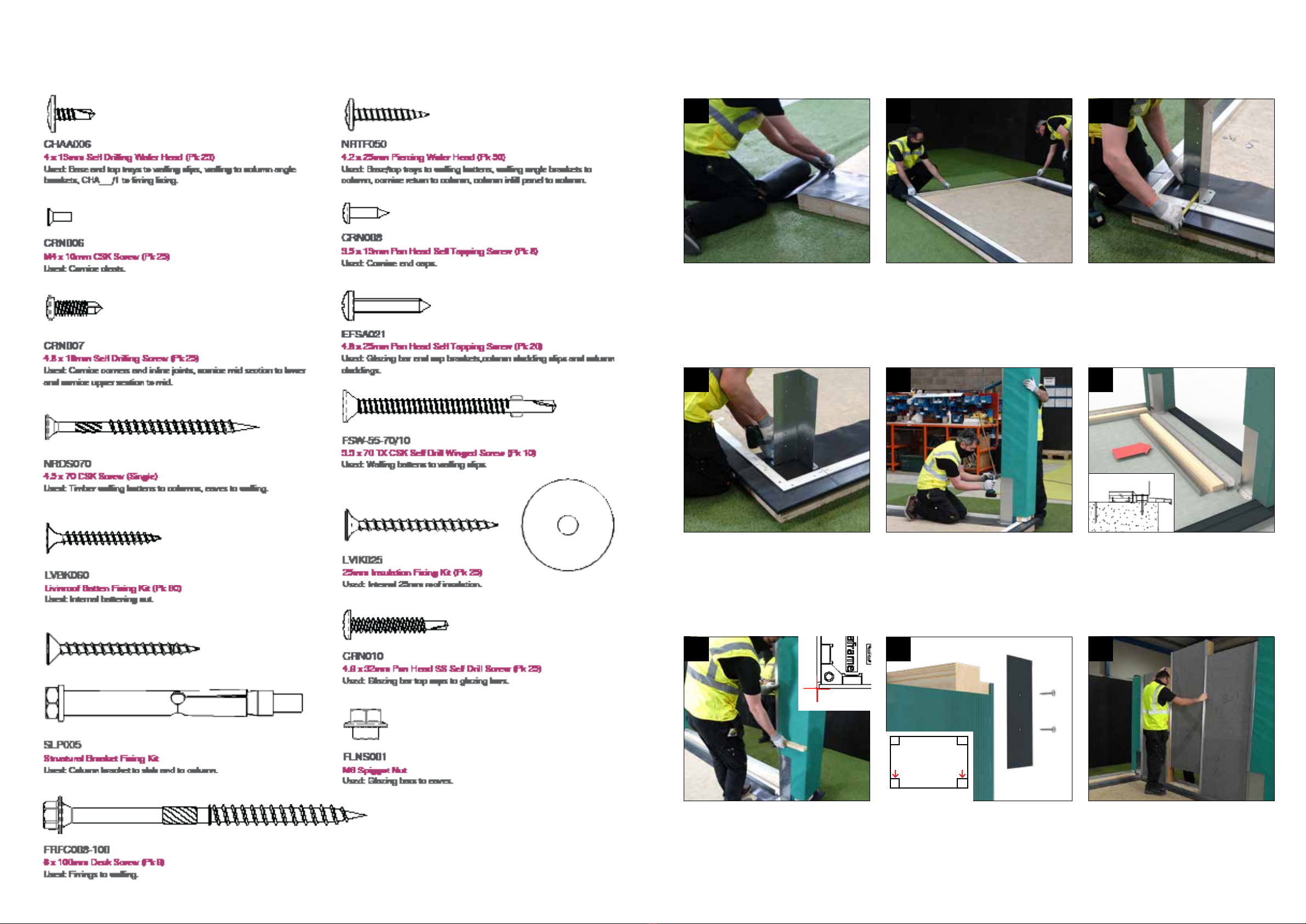

8 9

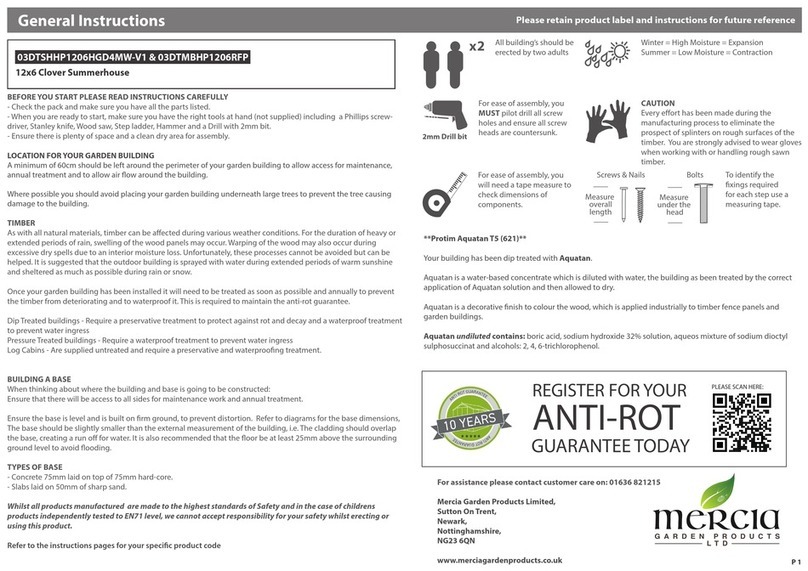

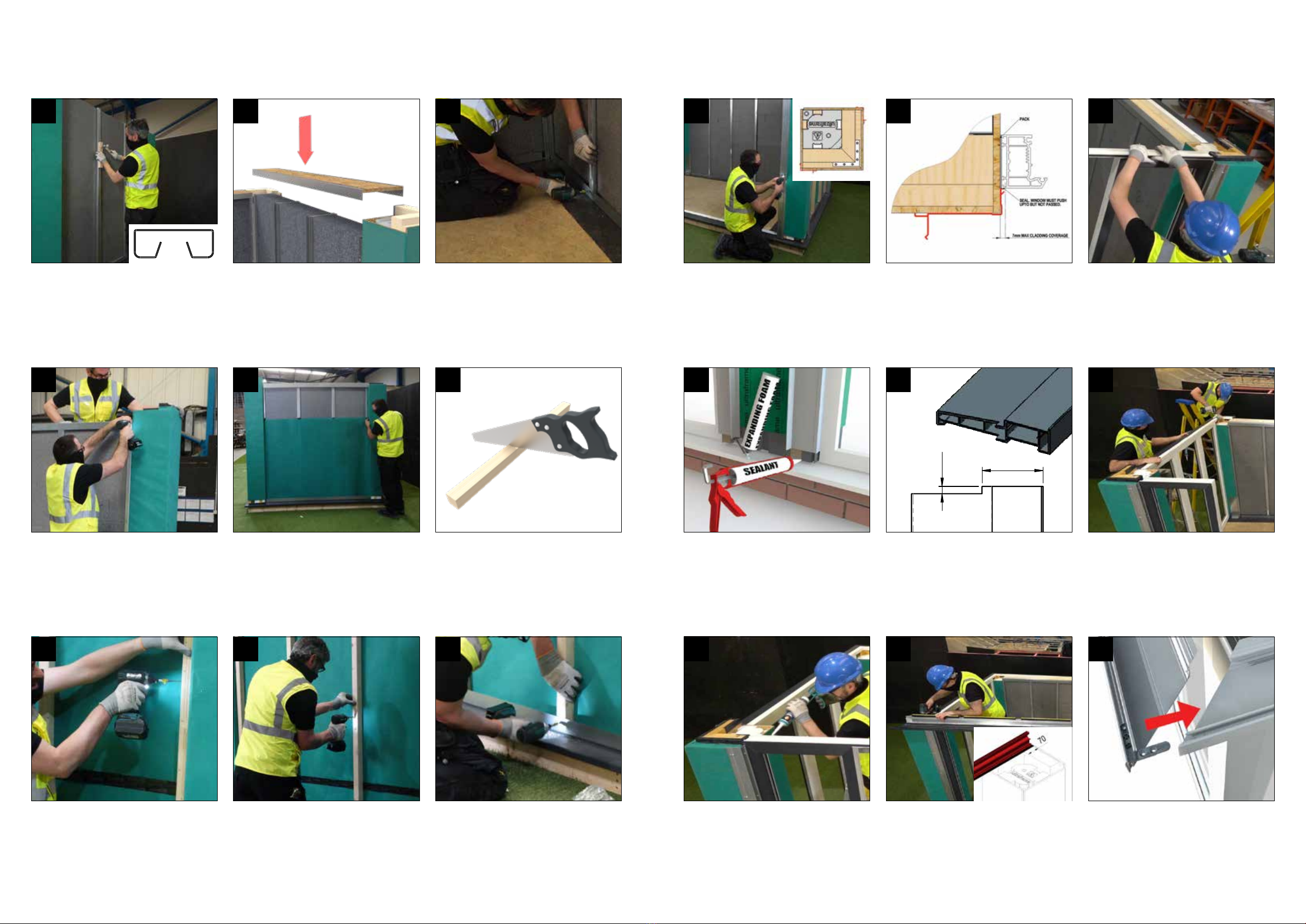

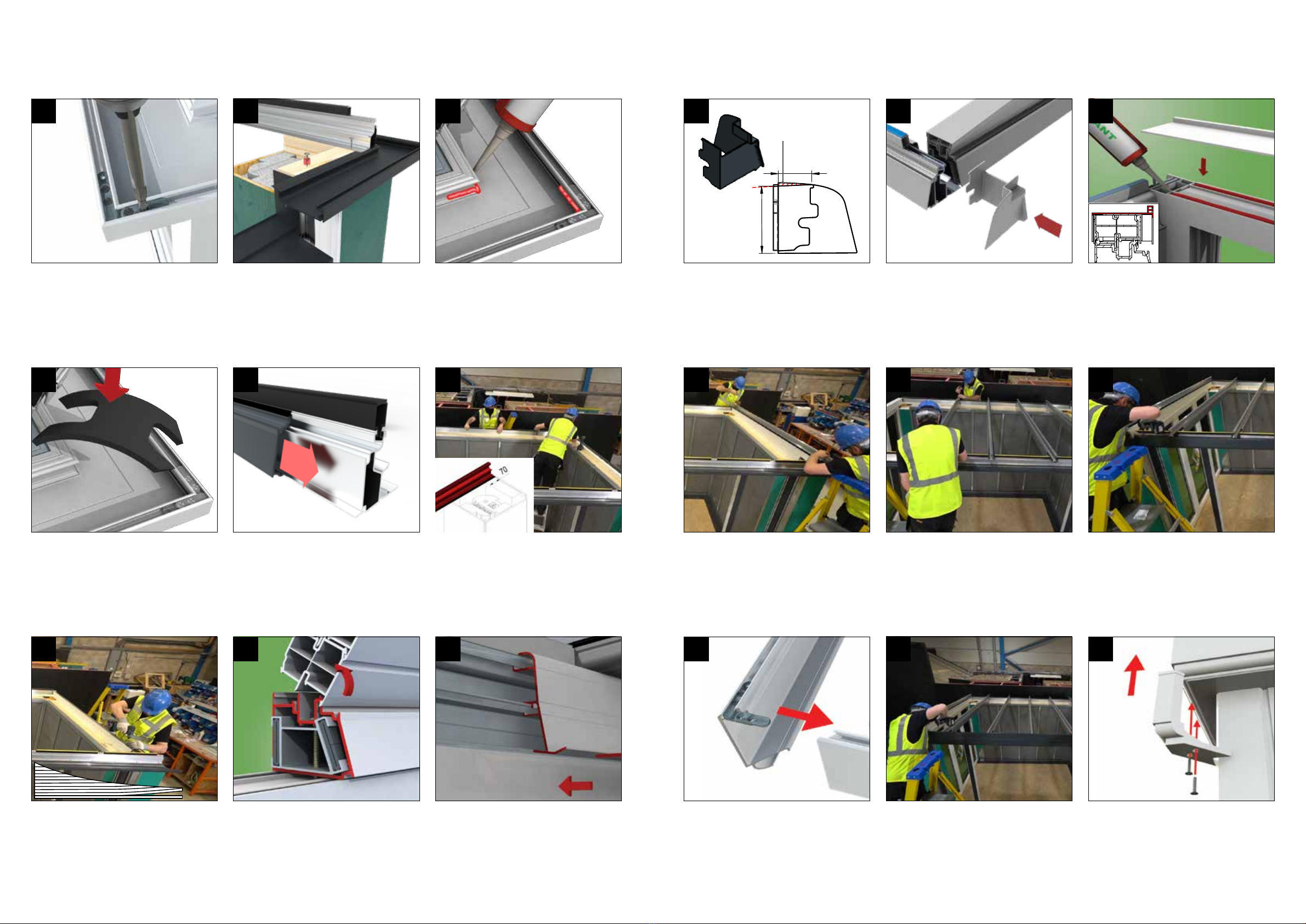

Ensure the walls are pushed against the internal

steel of the base trays and x in position

through the pre punched holes in the base

trays using the provided screws (CHAA006).

12

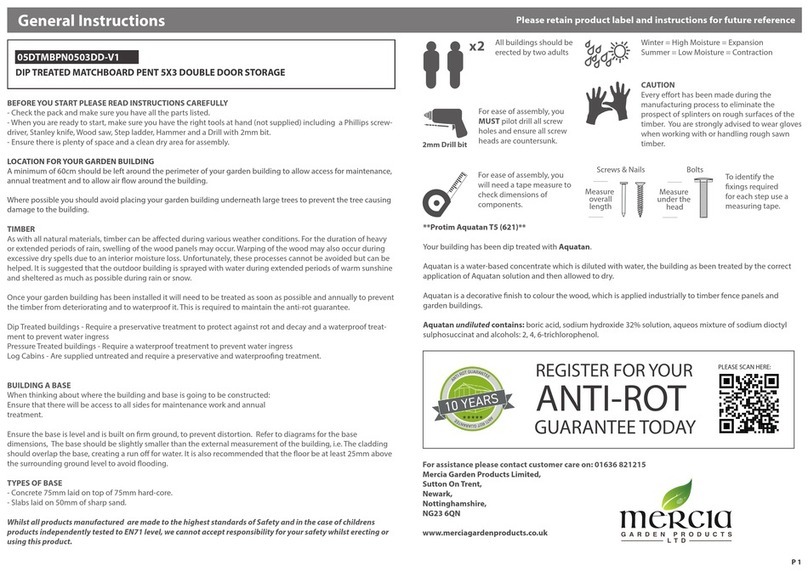

Installation

Using the provided roll of membrane, stretch

out horizontally across the lower half of the wall

and temporarily pin in place using staples or

tacks into the corner columns. Repeat across

the upper half of the wall overlapping the lower

covered area. Repeat the process on all walls.

14

Secure the battens to each of the clips by

positioning it behind the base tray and top tray

steels and centred vertically with the walling

panel clips using the provided 5.5mm x 70mm

screws (FSW-55-70/10) towards the top, centre

and bottom of the timber.

17

Cut the 45 x 45mm battens to length, these

should be cut to the same length as the external

walling clips.

15

Secure the column angles and top tray to the

interior wall panels through the pre punched

holes using the supplied 13mm self drilling

screws (CHAA006).

13

Starting with the clips closest to the columns,

x the battens to the columns using provided

xings (NRDS070), pushing the batten up

against the underside of the top tray. The

timbers can then be xed into the walling panel

clips using FSW-55-70/10 towards the top,

centre and bottom of the timber batten.

16

Now secure the top tray and base tray steels

to the timber through the pre punched holes

using 4.2x25mm wafer head screws provided

(NRTF050).

18

Remove the plastic column corners. Fix the

column cladding clips in position aligning the

top edge of the column outer boarding, this

is important to prevent interference when the

eaves beam is tted. Screw x through the

holes into the column using the 4.8 x 25mm

screws provided (EFSA021). These clips can

then be used as a datum point for setting out

the frames.

19

*

*

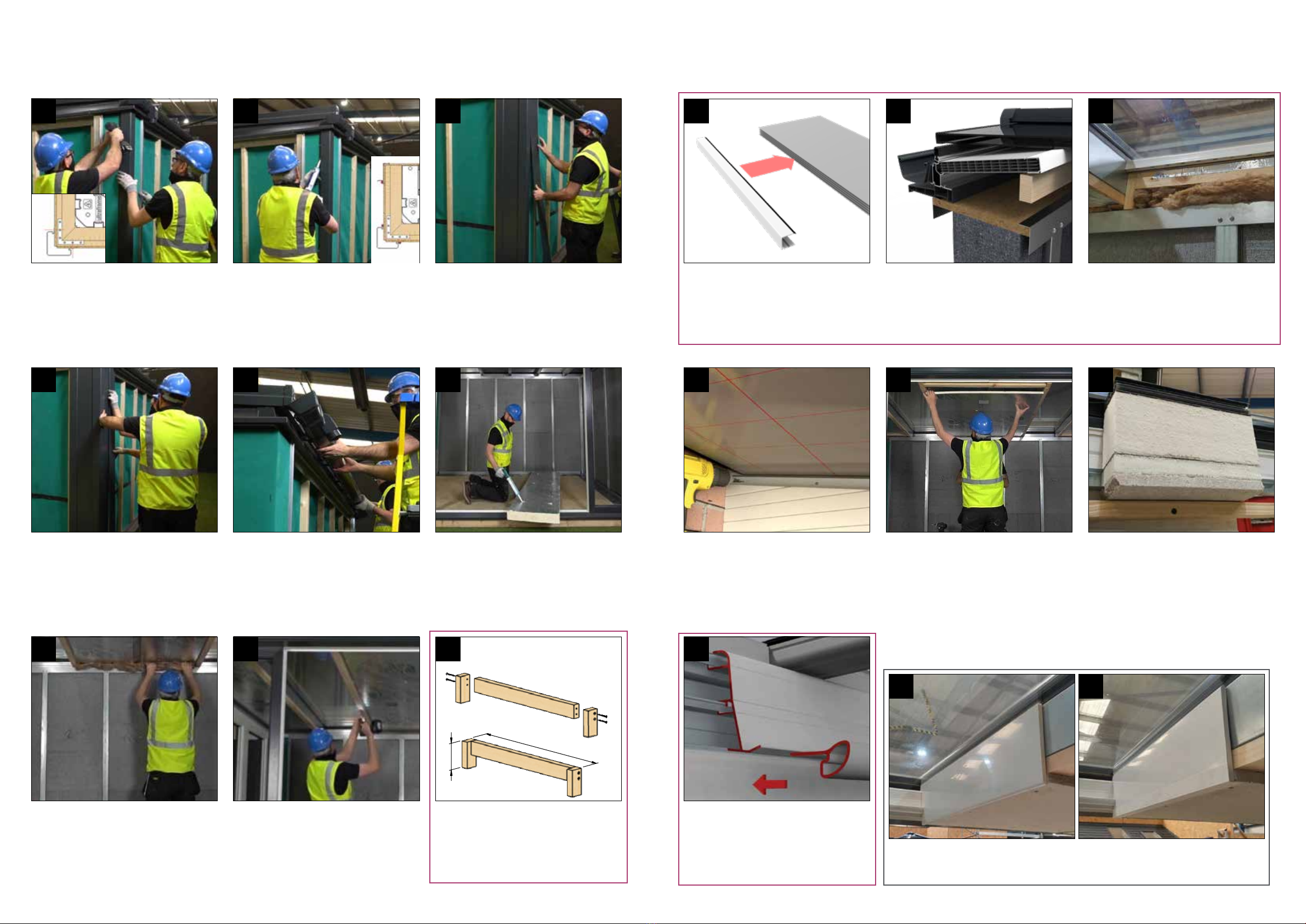

Position the walling top tray on the walls so that the

internal steel flange is against the walling clips. It may

help at this stage to secure the top tray to the column by

diagonally fixing into the column through the OSB tray

pulling the two components together. Ensure the top

tray is level and flush with the tops of the rear columns.

Fitters Tip: A timber block can be temporarily tted

to the top of the top tray and a clam used to pull the

columns and walling in tight together.

11

Fit the window and door frames into position

against the vertical aluminium clip, ensure

plumb and level and secure using appropriate

xings.

20

Installation

Run a bead of sealant across the top of the

rear and side walls/frames. Position the cill so

that the internal frame datum of the cill lines

through, measure the diagonals to ensure

square and x in place.

24

To t the short cornice returns, start by tting

the cleats and oering up to the tted section.

27

Run a bead of sealant across the top of the

front frames and rear/side cills.

25

72

8.50

Prepare the cill that abuts the tall columns with

the detail shown to accommodate the column

claddings.

23

Locate the front eaves beam (which has a

factory tted lower cornice section) so that the

eaves beam leg is in line with the internal frame

and timber upstands on columns. Fix the eaves

down into the columns and the frames using an

appropriate xing.

26

Weatherseal any joints/gaps under columns/

walls and between windows/doors/walls and

columns. Use foam and/or appropriate sealant.

22

Fit recommended frame addon (15mm min.)

above the front elevation frames.

21

Secure walling panels together using the

provided steel clips both internally and

externally, these can either be pushed into

place or slid down from the tops of the panels.

Ensure the walls are plumb and level.

10

MODEL NAME: 11977 / CONFIG. NAME: 6000mm

ALL DESIGN & OTHER INFORMATION IS CONFIDENTIAL TO & THE PROPERTY OF

ULTRAFRAME (UK) LTD. ALL DESIGN RIGHT, COPYRIGHT & OTHER INTELLECTUAL

PROPERTY RIGHTS IN & TO THE DESIGNS & INFORMATION & ANY CHANGES

THERE TO & DEVELOPMENTS THERE OF BY ULTRAFRAME OR ANY THIRD PARTIES

ARE OWNED BY AND/OR ASSIGNED TO ULTRAFRAME COMPLETELY.

DESCRIPTION:

STOCK CODE:

11977

DRAWING No:

DRAWN BY:

SCALE:

SHEET 1 OF 1, SIZE A3

REV:

STATUS:

DATE CREATED:

ENTERPRISE WORKS, SALTHILL Rd, CLITHEROE, LANCASHIRE, BB7 1PE

1:2

14/04/2021

CAD MODEL IS MASTER

14/04/2021

QM 012, SKETCH SHEET FORMAT, ISSUE 2

Internal

External