RVE MERAK E750 - ASSEMBLY INSTRUCTIONS

INTRODUCTION 4

ASSEMBLY RECOMMENDATIONS 4

MINIMUM REQUIRED TOOLS 5

OPTIONAL TOOLS 5

OTHER COMPONENTS REQUIRED 5

MAIN CHASSIS ASSEMBLY 6

TAIL PINION BEARING BLOCK (1-1) 6

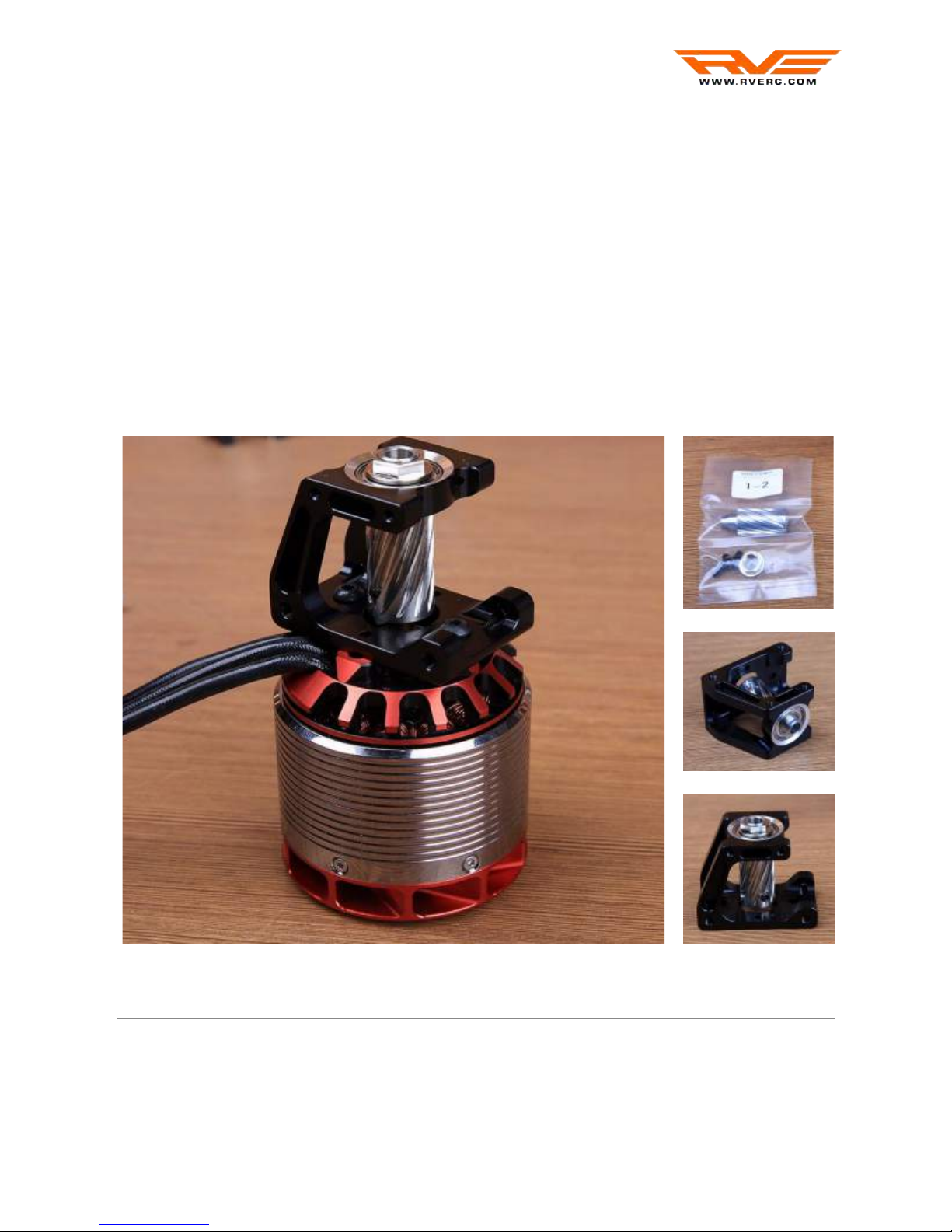

MOTOR BLOCK (1-2) 7

SWASH CONTROL LEVERS (1-3) 8

TAIL CONTROL LEVER (1-4) 10

ESC SUPPORT (1-6) 10

CONTROL LEVERS AND CABIN SUPPORT INSTALLATION (2-1) 11

MAIN MAST BEARING BLOCKS AND ELEVATOR LEVER INSTALLATION (2-2) 13

BATTERY TRAY SUPPORTS INSTALLATION (2-3) 15

SKID SUPPORTS INSTALLATION (2-4) 16

ESC SUPPORT INSTALLATION (2-5) 16

ELECTRONICS TRAY INSTALLATION (2-7) 17

SKID SUPPORTS REINFORCEMENT AND VIBRATION DAMPERS INSTALLATION (2-8,

2-9) 17

MAIN GEAR AND

AUTOROTATION BLOCK ASSEMBLY (3-1) 18

TAIL GEAR ASSEMBLY (3-2) 19

TAIL PINION BEARING BLOCK AND TAIL BOOM SUPPORT INSTALLATION (3-3) 20

MOTOR BLOCK INSTALLATION (3-4) 21

MAIN MAST AND GEARS INSTALLATION (3-5, 3-6) 21

MAIN ROTOR ASSEMBLY 23

SWASHPLATE ASSEMBLY (4-1) 23

PHASE ARM ASSEMBLY (4-2) 24

CENTER HUB ASSEMBLY (4-4) 25

BLADE HOLDER ASSEMBLY (4-6) 25

SPINDLE SHAFT AND BLADE HOLDERS INSTALLATION (4-5, 4-7) 26

MAIN ROTOR INSTALLATION (4-4) 27

TAIL ASSEMBLY 28

TAIL PULLEY ASSEMBLY (5-1) 28

2