Page 4

U.S. FAN INTERNATIONAL®

P.O. Box 978

Muskogee, Oklahoma 74402

MODELS • UVQL100 • UVQL150

UVQL200 • UVQL250 • UVQL300

SERVICE PARTS SERVICE PARTS

WARRANTY

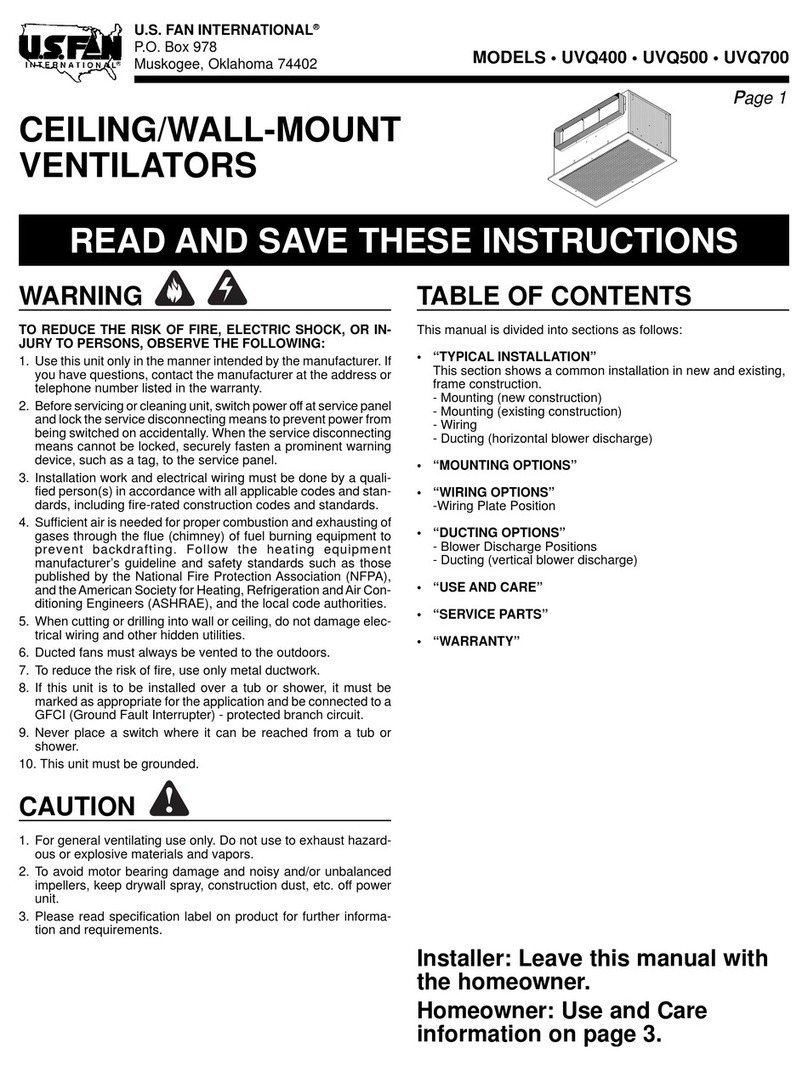

KEY NO. PART NO. DESCRIPTION

1 97014735 Housing Assembly (UVQL100 & UVQL150)

97014736 HousingAssembly

(UVQL200, UVQL250, & UVQL300)

2 97014728 Mounting Bracket (2 req.)

3 97014760 Damper Assembly (6” dia.)

97014761 Damper Assembly (8” dia.)

4 99390098 Duct Connector (6” dia.)

99390099 Duct Connector (8” dia.)

5 99150415 Screw, 8-18 x ¼ (12 req.)*

6 98005513 Wire Box Cover

7 99400035 Strain Relief Bushing

8 98005512 Wiring Plate

9 99150471 Ground Screw, 10-32 x ½ (2 req.)

10 97014774 Scroll Assembly (UVQL100 & UVQL150)

97014775 ScrollAssembly

(UVQL200, UVQL250, & UVQL300)

11 98009399 Inlet Ring

12 99110805 Blower Wheel

13 99080481 Motor (UVQL100)

99080482 Motor (UVQL150)

99080483 Motor (UVQL200)

99080484 Motor (UVQL250)

99080485 Motor (UVQL300)

14 99260558 Lock Nut, 8-32 (4 req.)*

15 99250959 Washer (4 req.)*

16 99100491 Grommet (4 req.)

Blower Assembly, Complete

(Includes Key Nos. 10-16)

97014800 (UVQL100)

97014801 (UVQL150)

97014802 (UVQL200)

97014803 (UVQL250)

97014804 (UVQL300)

17 99260477 Nut, ¼-20 (6 req.)*

18 97006039 Wire Harness

19 98009417 Access Panel

20 99420470 Cover Nut (2 req.)

21 99150472 Cover Mounting Screw (2 req.)

22 99150591 Screw, 10-16 x 7/8 (4 req.)*

Order replacement parts by PART NO. - not by KEY NO.

* Standard hardware - may be purchased locally.

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: U.S. Fan International extends this limited warranty to the original buyer and warrants that products manufactured by the Company shall be free from original defects in

workmanship and materials for two years from date of shipment, provided same have been properly stored, installed, serviced, maintained and operated. This warranty shall not apply to products which

have been altered or repaired without the Company’s express authorization, or altered or repaired in any way so as, in the Company’s judgment, to affect its performance or reliability, nor which have been

improperly installed or subjected to misuse, negligence, or accident, or incorrectly used in combination with other substances. The Buyer assumes all risks and liability for results of use of the products.

Warranties on purchased parts, such as but not limited to bearings, sheaves, belts, couplings, electric motors, pumps and controls are limited to the terms of warranty extended by our supplier.Polyethylene

tubing and cooling pads are warranted to be free of defects in material and workmanship for a period of 90 days from date of shipment and a like warranty applies to the cross fluted cellular type cooling

cells for a period of two years from date of shipment provided same have been properly handled, stored, installed, serviced, maintained and operated. And further, not subjected to excessive heat,

corrosive agents or chemicals, or mechanical abuse that may cause tearing, crushing or undue deterioration nor used on a system or in a manner other than that for which it was designed as explained

in the product literature.

LIMITATION OF REMEDY AND DAMAGES: All claims under this warranty must be made in writing and delivered to P. O. Box 978, Muskogee, Oklahoma, 74402, within 15 days after discovery of the

defect and prior to the expiration of two years from the date of shipment by the Company of the product claimed defective, and Buyer shall be barred from any remedy if Buyer fails to make such claim within

such period. Within 30 days after receipt of a timely claim, the Company shall have the option either to inspect the product while in Buyer’s possession or to request Buyer to return the product to the

Company at Buyer’s expense for inspection by the Company. The Company shall replace, or at its option repair, free of charge,any product it determines to be defective, and it shall ship the repaired or

replacement product to Buyer F.O.B. point of shipment; provided, however, if circumstances are such as in the Company’s judgment to prohibit repair or replacement to remedy the warranted defects, the

Buyer’s sole and exclusive remedy shall be a refund to the Buyer of any part of the invoice price, paid to the Company, for the defective product or part.The Company is not responsible for the cost of

removal of the defective product or part, damages due to removal, or any expenses incurred in shipping the product or part to or from the Company’s plant, or the installation of the repaired or replaced

product or part.Implied warranties, when applicable, shall commence upon the same date as the express warranty provided above, and shall, except for warranties of title, extend only for the duration of

the express warranty. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. The only remedy provided to you under an applicable implied

warranty and the express warranty shall be the remedy provided under the express warranty, subject to the terms and conditions contained therein. The Company shall not be liable for incidental and

consequential losses and damages under the express warranty, any applicable implied warranty, or claims for negligence, except to the extent that this limitation is found to be unenforceable under

applicable state law. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific

legal rights, and you may also have other rights which vary from state to state.No employee, agent, dealer, or other person is authorized to give any warranties on behalf of the Company or to assume for

the Company any other liability in connection with any of its products except in writing and signed by an officer of the Company.

REPLACEMENT PARTS If replacement parts are ordered, buyer warrants that the original components in which these replacement parts will be placed are in satisfactory working condition, and when said

replacement parts are installed, the resultant installation will operate in a safe manner, at speeds and temperatures for which the original equipment was purchased.

TECHNICAL ADVICE AND RECOMMENDATIONS, DISCLAIMER: Notwithstanding any past practice or dealings or any custom of the trade, sales shall not include the furnishing of technical advice or

assistance or system design. Any such assistance shall be at the Company’s sole option and may be subject to additional charge.The Company assumes no obligation or liability on account of any

recommendations, opinions or advice as to the choice, installation or use of products. Any such recommendations, opinions or advice are given and shall be accepted at your own risk and shall not

constitute any warranty or guarantee of such products or their performance.

GENERAL In no event shall any claim for consequential damages be made by either party. The Company will comply with all applicable Federal, State, and local laws.

WARNING

U.S. Fan International products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of defects. Even reliable products will experience occasional

failuresandthispossibilityshould be recognizedby the User. If these products are used in a life support ventilation systemwherefailure couldresult in lossor injury, the User should provide adequate back-

up ventilation, supplementary natural ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury. WARNING DO NOT use in HAZARDOUS ENVIRONMENTS

where fan’s electrical system could provide ignition to combustible or flammable materials unless unit is specifically built for hazardous environments. CAUTION Guards must be installed when fan is within

reach of personnel or within seven (7) feet (2.134 m) of working level or when deemed advisable for safety. DISCLAIMER The Company has made a diligent effort to illustrate and describe the products

in this literature accurately; however, such illustrations and descriptions are for the sole purpose of identification, and do not express or imply a warranty that the products are merchantable, or fit for a

particular purpose, or that the products will necessarily conform to the illustrations or descriptions or dimension.

1

2

3

5

6

7

8

9

10

11

12

13

14

15

18

19

20

21

17

16

5

22

22

16

55

5

4

BLOWER

ASSEMBLY

613124 April 2000 99042742D