2.4 Principle of preventing liquid leakage

a. Complete sealed structure

VRLA battery is structurally completely airtight under the normal atmosphere. Especially,

vent hole is mechanically tight by valve and the safety valve was mounted with pressure

adjusting function if excessive pressure is filled inside of the battery taking into account of

safety.

b. Free move prevention structure of electrolyte

The electrolyte inside of battery is completely absorbed by glass fiber mat or gel which

absorption of liquid is very good and cannot freely move within the battery. Since therefore,

there is no worry about leakage of liquid as there is no electrolyte freely move even if the

battery is laid down or upside down.

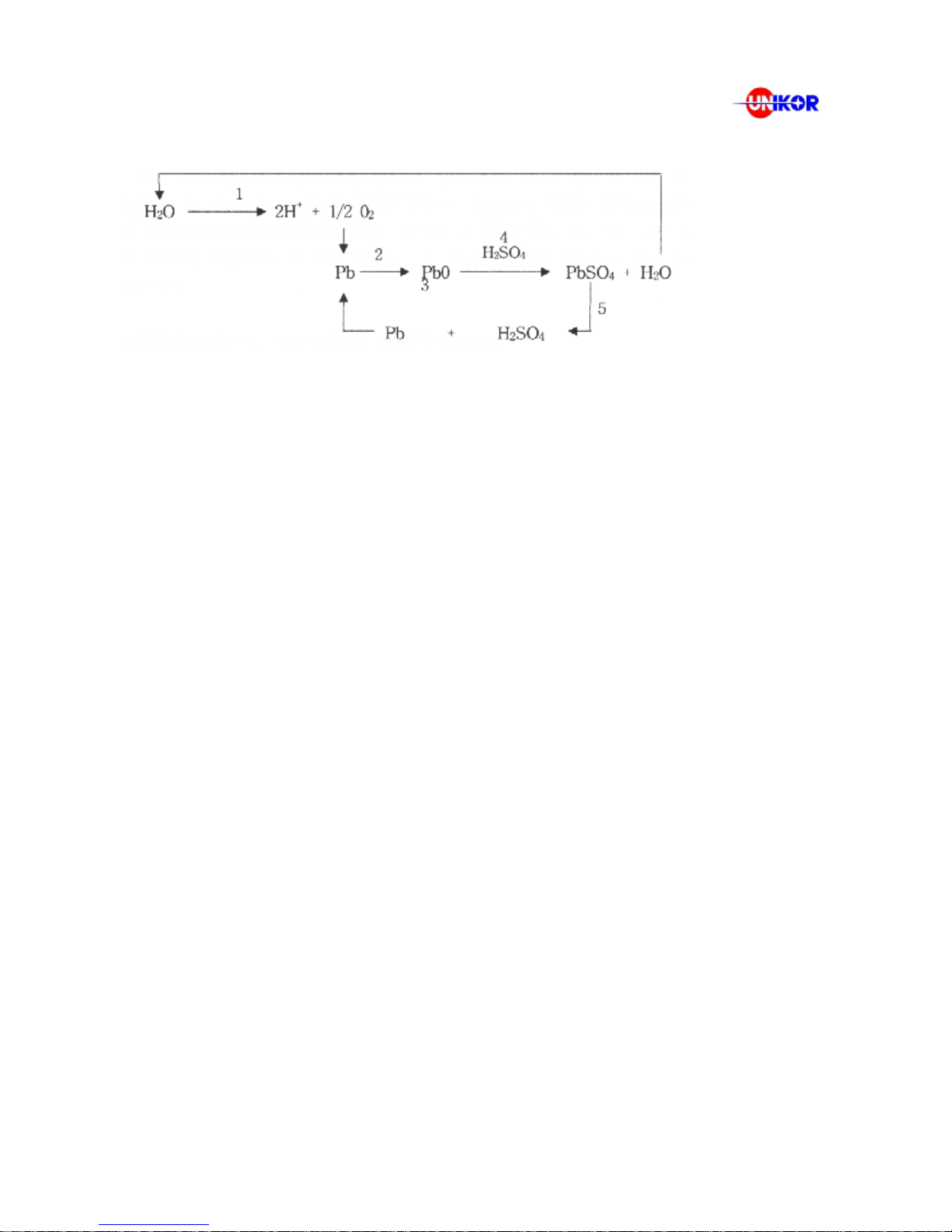

2.5 Principle of self-electric discharge

The self-electric discharge phenomenon of lead-acid battery is by interaction between

active material of negative pole and electrolyte and the element incurs self-electric

discharge are largely classified into two(2) sorts as follows:

(a) Constituents consist electrolyte (hydrogen ion in sulfuric acid)

(b) Impure substances contained in electrolyte

Out of the two sorts above a is unremovable element but (b) is removable but (a) that is to

say the electrolyte itself cannot be eliminated and so, the electric discharge phenomenon by

lead battery cannot completely be restrained. However, electric discharge volume may be

reduced. VRLA battery has very small electric discharge volume than the existing lead

antimony battery and this is because of use of alloy of lead & calcium in lieu of alloy of lead

& antimony as the grid material. The plate alloyed by lead & calcium has very big resistance

against electric discharge. On the alloy grid surface of lead & calcium the sponge lead

which is negative pole active material is not easily discharged electricity since hydrogen is

difficult to be generated (high hydrogen over voltage)

For your information the electric discharge principle by hydrogen ion in electrolyte is as

follows:

(-) pole - hydrogen ion in electrolyte

2H+ + 2e ---→ H2(gas) ------------------------- (1)

(-) pole - lead which is active material

Pb + H2SO4 --→ PbSO4 + 2H+ + Ze -------------- (2)

To sum up (1) reaction & (2) reaction

Pb + H2SO4 --→ PbSO4 + H2 ↑

(charged condition) (discharge condition)

3. BEFORE USING

Please read following specification before using.

When we release the battery to the users, the battery keep initial charged state which can be

generated of flammable gas. Don't short each connection before sufficient ventilation of

Installed places and just keep it away from fire in order to prevent dangerous factors.