19

18 User Manual

discharges. Second, the charging process should return additional capacity (in amp-

hours) to offset the thermodynamic inefciencies inherent in the charging process. This

additional capacity can be measured as a charge factor calculated by: charge Ah in /

discharge Ah out. The charge factor varies with temperature, condition and age of the

battery but is usually in the range of 105 - 150%. Third, the charging process should

charge the battery at a voltage and/or charge rate at the end of charge that will result

in controlled gassing of the electrolyte. This gassing is required to mix the electro-

lyte to prevent stratication. Without proper mixing of the electrolyte, the heavier acid

generated during charging can sink to the bottom of the cell and will adversely affect

performance and life of the battery. Finally, the charging process should result in a

fully charged battery with electrolyte specic gravity that is constant over several end-

of-charge readings, consistent between and among the cells of the battery pack, and

within the proper range for the battery type per U.S. Battery’s specications.

U.S. Battery is active in the development of new charging methods and regularly tests

and evaluates new charger technologies. As part of U.S. Battery’s charging recom-

mendations, charging methods are categorized into three basic methodologies based

on the number of charge stages used in the charging process. It should be noted that

the basic charge stages should result in a fully charged battery at the end of the nal

charge stage. Using this criterion; oat charging, maintenance charging, and equal-

ization charging are not considered to be one of the basic charge stages. These basic

charge stage methodologies can be dened as follows:

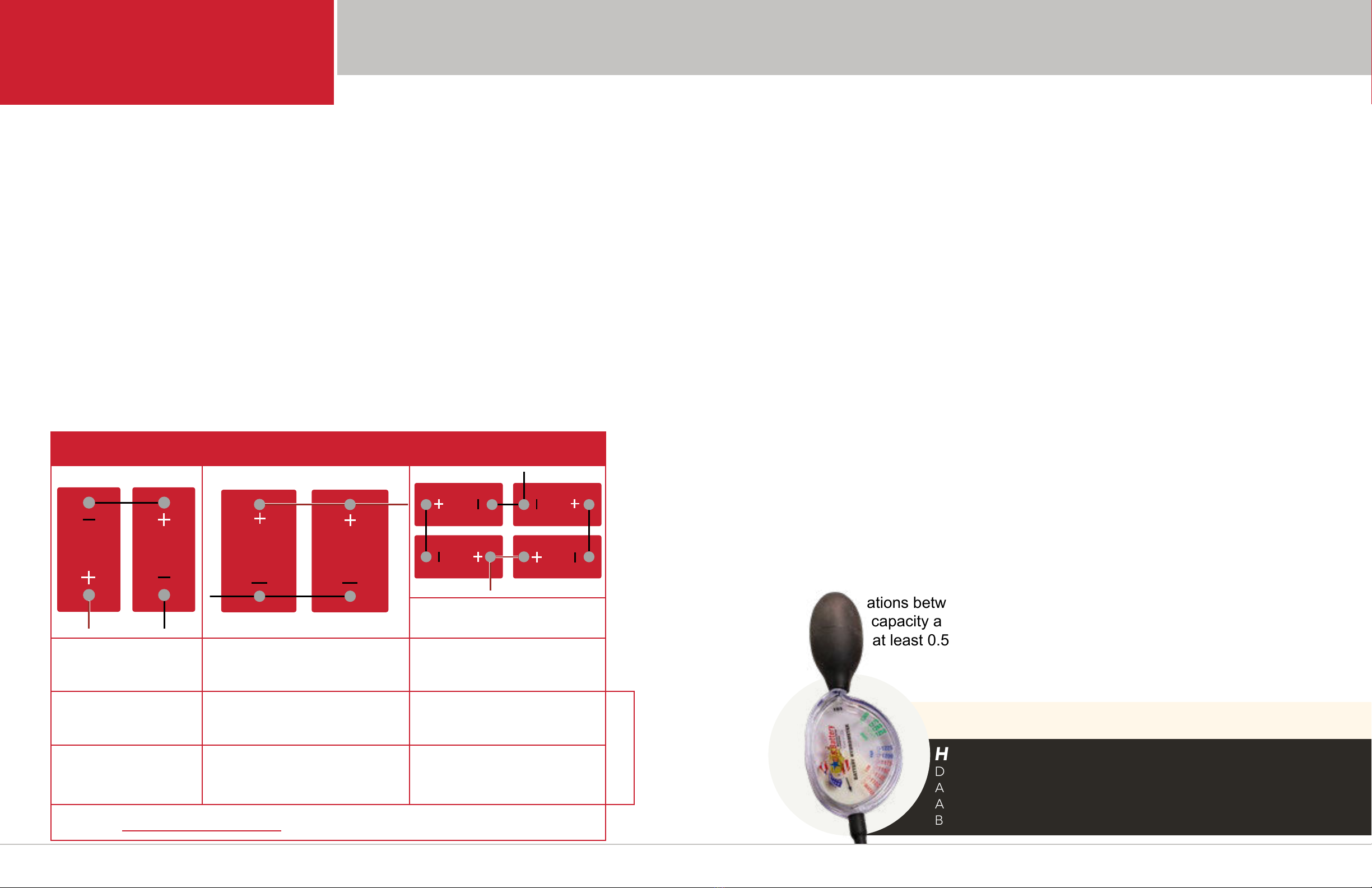

1. Three-Stage Charging – Charging using bulk charge, absorption charge, and

nish charge (usually constant current - constant voltage – constant current).

“Diagram 5”

2. Two-Stage Charging – Charging using bulk charge and absorption charge only

(Usually constant current - constant voltage). “Diagram 6”

U.S. Battery’s charging recommendations for deep cycle ooded lead-acid (FLA) and

sealed absorptive glass mat (AGM) batteries are found below. Note that the charging

parameters recommended for each of these depend on both the battery type and char-

ger type. These charging parameters are often controlled by specic charge algorithms

that can be selected or programmed by the user. Users should consult the charger

manufacturer and/or U.S. Battery for proper selection or programming of algorithm

controlled chargers. U.S. Battery prefers the use of Three-Stage Charging with dV/dt

charge termination to minimize the charge time required for full charge and to reduce

the risk of abusive undercharging or overcharging of batteries and battery packs.

FLOODED LEAD ACID CHARGING RECOMMENDATIONS

Three-Stage Charger (Constant Current-Constant Voltage-Constant Current)*

Following is the charging recommendation and charging prole using 3 stage chargers

for US Battery deep cycle products.

*Equalization and oat charge modes are not considered to be one of the stages in a

charging prole.

1. Bulk Charge Constant current @~10% of C/20 Ah in amps to 2.40+/-0.05

volts per cell (e.g. 7.20 volts +/-0.15 volts per 6 volt battery)

2. Absorption Charge Constant voltage (2.40+/-0.05 vpc) to 3% of C/20 Ah in amps then

hold for 2-3 hours and terminate charge. Charge termination can

be by maximum time (2-4hr) or dV/dt (4 mv/cell per hour)

3. Finish Charge Constant current at 3% of C/20 Ah to 2.55+/-0.05 volts per cell

(e.g. 7.65 volts +/-0.15 volts per 6 volt battery).

Charge termination can be by maximum time (2-4 hr) or dV/dt (4

mv/cell per hour.

• (Optional Float Charge) Constant voltage 2.17 vpc (6.51 volts per 6 volt battery) for

unlimited time

• Equalization Charge Constant voltage (2.55+/-0.05 vpc) extended for 1-3 hours

after normal charge cycle (repeat every 30 days)

Notes: Charge time from full discharge is 9-12 hours.

Absorption charge time is determined by the battery but will usually

be ~3 hours at 2.40 volts per cell. Float time is unlimited at 2.17

volts per cell. Specic gravity at full charge is 1.270 minimum

Two-Stage Charger (Constant Current-Constant Voltage)*

Following is the charging recommendation and charging prole using 2 stage chargers

for US Battery deep cycle products.

*Equalization and oat charge modes are not considered to be one of the stages in a

charging prole.

1. Bulk Charge Constant current @~10% of C/20 Ah in amps to 2.45+/-0.05

volts per cell (e.g. 7.35 volts +/-0.15 volts per 6 volt battery)

2. Absorption Charge Constant voltage (2.45+/-0.05 vpc) to 3% of C/20 Ah in amps then

hold for 2-3 hours and terminate charge. Charge termination can

be by maximum time (2-4hr) or dV/dt (4 mv/cell per hour)

• (Optional Float Charge) Constant voltage 2.17 vpc (6.51 volts per 6 volt battery) for

unlimited time

• Equalization Charge Constant voltage (2.55+/-0.05 vpc) extended for 1-3 hours

after normal charge cycle (repeat every 30 days)

Notes: Charge time from full discharge is 9-12 hours.

Absorption charge time is determined by the battery but will usually

be ~3 hours at 2.45 volts per cell. Float time is unlimited at 2.17

volts per cell. Specic gravity at full charge is 1.270 minimum

4CHARGING AND

EQUALIZING