Trueshopping 62cc Installation and operating instructions

Long Reach Petrol Pruner

Assembly / Owner’s Manual

©Trueshopping LTD Issue 01 mc-rt

1

Original instructions

CONTENTS

Model coverage 3

Safety instructions a,b,4

Protecting yourself 4

Fuelling 4

Vibrations 4

Protecting others 4

Protecting the machine 5

Minimum age 5

Recommended use 5

Emergency action 5

Safe operating instructions 5

What’s in the box? 6

Contents 6

Assembling the unit 6

Pruning saw 7

Pole attachment 7

Mounting the guide rail and chain 8

Tensioning the chain 9

Filling with oil 9

Shoulder harness assembly 10

Fuelling the machine 10

Starting the machine 10

Operation advice 11

Storage instructions 12

Guide rail maintenance 12

Fuel pipe / tank grommet exchange 12

Fuel filter exchange 15

Changing / checking the sparkplug 17

Air filter cleaning / exchange 18

Carburettor exchange / inspection 19

Online help 21

Troubleshooting 22

Specifications 22

Contact us 23

THIS GUIDE COVERS THE FOLLOWING

MODEL NUMBERS –

MFS260C / MFS260CO

MFS330C / MFS330CO

MFS430C / MFS430CO

MFS520C / MFS520CO

MFS550C / MFS550CO

MFS580C / MFS580CO

MFS620C / MFS620CO

MFS650C / MFS650CO

MFS680C / MFS680CO

*While every effort is made to ensure the

accuracy ofthe information in this

manual,occasionally minor design

changes can occur,if indoubt please visit

the manufacturers website for the most

up to date version of this guide.

3

Labels on the Machine and their Meanings

IMPORTANT SAFETY INFORMATION

•Please note that the cutting blade

continues to run for a short period

after you let go of the throttle trigger

–This is called the flywheel effect.

•Do not lend or rent your power tool

without the instruction manual. Be

sure that anyone using your power

tool understands the information

contained in this manual.

•Persons with pacemakers only: The

ignition system of your power tool

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers.

Consult your doctor if you have

concerns.

•Do not use a pressure washer to clean

your power tool. The solid jet of water

may damage parts of the power tool.

•Do not spray the machine with water.

•Work calmly and carefully – in

daylight conditions and only when

visibility is good. Stay alert so as not

to endanger others.

•Your power tool produces toxic

exhaust fumes as soon as the engine

is running. These fumes may be

CAUTION! HOT EXHAUST

DO NOT USE NEAR

NAKED FLAMES

Machine Noise

information

Model information

(Differs by model)

a.

Important information

Important information

colourless and odourless and contain

unburned hydrocarbons and benzoyl.

Never run the engine indoors or in

poorly ventilated locations.

•The dusts, vapour and smoke

produced during operation may be

dangerous to health. If the work area

is very dusty or smoky, wear

appropriate safety equipment.

•If your power tool is subjected to

unusually high loads for which it was

not designed (e.g. heavy impact or a

fall), always check that it is in good

condition before continuing work

b.

Safety Instructions

Read this manual in full before operating this

machine for the first time. If you have any

questions regarding the operation of the

machine, please contact the manufacturer.

CAUTION! In order toensure your safety you

must follow the safety, installation and

operation instructions. Any person who uses

this machine should be fully aware of the

potential risks.

!You must be 18orover to operate this

machine. Children must notoperate this

machine.

! The manufacturer shall not be held liable if

the unit is altered outside of the information

printed in this guide.

! Always turn the engine off before

performing any maintenance

! Some components will become hot during

use

Protecting yourself

!Do not use this machine in areas with poor

ventilation or indoors, when switched on, the

machine produces carbon monoxide!

! Do not operate this machine in adverse

weather or in situations where sure footing is

not guaranteed.

! Exercise common sense when operating this

machine, do not operate when under the

influence of alcohol or medication which may

impair judgement and concentration.

FUELLING

! Always switch the engine off before fuelling.

Open the tank cap slowly to avoid spillage due

to internal pressure. If the unit has recently

been in use, allow to cool down first. Not

allowing the unit to cool could cause the fuel to

ignite.

When replacing the fuel, be careful not to over

fill the tank. Any spillages should be cleaned up

immediately.

After filling ensure that the cap is secured

properly and that it will not work loose while

the machine is switched on.

VIBRATIONS

Vibrations from the machine make it difficult to

hold for long periods of time, this time can be

prolonged by wearing suitable gloves.

Protecting others

! Do notallow anyone toapproach the

machine while in use, ensure the working

area isclear.

! Avoid jamming the blade as this can make

the machine suddenly difficult to control.

! Do not use the machine for any purposes

other than outlined in this book.

! WEAR EAR PROTECTION!

! SAFETY BOOTS MUST BE WORN

WHILE OPERATING THE MACHINE!

! WEAR SUITABLE EYE

PROTECTION!

! WARNING, PETROL IS

FLAMMABLE, TAKE

APPROPRIATE CARE!

4

!Itis good practise to clearly mark your

working area.

! Turn the machine off when moving location.

Protecting the Machine

! Only use recommended parts, consult the

manufacturer to obtain these.

!Always use the correct tool for the

correct job.

! Ensure that the machine is stored in a dry

area in a secure place. Parts of the tool are

sharp and should not be left within reach of

children / pets.

! Inspect the machine for damage before use,

and ensure all components are properly

aligned.

Minimum Age

Only persons over 18 years of age are legally

allowed to operate this machine unless under

training supervision.

Recommended use

The unit is recommended for general use in

agriculture, forestry and gardening.

Emergency Action

In the event ofinjury, seek qualified medical

assistance.

!The user isresponsible for any material /

personal damage resulting from improper use.

! Please note that if not properly used, the

following injuries can be caused –

Hearing problems if proper ear protection

not used.

Carbon monoxide poisoning if used in an

enclosed area.

Safe Operating Instructions

! Do not operate the machine if you suspect

the machine has a problem.

•Always visually inspect to see that the

chain and cutter assembly are not

worn or damaged. Ensure the engine

vents are free from any dirt or

remnants.

•Operate the machine at the lowest

possible engine speed to do the job.

•Keep your hands and feet clear of the

attached tool when the machine is

running.

•Keep both hands firmly on the machine

at all times.

•Always use the machine with the

supplied carry strap.

•Always wear appropriate hand, feet

and hearing / eye protection when

operating the machine.

•Pay attention, the machine will

continue to run for five seconds after

the engine has stopped.

5

What’s in the Box?

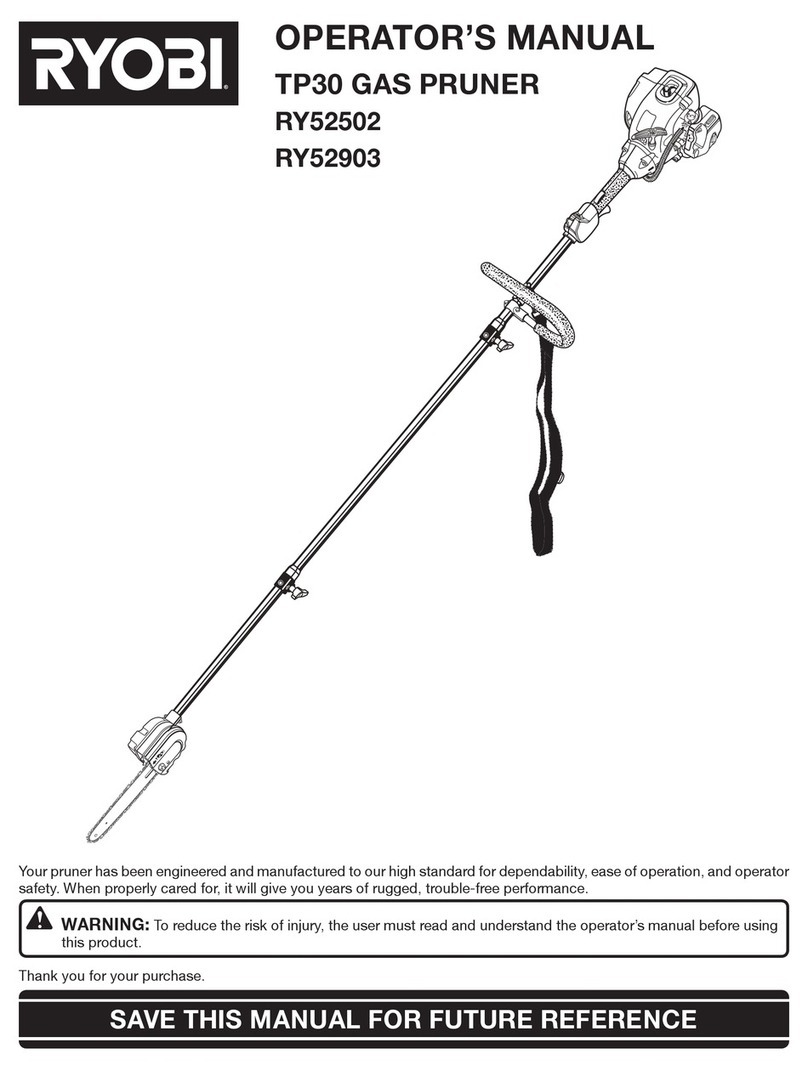

This long reach pruner is ideal for an array of

tree maintenance tasks including trimming tall

or wide hedges and small leafed trees. It has a

powerful two stroke engine for exceptional

performance. Its long reach pole allows for the

trimming of hard to reach branches without the

need for stepladders or extra physical exertion.

Contents

•Main engine with attached handle

•Tools

•Extension handle

•Handle

•Pruner

•Carry strap

•Mixing bottle

Assembling the unit

1. Handle

2. Harness loop hole

3. Stop switch

4. Throttle lockout

5. Air filter

6. Starter handle

7. Fuel tank

8. Throttle trigger

9. Shoulder harness

10. Attachment bracket

11. Locking switch

1. Fuel cap

2. Choke lever: Facilitates the engine

starting

3. Fuel pump

4. Screw on the carburettor

5. Engine support

6. Fuel tank

7. Exhaust

6

1. Chain

2. Guide rail

3. Oil tank

4. Oil tank lid

5. Drive shaft

6. Chain wheel housing

7. Hook

8. Chain guard

9. Sprocket

10. Chain tensioner

Pruning saw

! If you require the useofthe extension pole

then attach it first in the same way asthe

following.

!When you are ready to assemble / use the

product, remove the protective cover from

the saw. Take care asthe chain is very sharp.

!Ensure the engine is switched off before

using the saw.

Pole Attachment

To fit the different attachments to the

machine, you need toconnect them tothe

coupling on the end ofthe fixed engine pole.

1. Open the coupling and turn the retaining

handle to loosen the connection.

2. Line up the hole on the required tool

pole as shown below and push firmly

into the coupling.

3. Close the coupling again, tighten the

retaining handle, and pull and twist

the pole to ensure that it is secure.

7

Mounting the guide rail and chain

•Loosen the nut and remove the

chain guard.

•Tighten the adjuster with a

screwdriver so that it is all the way

to the right (circled) then sit the

bar in position.

•Put the chain in place and start

from the top end of the rail,

ensuring that the chain teeth go

around the bar as pictured.

•Place the plastic cover onto the

assembly and loosely screw the nut

on. (DO NOT TIGHTEN)

8

•Turn the tightening screw (Circled)

clockwise until the chain on the

underside of the rail is slightly

hung up and the links are located

into the groove of the guide rail.

•Refit the chain guard and tighten

the nut by hand.

Tensioning the chain

A new chain has to be tensioned

frequently remember to check the

chain tension regularly.

To do this –

1. Stop the engine and loosen the

guard nut.

2. Keep the guide rail tip pointing

upwards.

3. Use a screwdriver to tighten the

clamping screw clockwise until the

chain once again rises tightly against

the underside of the rail.

4. Retighten the nut.

Filling with oil

For the purpose of automatic and reliable

lubrication on the chain and guide rail, please

use high-quality environmentally friendly

lubricating oil mixed with adhesive additive.

The need for maintenance depends on the

quality of lubricating oil. Therefore using

designated chain lube is ideal.

To fill the chain pruner with oil-

•Remove the black plastic cap on

the chain pruner by turning it anti

clockwise.

•Fill with oil and then replace the

cap.

If the oil level in the tank doesn’t fall, there

may be a problem in the oil supply:

Check the state oflubrication ofthe

chain, clean the oil line andcontact your

supplier if required.

9

Shoulder harness assembly

The shoulder harness attaches to the clip on

the main handle as shown above.

Fuelling the machine

! Switch the engine off and ensure that it is

cool before fuelling.

! The use of unleaded petrol is recommended

! Only use two stroke engine oil for air-cooled

machines

•Mix the fuel/oil together at a ratio

of 25/1 in the provided mixing

bottle.

! The mixing bottle is not designed

to be used for fuel storage

•Open the fuel tank cap carefully to

ensure any overpressure may be

released without spilling fuel.

•Fill the tank with fuel

! Any spillages should be removed

before attempting to use the

machine

•Replace the fuel cap ensuring a

tight seal is maintained.

After fuelling ensure that the cap is tight and

will not be worked loose by machine vibrations

during operation.

! If you notice any leaking fuel, discontinue

use immediately and contact the supplier

Starting the machine

! Please be aware that a certain degree of

effort is required to successfully start the

multi-tool, please persevere if you are

struggling to start the engine.

•Pull the switch into the on “I” position and

hold the throttle lockout and then pull the

throttle trigger.

•While still holding the above, press in the

switch next to the on/off switch.

•Slowly release all three and you should

note that the switch stays pressed in.

PLEASE ENSURE THAT A 25/1

FUEL/OIL MIX IS USED

10

**The following applies to the 26cc 33cc

43cc 49cc and 52cc version, for the 55cc

58cc 62cc 65cc 68cc the worded

instruction is the same but with slight

visual differences of the engine block **

•Now we need to prime the engine with fuel

for use. Press the priming bulb on the unit

several times (8-10) to prime the machine.

•To start the engine, push the choke lever

upwards and pull the starter cord.

•Do this until you hear a splutter or cough

from the engine. Once this has happened,

push the choke lever down and pull the

starter cord and the engine will start. You

can then pull the throttle trigger to start

the tool working.

**Please note that it can take several

attempts at pulling the starter cord to start

the machine.

•To turn the machine off push the on/off

switch to “O”.

Operation advice

! Fully inspect the machine before use, ensure

the chain is not damaged and that all

components are secure.

! Operate the machine at the lowest possible

engine speed to do the job.

!Ensure your hands and legs are clear ofthe

chain when the machine is in operation.

!Always hold the machine atan appropriate

safe distance from your body and ensure that

you have steady footing on a solid surface.

!Keep both hands on the machine atall times.

!Always usethe machine with the supplied

strap/harness.

!Ensure that you wear appropriate safety

protection.

11

! Be careful when shutting down the machine

as it will continue to run for several seconds

before coming to a stop.

!Beware offalling branches and branches

that may spring back on you.

!You must usethe provided extension pole,

do notlean or stretch as this may cause you to

fall.

!Donotusethe pruning saw when standing

on a ladder oruneven surface, you may lose

balance and cause severe injury to yourself or

others.

!The machine produces exhaust fumes

including Carbon Monoxide, do notusethe

unit indoors orin non-ventilated areas.

!This machine should not be operated by

anyone underthe age of18.

!This machine should not be operated by

persons oflimited capacity.

! Do not operate the machine if under the

influence of alcohol, prescription medicine or

any substances which may impair your

judgement

!Bewary ofyour environment, do not

operatethe machine in adverse weather

conditions. Clear any obstacles from the

working area.

Storage instructions

If the unit is to be stored for long periods of

time please read the following –

•Drain the oil and fuel tank, fuel vapours

can build up and pose a fire hazard

•Remove and clean the blade

•Wipe the machine down with a cloth

soaked in mild soap solution and dry fully

•Store in a dry place

•Keep in a locked area and keep out of the

reach of children

•Allow the engine to cool before storing

•Ensure all fixings are tight on the unit

Inspection and maintenance

Regularly check:

•The air filter

•The spark plug

•The chain bar and blade

Guide Rail Maintenance

Turn the guide rail every time the chain is

replaced or sharpened. This will prevent one

sided wear of the rail, particularly on the top

and bottom. Clean regularly.

Fuel pipe / Tank grommet exchange

! Please ensure the unit is completely drained

of fuel before attempting this procedure.

•Unscrew the retaining cap and remove

the air filter cover. **The retaining

cap will be a Philips screw on certain

models**

•Remove the fuel pipes from the

carburettor using long nosed pliers and

a small flat headed screwdriver, noting

the location of each pipe before

removal.

Black pipe = Feed/Supply

Clear Pipe = Return

12

•Unscrew the fuel cap and remove it by

pulling the retaining strap from inside

the fuel tank.

•Using a blunt pointed object, push the

fuel pipe grommet into the fuel tank,

then use your long nosed pliers to

withdraw the part through the fuel fill

hole.

13

•Insert the replacement fuel pipes /

grommet into the tank using a large

flathead screwdriver to push it into

position. Then reattach the pipes to

the carburettor connections

*WD40 may be sprayed around the

grommet to ease it into position.

•Finally replace the retaining strap back

into the fuel tank then screw the cap

back in place.

14

Fuel Filter Exchange

!Please ensure the unitis completely drained

of fuel before attempting this procedure.

•Remove the fuel tank cap by

unscrewing anti-

clockwise and pull out the cap

retaining strap from the tank.

•Using a piece ofcurved wire (e.g. a

tent peg or old coat hanger ) hook the

fuel feed pipe within the tank and pull

out as shown,the fuel filter is

attached to the end. •Remove the fuel filter by gripping the

feed pipe firmly and pulling the filter.

15

*If the pipe is damaged or frayed at

the end then trim it down with a pair

of scissors.

•Connect the replacement fuel filter by

pushing it into the fuel feed pipe,

ensuring the connection nozzle is not

visible. •Feed the fuel pipe and filter back into

the tank and replace the cap.

16

Changing/checking the sparkplug

! Exercise caution when following this

section, arisk ofelectric shock exists.

!Ensure all fuel hasbeen removed from the

unit.

•Remove the spark plug cover and dust

shield byfirmly pulling it away from

the spark plug.

•Using the provided tool, place the

socket over the spark plug and firmly

strike the screwdriver rod with the

palm of your hand in an anti-clockwise

direction to loosen the plug, then

unscrew the rest of the way toremove.

•At this point, if you are exchanging the

plug, discard the old one and pick up a

new plug. Remove the dust shield by

pulling it off the spark plug cover and

push the plug into the rubber cover

cap ensuring it goes all the way in.

•To check for a spark, the tip of the plug

must touch a metallic surface. The

easiest method is to push it against the

metal area on the engine next to

where the plug normally sits.

17

•Finally, position the switch to the “I

“setting on the throttle control.

•With the plug held against a metal

surface (and ensuring that you have

hold of the rubber plug cover toavoid

electric shock)pull the recoil starter

while observing the gap between the

electrode and the earth contact for a

spark (fig 1).

•Once the above is complete, reinsert

the spark plug by performing the first

two points in reverse.

Air filter cleaning / exchange

•Unfasten the retaining cap and remove

the filter cover. **on some models the

retaining cap will instead be a Philips

screw **

•Remove the foam air filter by carefully

pulling it away from the engine body.

18

Table of contents

Languages: