TSS CRJ-700 User manual

1. General

A. The maintenance procedure that follow is for the removal of contamination from the pilot

S2/copilot S1 static line.

2. Job Set−Up Information

A. Tools and Equipment

REFERENCE DESIGNATION

CTR200−580 OR EQUIVALENT Cart − Nitrogen, High and Low Pressure, Hangar Use (2 bottles)

G601R121605−1 Test Panel − Gaseous (0−100 psi)

ADCRJ−612 Connector Kit − Pitot Static Pressure Test

9235006 (FUTURE

PROCUREMENT P/N:50017A42−

6−0120 AND P/N:50017A43−6−

0120

Purging Kit − Drain Valves

50017A42−6−0120 Purging Hoses Assembly − Static Drain, 2 Pin

50017A43−6−0120 Purging Hoses Assembly− Pitot Drain, 3 Pin

B. Consumable Materials

REFERENCE DESIGNATION

05−002 Nitrogen, technical

C. Reference Information

MANUAL NO REFERENCE DESIGNATION

CSP−B−001 TASK 12−00−00−867−801 Standard Aircraft Configuration for Maintenance

CSP−B−001 TASK 24−00−00−910−801 Electrical/Electronic Safety Precautions

CSP−B−001 TASK 34−11−00−790−805 Leak Test of the P2 and Copilot S1 Systems

3. Job Set−Up

A. Make sure that the aircraft is in the standard configuration for maintenance

(TASK 12−00−00−867−801).

**ON A/C ALL

TASK 34−11−00−100−805−A01−PSA

Static Line Pilot S2/Copilot S1 Contamination Removal

Internal PSA Document

EFFECTIVITY: Ref page 1 of Blue Page

CRJ-700/900

AIRCRAFT MAINTENANCE MANUAL

PSA AIRLINES, INC REVISION

AMM - Insert after Task 34-11-00-100-805-A01 of AMM 34-11-00

34-11-00-100-805-A01-PSA Rev D

Remove Rev 34-11-00-100-805-A01-PSA Rev C dated 04/03/17 and insert 34-11-00-100-805-A01-PSA Rev D dated 08/13/18

08/13/18

Page 1 of 5

Audited By TSS Dept. 10/17/18

Blue Page Current For Rev. 59

Audited By TSS Dept. 05/02/19

Blue Page Current For Rev. 61

B. Obey all the electrical/electronic safety precautions (TASK 24−00−00−910−801).

WARNING: MAKE SURE THAT YOU OPEN, SAFETY, AND TAG THE CIRCUIT BREAKER FOR

THE PITOT HEAD HEATER. THE PITOT HEAD CAN GET VERY HOT AND CAUSE

BURNS.

C. Open and tag the circuit breakers that follow:

CB−PANEL CB−NO NAME

CBP−1 A14 HEATERS PITOT R

CBP−1 LOWER T7 HEATERS PITOT L

D. Open the access door that follows:

PANEL NAME MANUAL NO REFERENCE

811 Main Avionics Compartment Door

4. Procedure

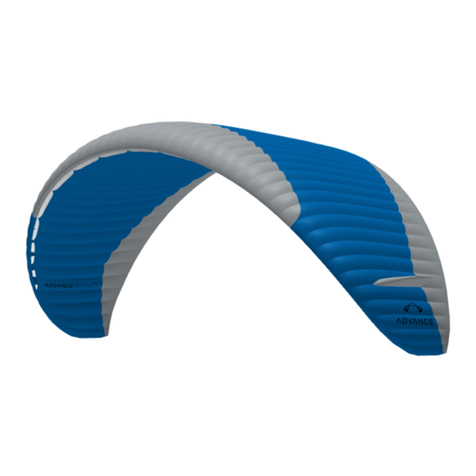

Refer to Figure 706

A. Do the pilot S2/copilot S1 static line contamination removal as follows:

CAUTION: MAKE SURE THAT THE PITOT AND/OR STATIC LINES ARE

DISCONNECTED FROM THE AIRCRAFT EQUIPMENT. IF THE LINES ARE

NOT DISCONNECTED, DAMAGE TO THE EQUIPMENT WILL OCCUR WHEN

PRESSURIZED NITROGEN IS SUPPLIED.

(1) Disconnect the static connector from the ADC 2.

(2) Install a cap on the static connector on the ADC 2.

(3) Remove the drain collector tubes from the static line drains that follow:

NOTE: The drain collector tube is attached to the drain assembly with a

quick−disconnect connector.

– S2/S1 drain assembly on the ADC 2 static line

– S2/S1 drain assembly on the static manifold.

(4) Remove any contamination collected in the two drain collector tubes.

(5) Install the pitot−static test adaptor on the P1 pitot−static head and P2 pitot−static head.

NOTE: Refer to the manufacturer’s instructions of the pitot−static test adaptors when you

install the adaptor.

Internal PSA Document

EFFECTIVITY: Ref page 1 of Blue Page

CRJ-700/900

AIRCRAFT MAINTENANCE MANUAL

PSA AIRLINES, INC REVISION

AMM - Insert after Task 34-11-00-100-805-A01 of AMM 34-11-00

34-11-00-100-805-A01-PSA Rev D

Remove Rev 34-11-00-100-805-A01-PSA Rev C dated 04/03/17 and insert 34-11-00-100-805-A01-PSA Rev D dated 08/13/18

08/13/18

Page 2 of 5

Audited By TSS Dept. 10/17/18

Blue Page Current For Rev. 59

Audited By TSS Dept. 05/02/19

Blue Page Current For Rev. 61

(6) On the P1 pitot−static test adaptor, connect the static hose assembly to the S2 static port.

(7) On the P2 pitot−static test adaptor, connect the static hose assembly to the S1 static port.

(8) Connect the other end of the static hose assembly to the pitot−static pressure output line of

the air test panel.

(9) Connect the dry compressed air source to the air test panel.

(10) Start an airflow at 20 psi (137.90 kPa) into the P1 static port S2 and P2 static port S1.

(11) Connect the purging hose on the openings that follow and make sure that there is an

airflow:

– Static connector for the ADC 2

– S2/S1 drain assembly on the ADC 2 static line

– S2/S1 drain assembly on the static manifold.

(12) Disconnect the purging hose.

(13) Decrease the airflow to the static ports to 0 psi (0 kPa).

(14) Remove the pitot−static test adaptors from the P1 and P2 pitot−static heads.

NOTE: Make sure that there is no fluid or other contamination on the pitot−static head.

(15) Install the drain collector tubes on the static line drains that follow:

– S2/S1 drain assembly on the ADC 2 static line

– S2/S1 drain assembly on the static manifold.

(16) Remove the cap from the static connector on the ADC 2.

(17) Connect the static connector to the ADC 2.

(18) Disconnect the dry compressed air source from the air test panel.

(19) Disconnect the pitot−static test adaptor from the pressure output line of the air test panel.

5. Close Out

A. Remove the tag and close the circuit breakers that follow:

CB−PANEL CB−NO NAME

CBP−1 A14 HEATERS PITOT R

CBP−1 LOWER T7 HEATERS PITOT L

Internal PSA Document

EFFECTIVITY: Ref page 1 of Blue Page

CRJ-700/900

AIRCRAFT MAINTENANCE MANUAL

PSA AIRLINES, INC REVISION

AMM - Insert after Task 34-11-00-100-805-A01 of AMM 34-11-00

34-11-00-100-805-A01-PSA Rev D

Remove Rev 34-11-00-100-805-A01-PSA Rev C dated 04/03/17 and insert 34-11-00-100-805-A01-PSA Rev D dated 08/13/18

08/13/18

Page 3 of 5

Audited By TSS Dept. 10/17/18

Blue Page Current For Rev. 59

Audited By TSS Dept. 05/02/19

Blue Page Current For Rev. 61

B. Do a leak test of the P2 and copilot S1 systems (TASK 34−11−00−790−805).

NOTE: The static fittings on the drain collector tubes and the ADC are quick−disconnect

fittings. The leak test is necessary only if the regulatory authority of the country of

aircraft registration makes a leak test mandatory.

C. Remove all tools, equipment, and unwanted materials from the work area.

D. Close the access door that follows:

PANEL NAME MANUAL NO REFERENCE

811 Main Avionics Compartment Door

Internal PSA Document

EFFECTIVITY: Ref page 1 of Blue Page

CRJ-700/900

AIRCRAFT MAINTENANCE MANUAL

PSA AIRLINES, INC REVISION

AMM - Insert after Task 34-11-00-100-805-A01 of AMM 34-11-00

NOTE: The leak test is not required due to system quick-disconnect fittings meeting FAR

regulations approved by the FAA.

34-11-00-100-805-A01-PSA Rev D

Remove Rev 34-11-00-100-805-A01-PSA Rev C dated 04/03/17 and insert 34-11-00-100-805-A01-PSA Rev D dated 08/13/18

08/13/18

Page 4 of 5

Audited By TSS Dept. 10/17/18

Blue Page Current For Rev. 59

Audited By TSS Dept. 05/02/19

Blue Page Current For Rev. 61

ba796a01.cgm

B

A

B

A

P1 PITOT−STATIC

HEAD

(P2 PITOT−STATIC

HEAD − OPPOSITE)

S2/S1 DRAIN

COLLECTOR

TUBE

STATIC

CONNECTOR

ADC 2

S2/S1 DRAIN

COLLECTOR

TUBE

Static Line Pilot S2/Copilot S1 − Cleaning/Painting

Figure 706

Internal PSA Document

EFFECTIVITY: Ref page 1 of Blue Page

CRJ-700/900

AIRCRAFT MAINTENANCE MANUAL

PSA AIRLINES, INC REVISION

AMM - Insert after Task 34-11-00-100-805-A01 of AMM 34-11-00

34-11-00-100-805-A01-PSA Rev D

Remove Rev 34-11-00-100-805-A01-PSA Rev C dated 04/03/17 and insert 34-11-00-100-805-A01-PSA Rev D dated 08/13/18

08/13/18

Page 5 of 5

Audited By TSS Dept. 10/17/18

Blue Page Current For Rev. 59

Audited By TSS Dept. 05/02/19

Blue Page Current For Rev. 61

This manual suits for next models

1

Table of contents

Popular Aircraft manuals by other brands

Flusurfer

Flusurfer Speed 3 user manual

NIVIUK GLIDERS

NIVIUK GLIDERS KOYOT 5 user manual

SKY PARAGLIDERS

SKY PARAGLIDERS APOLLO BI user manual

Cessna

Cessna 172R Pilot operating handbook

Piper

Piper SARATOGA II HP PA-32R-301 Maintenance manual

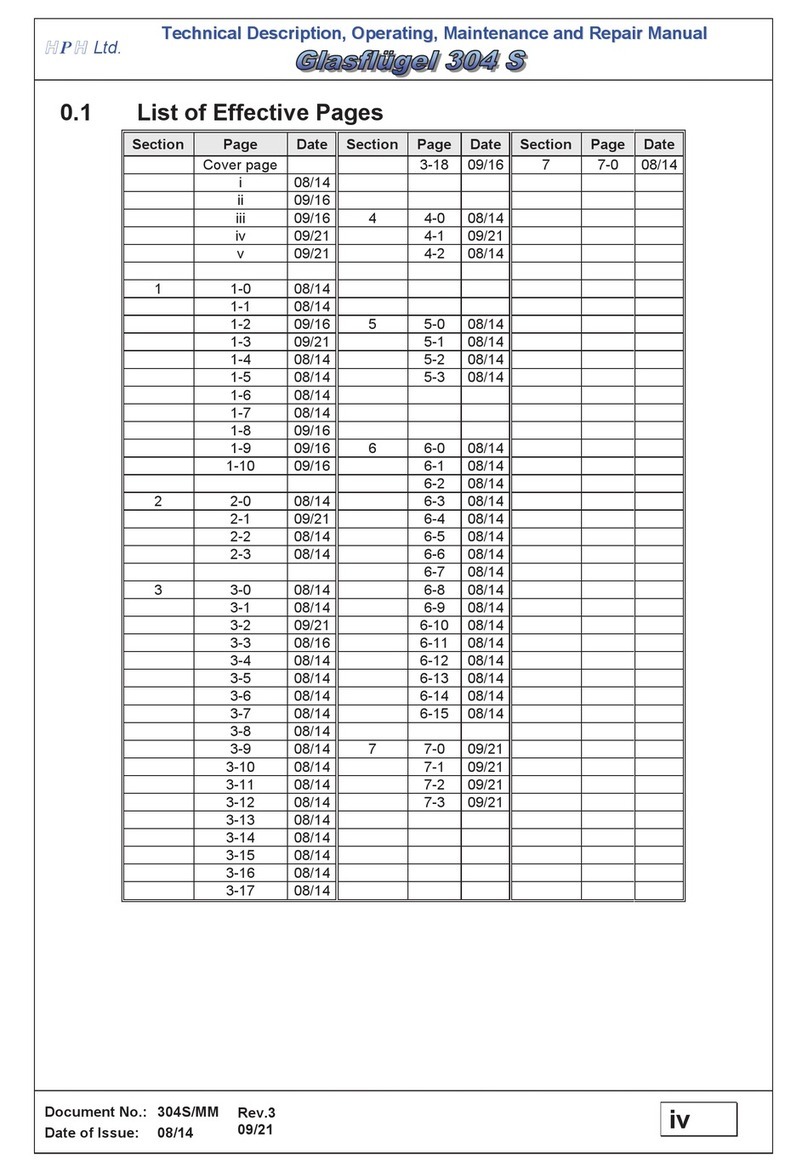

HPH

HPH Glasflugel 304S Technical Description, Operating, Maintenance and Repair Manual