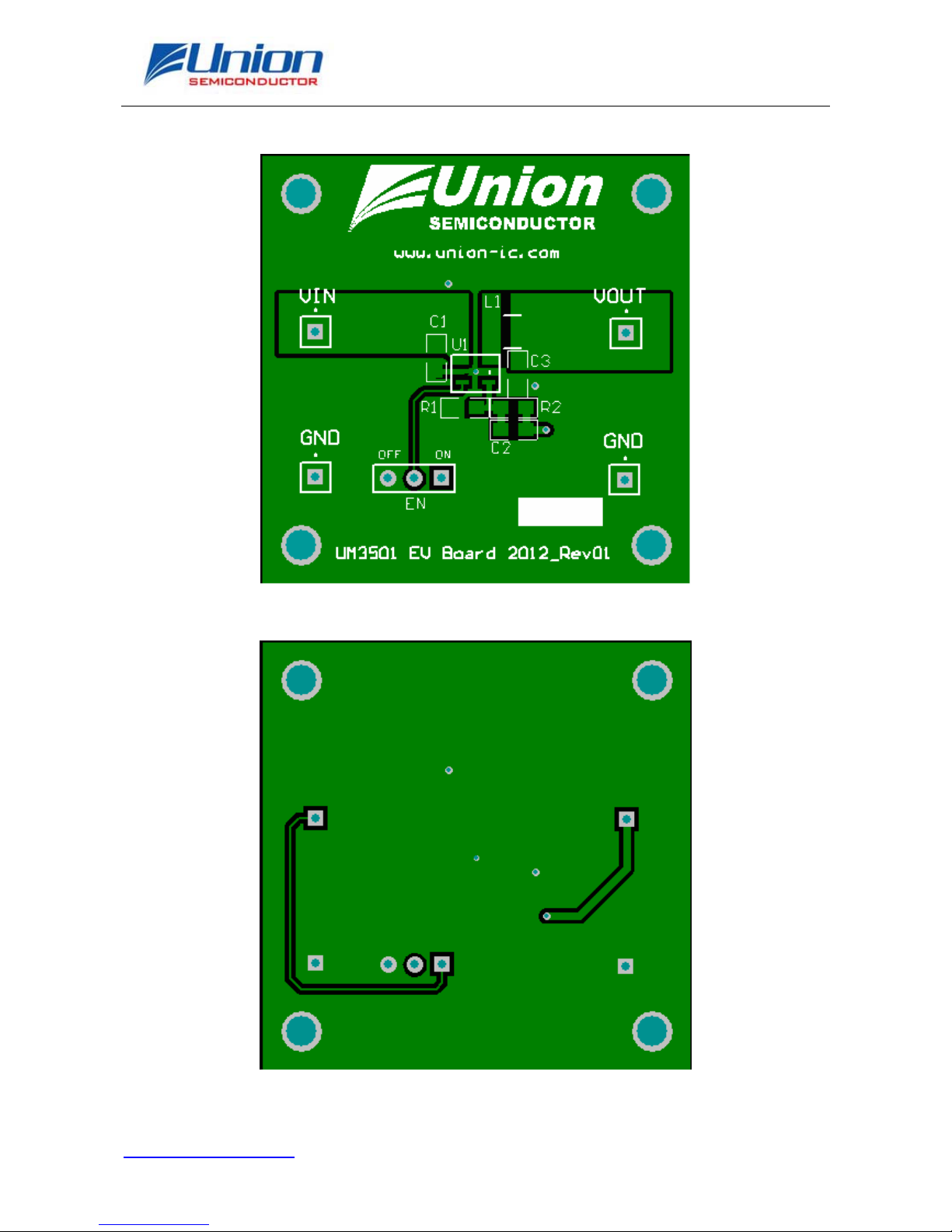

UM3501 EV Board User’s Guide

http://www.union-ic.com 7/10

The output voltage of UM3501 is set by the external resistor divider. See Figure

1.1.The output voltage is calculated as VOUT=0.6V×(1+R2/R1) with R1+R2≤1MΩ.

For stability, R1+R2 should not be greater than 1 MΩ. To keep the operating

quiescent current to a minimum, the feedback resistor divider should have high

impedance.

For example: Use 634 k ohms R1 and 316 k ohms R2 to get a 1.8V output.

VOUT=0.6V×(1+R2/R1)=0.6V×(1+634 /316)=1.80V

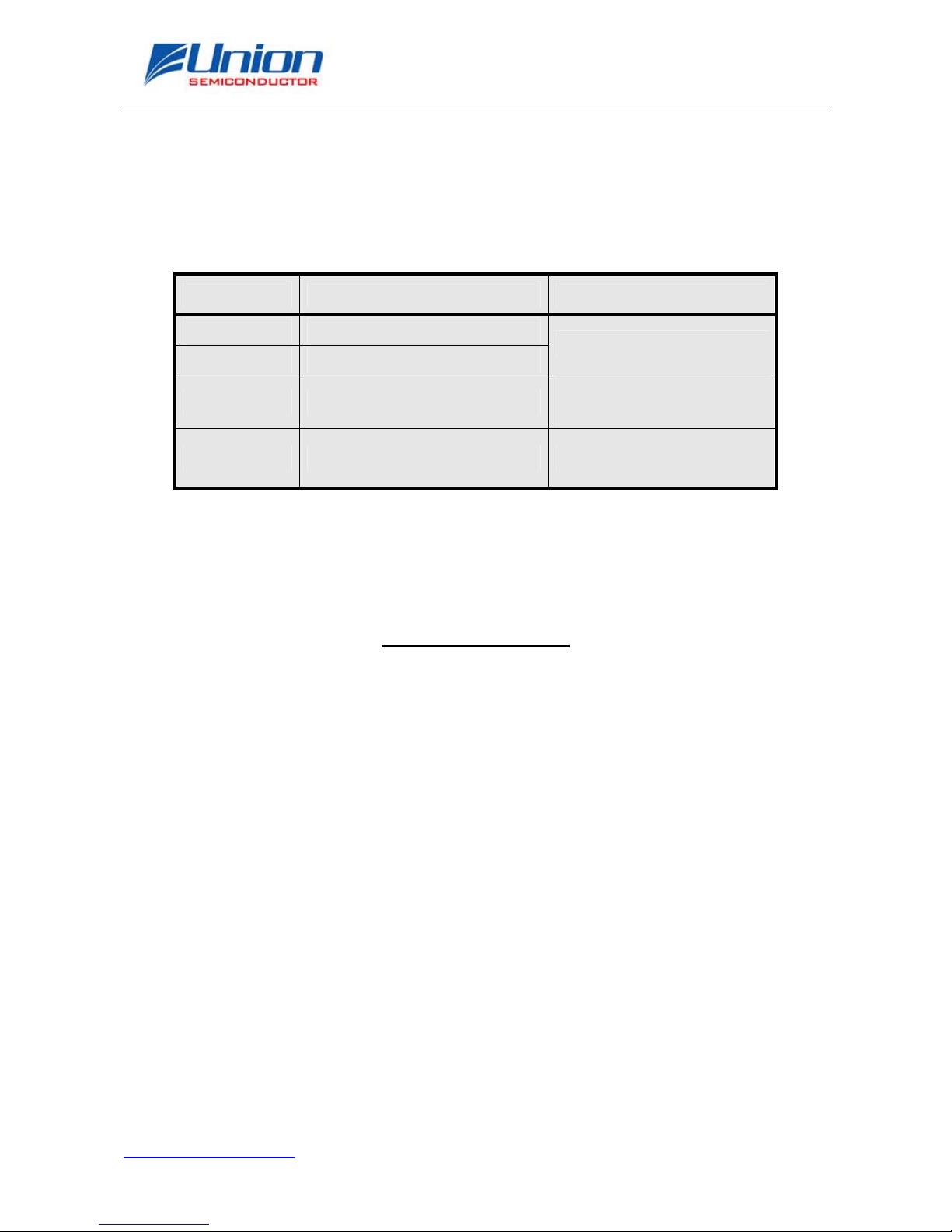

3. Board Component

Tab 3.1 is the recommended BOM list of UM3501 EV board.

Tab 3.1 UM3501 EV board recommended BOM list

Reference Description Part No. Manufacturer.

U1 Union Buck Converter. UM3501 Union

C1 Capacitor,4.7uF,6.3V,Ceramic,X5R,0805. JMK212BJ475MG Taiyo

C2 Default for UM3501 Evaluation - -

C3 Capacitor,10uF,6.3V,Ceramic,X5R,0805. C2012X5R0J106M TDK

L1 Inductor,2.2uH,850mA,33mΩ,SMT. CDRH2D18/LD-2R2 Sumida

R1,R2 Resistor, 1%,0603 or 0805 Std Std

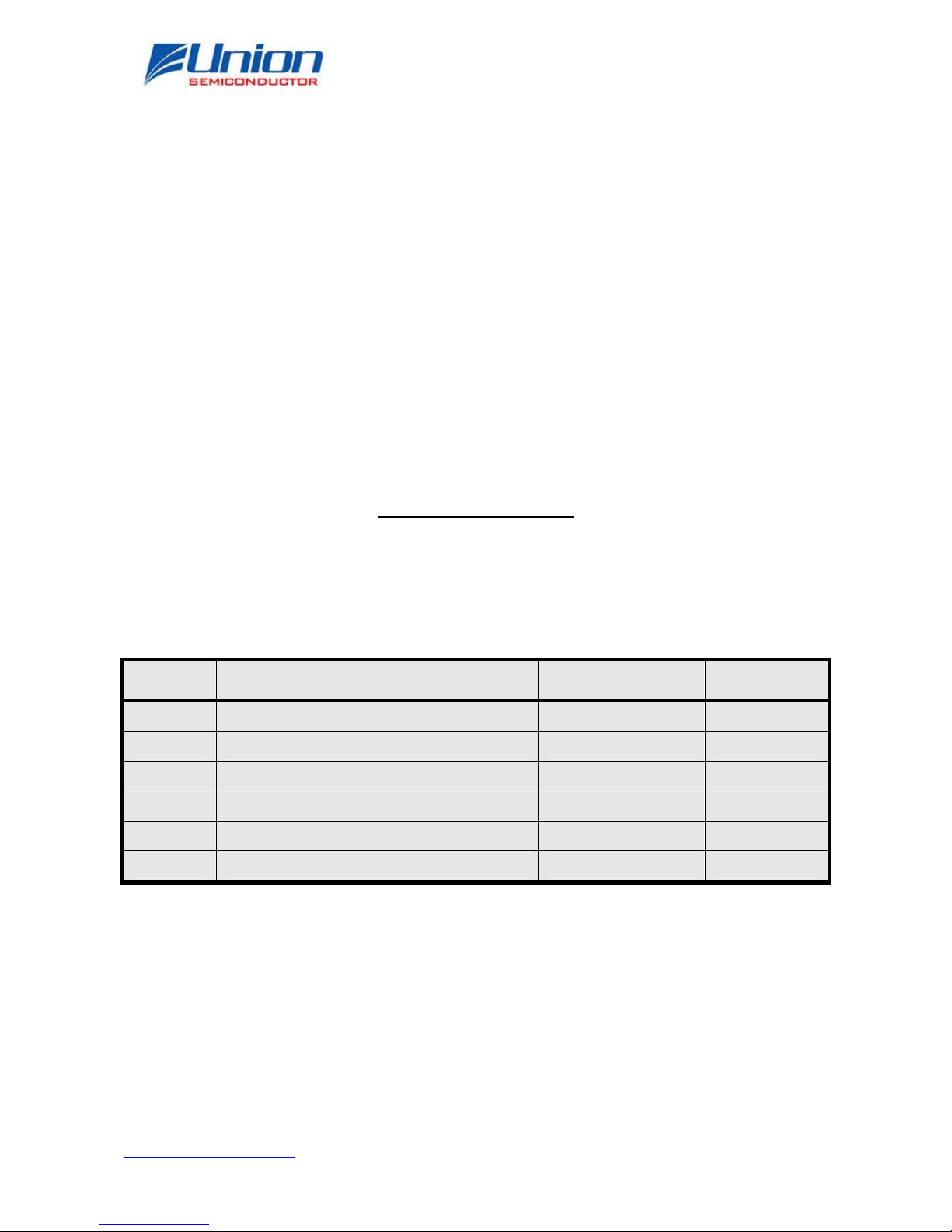

3.1 Input Capacitor

The input capacitors reduce the current peaks drawn from the battery or input power

source and reduce switching noise in the IC. Ceramic capacitors with X5R or X7R

temperature characteristics are highly recommended due to their small size, low ESR,

and small temperature coefficients. A 4.7µF X5R or X7R capacitor (C1) from VIN to