Trick-tools BGB - 2.5 User manual

-1 -

IOM-B-120225

HardCore Belt Grinder

Installation and Operation Manual

for models;

BGB – 2.5

BGB - 4.0

BGB – 6.0

IMPORTANT !!!!

It is the responsibility of the owner of this product to

ensure that the user will read and comply with the

provisions of this manual, which is intended to be an

integral part of your HardCore belt grinder. As

operation of this powertool can be hazardous, and even

cause serious personal injury, this manual should be

kept with the machine at all times for reference by the

user, each time prior to use.

-2 -

DANGER !!!!

This machine MUST be securely fastened to a suitable

work bench, or floor mounted pedestal, prior to

operation. In addition, proper work attire (which

complies with all applicable federal and / or state laws

and regulations) must be worn at all times while

operating this machine.

This includes;

1. Proper eye and/or face protective gear

2. Proper respiratory protection

3. Proper hand and body protection (i.e. leather work

gloves and apron in order to prevent any article of

clothing from becoming entangled in the moving

parts of the equipment)

Failure to comply with the above

requirements can result in

SERIOUS personal injury!

- 3 -

NOTE:

The following instructions refer to the two attached

illustrations for component identification.

Preparation;

1. After unpacking, mount the motor assembly to a

suitable floor mounted pedestal or work bench.

(provided fasteners may not be adequate)

Initial Setup;

1. Rotate the beam assy. to the vertical position by

loosening the pivot lock screw.

2. Tighten the pivot lock screw to secure the beam.

3. Remove the idler wheel screw from the idler

support, leaving the spring in place.

4. Install the idler guard, making sure that the idler

guard screws (2) align with the recesses in the idler

support for proper orientation and spacing.

5. Re-install the idler wheel screw through the idler

guard & into the idler support about 2 turns.

6. Install the platen mount assy. to the beam leaving

the screws (4) slightly loose for platen adjustment.

7. Install the idler wheel assembly and tighten the

idler wheel screw with a 3/16 in. allen wrench.

8. Install the workrest arm assy. onto the contact

support, making sure it is up against the shoulder.

- 4 -

9. Remove the nut & washer from the contact shaft.

10. Install the contact wheel (inside marked), washer,

and nut. Tighten the contact nut (15/16” socket or

wrench) by depressing the spring-loaded wheel

lock button and rotating the contact wheel until

full engagement of the wheel lock is felt. After

tightening, release the wheel lock button.

11. Using a straight-edge, align the platen with the

tangents of the center portions of the contact and

idler wheels and tighten the mount screws (4).

12. Install the remaining platen screws (2).

13. Install the belt guard standoffs (2) to the beam.

14. Rotate the take-up lever to the “release” position

(towards the motor) and install the desired

grinding belt over the center of the idler and

contact wheels. Rotate the take-up lever to the

“lock” position (away from the motor, until the

over-center stop is felt) in order to proceed with

initial belt tensioning.

15. Adjust for the desired belt tension by rotating the

tension knob clockwise (from top) to increase, or

counter-clockwise to decrease. Adequate tension is

required for the belt to “track” properly. Rotate

the idler wheel by hand to make sure that the belt

is not tracking too far off of the idler and contact

wheels.

16. Attach the belt guard to the standoffs using the

wing screws (2).

17. Adjust the belt guard guide so that the guide

engages the hole in the guard, up against the

washer, and tighten the jam nut against the beam.

- 5 -

18. Verify that both the “Power” and “Run” switches

are in the “OFF” position (down) and connect the

power cable to a properly grounded outlet.

19. Turn the “Power” switch to “ON”. This switch

enables the motor drive functions (on / off,

acceleration, deceleration, etc.). The “Power”

indicating lamp (red) will turn on. During this

“stand-by” period the motor drive will be using

power equivalent to a 20 watt light bulb. Although

this is satisfactory for periods when the motor is

not running (accessory changes, belt changes, etc.)

the “Power” switch should be turned “OFF” when

the grinder is not in use for longer periods of time,

in order to conserve energy. When attempting to

rotate the contact wheel during “stand-by” a slight

resistance will be evident.

20. Set the “Speed” control knob to about 20%. The

attached belt speed chart correlates the speed

control settings to actual belt speed (SFM).

21. Briefly turn the “Run” switch to “ON” to start the

motor and ensure reasonable belt tracking. If the

belt tracks evenly with the contact wheel, the motor

can be left running for the next step.

22. While the motor is running, rotate the track knob

to position the belt in the desired location on the

contact wheel.

NOTE:

Excessive tracking adjustments may require slight

belt tension adjustments with the tension knob.

- 6 -

23. Turn the “Run” switch to “OFF” and wait for all

motion to stop.

24. Attach the workrest assembly to the workrest arm

assembly and adjust as required.

Operational Instructions;

1. The beam can be re-positioned by loosening the

pivot lock screw.

DANGER

Never loosen the pivot lock while the grinder is running.

NOTE:

Always support the beam when loosening the pivot lock

screw. The pivot drag screw (located opposite of the

pivot lock screw) can be adjusted to provide adequate

friction while the pivot lock is loosened.

2. Re-tighten the pivot lock.

3. When belt changes are required, the belt can easily

be removed by turning the “Run” switch to “OFF”

(allowing all motion to stop) and removing the belt

guard.

4. Rotate the take-up lever to the “release” position

and remove the belt.

5. Install the new belt and rotate the take-up lever to

the “lock” position. Tension may vary between

different belts.

- 7 -

6. Replace the belt guard.

7. Turn the “Run” switch to “ON” and adjust for

proper tracking, if necessary.

8. The contact wheel can be removed / replaced by

first removing the belt guard & grinding belt, then

depressing the spring-loaded wheel lock button and

rotating the contact wheel until full engagement of

the wheel lock is felt. After breaking the contact

nut loose, release the wheel lock button.

9. Install the replacement contact wheel (inside is

marked), washer, and nut. Tighten the contact nut

by depressing the wheel lock button and rotating

the contact wheel until full engagement of the

wheel lock is felt. After tightening, release the

wheel lock button.

DO NOT OVER_TIGHTEN!

WARNING

Never attempt to use the wheel lock as a “braking”

device while the machine is running as damage to the

internal parts WILL occur.

10. Re-install the grinding belt and belt guard.

-End of procedure-

-1 -

PM-B-120225

HardCore Belt Grinder

Packing Instructions

for models;

BGB - 6.0

BGB - 4.0

BGB - 2.5

- 2 -

1. Remove the Wing Screws (2) & Belt Guard. Bag &

label the Wing Screws.

2. Remove the Workrest Assy.

3. Remove the Idler Wheel Assy.

4. Remove the Contact Wheel.

5. Bag & label the Contact Nut & Washer.

6. Remove the Workrest Arm Assy.

7. Remove the Belt Guard Guide (3 pcs), bag & label.

8. Remove the Belt Guard Standoffs (2).

9. Remove the inside Platen Screws (2), bag & label.

10. Remove the Platen Mount Screws (4) & Platen

Mount, bag & label the Platen Mount Screws.

11. Remove the Idler Guard.

12. Replace the Idler Wheel Screw.

-End of procedure-

-1 -

SM-B-120225

HardCore Belt Grinder

Service Manual for models;

BGB – 2.5

BGB – 4.0

BGB – 6.0

DANGER !!!!

Be sure that the grinder is un-plugged

from the wall power source prior to any

disassembly / assembly

NOTE:

Before proceeding with the following procedure it is

imperative that the operator fully understands the

installation / operation manual

- 2 -

Fastener / Hardware Abbreviations;

DP Dowel Pin

FHSC Flat Head Socket Cap screw

FW-NAS640 Flat Washer – Mil Spec

FW-NAS1140 Flat Washer – Mil Spec

FW-NEO Flat Washer – Neoprene

FW-TFE Flat Washer – Teflon

FW-USS Flat Washer – US Standard

HCS Hex Cap Screw

HN Hex Nut

HN-EL Hex Nut – Elastic Lock

HN-J Hex Nut – Jam

HN-ML-T Hex Nut – Mech. Lock - Thin

LW-S Lock Washer – Split

SHCS Socket Head Cap Screw

SSS Socket Set Screw

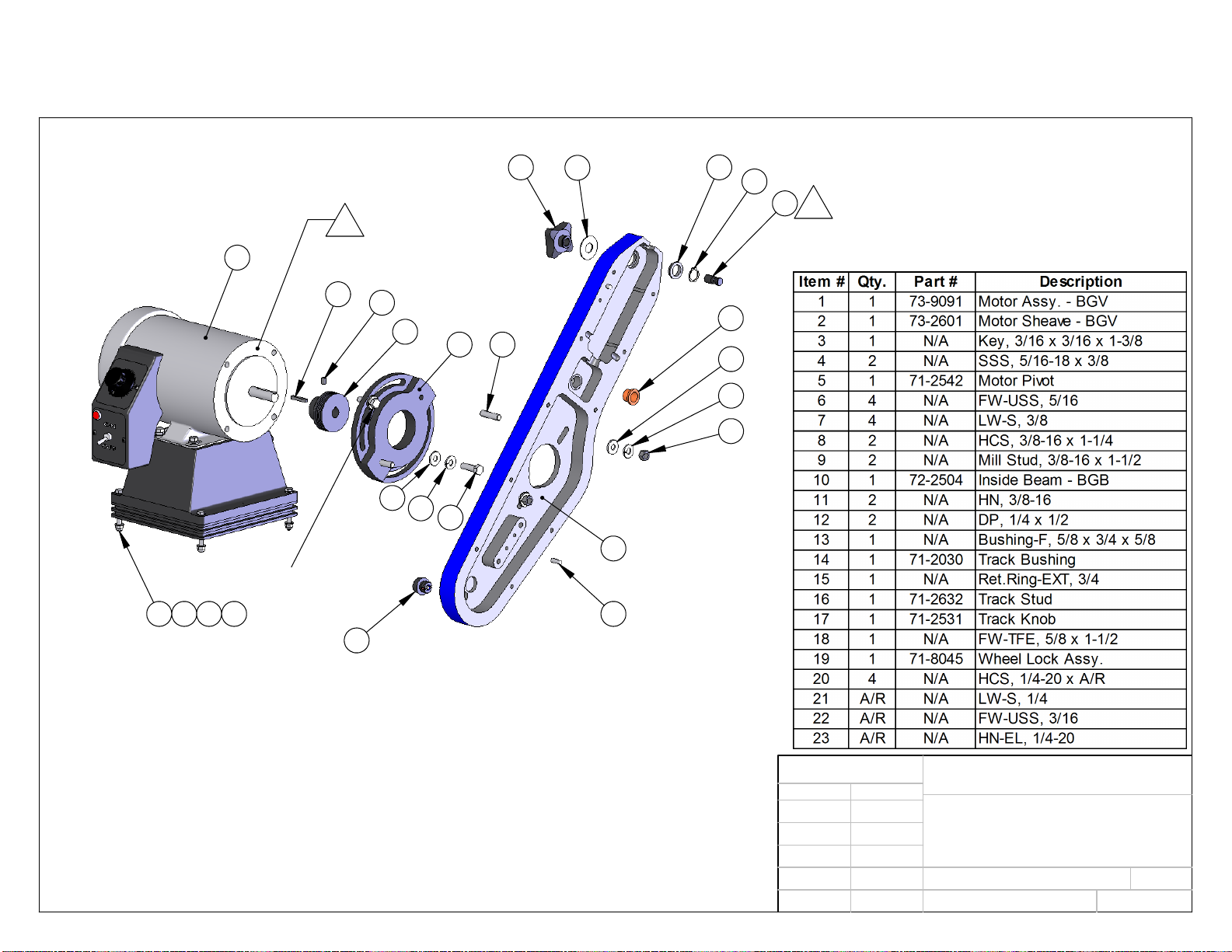

NOTE:

The following instructions refer to the attached

illustrations for component identification.

Figures 6 thru 8 are for reference only.

- 3 -

Disassembly Instructions

1. Position the beam at about 45 degrees.

2. Remove the workrest assembly. (Fig. 5)

3. Remove the wing screws (2) and belt guard.

4. Remove the grinding belt.

5. Remove the contact wheel nut & washer.

6. Remove the contact wheel.

7. Remove the belt guard standoffs (2).

8. Remove the belt guard guide w/nut & washer.

9. Remove the platen screws (4 or 8) & platen.

10. Remove the workrest arm assembly. (Fig. 4)

11. Remove the platen mount screws (4) & mount.

12. Loosen the idler wheel screw (3/16 allen) and

remove the idler wheel assembly.

13. Remove the idler wheel screw.

14. Back-off the idler guard screws (2) two turns and

remove the idler guard.

15. Remove the idler seal spring and idler seal plate

(with idler seal) from the idler support.

16. Remove the tension knob screw by holding the

knob with a strap wrench and turning the screw

counter-clockwise (from top) with a 5/16 in. allen

wrench.

17. Loosen the tension knob by holding the knob with

a strap wrench and turning the tension bushing

clockwise with a 3/8 in. allen wrench, and remove.

18. Remove the tension knob spring, tension seal

retainer, & tension knob seal.

19. Remove the take-up lever screw and remove the

take-up lever and take-up shaft seal.

- 4 -

20. Position the beam horizontally.

21. Remove the cap plugs (2) from the beam. (Fig. 3)

22. Use a 9/16 in. socket to loosen the drive belt tension

nuts (2) just until belt tension is released. (Fig. 1)

23. Remove the 1/4 in. (10) and 5/16 in. (2) beam

screws. (Fig. 3) The outside beam should remain in

place, supported by dowel pins.

24. Carefully remove the outside beam assembly,

making sure to keep the tension slide assembly

attached to the inside beam. The drive belt is also

disengaged at this time.

25. Rotate the track knob until the tension bushing can

just be removed from the tension slide assembly.

26. Remove the tension slide assembly by lifting the

tension shaft off of the take-up shaft assy. and out,

in order to disengage the slide from the track stud.

27. Remove the take-up shaft assembly.

28. Remove the track stud from the track knob. (Fig.1)

29. Remove the retaining ring from the track knob.

30. Remove the track knob & washer.

31. Remove the wheel lock assy. (special tool required)

32. Remove the drive belt tension nuts (2), lock

washers (2), and flat washers (2).

33. Remove the inside beam from the motor pivot.

34. Remove the pivot lock screw, lock washer, and flat

washer.

35. Remove the pivot drag screw, lock washer, and flat

washer.

36. Remove the motor pivot from the motor.

37. Remove the set screws (2) from the motor sheave.

- 5 -

38. Remove the motor sheave from the motor shaft.

(gear puller required)

39. Remove the key from the motor shaft.

40. Remove the contact sheave nut by holding the

sheave with a strap wrench. (Fig. 2)

41. Remove the flat washer, sheave, & woodruff key.

42. Remove the screws (3) and remove the contact

shaft assembly from the outside beam.

- End of Procedure -

- 6 -

Assembly Instructions

Note:

Be sure to observe where lubrication (grease) is

required as shown in the illustrations.

1. Place the motor pivot onto the motor (studs level)

and attach the pivot lock screw, lock washer, and

flat washer, into the threaded motor hole at the

10:00 position. (Fig. 1)

2. Attach the pivot drag screw, lock washer, and flat

washer at the 4:00 position.

3. Place the motor sheave and drive key onto the

motor shaft.

4. Tighten the motor sheave set screws (2) securely so

that the distance from the motor pivot face to the

outside of the sheave is 1.275 inches.

5. Place the inside beam onto the motor pivot studs

and attach new drive belt tension flat washers, lock

washers, and nuts. (Light snug only as beam must

be able to slide)

6. Attach the track knob & washer to the inside beam

and secure with the retaining ring.

7. Thread the track stud into the track knob about 2

turns, aligning the flats with the long axis of the

inside beam.

8. Check that the wheel lock is properly attached to

the inside beam.

9. Install the dowel pins (2) onto the inside beam.

10. Position the beam horizontally.

- 7 -

11. Place the contact support assy. into the outside

beam & tighten the fasteners (3). (Fig. 2)

12. Install the woodruff key, contact sheave, flat

washer, and new lock nut.

13. Tighten the lock nut by holding the sheave with a

strap wrench, then verify freedom of rotation.

14. Place the take-up shaft assy. into the bushing of the

inside beam & rotate counter-clockwise. (Fig. 3)

15. Place the tension slide assy. t-slot onto the track

stud and position the slide dowel pins into the slots

on the inside beam. (It may be necessary to lift the

tension shaft over the take-up shaft assy. bearing)

16. Place the tension bushing onto the tension shaft.

17. Rotate the track knob until the tension slide is

parallel with the inside beam, taking care to engage

the tension bushing correctly with the beam.

18. Position the drive belt onto the motor sheave so

that the belt remains inside of the beam cavity.

19. While maintaining tension on the drive belt, install

the outside beam assy. making sure that the contact

sheave is fully engaged and centered with the belt.

This is best achieved by “hanging” the outside

beam over the idler support, then pulling the far

end of the belt out of the inside beam (slightly) in

order to position it over the contact sheave.

20. Maintaining tension on the belt, slide the inside

beam so that the dowel pins engage and the beams

come together. The tension slide and take-up shaft

will also align with the outside beam at this time.

- 8 -

21. Continue to maintain belt tension and separate the

beams slightly. Rotate the contact shaft to visually

ensure correct drive belt alignment.

22. Push the beams back together and rotate the beam

to a vertical position, which will provide some drive

belt tension.

23. Install and tighten the 1/4 in. (10) & the lower of

the 5/16 in. beam screws.

24. Start the upper 5/16 in. beam screw 2 turns.

25. From the front side of the grinder, position a lever

(a long screwdriver will work) on top of the head of

the 5/16 in. screw & underneath the rear of the

motor pivot, up against the inside beam. Adjust

the drive belt tension by applying force in the

appropriate direction and tightening the upper belt

tension nut.

26. Rotate the contact shaft by hand to ensure that the

drive belt is tensioned and aligned correctly. (Belt

tension can be verified by reaching into the cap

plug hole on the outside beam with your finger)

27. Re-tighten both drive belt tension nuts securely.

28. Tighten the remaining 5/16 in. beam screw.

29. Connect the power source and turn on the motor.

Check that there are no vibrations or rumbling in

order to verify correct assembly to this point.

30. Turn off the motor and remove the power source.

31. Install the cap plugs (2) into the outside beam.

32. Place the tension seal retainer (with tension knob

seal) and tension knob spring onto the tension

bushing. (Fig. 4)

- 9 -

33. Install the tension knob and tighten (holding the

knob with a strap wrench) by turning the bushing

counter-clockwise with a 3/8 in. allen wrench.

34. Install the tension knob screw and tighten (holding

the knob with a strap wrench) by turning the screw

clockwise with a 5/16 in. allen wrench.

35. Attach the take-up lever (with seal) to the take-up

shaft so that the lever is parallel with the long axis

of the beam (when in the “lock” position) and

tighten the screw.

36. Place the idler seal plate (with seal) and idler seal

spring onto the idler support.

37. Install the idler guard, making sure that the set

screws (2) align with the recesses in the idler

support for proper orientation and spacing.

38. Install the idler wheel screw through the idler

guard & into the idler support about 2 turns.

39. Install the platen mount to the beam leaving the

screws (4) slightly loose for platen adjustment.

40. Install the platen to the platen mount, leaving the 2

inside screws for later.

41. Install the idler wheel assembly and tighten the

idler wheel screw with a 3/16 in. allen wrench.

42. Install the workrest arm assy. onto the contact

support, making sure it is up against the shoulder.

43. Install the contact wheel, washer, and nut.

44. Using a straight-edge, align the platen with the

tangents of the center portions of the contact and

idler wheels and tighten the mount screws (4).

45. Install the remaining platen screws (2).

46. Install the belt guard standoffs (2) to the beam.

- 10 -

47. Install the belt guard guide w/nut & washer,

leaving about 1 in. from the beam to the outside.

48. Install the desired grinding belt.

49. Adjust for the desired belt tension.

50. Attach the belt guard to the standoffs using the

wing screws (2).

51. Adjust the belt guard guide so that the guide

engages the hole in the guard, up against the

washer, and tighten the jam nut against the beam.

52. Attach the workrest assembly to the workrest arm

assembly and adjust as required.

- End of Procedure -

1

2

4

3

5

678

9

10

6

7

11

12

13

14 15

16

18

17

19

20 21 22 23

G

face only

drive belt

tension nut

pivot lock

screw

pivot drag

screw

G

threads only

Figure 1

REV:

PART NO:

DATE

Q/A:

MFG:

ENG:

CHK:

DRW:

APPROVALS

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

SHEET:

1 of 1

A

02-25-12

MH

00-0000

INSIDE BEAM ASSEMBLY

BGB-2.5 (4.0 & 6.0) - SM

Assy,Inside Beam-2.5-BGB-mda-X

HardCore Products

CAD FILE:

This manual suits for next models

2