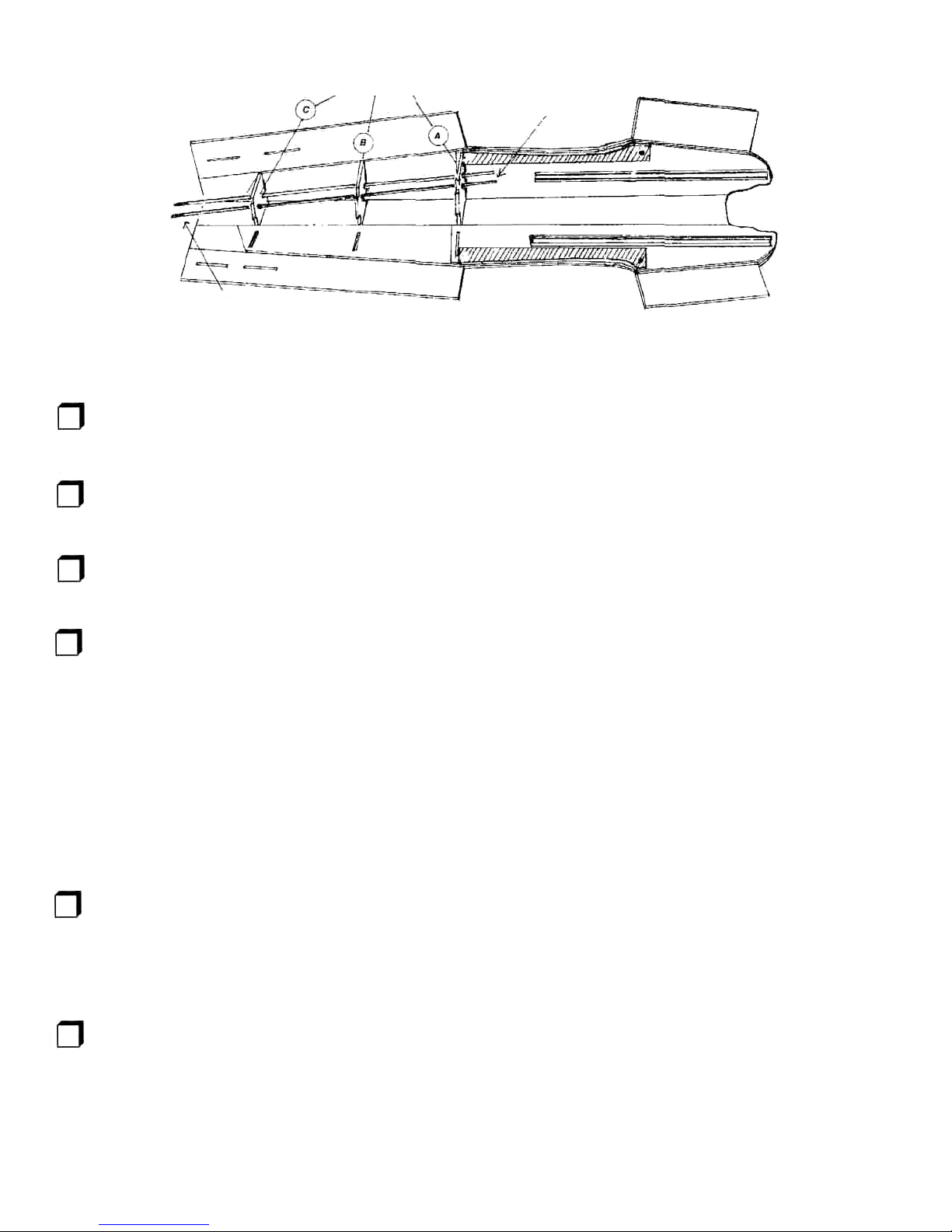

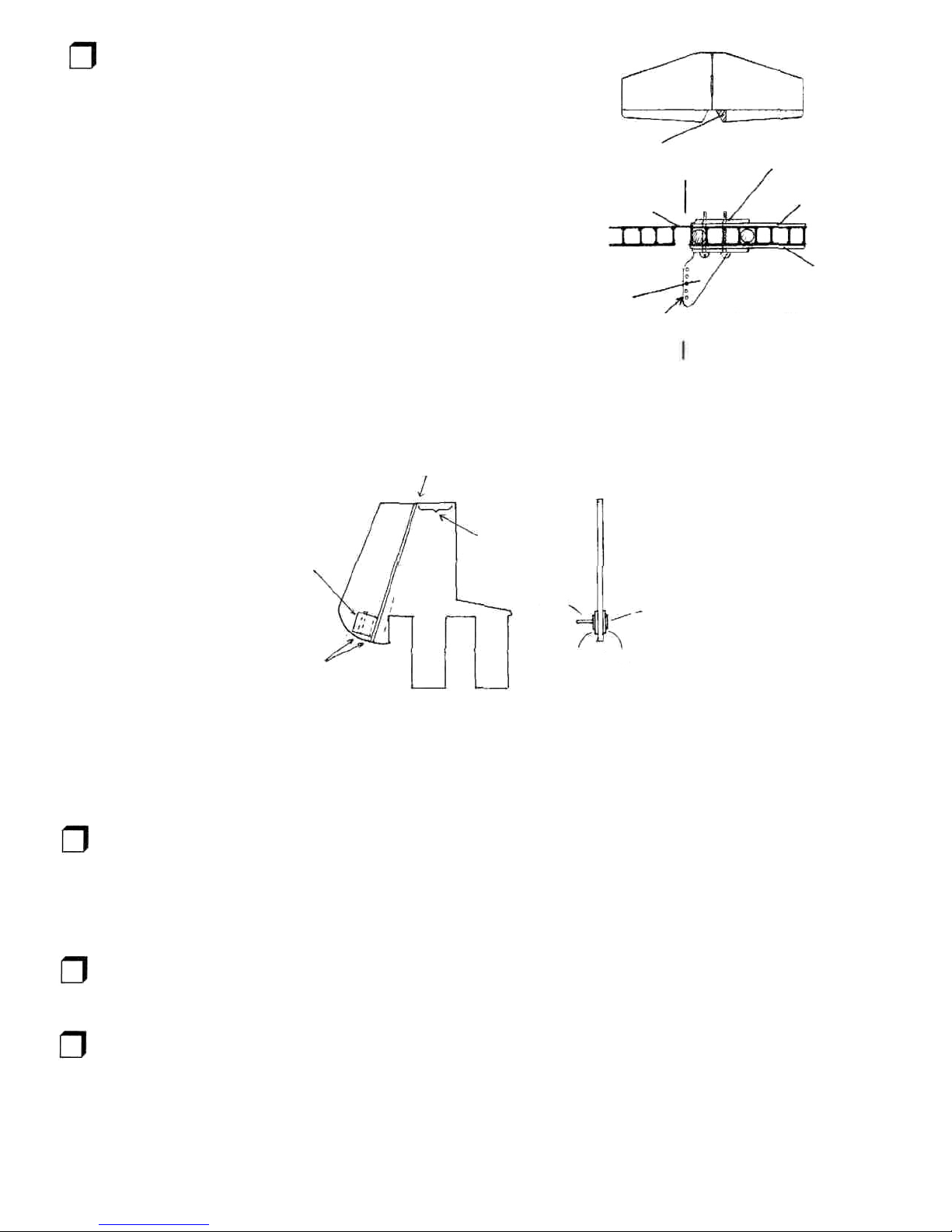

1.3Usingepoxy, glue the two 1/8" die-cut plywood

cartridge halves together. Assemble and fuelproof the PC.

Glue and clamp the reinforcing doublers on the top and

bottom of the engine mount area. Besure to line upthe

inside cavity edges of the PCwith the doublers while

clamping. Once the doublers are inplace, glue and clamp

the nose gear block asshown between the engine mount

and the tank opening on the bottom of the PC.Using a

5/32" drill bit,carefully drill a hole as shown inthe

illustration for a nose gear.

Note - the Power Cartridge is designed to be used with or

without a nose gear. Your COLT may be set up with one if

desired, and there are notes in this manual to help you use

nose gear. Whether or not you will use one with your COLT,

this is a good time to mount the nose gear block for use on

future planes.

GLUE & CLAMP

FIGURE2 - ASSEMBLY OF POWER CARTRIDGE

1.4Check the Power Cartridge (PC) andrailsfor a

sliding fit.Locate your 17"long PCrailsandfit them to the

sides of the PC.The PCshould beable to slide on the rails.

You want a good, sliding fit.Ifthe PCistoo snug, use sand

paper on the topandbottomofthe PCedges untilthe fit is

correct.

Aftergluinganddrilling,we liketolightlysand andpaintour

PCwith a coat of black paint before fuel proofing just for

looks.Finally,fuel proof the PCbycoating itwith thinned

epoxy (thin epoxy bymixing itas usual, then adding some

rubbing alcohol until the mixture isthin enough to "paint" on

to the PC). This isan important step. The PCmustbefuel

proofinorder to perform reliablyfor you.

DRILL5/32"HOLE

ENGINE MOUNT

TANK OPENING

FIGURE 3

MOUNTINGTHE NOSE GEAR BLOCK TOTHE PC

NOSE GEAR BLOCK

SIDEVIEW

BUILDER'S NOTE - IF YOU ARE ALREADY ACCOMPLISHED WITH A TRAINER, WE ENCOURAGE YOU TO BUILD THE "TURBO"WING FOR YOUR COLT.

YOU MAY WISH TO OWN BOTH A "TURBO WING" AND A STANDARD WING. THE TURBO WING ISA 58" WING FOR SNAPPIER AEROBATICS AND

FASTER PERFORMANCE. WE HAVE WING KITS FOR THE COLT AVAILABLE. FOR FLOATS OR GENERAL "TOOLING AROUND" USE THE

STANDARD HIGH LIFT WING. FOR HIGH-SPEED AEROBATICS, USE THE TURBO WING. IF YOU ARE BUILDING A "TURBO" VERSION, ALL

COMPONENTS OF THE WING ARE CLIPPED 3" AT THE ROOT, INCLUDING THE WING HALVES, HINGE STRIPS, AILERONS AND SPARS, PRIOR TO

ASSEMBLY. THE SPAR WILL HAVE TO BE BUILT WITH THIS IN MIND. SEE THE SECTION ON BUILDING THE TURBO WING

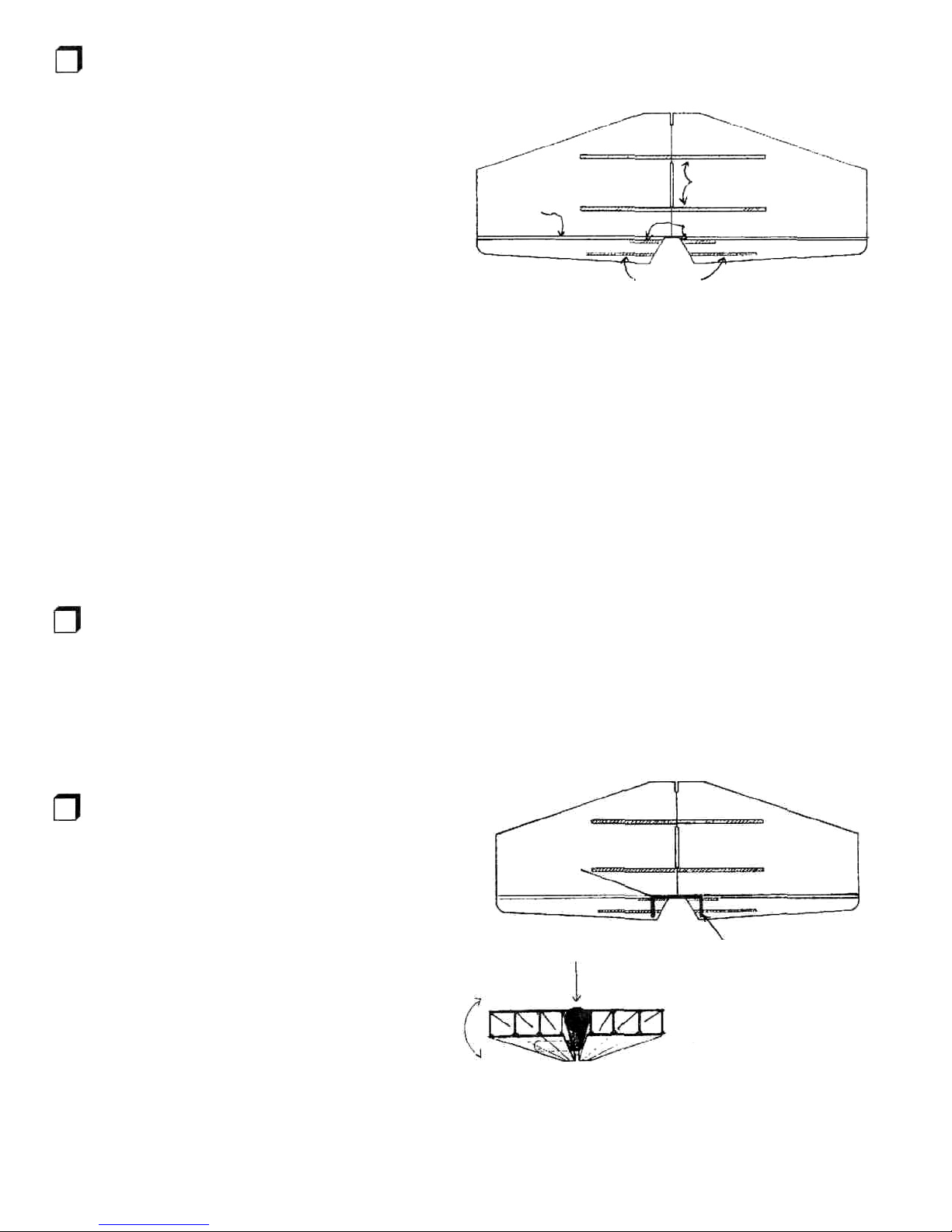

1.5Buildthe spar. Bothspar halves are identical and

angle upatthe tips. Lightly sand the spars to remove any

rough edges. Mark a centerline vertically on each dihedral

brace to identify where the spars will meet. Use slow CA

glue or 5 minute epoxy and glue the spars to one of the

dihedral braces, aligning the spars inthe center of the

brace. Clamp untildry; Now glue on the other dihedral

brace and clamp. The dihedral brace sets the "dihedral

angle" of the wing, and this angle isimportant inproviding

flight stability to your airplane. Itisimportant when

assembling the spar to observethe dihedral angle

prescribed bythe dihedral brace and to clamp while gluing

to achieve a goodbond between the spars and the braces.

TIPSOF THE SPAR ANGLE UP

USETHICKCAOREPOXYANDCLAMPUNTILDRY

DIHEDRAL BRACE

1/8"

PLY

DIHEDRAL BRACE

1/8"

PLY

TIPS OF THE

SPARANGLEUP

(DIHEDRAL IS PRESET AT 4 DEGREES)

FIGURE4 - SPAR ASSEMBLY

4