Trueshopping BX1-B User manual

Offering a wide selection of products at competitive prices

AC ARC WELDING SERIES

Instruction Manual

Trueshopping

Introduction

Thank you for purchasing the X1- and X1-C series portable moving coil type AC

ARC Welder. Please read this manual carefully before using.

The portable moving coil type AC ARC Welder is designed and manufactured by our

company and has many advantageous features: National technique, novel style,

portable volume, and excellent performance.

This machine is fitted with automatic temperature control and a wind-cooling device

for ensuring long-term efficient and safe work. It adopts moving coil controllable

current design with 400V or 230V, 50/60 Hz AC power. It's convenient to use and

belongs to initiate portable products in the domestic market.

The quality is steady and reliable with good performance for thick and thin board

welding. You can use single-phase power, particularly suitable for mobile and field

operation.

X1-80C, X1-100C, X1-130C, X1-130C, X1-160C Welder is designed and

manufactured by standard EN 50060.

X1-180C, X1-200C, X1-250C Welder is designed and manufactured by standard

IEC 60974-1.

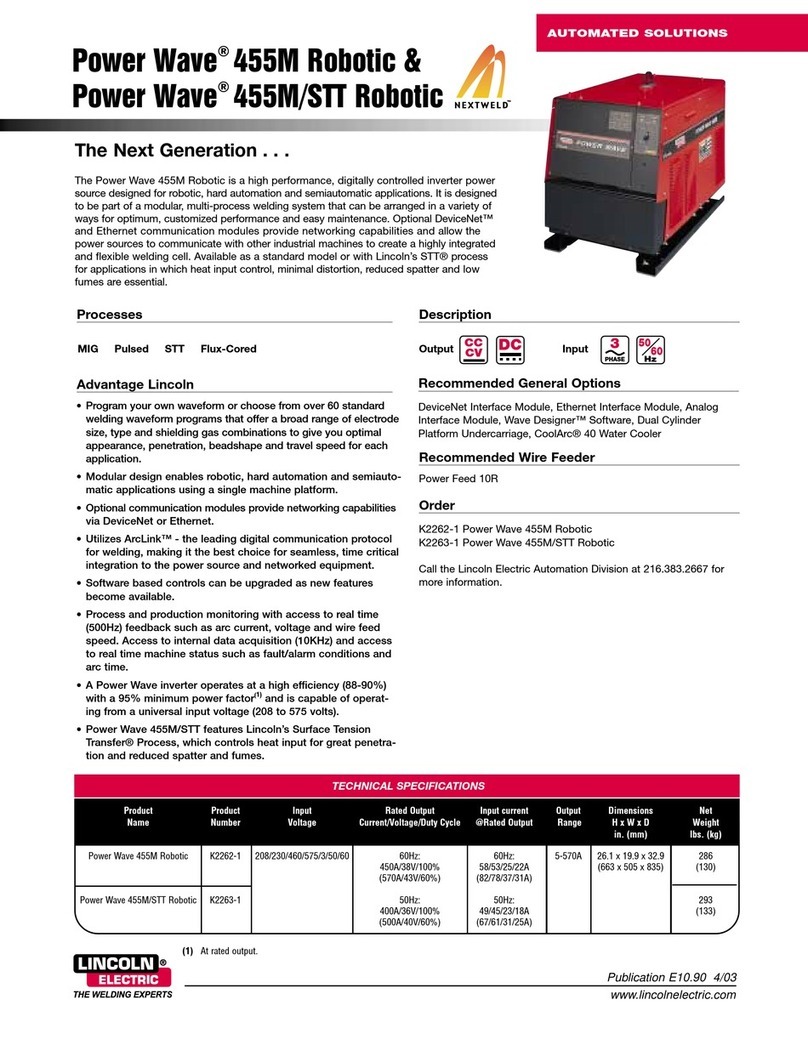

Technical Specification

www.trueshopping.co.uk

Trueshopping

Product Sketch

www.trueshopping.co.uk

Trueshopping

Use of Welder

Placement of welder

1. Set it in less-vibration and flat place above 200mm away from the wall.

2. Store in a clean and dry place away from iron power, dust, and paint.

Connection

1. Ground.

1a. There is ground terminal under the shell board. Please ground with copper wire

over 14mm.

1b. Arrange for a qualified electrician to ground.

www.trueshopping.co.uk

Trueshopping

Power Connection

Each welder needs to be equipped with a distributor box with switch and over-current

protection device. Please lead the power from the distributor box to input terminal of

welder by cable. The capacity of distributor box and cross-sectional area of cable

refer to the above table. (The above cable has copper coil.)

Connection of welding end

One end adjoins the cable for welding torch through quick joint, and the other end

adjoins the workpiece by cable with quick joint. The quick joint at the output end

must be screwed clockwise firmly for safety. The workpiece must ground in

operation.

Notice:

1. Switch off the power distributor box when adjoining the cable.

2. The cables must be connected with copper terminal. Please use insulating tape

after fixing it with bolt and nut.

Operation Instructions

Operate as follows:

1. Switch on the distributor box and power.

2. Tum on the power switch of welder → Turn the switch handle at 400V/230V.

3. Adjust welding current → Rotate the hand-wheel clockwise, and the current

increase.

Rotate the hand-wheel anti-clockwise, to the current decrease.

4. Operate welding → Wear proper clothes and protective apparatus.

5. End operation.

6. Turn off the power of welder.

7. Switch off the distributor box.

Read this manual carefully before using in order to avoid accident. Incorrect

operation can cause injury.

Features

www.trueshopping.co.uk

Trueshopping

Thermal cut out

If the machine stops at any time and the amber light on the front panel illuminates,

the thermal cut out has activated. Wait until the transformer has cooled sufficiently

(the amber light goes out) before restarting work.

Using the welder

Setting the welder current

www.trueshopping.co.uk

Trueshopping

1. Select the welding current by turning the welding current selector and observing

the setting on the scale, on top of the machine.

2. The chart below is an indicator of the thickness of material/welding rod thickness

and the corresponding welding current. This is intended as a guide only.

Notice: With practice, you will get a feel for the best settings for different welding rod

thicknesses.

Striking an RC

Warning: efore you strike an arc, bring the face shield up to protect your eyes.

www.trueshopping.co.uk

Trueshopping

1. Switch on the machine.

2. Line up the electrode exactly over the spot where you want to strike.

3. Position your shield in the front of your face and tap down firmly with the

electrode. Once you tap down and contact is made, you must instantly raise the

electrode to the required arc gap.

3a. The arc gap should be roughly the same as the diameter of the electrode.

3b. If you withdraw the electrode too far once the arc is struck, you will lose the arc

and have to try again.

4. Once the arc is struck, move the electrode along its intended path, keeping in the

molten pool at all times.

4a. You must also get used to feeding down the electrode steadily as it burns away.

4b. An even crackling noise should be heard, which is an indication of a good weld.

5. Inspect the job carefully, the area of weld should be a complete fusion of the

electrode and parent metals.

5a. Any slag which forms on the surface should be chipped away with the

hammer/brush supplied.

5b. If the weld looks messy and irregular, this is an indication of porosity or slag

contamination, and you have probably failed to achieve the correct combination of

working speed and current. This is a common problem, so do not worry as practice

will resolve this.

Safety Notices

Warning: Incorrect operation can cause serious injury (electric shock, fracture,

poisoning, burns) or death.

Notice: Incorrect use may cause destruction of matter.

The following signs show ‘must do’ and ‘forbid to do’.

Danger!

To avoid serious injury caused by accident, please observe the following

items.

1. The construction of input power source, the selection of the site for machine, the

upkeep of work according to the relevant rules and internal standard of your

company.

2. Unauthorised personals are forbidden to enter the site of welding.

3. Persons using heart/stroke pacemaker must not draw near to welder in use or the

surrounding of the welding site without the permission of a doctor.

4. Let professional or expert persons install, maintain and operate the machine.

5. Only use this machine for welding.

www.trueshopping.co.uk

Trueshopping

Danger!

To avoid getting an electric shock, please observe the following rules.

Touching the electric parts may cause lethal shock or burn.

1. Do not touch electric parts.

2. Let an electrician ground the welder and machine tool according to the regulation.

3. When installing and repairing, turn off the power of distributor box, and

operate in five minutes.

4. Do not utilise the cable less of capacity with damaged insulated protective

cover and exposed conductor.

5. Ensure the insulation of the joint part of cable.

6. Do not use the welder without shell.

7. Always use dry insulated glove.

8. Please use safe net when operating in high places.

9. Maintain and repair regularly.

10. Please turn off all input power.

11. Please use shock-proof device when using the machine in narrow or high places.

Notice:

To avoid accident such as fire and explosions, please obey the following rules:

1. Do not set flammable matter in welding site.

2. Do not weld near flammable gas.

3. Do not place hot machine tool near the flammable matter.

4. The joint parts of the cable must be completely insulated.

5. When welding well, ground and wall, please clear away the flammable matter on

the back.

6. The cable joint with the side of machine tool should approach the welding parts.

7. Do not weld pipe with gas or sealed container. Please set fire extinguisher near

the site of welding.

Notice:

Contact with the revolving parts may cause injury, please observe the

following regulation:

1. Do not use the welder without the shell.

2. Let a professional person install, operate, maintain and repair the machine.

3. Keep your fingers, hair, loose clothes etc away from the revolving parts such as

cooling fan.

www.trueshopping.co.uk

Trueshopping

Notice:

Entry of splash and iron powder caused in welding and polishing into the

inside of power, will lead to the deterioration of insulation. To avoid the fire

caused by the deterioration of the power's insulation, please obey the rules:

1. Please separate the welding power from the operation of welding and polishing.

2. Please maintain and repair regularly to avoid the deterioration of the insulation

caused by the pilling of dust.

3. When splashed iron powder into the inside of power, please turn off the switch of

welder power and distributor box, then blow it clean by air.

Notice:

In order to prolong the service life of the machine, please pay careful attention

to its upkeep and repair. Please maintain the welder once at least every six

months as stated below. The power of distributor box and welder must be

switched off.

1. Use resistance instrument to measure the resistance between ground and the

primary winding. Secondary winding, and each other winding. And the resistance

should be more than 1MΩ.

2. Winding over-heated. You need use compressed air to blow the dust in the

winding and other parts away.

3. Examine the contact state of power switch. If it is burnt on the surface, it should be

changed.

4. Examine whether the bolt and nut is tightly fixed. If they are loose, you need to

screw it tightly.

5. When the machine needs to be repaired, please inform the distributor with the

model and product number as soon as possible.

Notice:

1. Please confirm the rated specifications and then make use of it.

2. Avoid over-load usage.

2a. Serious over-load can burn machine and shorten the service life.

2b. Over-load may cause noise and make the rotation of hand-wheel difficult.

3. The connection of cable and terminal of machine should be steady. Or it will cause

local running hot to burn the terminal and cable.

4. A too long output cable will lead to impediment current circulation and cause

electric power loss. If the surface insulation of cable is soiled, the arc will be

unstable. So you need to change the old cable in time.

5. The power must be switched off after operation.

6. The internal movable iron-core sleek structure has been adjusted well. Do not

move it unnecessarily.

7. Place the welder in the shade. Do not keep the machine in the sun for a long time.

www.trueshopping.co.uk

Trueshopping

8. The temperature of shell will rise in operation. The insulation of winding belongs to

H grade. Please use the machine at rated duty cycle.

9. Keep the voltage as stable as possible.

If the voltage is higher than rated input voltage:

1. The welding current is too low.

2. The arc may break or be unstable.

If the voltage is higher than rated input voltage:

1. The welding current is too high.

2. It will make noise.

3. The current adjusts the rotation of hand wheel hard.

4. It shortens the service life of welder.

5. Please remember to wear suitable protective clothing/apparatus for health and

safety.

www.trueshopping.co.uk

This manual suits for next models

8

Table of contents

Other Trueshopping Welding System manuals

Popular Welding System manuals by other brands

Tregaskiss

Tregaskiss TOUGH GUN TT4A owner's manual

Hobart Welding Products

Hobart Welding Products Cyberstick 250 AC/DC owner's manual

Everlast

Everlast POWERTIG 210 EXT Operator's manual

Lincoln Electric

Lincoln Electric BULLDOG 5500 Installation

Questt

Questt Robot150J user manual

Miller

Miller Spectrum 625 X-TREME owner's manual