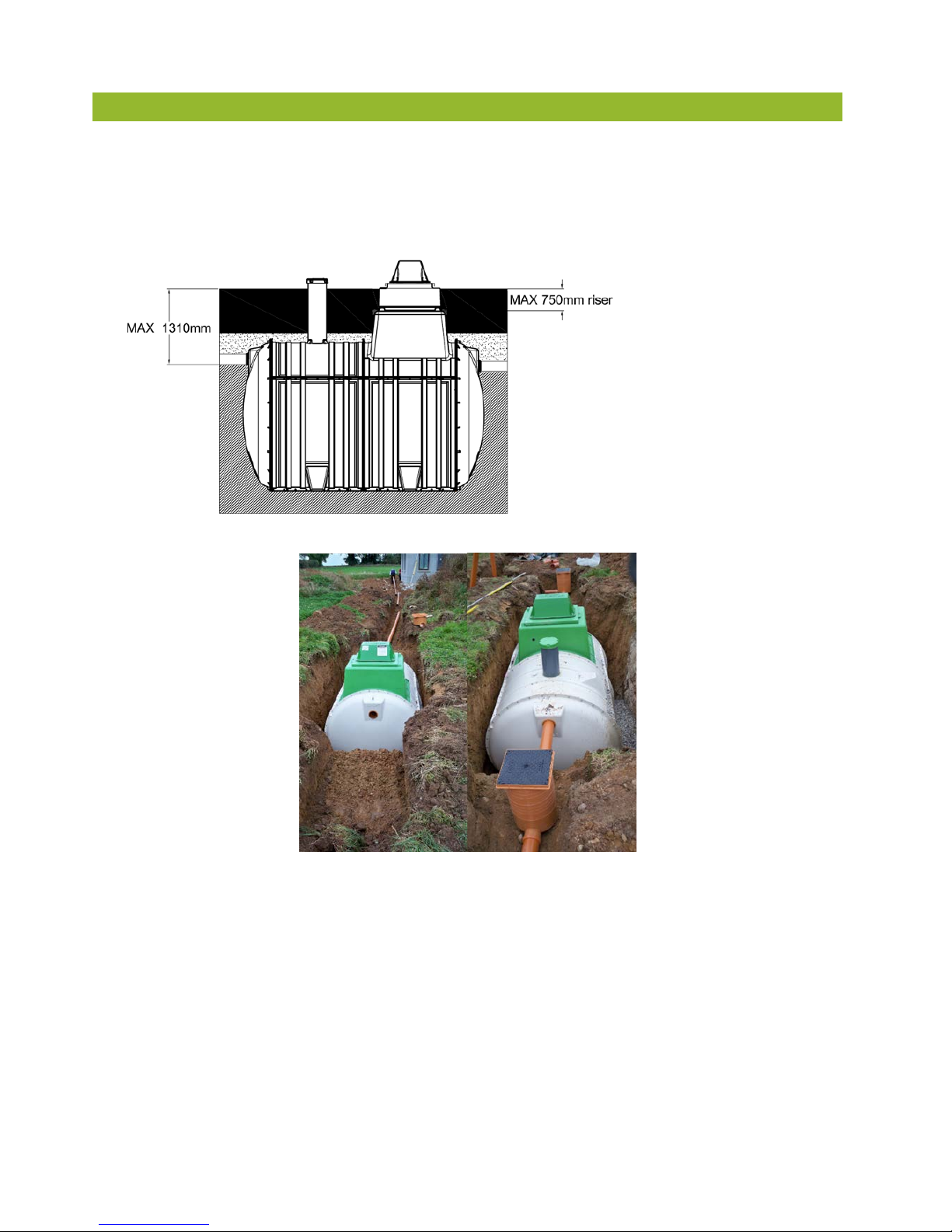

9. Manhole risers – (deep inverts): .................................................................................................................. 16

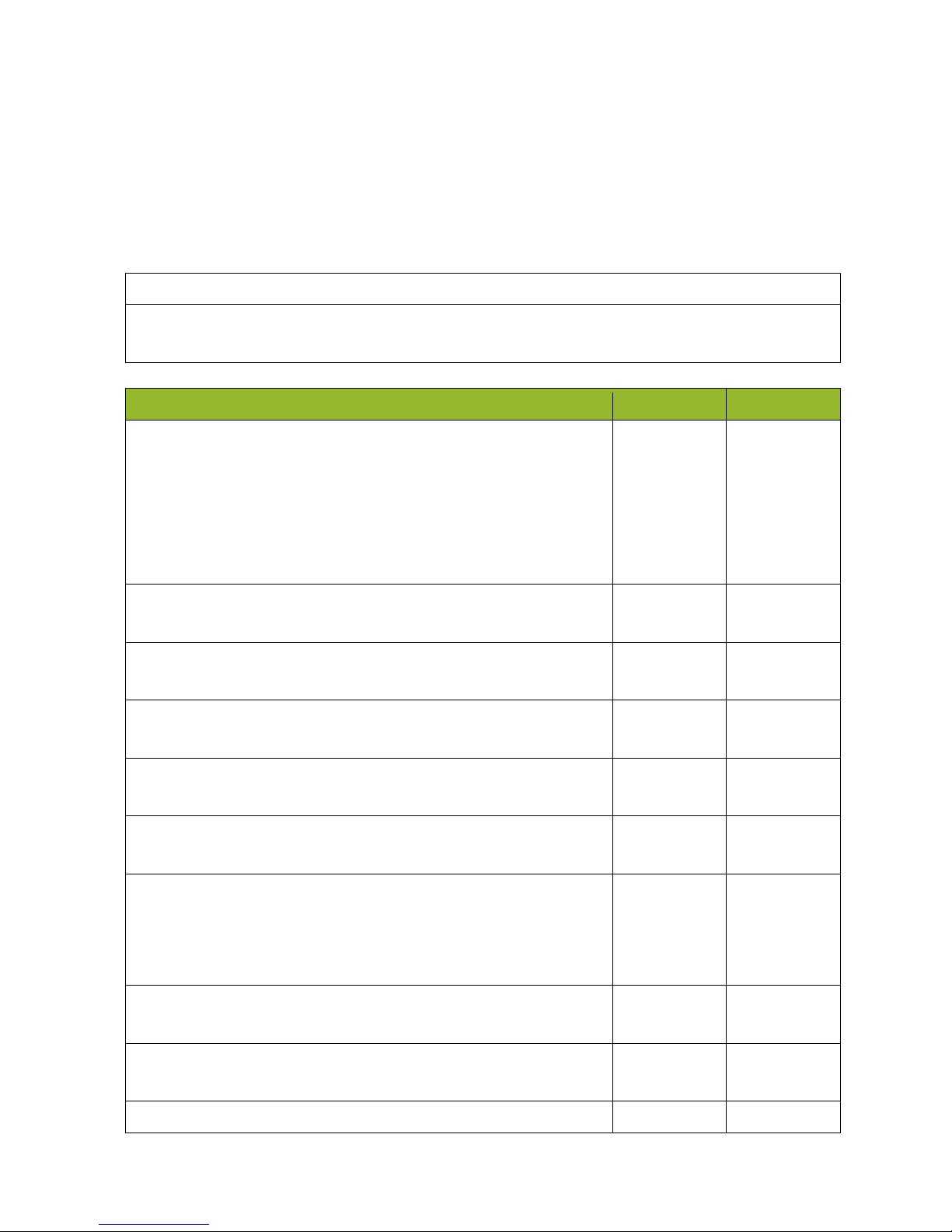

10. Installation: ................................................................................................................................................. 17

10.1 Pre –installation tank inspection: ............................................................................................................................... 17

10.2 Quick installation guidelines:...................................................................................................................................... 18

10.3 Detailed installation information:.............................................................................................................................. 20

10.4 Gravel installation:......................................................................................................................................................... 23

10.5 Concrete installation: .................................................................................................................................................... 24

10.6 Plinth and Backfill specifications: .............................................................................................................................. 25

11. Electrical installation:.................................................................................................................................. 27

12. Plumbing the plant: ..................................................................................................................................... 27

13. Ancillary installation notes:......................................................................................................................... 28

13.1 Ventilation:....................................................................................................................................................................... 28

13.2 Control housings:............................................................................................................................................................ 28

13.3 Access:............................................................................................................................................................................... 29

14. Plant operation: ........................................................................................................................................... 29

15. Disposal of treated water: ........................................................................................................................... 29

16. Maintenance: ............................................................................................................................................... 30

16.1 Regular maintenance:.................................................................................................................................................... 30

16.2 Yearly maintenance: ...................................................................................................................................................... 30

16.3 Production of sludge: .................................................................................................................................................... 31

17. Operating conditions: .................................................................................................................................. 31

18. Troubleshooting: ......................................................................................................................................... 33

TTM T106 Rev 09 – 28 Mar 2014