Werner A330000 User manual

with certication of a qualied person, or 5,000 pounds (22.2 kN)

without certication.

2. SUBSTRATE: D-Ring Anchorage Connectors must only be used on

steel with a minimum thickness of ¼inch (6.4 mm).

3. FASTENERS: Only use Grade 5 or stronger ⅝inch - 11 steel hex

head bolts and nuts (sold separately).

4. LOADING: D-Ring Anchorage Connectors are permitted to be loaded

in all directions.

5. CONNECTION: Only one travel restraint, work positioning, fall arrest,

or rescue system may be attached to an individual connect point.

6. EXTREME TEMPERATURE: D-Ring Anchorage Connectors are

designed to be used in temperatures ranging from -40°F to +130°F

(-40°C to +54°C). Protection should be provided when used near

welding, metal cutting or similar activities. Contact WernerCo with any

questions concerning high temperature environments.

7. CONTAMINATION: Remove any surface contamination

such as concrete, stucco, roong material, etc., that could

accelerate cutting or abrasion of attached components.

8. ELECTRICAL HAZARDS: Use extreme caution when working near

high voltage power lines due to the possibility of electric current

owing through the D-Ring Anchorage Connector or connecting

components.

9. HEALTH: Minors, pregnant women and anyone with a history of either

back or neck problems should not use this equipment.

10. RESCUE: In the event of a fall over the edge, special rescue

measures may be required.

11. TRAINING: Do not use D-Ring Anchorage Connectors without proper

training from a “competent person” as dened by OSHA 29 CFR

1910.140(b) and 1926.32(f).

12. REPAIRS: Only WernerCo, or persons or entities authorized in writing

by WernerCo, may make repairs or alterations to the equipment.

COMPATIBILITY LIMITATIONS

All connecting subsystems must only be coupled to compatible connectors.

OSHA 29 CFR 1910.140 and 1926.502 prohibit snap hooks from being

engaged to certain objects unless two requirements are met: snap

hook must be a locking type and must be “designed for” making such a

connection. Under OSHA “designed for” means that the manufacturer of

the snap hook specically designed the snap hook to be used to connect

to the equipment in question.

The following connections must be avoided because they can result in

rollout* when a non-locking snap hook is used:

• Direct connection of a snap hook to horizontal lifeline.

• Two (or more) snap hooks connected to one D-ring.

• Two snap hooks connected to each other.

• A snap hook connected back on its integral lanyard.

• A snap hook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in

relation to the snap hook dimensions that would allow the snap hook

keeper to be depressed by a turning motion of the snap hook.

*Rollout: A process by which a snap hook or carabiner unintentionally

disengages from another connector or object to which it is coupled.

D-Ring Anchorage Connector

User Instruction Manual

A330000

WARNING: Compliant fall protection equipment must

only be used as it was designed. Users MUST read and understand

all user instructions provided with the product. Before using a

fall arrest system, users must be trained in the safe use of the

system, as required by OSHA 29 CFR 1910.30 and 1926.503, or local

safety regulations. Misuse or failure to heed these warnings and

instructions may result in injury or even death.

WORK SAFE! WORK SMART!

IMPORTANT

Before use, the user must read and understand these User Instructions.

Keep these User Instructions for reference.

PURPOSE

WernerCo D-Ring Anchorage Connectors are designed to function as an

interface between the anchorage and travel restraint, work positioning, fall

arrest, or rescue system.

USE INSTRUCTIONS

1. Failure to follow all instructions and limitations on the use of the

D-Ring Anchorage Connector may result in serious personal injury or

death.

2. Before using a personal fall arrest system, employees must be trained

in accordance with the requirements of OSHA 29 CFR 1910.30 and

1926.503 in the safe use of the system and its components.

3. Personal fall arrest and rescue systems, including the D-Ring

Anchorage Connector, must be inspected prior to each use for

wear, damage, and other deterioration. Defective components

must be immediately removed from service in accordance with the

requirements of OSHA 29 CFR 1910.140 and 1926.502.

4. The complete fall arrest system must be planned (including all

components, calculating fall clearance, and swing fall) before using.

5. Users must have a rescue plan, and the means at hand to implement

it, that provides for the prompt rescue of the user in the event of a fall,

or assures that the user is able to rescue themselves. A fall over an

edge may require special rescue measures.

6. Store the D-Ring Anchorage Connector in a cool, dry, clean

environment, out of direct sunlight, when not in use.

7. After a fall occurs on the system, immediately remove from service

until a “competent person” can make the determination for reuse or

disposal.

8. WernerCo will provide design information upon request.

9. Field serviceability testing is not required and is not

recommended to be performed by the user.

USE LIMITATIONS

D-Ring Anchorage Connectors have been tested in compliance with the

requirements of ANSI/ASSE Z359.7. Compliance and testing covers only

the hardware and does not extend to the anchorage and substrate to

which the D-Ring Anchorage Connector is attached.

1. ANCHORAGE: D-Ring Anchorage Connectors must only be used

on structures capable of supporting loads applied in all directions

permitted by the fall arrest system of at least: 3,600 pounds (16.0 kN)

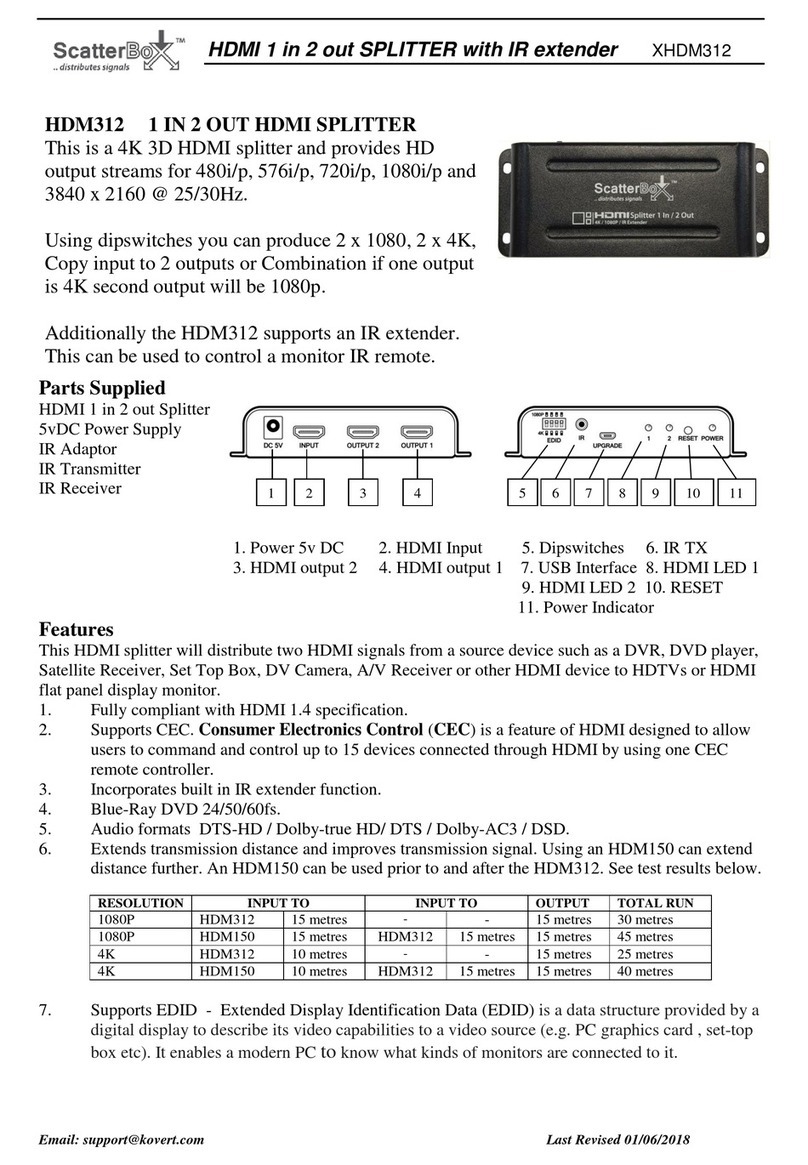

Model No.

Material Length Width Connection Size Hole Diameter Weight MBS Compliance Standards

A330000 Alloy Steel;

Stainless Steel

6 in

(154 mm)

3 ⅛in

(80 mm)

2 ⅜in

(61 mm)

5/8 in

(17 mm)

9.5 oz

(268 g)

5,000 lbs

(22.2 kN)

ANSI Z359.18-2017 Type A

OSHA 1910 & 1926

D-Ring Anchorage Connector

120658-01 ©2019 WernerCo Rev B 04/20

User Instruction Manual

A330000

WernerCo Corporate Headquarters: 555 Pierce Road, Suite 300, Itasca, IL 60143

TEL: 888-523-3370 FAX: (724) 588-0315 www.wernerco.com

INSTALLATION

Drill a ⅝inch hole where needed in the anchorage structure. Attach the

D-Ring Anchorage Connector using a ⅝inch - 11 Grade 5 steel hex head

bolt and nut. Torque bolt to 100-150 ft-lbs.

If attaching the D-Ring Anchorage Connector to the support structure

by methods other than instructed, the attachment must be certied by a

qualied person to meet the requirements of the system that will connect to

the D-Ring Anchorage Connector.

INSPECTION

All components of D-Ring Anchorage Connector’s must be inspected

prior to each use and annually by an OSHA dened “competent person”

other than the user. Local, state, governmental and jurisdictional agencies

governing occupational safety may require the user to conduct more

frequent or mandatory inspections.

WARNING: If inspection reveals any defect, inadequate

maintenance, or unsafe condition, remove from service until a

“competent person”, as dened by OSHA 29 CFR 1910.140(b) and

1926.32(f), can determine the need for authorized repair or disposal.

WARNING: Any equipment that has been subjected to the

forces of arresting a fall, or that has a deployed load indicator, must

be removed from service until a “competent person” can determine

the need for authorized repair or disposal.

All D-Ring Anchorage Connectors must be free of corrosion, chemical

attack, alteration, excessive heating or wear.

All markings must be legible and attached to the product.

WARNING: Only WernerCo, or persons or entities authorized

in writing by WernerCo, may make repairs or alterations to the

equipment.

CLEANING AND MAINTENANCE

D-Bolt Anchorage Connectors may be wiped down to remove grease or

dirt with a clean dry cloth.

6 inch

(154 mm)

2 ⅜in

(61 mm)

3 ⅛inch

(80 mm)

⅝inch

(18 mm)

⅝inch

(17 mm)

93 Werner Road, Greenville, PA 16125

888-523-3371

Model: A330000

© 2019 WernerCo

P/N 120674-01 Rev A 9/19

WARNING:

User must follow manufacturer’s

instructions included with the

equipment at the time of shipment

from the manufacturer.

Refer to the instruction manual for

proper installation and stability and

compatibility limitations.

Inspect prior to use.

ADVERTENCIA:

El usuario debe seguir las

instrucciones del manufacturero

incluidas con el equipo al tiempo de

embarque del productor.

Refiera al manual de la instrucción

para las limitaciones apropiadas de la

instalación y de la estabilidad y de la

compatibilidad.

Inspeccione antes de usar.

Standards/Estándares

ANSI Z359.18-2017

Type A OSHA 1910, 1926

Material: Steel/Stainless Steel

Materiales: Acero

Minimum Breaking Strength (MBS): 5,000 lbs

Resistencia Mínima a la rotura: (22.2kN)

Year of manufacture: [YYYY]

Año de la fabricación:

[Serial number]

Inspection Log/Registro de Inspección

1

Year 1

2 3 4 5 6 7 8 9 10 11 12

Year 2

Year 3

Year 4

Year 5

Popular Cables And Connectors manuals by other brands

Cypress

Cypress CLUX-12S Operation manual

Siemens

Siemens 3VL9000-8AQ10 operating instructions

Gleason Reel

Gleason Reel Direct Drive Hazardous Duty Electric Cable Reels... Installation and maintenance instructions

CONCORD

CONCORD CS4WH20B4KDS-A manual

Burndy

Burndy Continental Industries thermOweld CB-15 instructions

E1DT

E1DT E1DT-ASSY-0058 Installation and operation