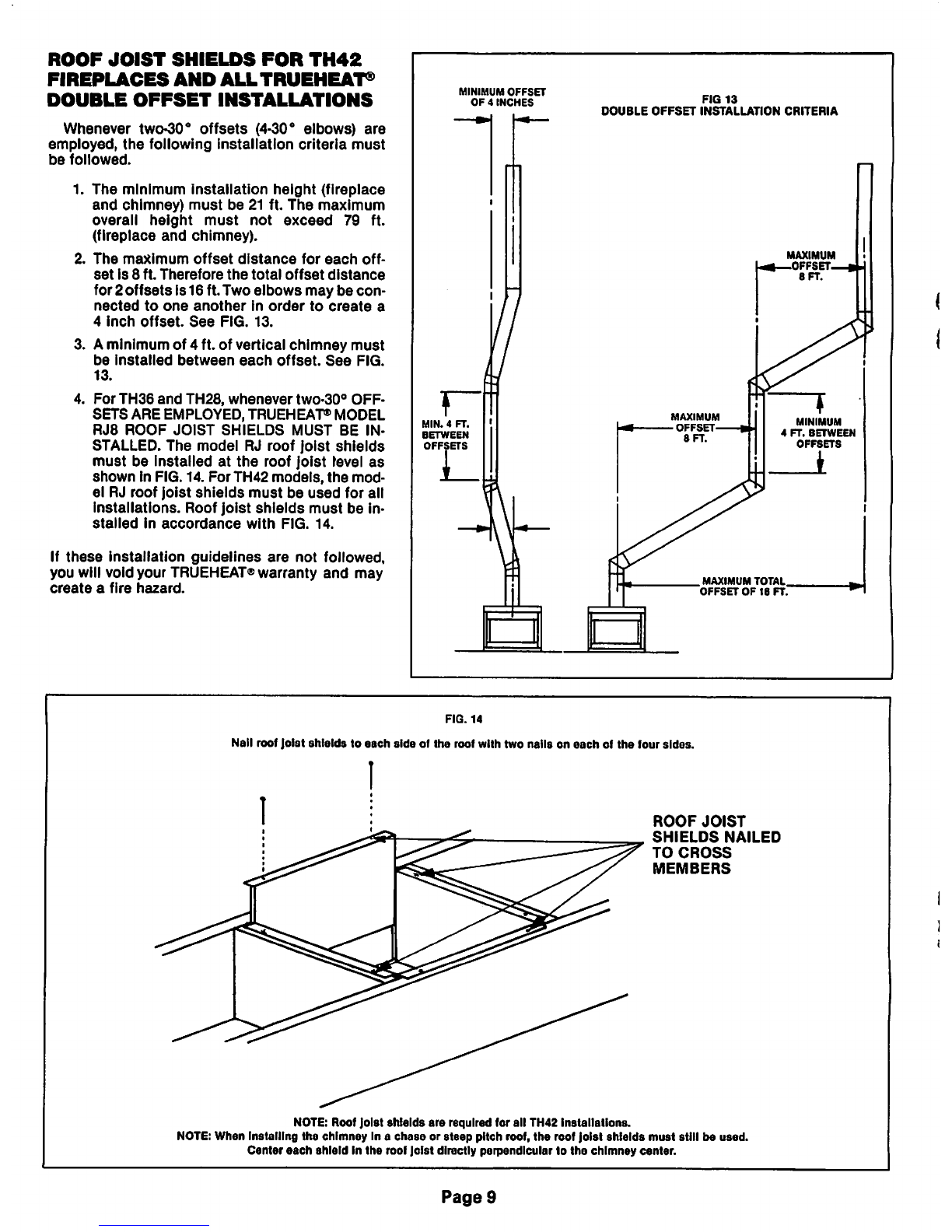

Step 6. Firestopspacers should nowbe installedat

every

joist

level

except the

roof.

Thefirestop spacers should be

nailed

upto the bottomof the joist between

living

spaces and nailed

down

to the top of the joist in the attic space. See

FIG.

22.

Please note that roofjoist shields must be installed

as

outlined on page 9 for the TH42series and all double offset installations.

Step

7:

You

are

now ready to install

the

fireplace

chimney system. Determine the numberof chimney

sections required to reach

the

desired height

and

install the shortest chimney section first to

the

top

of the fireplace. The reason for installing

the

shortest

sections

first is

so

there

are

fewer joints

of pipe above

the

roof. To install a

section

of pipe,

firmly

push the inner (stainless steel) pipe down in

to

the

8 or 10inch starting flue on

the

fireplace. The

pipe

must

lock

securely

into

position.

To

check

the

fit, pull up on pipe

section.

Ifproperly

installed

the

pipe will not pull

out

of

the

flue on

the

fireplace.

If

the

pipe

pulls

out

push

it

back

down

inside

the

pipe until it locks. Next, install

the

outer

pipe. Push

the

outer

pipe

down

over

the

starting

collar

on

the

fireplace. Again, pull up on

the

pipe

to

make

sure

it is properly locked. Install

the

remaining pipe in

the

same

wayalways inserting the flue (center) pipe

inside

the

previous

section

and

installing

the

outer

section

over

the

outside

of

the

previous

section.

Check

each

section

to

make

sure

it is properly

locked

to

the

previous

section.

To

ensure

that

the

pipedoes not-come apart, the.instalier, at his option, mayattach the outer walls of the chimney pipe with 2

sheet

metal screws.

Drill

two holes 180°apart using %drillbit less than 2inches longand screw

sections

together. WARNING: BE

VERY

CAREFUL,

WHEN

DRILLING

HOLES IN THE OUTER PIPE, NOTTO

DRILL

THROUGH THE STAINLESS STEEL FLUE,

FIG.

22

MOUNT

FIRESTOP

SPACER

IN

THIS

MANNER

WITH

ATTIC

ABOVE

CEIUNG.

MOUNT

FIRESTOP

SPACER

IN

THIS

MANNER

WITH

ANOTHER

ROOM

ABOVE

CEILING

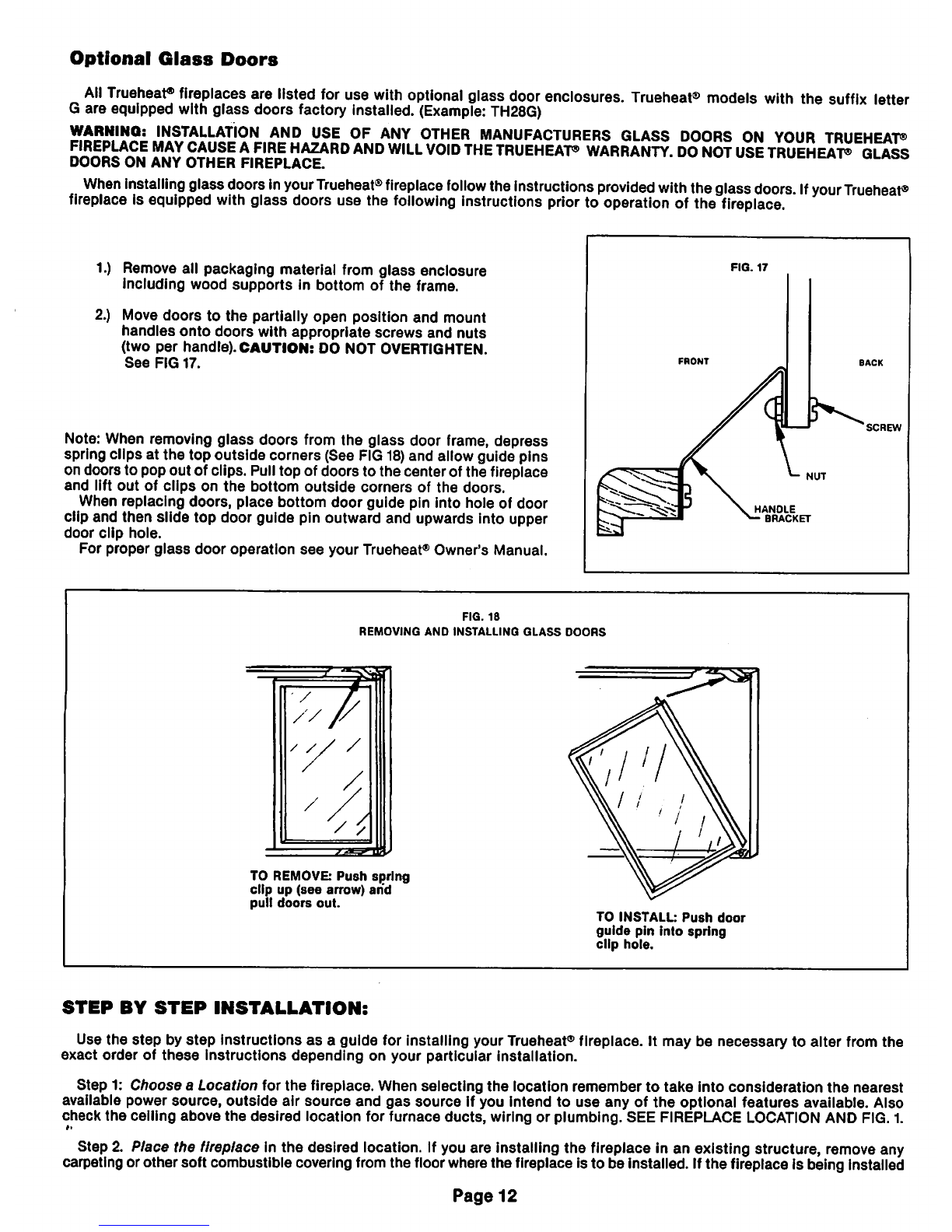

TABLE

5

PITCH

MINIMUM

ROOF

OPENINGS/

FRAMING

MEMBERS

TH28,

TH36

x/12

2x4

2x6

2x8

2x10 2x12

0/12 18x18 18x18

18x18

18x18

18x18

1/12

18x18'/!

18x18%

18x18%

18x19%

18x19%

2/12

18x19

18x19'/.

18x19%

18x20

16x20'/.

3/12

18x19'/.

18x20'/.

18x20

>/.

18x21V.

16x21 V.

4/12

18x20%

18x21

18x21%

18x22% 18x23

5/12 18x21 •/.

18x22

18x22'/.

18x23'/.

18x24%

6/12 18x22'/,

18x23% 18x24%

18x25'/,

18x26%

7/12 18x23 18x24'/.

18x25% 18x26%

18x27'4

8/12

18x24'/,

18x25'/,

18x26'/.

18x26%

18x29%

9/12

18x25%

18x27 18x28%

18x30

18'/.x31%

10/12 18x26"/.

18x28%

18x30

18x31 V.

18x33%

11/12

18x27

V,

18x29%

18x31% 18x33%

18x35%

12/12

18x29'/.

18x31'/.

18x33%

18x35%

18x37%

TABLE

6

PITCH

MINIMUM

ROOF

OPENINGS!

FRAMING

MEMBERS

TH42

x/12

2x12

2x4

2x6

2x8

2x10

0/12

19x19 19x19

19x19

19x19

19 x 19

1/12 19X20% 19 x 19% 19 x

19%

19x19%

19x20%

2(12

19x21%

19x20

19 x 20%

19x20%

19x21

3/12 19 X

22%

19 x

20'/.

19x21% 19x21%

19 x

22%

4/12

19x24

19x 21'/,

19x22

19x22%

19 x

23%

5/12 19 x

25%

19 x

22%

19x23

19 x 23%

19x24%

6/12

19x 27%

19x23%

19x 24% 19x 25% 19x

26%

7/12 19 x

28%

19x24

19 x

25%

19x26%

19 x

27%

8/12

19 x

30%

19 x 25% 19x

26%

19 x

27%

19x 29%

9/12

19x32% 19x26%

19 x 26 19 x

29%

19x31

10/12 19 x

34%

19 x

27%

19x29%

19x31

19x32%

11/12

19x 36% 19 x

28%

19x30%

19 x

32%

19x34%

12/12

19 x 38% 19 x 30% 19 x

32%

19 x

34%

19 x 36%

Note:

Some

local

building

codes

require

that

the

chimney

sections

be

secured

with

sheet

metal

screws.

Check

your

local

building

codes

for

details.

Note:

When

the

fireplace

chimney

height

exceeds

30 ft. a

chimney

support

piece

must

be

used.

The

support

section

should

be

secured

to

the

framing

members

as

shown

in FIG 27,

page

17.

Page

14