TRM SR-ACC-SPL Service manual

Product

Certifications:

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

Item Quantity Description

A 1 Clamp Tie

B 1 Black Cloth Tape (6” long)

C 1 Heat Shrink Tubing (8” x 1”)

D 3 Cable Ties

E 5 Mastic Strips (1 ½” x ½”)

F 3 Heat Shrink Tubing (1” x ½”)

G 6 Heat Shrink Tubing (1” x 1/8”)

H 2 Heat Shrink Cap

I 2 Insulated Bus Wire Crimps

J 1 Heat Shrink For Ground (1” x ½”)

K 1 Uninsulated Braid Crimp

Kit Contents:

WARNING:

Electric Shock Hazard. You MUST disconnect all power before installing or servicing

heating cable and accessories. A qualified electrician must perform installation and

servicing of heating cables and accessories. Heating cables must be grounded in

accordance with the National Electrical Code. Failure to comply with this code can

result in personal injury or property damage.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

Important notes:

1) All electrical wiring including GFCI (ground fault circuit interrupters) must be installed

in compliance with the National and Local Electrical Codes by qualified person(s)

2) Article 426 of ANSI/NFPA 70 of the National Electrical Code (NEC Section 62 of

CAN/CSA-C22.1, Canadian Electrical Code, Part 1 (CEC)) Governs the installation of

these heat tracing systems

3) TRM SR-ACC-SPL/TEE (Splice and Tee Kit) is suitable for use with TRMSR heating

Cables

4) Cables should be terminated into certified junction boxes that are appropriate for the

cable termination location

5) Use 30-mA ground fault protection on each heating cable circuit for maximum

protection

6) The black heating cable core is conductive and can short. It must be properly insulated

and kept dry

7) Keep ends of heating devices and kit components dry before and during installation

work

8) The conductive layer of this heating device must have a suitable grounding/earthing

terminal

9) Do not break braid or bus wire strands when scoring the jacket or conductive core.

Damaged bus wires can overheat or short out

10) Keep bus wires separated. Bus wires will short if they touch each other

11) Replace damaged components. Components damaged by heat can short.

12) Utilize a heat gun with a low heat flame, do not use a torch with a blue flame as that

would melt/compromise the heat shrink tubing. Charring or burning the heat shrink

tubing can produce fumes that may cause irritation to skin,, eyes, nose, and throat

13) Do not heat up components of this kit (except for the heat shrink tubes)

14) When installing this cable, only use fire-resistant insulation materials such as fiberglass

wrap

15) Do not twist the cable during installation

Assembly Tools Required:

Utility knife, scissors, side cutters, needle-nose pliers, linesman pliers, channel lock

pliers, crimping tool, flathead screwdriver, heat gun, measuring tape/ruler.

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

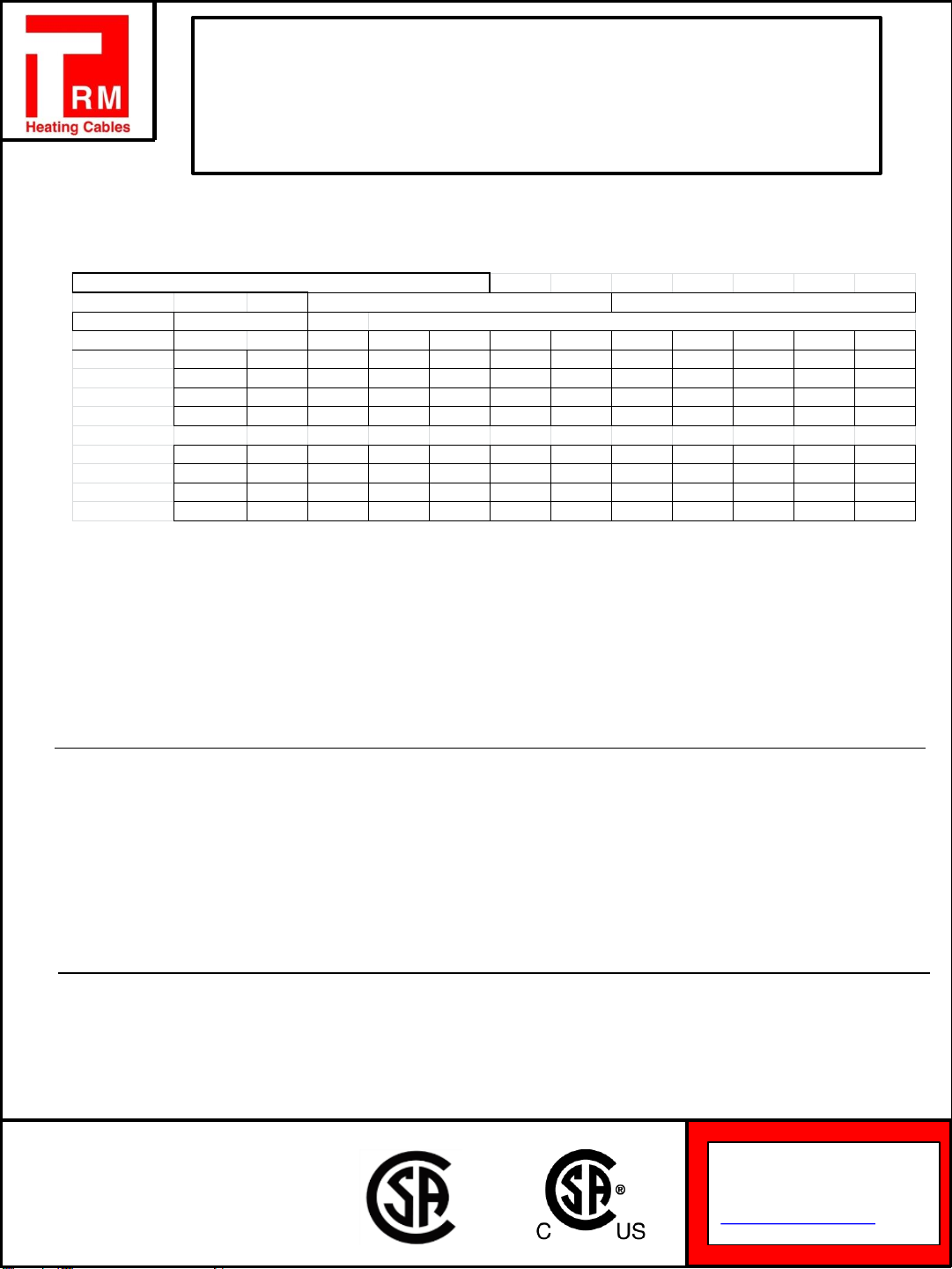

•The multiplier for power output (w/ft) for 5W TRM BR type cables for 208VAC operation is .85

•The multiplier for power output (w/ft) for 8W TRM BR type cables for 208VAC operation is .89

•The heating circuit lengths calculations would also change for 208VAC operation, the multiplier for AL type cables would

be 0.93, and the multiplier for BR type cables would be .92

Cable Selection

F C 15A 20A 30A 40A 15A 20A 30A 40A

TRM BR SR 50 10 225 265 265 265 450 530 530 530

5W 32 0225 265 265 265 450 530 530 530

14 -10 180 235 265 265 360 470 530 530

-22 -30 125 165 245 265 245 325 490 530

TRM BR SR 50 10 150 200 210 210 300 400 420 420

8W 32 0125 175 210 210 250 350 420 420

14 -10 110 150 210 210 220 300 420 420

-22 -30 85 115 175 210 170 230 350 420

240V

120V

Maximum Circuit Lengths

Start-Up Temperature

Breaker Sizes

Controls and GFI:

TRM SR can function safely without the use of controls, but it is strongly recommended to utilize thermostats or controllers

to maximize the efficiency of the cables while simultaneously minimizing electrical costs.

For further information or for design assistance with controls and/or sensors that work in concert with our SR cable, please

call TRM directly

Circuit protection depends on the breaker size being used and the start-up temperature. NEC 1999 requires the use of

ground fault protection breakers for heating cable. The above chart shows the maximum circuit length for a given breaker

rating. To determine the number of circuits required for each pipe, divide the total cable (circuit) length by the maximum

circuit length found in the chart. Round up to the next higher number.

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

B

SR Cable Construction

Standard

A. Buss Wires

Twin 16 AWG copper buss

wires provide good current

capability

B. Matrix

A semi-conductive polymer

core whose electrical

resistance varies with

temperature. When process

temperature drops, the core’s

heat output increases;

conversely, as process

temperature rises, heat

output decreases

A B C D

C. Tinned Copper Braid

The braid covering the jacket

provides an effective ground

path and mechanical

Protection

D. Jacket

The flame retardant insulation

jacket is a polyolefin material with

excellent water resistance. It also resists

certain mildly corrosive Chemicals

Description

Thermal Resources Management brand SR

cable is ideal for keeping metal and plastic

pipes warm in commercial construction,

institutional buildings and some industrial freeze

protection applications. TRM SR cable is

constructed of a self-regulating polymer core

that varies its output along its entire length,

saving energy and eliminating hot spots along

the pipe. Parallel construction makes it easier to

install than zone or series types of cable since it

can be cut to length at any point on the pipe. It

can be single overlapped without overheating

the cable.

Approvals

Certified for ordinary areas

Applications

Commercial

Construction

•Cooling Towers

•Chilled Water and Plumbing

Pipes

•Sump Discharge Pipes

•Wet Sprinkler System

•Exposed P-traps

•Roof and Gutter Deicing

•Heat Loss Replacement

Industrial

•Water Treatment Facilities

•Vessel Freeze Protection

•Safety Shower Lines

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

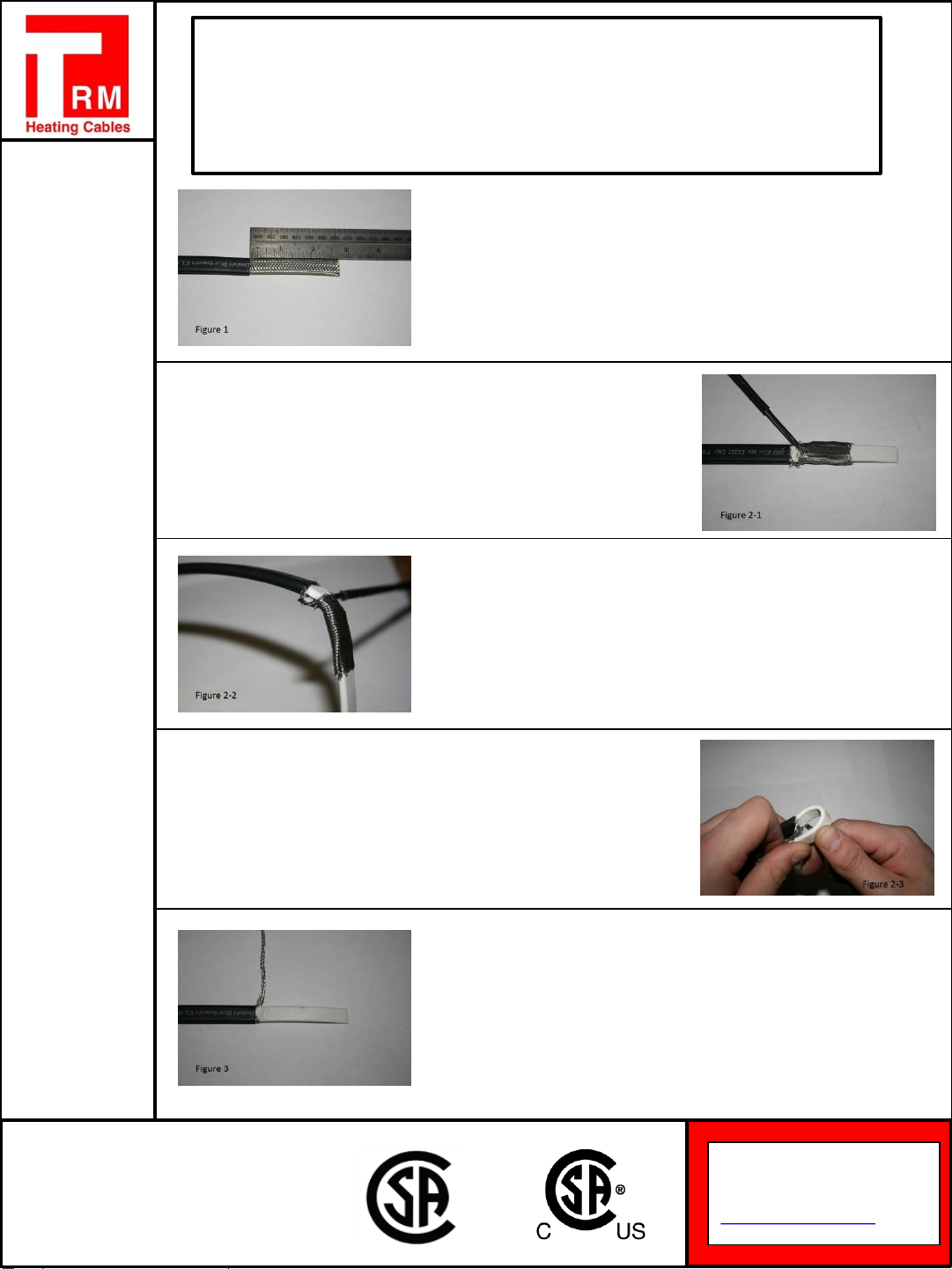

1.) Figure 1: Slice completely around the black outer

jacket 2 ¾” from the cables end, being careful not to cut

braid or inner jacket. Then, bend the cable where sliced to

break jacket, and peel off.

2.) Figure 2-1: Carefully push braid back (away from the

end of cable) to loosen and spread apart as shown

2.) Figure 2-2: Bend the cable and push the braid until

there is enough room between the bottom of the cable

and the braid to fit a screwdriver

2.) Figure 2-3: Bend the cable over and hold in left hand

while keeping it pinned between your screwdriver and

your right thumb as shown. Slowly pull the cable back and

out of the braid. The heating cable must be bent as

shown, so it can be pulled through the braid opening

3.) Figure 3: Twist together braid and put off to one side

as shown.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

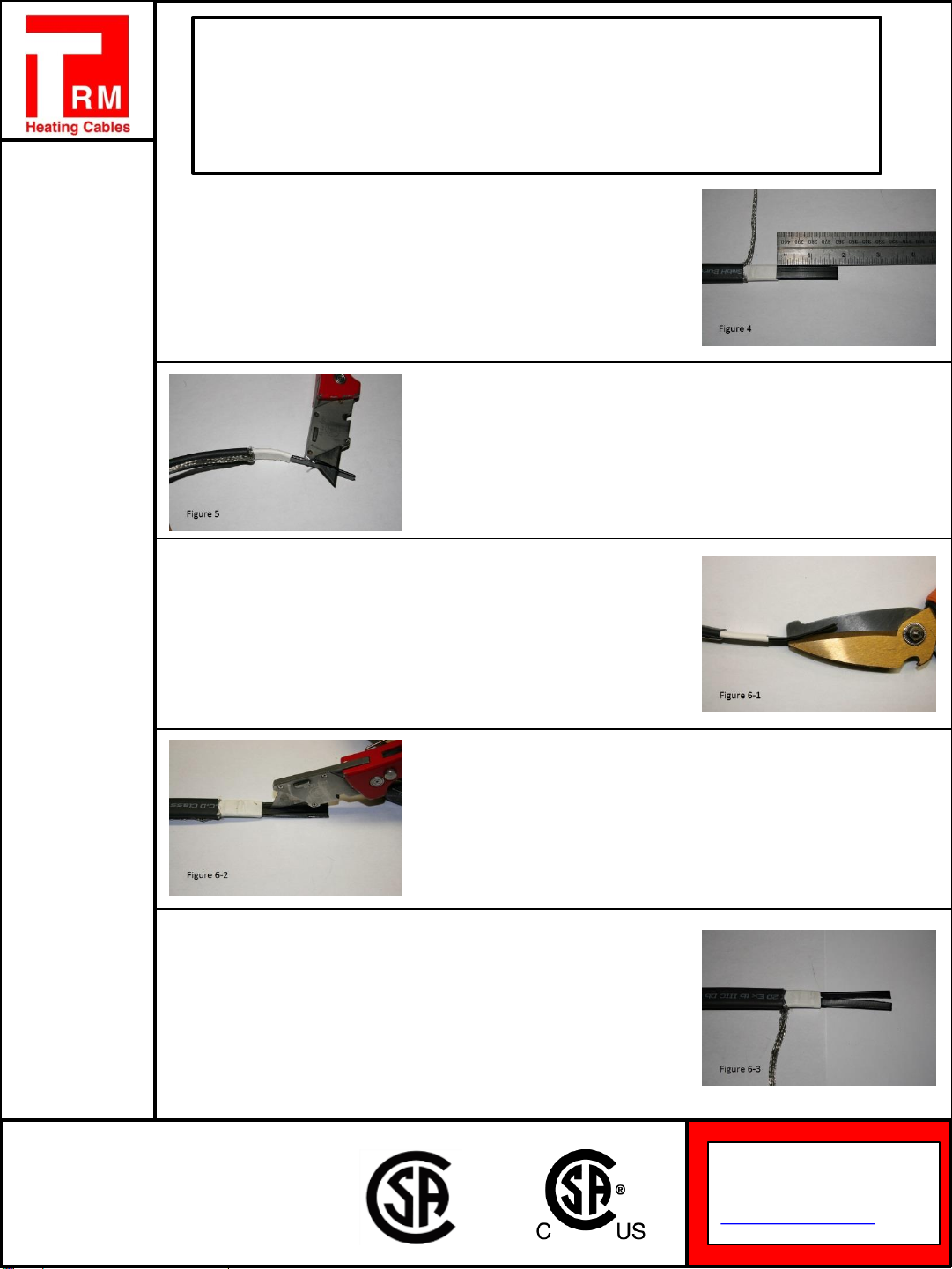

4.) Figure 4: Score the inner jacket of cable 1 ¾” from the

cable’s end. Bend cable to break jacket at score, then

peel off

5.) Figure 5: Shave off the outer matrix material from

conductor with a utility knife. Repeat on opposite side of

cable for the second conductor

6.) Using either a pair of scissors (Figure 6-1) or a utility

knife (Figure 6-2) make a cut through the centre matrix

material 1 ¾”, down to where the inner jacket begins

(Figure 6-3).

6.) Using either a pair of scissors (Figure 6-1) or a utility

knife (Figure 6-2) make a cut through the centre matrix

material 1 ¾”, down to where the inner jacket begins

(Figure 6-3).

6.) Using either a pair of scissors (Figure 6-1) or a utility

knife (Figure 6-2) make a cut through the centre matrix

material 1 ¾”, down to where the inner jacket begins

(Figure 6-3).

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

7.) Figure 7-1: using a utility knife, cut the matrix material

around the base of each conductor. Be careful not to cut

the conductor

7.) Figure 7-2: Once cut is done from 7-1, carefully peel

off the matrix material from the conductors

8.) Figure 8-1: Slip black heat shrink tubes (G) onto

conductors up to the inner jacket

8.) Figure 8-2: Shrink tubing by moving heat source side

to side continuously. Be careful not to leave the heat

source on one area for very long

9.) Figure 9-1: Centre the black heat shrink (F) over the

end of cable as shown

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

9.) Figure 9-2: Heat the tube evenly until it shrinks and

adhesive flows out of both ends.

9.) Figure 9-3: While tubing is still hot; pinch the end of

the tube between the two conductors with needle nose

pliers, and hold for 10 seconds to ensure seal.

9.) Figure 9-4: Repeat steps 1 through 9 for remaining

two cables.

10.) Figure 10-1/10-2: Remove paper from mastic strip

(E). Wrap a piece of mastic around the outer jacket on

each heating cable, 2” down from the end of the outer

jacket. (If needed, each mastic strip can be stretched to

accommodate thicker types of heating cable)

10.) Figure 10-1/10-2: Remove paper from mastic strip

(E). Wrap a piece of mastic around the outer jacket on

each heating cable, 2” down from the end of the outer

jacket. (If needed, each mastic strip can be stretched to

accommodate thicker types of heating cable)

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

11.) Figure 11-1: Carefully align each heating cable on

top of one another, pressing mastic strips together.

Fasten with a cable tie (D) at 7 ¾” and 10 ¾” from the end

of the cable as shown.

11.) Figure 11-2: Twist together each of the cables

ground braids

11.) Figure 11-3: Slide uninsulated crimp (K) over braid to

within ½” of heating cable.

11.) Figure 11-4: Crimp braid as shown, at least twice,

using a crimping tool.

12.) Figure 12-1: Cut off the excess braid.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

12.) Figure 12-2: Position the braid crimp connector as

shown. Ensure crimp connector lays flat.

13.) Figure 13-1: Slide the black heat shrink tube (J) over

uninsulated braid crimp (K).

13.) Figure 13-2: Heat tube evenly until it shrinks and

adhesive flows out of both ends.

13.) Figure 13-3/13-4: Immediately after shrinking, pinch

the end of the tube with a pair of pliers and hold until the

end stays sealed

13.) Figure 13-3/13-4: Immediately after shrinking, pinch

the end of the tube with a pair of pliers and hold until the

end stays sealed

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

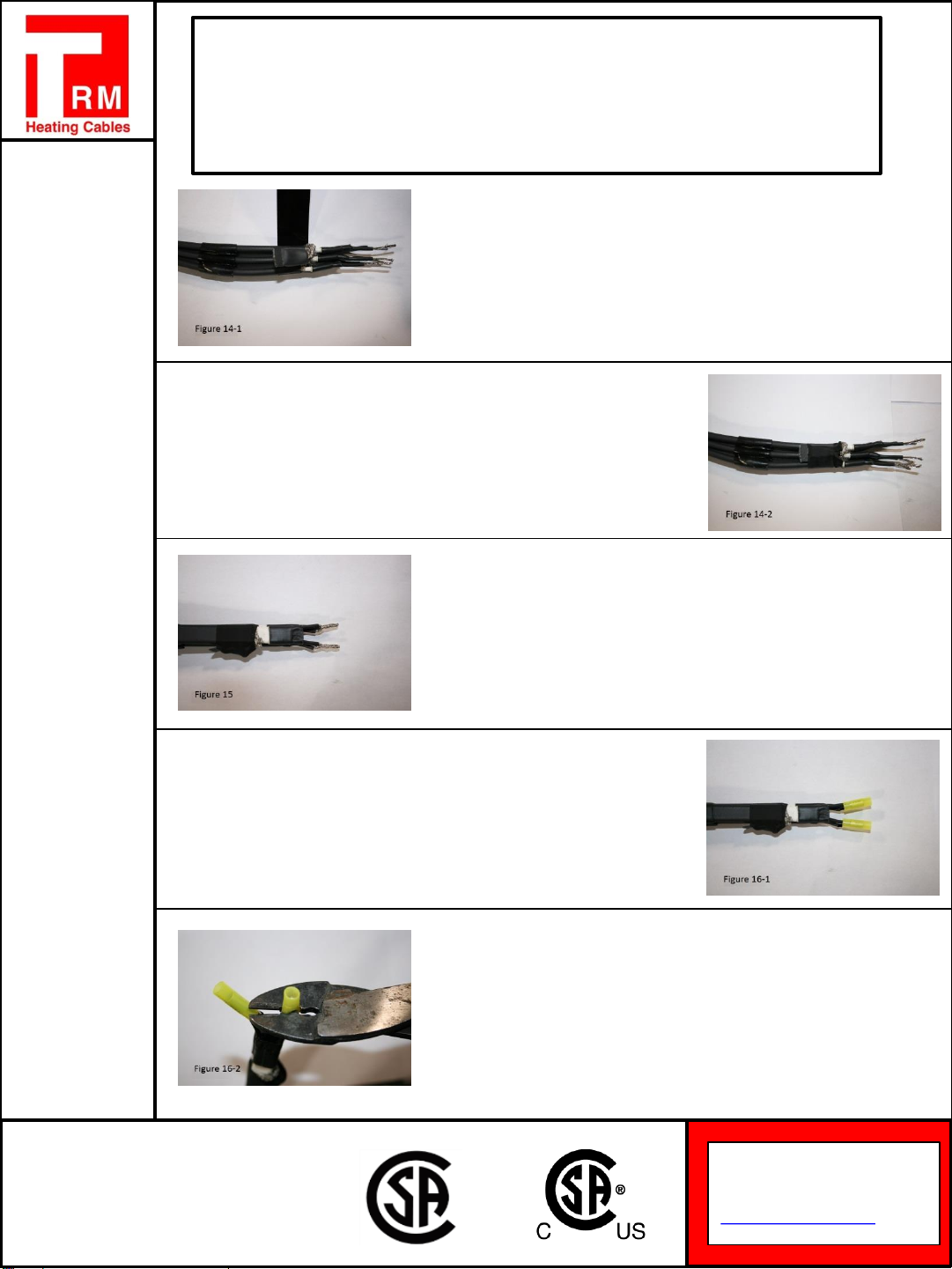

14.) Figure 14-1/14-2: Fold the crimped braid back on top

of the heating cables. Then wrap the black cloth tape (B),

around the crimp and heating cables. Ensure to cover the

crimp completely.

14.) Figure 14-1/14-2: Fold the crimped braid back on top

of the heating cables. Then wrap the black cloth tape (B),

around the crimp and heating cables. Ensure to cover the

crimp completely.

15.) Figure 15: Take one conductor from the same side

of each cable and twist the wires together as shown. Be

careful not to twist together conductors from the same

cable.

16.) Figure 16-1: Slide insulated bus wire crimps (I) over

each conductor

16.) Figure 16-2: Using a crimping tool, crimp each set of

conductors together

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

17.) Figure 17-1: Slide heat shrink cap (H) over each set

of bus wire crimps.

17.) Figure 17-2/17-3: Apply heat from the end of the cap

evenly until it shrinks and adhesive flows out. If adhesive

does not appear, additional heat is needed.

17.) Figure 17-2/17-3: Apply heat from the end of the cap

evenly until it shrinks and adhesive flows out. If adhesive

does not appear, additional heat is needed.

18.) Figure 18-1: If the adhesive seals from the heat

shrink tubes (F) melt while shrinking cap, pinch again with

needle nose pliers as shown.

18.) Figure 18-2: Ensure the heat shrink tube is

completely sealed between the two conductors and that

there are no visible gaps.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

19.) Figure 19-1: Remove release paper from mastic strip

(E) and stretch the width (1” side) of the mastic strip as

shown. (Stretching the strips is necessary because the

width cannot fully wrap around each of the heat shrink

caps).

19.) Figure 19-2/19-3: Wrap a stretched mastic strip

around each of the heat shrink caps as shown. Press

mastic strip into itself to ensure a good grip

19.) Figure 19-2/19-3: Wrap a stretched mastic strip

around each of the heat shrink caps as shown. Press

mastic strip into itself to ensure a good grip

20.) Figure 20: Squeeze the mastic strips together and

hold for 5 seconds.

21.) Figure 21-1: Slide the heat shrink tube (C) over

cables. Place the edge of heat shrink ½” past the edge of

the mastic strips on each cable.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

21.) Figure 21-2: Starting at the point shown, apply heat

to tube while working your way toward the end of the

cable

21.) Figure 21-3: When heating, work the heat gun side

to side to ensure an even distribution of heat along the

tube.

21.) Figure 21-4: Shrink the start of the tube completely,

until adhesive appears at the bottom and you can see the

shape of the mastic strips underneath. Continue to heat

the tube completely. Make sure to keep heating after the

tube has shrunk, to melt the adhesive and the mastic

strips inside the tube.

22.) Figure 22-1: Immediately after shrinking, pinch the

end of the tube with pliers until the end seals.

22.) Figure 22-2/22-3: If the width of the pliers isn’t wide

enough to pinch the entire tube, pinch a second time at

the end of the cable.

Product

Certifications:

Thermal Resources Management (TRM)

175 Idema Road, Markham,

ON, Canada, L3R 1A9

Tel: 1-905-940-4737

Fax: 1-905-940-4731

www.TRMheatingcables.com

TRM SR-ACC-SPL/TEE

Self Regulating Cable Splice and Tee Kit

Installation Instruction Manual

22.) Figure 22-2/22-3: If the width of the pliers isn’t wide

enough to pinch the entire tube, pinch a second time at

the end of the cable.

22.) Figure 22-4/22-5: Ensure the end of the heat shrink

is completely sealed with adhesive.

22.) Figure 22-4/22-5: Ensure the end of the heat shrink

is completely sealed with adhesive.

23.) Figure 23: After the heat shrink has cooled, fold over

the connection end and fasten it with the third cable tie.

Refer to applicable application instruction manual(s)

for installation and testing instructions and

guidelines

This manual suits for next models

1

Table of contents