Page 2 of 6 - 1/28/2008 – Rev122006

PLEASE READ ALL SAFETY WARNINGS AND INSTRUCTIONS THOROUGHLY BEFORE STARTING INSTALL

SAFETY WARNING!INSTALLATION REQUIRES 2 PEOPLE AND HEAVY LIFTING. Only use the handle

to maneuver the drawer. All fasteners will need to be periodically checked for looseness or wear. The slides should be

checked regularly for damage. The slides will need to be cleaned regularly to ensure smooth operation. Only operate drawer

when the vehicle is level. Do not load more weight than the drawer is rated to handle at the proper settings. Do not use the

drawer for any other applications than it is designed for. No one should ever stand or sit on the drawer whether it is in

operation, latched open, or latched shut whether the vehicle is in motion or still. Everyone except the operator should

maintain a safe distance of 4’ while the drawer is being maneuvered to avoid pinch points and shifting. No one should ever be

under the drawer. The vehicle should never be operated unless the drawer is latched securely in its closed position and the

tailgate is secured shut. The drawer should never be used in a vehicle without a tailgate. All loads on top of the drawer

enclosure should be secured down when the vehicle or drawer is in operation. Large loads and heavy loads on top of the

drawer should always be secured to the vehicle; they should not be only secured to the drawer enclosure. Use common sense

when using this product.

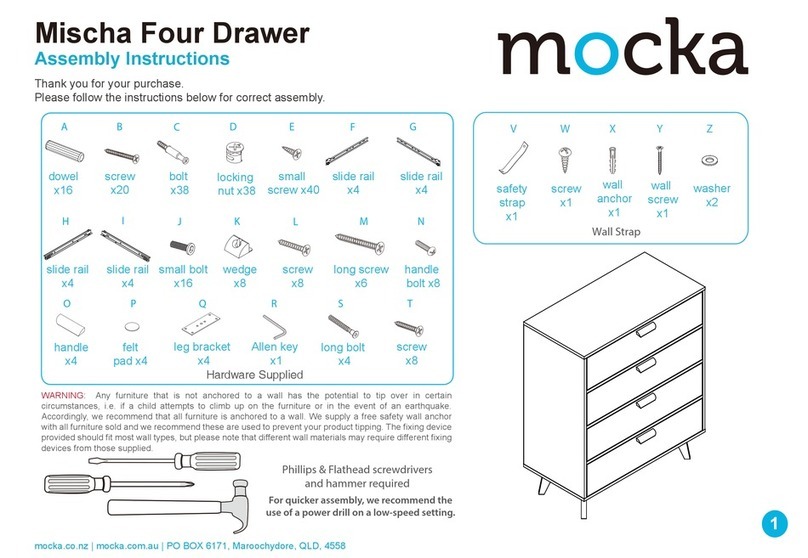

WEIGHT RATINGS

LOAD BEARING TOP RATED TO 550#

FULLY EXTENDED WEIGHT RATING FOR EVENLY DISTRIBUTED LOADS (FACTORY SETTING):

PART# 115 = 500#

PART# 109 = 600#

PART# 123 = 700#

THE STOP BOLT CAN BE RE-LOCATED TO LIMIT THE DRAWER EXTENSION TO 75% WHICH WILL INCREASE THE

WEIGHT RATING FOR EVENLY DISTRIBUTED LOADS TO 1500#.

INSTALLATION

1. The drawer assembly comes mounted to a pallet. Pay close attention when removing the drawer from the pallet; it will be

mounted in the vehicle the same way it is mounted to the pallet.

2. First remove all the packaging around the drawer and inspect the drawer assembly for damage.

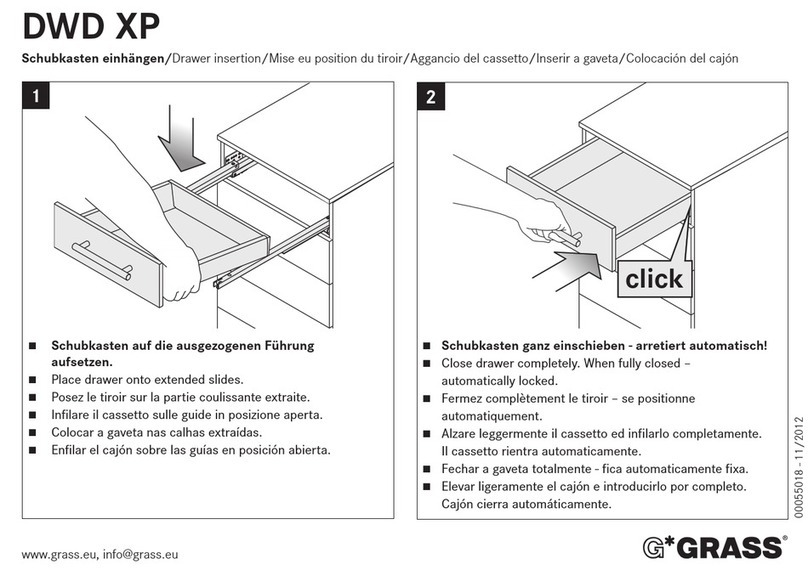

3. Remove the drawer from the enclosure. To do this unlock the camlock then rotate the handle on the front of the drawer up to

disengage the slide lock assembly. Then pull the drawer out until it hits the stops, lift up on the front end of the drawer to allow

the stop bolt to clear the stop bracket and continue pulling the drawer until it is all the way out. (See Figure 1)

FIGURE 1